Abstract

Hydroponic cultivation is an efficient, resource-saving technology that produces high yields of high-quality products per unit area without soil. While this technology can save water and fertilisers, water recirculation increases the accumulation of root exudates known to be toxic to the plant, causing growth inhibition. The usage of bioelectrochemical systems (BESs) is well-documented for wastewater treatment, desalination, contamination remediation, bioelectricity generation, etc. In this review we explore the issues associated with the usage of traditional approaches in detecting and removing the phytotoxic substances exudated from plant roots. Furthermore, we investigate the prospects of deploying BESs in hydroponic systems and highlight potential benefits and challenges. The application, feasibility and scalability of BES-hydroponic systems, as well as the possibility of integration with other technologies are all critically discussed. It is concluded that the use of BESs for hydroponic wastewater treatment and for real-time plant growth monitoring represents a novel and valuable strategy. This approach has the potential to overcome limitations of the existing treatment methods and contribute to the advancement of sustainable agriculture.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

At the current rate of population growth, estimated to be around 70 million annually (Worldometer 2024), efficient food production is an imperative. Generally, soil serves as the most readily available support medium in agriculture, providing essential nutrients, water and microorganisms (Khan 2018). However, the global availability of fertile soil surface coupled with adequate water supply for agriculture is decreasing due to factors such as urbanization, environmental pollution, and climate change (Chen 2007). The presence of disease-causing pests and pathogens significantly complicates agricultural practices (Sambo et al. 2019) and climate change is expected to further exacerbate this issue through the expansion of species ranges and potential changes to plant-pathogen interactions (Skendžić et al. 2021; Singh et al. 2023). Additionally, inappropriate agricultural techniques, poor drainage, and the intensification of production cycles, with monocultures becoming more common, have resulted in soil compaction and degradation, pathogen spread, and other related issues (Khan 2018).

Reducing the reliance of agriculture on soil is achievable through the adoption of hydroponic systems for crop cultivation. Hydroponic farming is considered a highly efficient approach for maximizing yields per unit area and producing high-quality crops within the shortest possible cycle (Mahjoor et al. 2016). It involves the placement of plant roots directly in contact with nutrient solutions instead of soil (dos Santos et al. 2013). This method not only decreases land usage but also minimizes the environmental impact of plant production by optimizing nutrient utilization in the hydroponic solution (Peer and Schippers 1989; Khalil et al. 2001). Studies suggest that land requirements can be reduced by up to 10 times, with yields per unit area potentially increasing by up to 11 times compared to traditional agriculture (Barbosa et al. 2015). While hydroponic systems predominantly rely on chemically-derived nutrients, natural compounds such as manure can also be utilized (Jones 2016). Moreover, hydroponic cultivation has a significant potential to save water through the recycling of hydroponic solutions (Carmassi et al. 2005).

Advantages of hydroponic systems include (Modu et al.; Ke and Xiong 2008; Suzui et al. 2009; Wang et al. 2011; Liu et al. 2012; Hussain et al. 2014): (a) Soil-free cultivation, which simplifies maintenance and cleaning, allowing for the effective management of pests and pathogens between growth cycles; (b) improved resource efficiency achieved through the management of inputs and recirculation of nutrients and water; (c) reduced carbon footprint, particularly when using renewable electricity, compared to traditional agriculture practices that largely rely on fossil fuels; (d) accelerated crop production per unit area compared to conventional agriculture; (e) reduced shipping costs when hydroponic systems are located within or near urban areas; and (f) year-round operation, even in northern locations when electric lighting is used to supplement or replace sunlight.

The nutrient solution is critical to a productive crop within a hydroponics system (Valentinuzzi et al. 2015), where both the levels of nutrients in the hydroponic solution and the interactions among different nutrients impact the physiological development and function of the plant roots (Sambo et al. 2019). Hydroponic systems can be classified into two main categories; Open and Closed systems. In an Open system, the nutrient solution only flows through the system once and is then discarded (Nederhoff and Stanghellini 2010). While this can create a simple and easy to manage system there is considerable water and nutrient waste, as it is continuously released from the system. In a Closed system, the nutrient solution is collected, monitored and treated to allow recirculation within the system. Closed systems are more costly and complex but the water and nutrient use as well as the impact of the nutrients on the environment are greatly reduced (Nederhoff and Stanghellini 2010).

The control of disease and management of changes in nutrient ion concentration in the nutrient solution are the two elements of a Closed hydroponics system that often receive the most attention (Ehret et al. 2001; Lykas et al. 2006). Plant roots also release exudates containing substantial quantities of organic acids and phenolic compounds. While these are important components of the plant root biome, including a carbon source for microbial metabolism in the rhizosphere (Hinsinger et al. 2006), elevated concentrations can have a negative impact on plant growth and productivity (Asao et al. 1998). While this is typically not an issue for soil cultivation, exceptions are known (Asao et al. 2003), in a Closed hydroponic systems root exudates accumulate over time and may reach levels where autotoxicity occurs (Waechter-Kristensen et al. 1993, 1997; Yu and Matsui 1993; Janda et al. 1999). Several physical methods such as activated charcoal (Asaduzzaman et al. 2012), membrane filtration (Steinkellner et al. 2008), slow sand filtration (Runia 1993a), as well as physico-chemical techniques like electro-degradation (Asaduzzaman et al. 2012), photocatalytic (Qiu et al. 2013) and heat treatment (Runia and Amsing 1999) exist for the removal of phytotoxic organic compounds from the feed solution. However, these methods have several drawbacks, including costs, energy consumption and changes to the nutrient solution pH and temperature. A detailed review of some of these methods is presented in the following section.

Bioelectrochemical systems (BES), also known as microbial electrochemical systems (MES), enable electron transfer between the electron acceptor and electron donor using electroactive microorganisms (Pant et al. 2012; Rosenbaum and Franks 2014). This novel concept holds great promise for addressing a broad range of biotechnological and environmental challenges, with the potential to enhance bioenergy and bioresource recovery as well as organic waste treatment (Hoang et al. 2022) and real time water quality monitoring (Wang et al. 2015) using biosensors (Sevda et al. 2020). BES typically consists of an anode, a cathode and an optional compartment separator (e.g. proton selective membrane), which can be assembled in several configurations. Microbial fuel cell (MFC) and microbial electrolysis cell (MEC) are two prominent types of BES. These systems serve as versatile platforms for various bioelectrochemical transformations (Sleutels et al. 2012), converting chemical energy into electricity at the anode or using diverse electron acceptors at the cathode to produce valuable compounds (Liu et al. 2020; Al-Sahari et al. 2021). Various other applications of BES technology have also been demonstrated, including metal removal/recovery (Wang et al. 2022a) and environmental remediation (Wang et al., 2015). BESs can degrade (treat) diverse biodegradable organic residues produced by the food industry, industrial and domestic wastewaters, landfill leachates, dairy and agricultural effluents, etc. (Gude 2016). In 2008, the concept of plant microbial fuel cell (pMFC) was proposed, whereby root exudates are converted into electricity without hindering plant growth (Strik et al. 2008). Yadav et al. (2020) demonstrated an integrated drip hydroponic—pMFC system that achieved removal efficiencies of 72 ± 2.4% of chemical oxygen demand (COD), 83 ± 1.1% of phosphate, and 35 ± 4.2% of ammonia. In the follow-up studies even higher COD removal of 93% was achieved (Yadav et al. 2022; Yadav and Siddharth 2023).

Additionally, Paucar and Sato (2022) reported an 80% COD removal in a MFC fed with hydroponic effluent. Khuman et al. (2020) demonstrated that the upflow hydroponic wetland-MFC that has a design similar to the pMFC, removed 91.5 ± 4.9% of COD. These findings underscore the potential of MFCs for combining the removal of organic materials with electricity production.

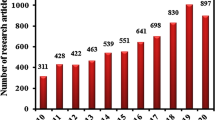

An examination of BES-related publications in the Scopus database reveals that within the past five years (2018–2023), 450 reviews have been published. These reviews encompass a broad range of BES applications and methods, including the removal of heavy metals from contaminated water (Wu et al. 2023), nurturing and using electroactive microorganisms (Logan et al. 2019), enhancing electron transfer mechanisms (Ivase et al. 2020), developing BES mathematical models and artificial intelligence-based methods for data analysis (Gadkari et al. 2018; Li et al. 2023). These reviews focus predominantly on aspects such as BES configuration, electrode materials, microbial populations, as well as on microbial electrosynthesis for diverse products. Wang et al. (2022b) is the only study to mention potential applications of BES in hydroponic agriculture. To address this gap, the review presented here aims to focus on issues related to the reuse of hydroponic solutions, including the limitations associated with traditional treatment methods. We introduce the concept of applying BES for the treatment and monitoring of hydroponic solutions and discuss potential directions for future development.

2 Challenges associated with Closed hydroponic systems

2.1 Autotoxicity

Autotoxicity, a form of allelopathy within plants, can present a challenge in Closed hydroponic systems (Singh et al. 1999). Generally, autotoxicity occurs when compounds within the naturally occurring root exudates accumulate above tolerable limits as the nutrient solution is reused. The loss of plant productivity is quantified through a number of plant phenotypic parameters including shoot and root development, flower count, harvested fruit per plant, and total yield (Yu and Matsui 1993; Miller 1996).

When plants experience autotoxicity, the uptake of ions and nutrients is hindered, as roots are the initial point of contact with autotoxins in the rhizosphere (Blum et al. 1999). The rate of loss of organic compounds (exudates) from plant roots varies, depending on factors such as the root-soil concentration gradient and plant type (Jones et al. 2009). Plant root exudates comprise over 200 organic compounds (Curl and Truelove 1986) and include various organic acids, such as adipic, maleic, succinic, palmitic, vanillic, lactic, benzoic, salicylic, among others. In particular, benzoic acid is recognized as a potent inhibitor of germination and growth and has been identified in reused plant nutrient solutions (Asao et al. 2004; Kitazawa et al. 2005a; Mondal et al. 2015).

Several experimental studies discuss the adverse effects of root exudates and autotoxicity on plants, such as lettuce, tomato, strawberry, cucumber, and beans (Yu et al. 1993; Yu and Matsui 1994; Asao et al. 1999; Oka 2002; Sato 2004; Kitazawa et al. 2005a; Lee et al. 2006; Asaduzzaman and Asao 2012, 2020), including plant performance during cultivation in Closed hydroponic systems (Hosseinzadeh et al. 2017b). Yield reduction due to unknown factors has been reported in strawberries cultivated in Closed hydroponics (Oka 2002). In the hydroponic cultivation of tomatoes, the accumulation of aromatic compounds in the nutrient solution exhibited inhibitory activity on growth (Yu and Matsui 1994). Asaduzzaman and Asao (2020) attributed the reduced growth of strawberry plants in hydroponic systems to root exudates, specifically phenolic acids that accumulated in the nutrient solution. In Closed hydroponic cultures of rose seedlings, both root and shoot growth were observed to diminish due to root exudates (Sato 2004). Asao et al. (1999) showed that root exudates cause a decrease in cucumber fruit yield during the late reproductive stage, with 2,4-dichlorobenzoic acid identified as the most effective inhibitor.

The synthesis and exudation of allelochemicals, as well as an increase in the overall production of root exudates, often increases under both biotic (Hickman et al. 2021) and abiotic (Inderjit and Weston, 2003) plant stress conditions. There is also evidence that plants recognize and respond to root exudates from other species (Semchenko et al. 2014; Li et al. 2016). While this is not an issue for large commercial facilities that typically grow a monocrop, this could have implications for smaller facilities that grow multiple species together. Within a properly managed hydroponics system plants are unlikely to be exposed to abiotic stress conditions; however, biotic stress remains an issue and allelochemicals will accumulate in the recycled nutrient solution without stress-induced increases in production. Furthermore, various factors, such as plant cultivar, species, age, and environmental conditions might also affect exudation profiles (Mimmo et al. 2011).

2.2 Pathogen development

While hydroponic systems create optimal conditions for plant growth, they can also be an ideal environment for plant pathogens (Owen-Going et al. 2003). The introduction of a pathogen into a hydroponics system can impact both productivity and quality, leading to substantial crop loss if not treated and controlled (Stanghellini and Rasmussen 1994). While pathogenic microorganisms can proliferate in both Open and Closed hydroponics systems their impact is amplified when the nutrient solution is recirculated, if adequate treatments are not used to prevent their reintroduction into the system.

Crops grown within a hydroponics system are typically housed within controlled environment structures with varying degrees of complexity, from high tunnels to glass houses to fully enclosed plant factories which use electric light as their sole light source. Various pests and pathogens can be an issue within a controlled plant growth environment, including a number of molds and mildews such as powdery mildew and grey mold, and a range of insect pests. While some pathogens use airborne spores or insect vectors to spread through a facility, others, such as Pythium, Phytophthora, Fusarium and Verticillium species, and a number of plant viruses, can readily move in the nutrient solution and spread to new host plants (Ehret et al. 2001).

Algae can also cause issues within a hydroponic systems and while it is not a plant pathogen it will proliferate within a Closed system and impact water quality characteristics such as dissolved oxygen, pH and nutrient composition (Abdel-Raouf et al. 2012). The algae will use nutrient resources intended for the plants and may produce toxic substances that inhibit plant growth (Schwarz and Gross 2004). Schwarz and Gross (Schwarz and Gross 2004) found that algae caused detrimental effects on lettuce grown in hydroponic systems, whereby the fresh weight, shoot/root ratio, as well as water and nitrogen uptake were significantly reduced.

2.3 Environmental implications

Hydroponic cultivation systems require substantial amounts of water and nutrients to maximize crop yield (Gagnon et al. 2010). In Open hydroponic systems, the volume of discharged water depends on factors such as plant species, growth stages, and meteorological conditions (Kumar and Cho 2014). Closed hydroponic systems exhibit a more efficient utilization of the nutrient solution (Seo 1999) through the recycling of nutrients, resulting in approximately 30% of water savings compared to Open systems (Van Os 1999). Periodic replacement of hydroponic nutrient solutions is required in Closed systems. These solutions comprise key components like nitrogen (N), phosphorous (P), potassium (K), magnesium (Mg), calcium (Ca), iron (Fe), copper (Cu), zinc (Zn), sulphur (S), manganese (Mn), and boron (B) (Kumar and Cho 2014).

In general, hydroponic wastewater contains elevated concentrations of nitrogen (200–300 mg L−1) and phosphorus (30–100 mg L−1), while organic carbon content is significantly lower (Prystay and Lo 2001; Park et al. 2008; Gagnon et al. 2010). High N and P content can result in a substantial point source pollution in receiving waters. Park et al. (2021) noted that wastewater from a Closed hydroponic farm had an average total nitrogen (TN) concentration of 402 mg L−1 and a total phosphate (TP) concentration of 77 mg L−1. These levels surpass the municipal and environmental discharge standards for rivers, with the TP exceeding the discharge norm by up to 994 times and TN by up to 6–19 times (Park et al. 2021). Nitrate leaching can also negatively impact the quality of drinking water extracted from impacted surface or ground water sources (Prystay and Lo 2001). Hydroponic systems also discharge other nutrients, but lack of information on the concentrations of these nutrients makes them challenging to monitor.

3 Current approaches to hydroponic solution management

3.1 Autotoxicity management

3.1.1 Activated carbon treatment

Activated carbon (AC) is an amorphous carbon that is relatively cheap and is a good performance adsorbent (Alhamed 2006). After specific treatment, AC can produce a highly developed internal pore structure and a large surface area. AC has been widely used in the removal of many organic compounds due to its aforementioned properties, and relatively low cost (Babel and Kurniawan 2003). AC adsorption is also considered the most common technology for removing root exudates from Closed-loop hydroponic nutrient solutions in various crops, e.g., bean, cucumber, leafy vegetables, lettuce, strawberry, taro, tomato, etc. (Hosseinzadeh et al. 2017b, 2019). Yu and Matsui (1993) showed that the addition of AC to tomato hydroponic solution reduced the concentration of organic compounds in the solution and increased the dry weight of plants and fruit yields. Lee et al. (2006) found that the use of AC (2.5 g L−1) can control the inhibitory effect of organic acids such as benzoic (25–200 μM) in lettuce nutrient solution. Asaduzzaman and Asao (2012) demonstrated that the number of pods, fresh pod weight, seed number, and fresh seed weight of plants grown in AC-free non-renewed culture medium were reduced by about half compared to those grown with AC. Biologically activated carbon (BAC) utilizes granular activated carbon to remove organic matter and has many advantages, including low operational cost, low energy requirements, low molecular weight organic matter, as well as high affinity for hydrophobic compounds (Ying and Weber Jr, 1979). However, since the micropores in commercially activated carbons are mainly irregularly shaped (size < 2 nm), the size-exclusion effect may significantly hinder the adsorption capacity of macromolecular organic compounds (Ji et al. 2010). Moreover, although activated carbon can effectively remove phytotoxic substances accumulated in nutrient solutions over a relatively short time, its removal capacity is limited and declines over time (Lee et al. 2006). Furthermore, AC treatment is not selective and results in the removal of nutrients (in addition to organic contaminants) from hydroponic solutions. In particular, removal of phosphates and nitrates by AC treatment is well documented (Almanassra et al. 2021; Ahmed et al. 2023). As a result, such treatment may be suitable for Open hydroponic systems but not in Closed hydroponic systems where nutrient retention is necessary.

3.1.2 Ion exchange resins

General ion exchange resins, especially weakly basic ion exchange resins can, at low concentrations, also be used to remove organic acids from the nutrient solution. Compared with strong base resins, weak base resins have greater acid adsorption capacity and are easily regenerated (Bhandari et al. 2000). Some experimental and theoretical studies on the adsorption of various acids by weak basic resins have been reported (Neumann and Römheld 2000; Hosseinzadeh et al. 2017a). However, compared with granular AC, the COD removal efficiency for ion exchange treatment is very low (22% vs. 74%) (Hosseinzadeh et al. 2017a), while materials are expensive.

3.1.3 Electro-degradation treatment

Electro-degradation (ED) is another way to detoxify allelochemicals in Closed hydroponic systems. It has been found that the phenolic compounds from organic waste or pollutants, such as phenol, catechol, droquinone or benzene, could be decomposed by the ED process at the anode to CO2 (Fleszar and Po̵szyńska 1985; Comninellis and Pulgarin 1991; Feng and Li 2003). Therefore, ED may help mitigate autotoxicity by breaking down allelochemicals, including benzoic acid, that leach from plants into nutrient solutions. Asao et al. (2008), using a titanium plate as the cathode and a ferrite rod as the anode, found that the application of ED significantly reduced seedling growth inhibition in nutrient solutions containing benzoic acid or in nutrient solutions used for strawberry culture. Furthermore, the use of alternating current during the ED process was shown to degrade benzoic acid faster and improve strawberry growth, yield, and quality (Talukder et al. 2019). However, it was also found that along with decomposing benzoic acid in the nutrient solution, ED also reduced the concentration of iron and calcium in the nutrient solution, lowered the solution pH and increased the solution temperature (Asaduzzaman et al. 2012).

3.1.4 Semiconductor photocatalytic treatment

Semiconductor photocatalysis has gained popularity due to its advantages for phytotoxic substance removal. There are many semiconductors such as metal oxides and sulfides (e.g., TiO2, ZnO, Fe2SO3, WO3, ZnS, etc.), but TiO2 is the most commonly used semiconductor due to its advantages of broad-spectrum of sterilization feature, complete decomposition, long repeated use, nontoxicity and absence of secondary pollution (Qiu et al. 2013; Hosseinzadeh et al. 2017b). TiO2 photocatalysis refers to the oxidation reaction that occurs when TiO2 absorbs ultraviolet light with a wavelength smaller than its band gap (about 385 nm) and oxidizes and decomposes organic matter adsorbed on the surface of TiO2 into CO2 and H2O (Gao et al. 2002). Miyama et al showed that before irradiation, the germination rate was 0%, demonstrating the strong inhibitory effect of rice husk extract, but after 4 days of irradiation, the germination rate returned to 100% (Miyama et al. 2009). Sunada et al. (2008) reported that asparagus growth in photocatalytically treated systems was better than in untreated systems. Similar results were also found by Miyama et al. on roses (Miyama et al. 2013). Qui et al. (2013) showed that that immobilized nano-TiO2 had a significant degradation effect on all phytotoxic substances (acetic acid, benzoic acid, ferulic acid, gallic acid, tannic acid, and salicylic acid) after 6 h treatment.

3.2 Pathogen treatment

3.2.1 Ultraviolet (UV) irradiation

Ultraviolet (UV) irradiation has proven to be a cost-effective treatment against pathogens in hydroponic nutrient solutions. Generally, the UV treatment involves exposing the hydroponic nutrition solution to light in the germicidal wavelength range of roughly 225–312 nm (Hijnen et al. 2006; Sholtes et al. 2016). The lamps used in these systems are generally classified as low-pressure or medium-pressure. While low-pressure lamps producing light at a single wavelength of around 254 nm,, medium-pressure lamps emit multiple wavelengths within the germicidal range (Loge et al. 1999). Application of low-pressure lamps is more commonly found in the literature than medium-pressure lamps. Radiation dose is the primary measure of UV disinfection capability, i.e. the energy received per unit area within a certain period (Mamane et al. 2010). The dose is affected by factors such as intensity, length of exposure, light reflection, and refraction (Hijnen et al. 2006), which determine the degree to which microorganisms in the water are inactivated (Hijnen et al. 2006). DNA damage is the primary mechanism of pathogen elimination, leading to failure to replicate and mRNA damage (Xu et al. 2018), with bacteria generally being the most susceptible to this damage, followed by protozoa, then viruses and bacterial spores (Hijnen et al. 2006). However, this order of sensitivity is a trend rather than a rule, and UV sensitivity varies widely between species and even between different strains of the same species (Hijnen et al. 2006). The source of the pathogen, laboratory environmental conditions, UV equipment used, etc. can all affect the results. Buyanovsky et al. (1981) demonstrated that applying UV radiation (171.6 mJ cm−2) to a circulating hydroponic system for 3 h per day reduced bacterial counts from 400 × 103 cells mL−1 to 50 × 103 cells mL−1. Mamane et al. (2010) reported that bacterial levels were reduced from 1500 bacteria mL−1 to 750 bacteria mL−1 when recirculating water was passed by a low-pressure UV disinfection unit (2–4 mJ cm−2). Research shows that continuous UV treatment can more significantly reduce potentially disease-causing bacteria (Ewart and Chrimes 1979). Continuous UV treatment has also been shown to eliminate 96.4–99.7% of bacteria at a dose of 250 mJ cm−2 and inhibit the growth of Phytophthora fruitum in rockwool hydroponic systems (Nordmo and Ramstad 1999). The disadvantages of UV treatment include relatively high energy consumption, removal of chelated iron from the nutrient solution, device fragility and short lifespan, use of mercury (in recent years LED technology is fast growing) with associated post-use disposal issues, and high heat output requiring extensive cooling facilities.

3.2.2 Ozone treatment

Ozone (O3) is an extremely reactive gas and is the strongest oxidant of the common oxidizing agents (Prabakaran et al. 2012). O3 can be produced by passing air/O2 through two electrodes with a high alternating potential difference, which causes the single "O" to rapidly combine with available O2 to form the highly reactive O3 (Baysan and Beighton 2007). O3 kills bacteria and is used for reducing cell counts at drinking water and wastewater treatment plants, in meat preservation during meat tenderization, as well as in many other applications requiring a strong oxidant. Typically, O3 -based disinfection is achieved by using 0.1 ppm O3. When microorganisms are exposed to ozone, their cell walls are destroyed, and the internal organic matter is oxidized. Ozone can directly stop the metabolism and reproduction of viruses and bacteria by decomposing macromolecular polymers (Peng et al. 2018). In addition to disinfection, ozone in combination with hydrogen peroxide was reported to oxidize root exudates (Han et al. 2023). As a recognized food processing method, interest in the use of ozone increased significantly after the US FDA verified it as a safe and approved food additive (Karaca and Velioglu 2007). Some studies showed that direct ozone water spray treatment is considered effective in controlling phytopathogenic fungal diseases of certain fruits and vegetables (bananas, apples, leafy vegetables, etc.) (Fujiwara and Fujii 2002; Graham et al. 2009; Guo and Wang 2017). O3 is relatively stable in the air but extremely unstable in water and will decompose within a short period of time. Therefore, it cannot be stored and must be continuously generated (Prabakaran et al. 2012). The only product of O3 is O2, so no disinfectant residuals are produced after O2 treatment (Prabakaran et al. 2012).

3.2.3 Hydrogen peroxide treatment

Hydrogen peroxide (H2O2) is an inexpensive, strong and unstable oxidizing agent that reacts to from H2O and an O•- radical (Watt et al. 2004). H2O2 is an endogenous reactive oxygen species (ROS) and at low concentrations it serves as an importance signaling molecule in various plant functions that can positively impact plant growth and yield (Hosseinzadeh et al. 2017a; Zheng et al. 2020). Similar to ozone treatment, H2O2 oxidizes pathogens as well as plant exudates. The by-products produced by the decomposition of H2O2 are H2O and O2. In hydroponic nutrient solutions, the released (unreacted) oxygen from the H2O2 decomposition can increase dissolved oxygen concentration in the root zone and help reduce oxygen loss that may occur due to biofilm and microbial respiration (Lau and Mattson 2021). Different H2O2 dosages are recommended by Runia (1993b) for different pathogens, such as Pythium spp. (0.005%), Fusarium spp. (0.01%), and viruses (0.05%). However, a concentration of 0.05% is also harmful to plant roots. This treatment method is inexpensive and can be an effective tool for controlling microbial growth within hydroponics systems, but care must be taken to manage dose levels and prevent overdose.

3.2.4 Filtration

Filtration can take the form of either high tech or low-tech solutions to remove pathogens from nutrient solution. Slow sand filtration represents a widely used technique that is low cost and effective (Ehret et al. 2001); however, due to the slow rate of the liquid percolating through the filter, the overall surface area of the system my need to be quite large to provide the necessary filtering capacity for a greenhouse facility. In cold climates it may be necessary to protect the filter from freezing, adding additional capital investment (Hong and Moorman 2005). The development of rapid sand filtration systems could help reduce the size of these systems in the future (Jeon et al. 2019). While a sterile filter bed can effectively remove fungal pathogens from the nutrient solution, the removal of smaller organisms appears to be dependent on the microbial colonization (Ehret et al. 2001). The effectiveness of slow sand filtration to remove pathogenic plant viruses from nutrient solution is not well understood but the elimination of tobacco mosaic virus from irrigation runoff has been documented (Oki et al 2017). This removal depended on the microbial colonization of the filter and viral removal did not occur until after 6–8 weeks of viral exposure (Oki et al. 2017). Membrane filtration can also effectively remove pathogens from a nutrient solution; however, in practise these systems can be problematic in a greenhouse environment because they can be prone to clogging and leaking (Ehret et al. 2001). Schuerger and Hammer (2009) reported that single and double membrane filter systems could not provide robust crop disease protection over time.

3.3 Beneficial microbial activity in hydroponics

Some plant growth-promoting rhizobacteria such as Pseudomonas spp. (aeruginosa, aureofaciens, chlororaphis, corrugate, fluorescens, fulva, marginalis, etc.), Bacillus spp. (amyloliquefaciens, cereus, subtilis, etc.), Enterobacter spp. (aerogenes), Streptomyces spp. (griseovirdis), Gliocladium spp. (catenulatum), and Trichoderma spp. (asperellum, atroviride, harzianum, etc.) exist in the hydroponic systems with positive influence on crop quality and quantity (Hibar et al. 2006; Lee et al. 2010). However, in many cases, their beneficial effects are insufficient to prevent disease outbreaks (Khalil and Alsanius 2009). These microorganisms have been used in agriculture as biocontrol agents, biofertilizers, and bioremediation agents to fix N2, extract nutrients from the soil, control plant stress, compete with pathogens, produce various phytohormones and biological control, as well as promote plant growth (Gaskins et al. 1985; Bull et al. 1991; Kloepper 1992; De Freitas et al. 1993; Lugtenberg and Kamilova 2009). Normally, environmental factors (e.g., temperature, pH, humidity, etc.) and nutrition sources could affect the composition of the microflora in hydroponic systems (Khalil and Alsanius 2001). Raaijmaker et al. (2010). found that Bacillus spp., Pseudomonas spp., and Streptomyces griseoviridis may prevent/diminish the influence of plant pathogens. In chrysanthemums, Pythium decreased about 20% after adding Pseudomonas chlororaphis or Bacillus cereus to Liu et al. (2007). The addition of Pseudomonas chlororaphis in hydroponic cultivated pepper system was effective in inhibiting P. aphanidermatum, P. dissotocum infections, and controlling root rot (Chatterton et al. 2004). Furthermore, biocontrol agents produced by Gliocadium catenulatum are effective in reducing root diseases caused by Pythium or Fusarium in hydroponic cucumbers and tomatoes (Rose et al. 2003; Khalil and Alsanius 2010).

4 Application of bioelectrochemical systems in hydroponics

Bioelectrochemical systems (BESs), such as MFCs and MECs (also called MxCs) enable a novel approach for developing new technologies for hydroponic nutrient solution treatment with the benefit of coupling biodegradation of organic wastes with the production of electricity or other value-added products. Potentially, BESs can replace the existing treatment methods summarized in Table 1 or complement conventional treatment. BESs have already received extensive attention from researchers due to their ability to effectively remove most biorefractory pollutants by the robust electroactive microbial community (Pant et al. 2012; Bajracharya et al. 2016). Owing to the high versatility of BESs, research is already underway to apply this novel approach to enhancing the performance of hydroponic systems. The following sections describe known BES applications in the area of hydroponic plant cultivation and suggest potential BES applications for nutrient solution treatment and reuse.

4.1 Microbial fuel cells

Historically, MFCs, which utilize electroactive microorganisms as biocatalysts to convert organic materials to bioelectricity, were the first type of BESs reported in the literature (Rabaey et al. 2009). Electricity production from organic wastes in an MFC is an environmentally friendly energy recovery method that can be used at a mesophilic range of temperatures and can operate on low-strength wastewater such as domestic sewage. MFCs can achieve high COD removal and high Coulombic efficiencies when operating even on complex wastewaters (Sevda et al. 2013).

The plant MFC (PMFC) converts solar energy into electrical energy by using root exudates and rhizosphere bacteria as the biocatalyst. PMFC technology can recover up to 60% of the energy from organic exudates (Chiranjeevi et al. 2019). Although PMFC current density is low because of low concentration of organic compounds in the soil, it is estimated that PMFCs have the potential to produce up to 3.2 W/m2 (280 MWh/ha a year) bioelectricity (Strik et al. 2011). PMFC can be divided into bioprocess and control units. In the bioprocess unit, the microbes living around rhizosphere act as the biocatalyst, absorbing root exudates as substrates and donating redox equivalents to the MFC anode (Chiranjeevi et al. 2019), while the control unit is designed to maximize energy harvesting (Wang et al., 2015b; Recio-Garrido et al. 2016). Some of the root exudates and microbial metabolites (e.g., biotin, formic acid, succinic acid, etc.) can act as mediators for electron transfer at the PMFC anode (Schröder 2007). Yadav et al. (2020) reported that the integrated drip hydroponic-MFC system achieved removal efficiencies of 72 ± 2.4% COD, 83 ± 1.1% phosphate, and 35 ± 4.2% ammonia, although power output was low. Paucar and Sato (2022) demonstrated that coupling of an MFC with a hydroponic system can result in 32%, 11%, and 80% removal of nitrate, phosphate and COD, respectively. Wen et al. (2021) found that more than 70% organic matter was removed in the anaerobic region of constructed wetland MFCs (CW-MFCs). Oon et al. (2015) designed an upflow CW-MFC for biodegradation of plant exudates and soil organic matter, with removal efficiencies of COD, NO3− and NH4+ reaching 100%, 40% and 91%, respectively. The main mechanism of nitrogen removal in a PMFC is biological denitrification (Liu et al. 2019b). Therefore, PMFC treatment of hydroponic effluents can remove nitrates by a combination of bioelectrochemical and biological pathways. Notably, the presence of dissolved oxygen in hydroponic solution is not expected to significantly limit the removal of nutrients and exudates, since the biofilm covering the MFC anode creates a significant oxygen gradient, leading to microaerobic or anaerobic conditions near the anode surface (in the biofilm core) and fostering an environment conducive to the growth of electroactive (microaerobic and/or anaerobic) and denitrifying bacteria. Notably, the degradation of organic materials in an MFC with an aerobic anode chamber has been observed (Ringeisen et al. 2007; Chen et al. 2014), although nitrate removal (denitrification) under such conditions can be limited. In addition to removing root exudates, recent experiments have shown that PMFCs can be successfully used to combine domestic wastewater treatment with electricity production and nutrient recovery (Yadav et al. 2022; Yadav and Siddharth 2023). These studies demonstrated that PMFCs can remove all organic materials (root exudates and organic materials from wastewater), achieving up to 93% removal efficiency. Additionally, the removal of emerging contaminants, such as sterols reached 95% efficiency.

Therefore, treating hydroponic solution in an MFC anode before its discharge to the environment or reuse is proposed, as shown in Fig. 1A. This configuration is expected to achieve a high degree of organic exudates removal, while partial removal of nutrients might also be expected. Furthermore, Fig. 1B shows the direct integration of a PMFC with a hydroponic. In this proposed configuration, the PMFC anode would consist of a porous conductive material, capable of supporting plant growth, replacing typical non-conductive hydroponic media such as coco coir, perlite, clay beads, etc. Alternatively, the PMFC could be constructed using a relatively thin (e.g. 5 mm) carbon felt anode, with the entire setup resembling a deep water hydroponic system. Such PMFC configurations would provide continuous removal of root exudates, at the expense of partial loss of nutrients, such as nitrates and phosphates.

Schematic diagrams of MFC-based hydroponic nutrient solution treatment systems. A Treatment before discharge in air-breezing MFC; B Combined hydroponic-MFC setup; C Treatment of exudates and nutrients in algae-MFC; D Hydroponic solution treatment in MDC with return of recovered nutrients. Dashed lines show partial return of treated nutrient solution

The photobioreactor-MFC, which is another novel MFC configuration, can also be utilized to process hydroponic wastewater. Photobioreactor-MFC can also be called photobioreactor-microbial solar cell (P-MSC). In this setup, algae placed in the cathode chamber are used as the “solar converter”, consuming nitrogen and phosphorus from wastewater and using carbon dioxide as a source of carbon (Wang et al. 2012; Kondaveeti et al. 2014). Microalgae have gained much interest for nitrogen and phosphorous removal, with several successful demonstrations of algal – based wastewater treatment systems for N, P, and COD removal (Xiao et al. 2012; Gouveia et al. 2014; del Campo et al. 2015). In an MFC anode, hydrolysis and fermentation of algal biomass by the mixed microbial community results in electricity production. At the same time, algal cultures can be used to provide oxygen to the MFC cathode (Hou et al. 2016; Kumar et al. 2018). Del Campo et al. (del Campo et al. 2015) proved the possibility of using algae-MFC to remove 59% of ammonium and 99% of phosphates. Gupta et al. (2021) used algal-assisted CW-MFC, integrated with a sand filter, to treat synthetic wastewater, effectively removing up to 96 ± 2.6% of COD, 85 ± 10.7% of NH4+, and 69 ± 10.1% of PO43−. Bolognesi et al. achieved 99% COD removal efficiency in an algae-MSC setup (Bolognesi et al. 2021). Xiao et al. (2012) reported that Chlamydomonas reinhardtii and Pseudokirchneriella subcapitata reduced 98% nitrogen and 82% phosphorus in municipal wastewater using an integrated algae-MFC system. Khandelwal et al. (2018) found that MFC fed with algal biomass residues, obtained after lipid extraction, achieved a higher maximum COD removal efficiency than when fed with fruit pulp waste (70.8% vs. 62.3%). Figure 1C presents a diagram of a proposed configuration of utilizing an algae-MFC for treating hydroponic effluents. Unlike the MFC or PMFC setups, in the algae-MFC system, both the anode and cathode compartments are used, with hydroponic water sequentially treated in each compartment. In this configuration, near complete exudate removal is expected in the anode compartment, while most of the nutrients would be utilized by algae growing in the cathode compartment. The algal biomass is then returned to the anode compartment to provide an additional carbon source to the electroactive bacteria. Overall, the algae-MFC system is expected to achieve high levels of both organics and nutrients removal, along with modest production of electricity.

When a third chamber (desalination chamber) is introduced to the MFC between the anode and cathode chambers, the new configuration is called a microbial desalination cell (MDC). MDC is regarded as a cost-effective method for combining wastewater treatment with the removal or recovery of value-added products or pollutants such as As, Cr, Cu, HCl, H2, H2O2, NaOH, etc. (Rahman et al. 2021). Notably, most of these pollutants can be found in hydroponic wastewater. MDC can have significant advantages over traditional wastewater treatment process as it does not require large energy inputs or high water pressure, while providing removal of a broad range of contaminants. It has been reported that the desalination, COD removal, and total nitrogen (TN) removal efficiencies of MDC reached approximately 52%, 97%, and 90%, respectively (Zuo et al. 2016). Zhu and Logan (2014) demonstrated simultaneous alkali recovery, high hardness removal (Ca2+ and Mg2+), high CO2 absorption, 94% COD removal rate, and 22% desalination rate in a MDC system. MDC with activated carbon electrodes showed 97% COD, 99% NH3-N, and 98% PO4 removal rates (Liu et al. 2019a). Once again, the MDC design can be adapted for treating hydroponic effluents, as illustrated in Fig. 1D. Notably, the accumulation of nitrogen, phosphorus, and potentially other essential nutrients and microelements, in the third (middle) compartment of the MDC system allows for at least partial return of these chemicals to the cultivation step. However, the selective transport of nutrients across the MDC membrane necessitates careful monitoring of (and possible means to control) concentrations to avoid any potential imbalance in the composition of nutrients and microelements in the hydroponic solution.

Beyond the typical MFC configurations, integrating hydroponic systems with PMFCs or MDC systems for simultaneous or sequential wastewater treatment presents a promising research avenue. These integrated systems (e.g. Figure 1C, D) could achieve high removal efficiencies for organic carbon, nitrogen and phosphorus. Consequently, these systems could be utilized for treating effluents from Open hydroponic systems or nutrient solutions discarded during Closed hydroponic system operations, while also producing modest amounts of electricity and enabling water reuse. However, significant removal of nitrogen and phosphorus compounds could lead to nutrient loss when integrating MFC-based exudate removal with the feed solution recycling process in Closed hydroponic systems.

4.2 Microbial electrolysis cells

Microbial electrolysis cells (MECs) have gained progressively increasing research attention since their introduction in 2005–2006 (Liu et al. 2005; Rozendal et al. 2006). MECs and similarly designed microbial electrosynthesis (MES) cells can convert organic carbon (wastewater) into hydrogen or inorganic carbon (CO2) into other valuable chemicals (Liu et al. 2005; Bajracharya et al. 2017). Electroactive microorganisms in the MEC anode degrade organic matter using the anode as a terminal electron acceptor, while hydrogen gas is produced electrochemically or bio-electrochemically (by electroactive bacteria) at the cathode. To overcome thermodynamic limitations of operating under anaerobic conditions at the cathode, additional energy has to be supplied by a power source. However, MEC energy consumption is very low as compared to electrochemical systems that need higher voltage to achieve water electrolysis (Kim et al. 2015; Rousseau et al. 2020). A broad range of organic materials can be fed to the anode (e.g., wastewater, fatty acids, sugar derivatives, furans, phenolic compounds, etc.) (Park et al. 2018). Several attempts to apply the MEC concept to the field of wastewater treatment have been reported (Katuri et al. 2019). Samsudeen et al. observed a COD removal efficiency of 78 ± 1% in a MEC treating distillery wastewater (Samsudeen et al. 2020). Tartakovsky et al. (2018) developed a membraneless MEC with porous flow-through electrodes for wastewater treatment, with up to 90–97% biochemical oxygen demand (BOD) removal efficiency and an energy consumption of 0.6 kWh/kg COD removed. Notably, due to the similarities between the anode compartments of MFC and MEC systems, the presence of oxygen in the MEC anode is not expected to significantly reduce its biodegradation efficiency (Rosenbaum et al. 2010). Furthermore, Pophail et al. (2020) found that photoanode-based MEC can reduce 95% of COD under visible light irradiation. Such photoanode-based MECs could be particularly suitable for hydroponic systems, since plants also need visible light irradiation. Low energy consumption and high efficiency of COD removal in a MEC makes this technology attractive for treating nutrient solutions.

Microbial electrolysis desalination cell (MEDC) combines MDC and MEC systems. In this setup, the electric power produced from MDC can be harvested by a capacitor or a more sophisticated power management system and provide energy for the operation of a MEC (Li et al. 2015), thereby achieving self-sufficiency in wastewater treatment and seawater desalination. Li et al. (2017) found that the hybrid MEDC achieved positive energy balance with 95% total nitrogen, and 99.5% lead (II) removal, while 64% of saline water at an initial concentration of 5 g L−1 was desalinated. MEDC reactor was also used for ammonia and phosphate recovery (Tice and Kim 2014). Li et al. (2020) demonstrated that MEDC systems applied to wastewater attained a removal efficiency of COD, nitrogen, and phosphate of 76 ± 1.4%, 66 ± 5.3%, and 67 ± 4.7%, respectively. It can therefore be concluded that MEDC can achieve nitrogen and phosphorus separation/recovery and water desalination on-site, partially utilizing the electricity generated by organic matter in wastewater to meet the needs of wastewater treatment. In this regard, MEDC is a potential technology for nutrient solution treatment as well as energy and nutrient recovery.

Since the driving voltage required for MEC operation is low, MFC can be a potential choice for powering a MEC operation, providing an economical and environmentally-friendly power source. However, MFC output voltage is significantly lower, than the voltage required for a MEC operation, e.g. 0.2–0.5 V vs 0.8–1.4 V, respectively. This problem can be overcome by connecting several MFCs in series and connecting such MFC stack to a MEC (Sun et al. 2008). In particular, Jiang et al. (2014). demonstrated sulfide removal combined with the production of methane from CO2 in a MFC-powered MEC setup. Also, Feng et al. (2020) obtained 39% COD removal with more than 90% ammonia removal rate by MFC-powered-MEC systems from ammonia-rich rice wastewater.

Overall, various configurations of MEC and MFC-MEC systems can be envisaged for treating hydroponic effluents, as illustrated in Fig. 2. As previously mentioned, in the simplest configuration, nutrient solution can be pumped through the anodic compartment of a two-compartment MEC (Fig. 2A). In another configuration that integrates plant growth and exudates removal, the anodic MEC compartment filled with a conductive cathode material, such as granular carbon, can be used for plant cultivation (Fig. 2B). In both configurations the cathode can be used for the production of hydrogen or other value-added products. Yet another configuration involves an MFC-powered MEC. In such a combined system several (e.g. 2–4) MFCs produce electricity (each typically outputting 0.2–0.3 V) to power one MEC (Fig. 2C). In this configuration, the hydroponic wastewater can be fed both to MFC and MEC setups for cleaning or, as in the configuration shown in Fig. 2B, plants can be grown in the MFC anode (PMFC), while the MEC is used for polishing the hydroponic wastewater (Fig. 2D).

Schematic diagrams of MEC-based hydroponic nutrient solution treatment systems. A Hydroponic solution treatment before discharge in H2-producing MEC; B Combined hydroponic-MEC setup; C Treatment in flow-through MEC; D Treatment in MEDC. Dashed lines show partial return of treated nutrient solution. PMS denotes power management system

Similar to the MFC applications described earlier, one potential drawback of MEC application for removing plant exudates is related to the partial removal of nitrogen, phosphorus and potentially other essential salts and microelements. Thus, MEC-based treatment can be applied to treating hydroponic wastewater, while its application for water reuse (i.e., a Closed system shown by dashed lines in Fig. 2) would necessitate the addition of nutrients to compensate for the partial removal of the nutrients. Overall, considering the relatively low concentration of exudates in hydroponic solutions, the primary economic benefit of MEC utilization for treating hydroponic solutions is expected to be in enhanced treatment quality. Furthermore, reintroducing the treated hydroponic effluent back to the Closed-loop operation can yield advantages such as significantly reduced water usage and savings in nutrients and microelements, particularly if essential nutrients as nitrogen and phosphorus are only partially removed.

4.3 Bioelectrochemical sensors

Hydroponic plants require 16 essential elements including carbon, hydrogen, oxygen (which can be obtained from the air) and the remaining 13 essential elements supplied from organic/inorganic fertilizers (Uchida 2000). Each plant is unique, with an optimal/minimal range of required nutrients. Below minimum levels, plants begin to show symptoms of nutrient deficiency. Excessive nutrient uptake can also lead to poor plant growth due to toxicity. Proper nutrient application doses are therefore important (Uchida 2000) and should be continually monitored and controlled. The current industry standard for inline monitoring of nutrient levels in hydroponic solution is electrolyte conductivity; however this method only monitors total salts within the solution. Ideally, nutrient monitoring would be performed using on-line sensors that can quickly, accurately, and cost-effectively detect contaminants and nutrient individual concentrations.

The accumulation of exudates in the hydroponic solution can be monitored using several analytical techniques, including gas chromatography coupled with mass spectrometry (GC–MS) (Lee et al. 2006; Asaduzzaman and Asao 2020), liquid chromatography coupled with ultraviolet absorbance detection (LC-UV) (Hao et al. 2007), fluorescence excitation-emission matrix (FEEM) spectroscopy (Hosseinzadeh et al. 2017b), and nuclear magnetic resonance (NMR) spectroscopy (Kim et al. 2010), among others. Analytical instruments, such as atomic absorption spectrophotometry and high-performance liquid chromatography or inductively coupled plasma can also be used to monitor nutrient ion levels. While these powerful analytical techniques can provide accurate measurements of nutrient levels and exudate concentration and composition, the off-line nature of the measurements implies relatively long sample processing times and high equipment costs. Recently developed analytical tools such as PeCOD® Chemical Oxygen Demand (COD) analyzer (Mantech Inc, Guelph, ON., Canada) and ion-selective electrodes for nutrient analysis (Aptisens, UK) can significantly reduce both time and cost of measuring concentrations of COD and nutrients. However, these methods still require sample collection and handling.

BES-based biosensors are transducer-free, time-saving, low-cost, maintenance-free and can operate in real time for a long time (Chouler and Di Lorenzo 2015; Grattieri et al. 2017). In particular, MFC-based biosensors are a promising tool for monitoring environmental pollutants, offering a fast, efficient and long-lasting monitoring of such parameters as biochemical oxygen demand (BOD), COD, dissolved oxygen (DO), volatile fatty acids and toxicants (Peixoto et al. 2011; Feng and Harper 2013; Wang and Ren 2013; Pasternak et al. 2017; Velasquez-Orta et al. 2017). Jin et al. (2016) reported a 3-chambered MFC biosensor for monitoring VFA, which had a wide detection range of 170–3400 mg L−1. A double-chambered MFC was successfully used to estimate the toxicity of polychlorinated biphenyls and diazinon with a detection ranges of 1–10 mg L−1 and 1–5 mg L−1 respectively (Kim et al. 2007). Jiang et al. (2017) achieved the lowest detection limit (5 mg L−1) of formaldehyde using a biocathode-based MFC sensor. Biffinger et al. (2008) reported that the driving force for the reduction of cathodic oxygen increased by 59 mV/pH as the acidity in the MFC-biosensor increased. In addition, MFC-based biosensors have also been utilized to monitor the status of plant health. This application is based on the correlation between MFC power output and the health indicators of microorganisms in the rhizosphere (Brunelli et al. 2016).

The mechanism of MEC-based biosensor is similar to MFC, except that it requires an external power source to overcome thermodynamic limitations of the cathodic reactions (Jin et al. 2017). Jin et al. (2017) found that the MEC-based biosensor has a good reproducibility, in the range of 5–100 mM, where the current density increased with the increase of the concentration of volatile fatty acids. However, Adekunle et al. (2019) reported that compared to the MEC-based biosensor, the MFC-biosensor showed a faster response time, higher sensitivity, and faster recovery time after the biosensor influent stream was spiked with a toxic compound.

In conclusion, it can be suggested that the various MFC and MEC configurations described above can be used not only for hydroponic wastewater treatment but also as biosensors to monitor nutrient levels and plant health in hydroponic systems. Such applications would require continuous monitoring of MFC and/or MEC outputs (e.g. current and/or voltage) and real time data analysis, possibly using modern artificial intelligence (AI) and machine learning (ML) algorithms. While BES-based biosensors are expected to provide qualitative rather than quantitative indications of plant health, their outputs could effectively distinguish between the changes in non-inhibitory, inhibitory organic compounds and nutrient concentration. For instance, an increase in the concentration of a non-toxic organic compound or an essential nutrient would likely result in a current increase, whereas the increase of organic inhibitory compounds would lead to a current decrease (Adekunle et al. 2023). Potentially, further insights could be obtained by analyzing the dynamic response of the biosensor through the utilization of ML algorithms.

Bioelectrochemical sensors can be installed either in an external recirculation loop of a hydroponic system as shown in Fig. 3A or in-situ (Fig. 3B). Owing to the low cost, small footprint, and low maintenance requirements of biosensors, a distributed network of biosensors installed throughout the hydroponic system can be envisioned (Fig. 3B), to monitor plant health at different locations of an industrial-scale hydroponic system.

5 Future opportunities

In this review we endeavoured to provide a broad view of existing methods for treating, reusing and monitoring hydroponic feed-solutions. The benefits of hydroponic food production are significant globally, but in particular for small and remote communities experiencing limited water and/or arable land resources as well as significant costs for mobilisation of fertilisers and other food-production inputs. These benefits extend also to environmentally-sensitive areas and receiving waters.

Along with the aforementioned benefits, hydroponic systems present inherent challenges that arise from the fact that the feed solution (in Closed systems) is recycled and reused continuously. Such recycling lends itself to vulnerabilities such as accumulation of root exudates and potentially quick proliferation of disease and harmful organisms. These vulnerabilities can be managed, but some require more research to overcome. Traditional methods for managing hydroponic nutrient solution include physical (e.g., activated carbon), chemical (UV, ozone, H2O2, etc.), and biological treatment methods. However, challenges such as high treatment costs, excessive energy consumption, chemical residues, etc. (see Table 1 for more details), persist, hindering the improvement of nutrient solution reuse and the quality of hydroponic water discharged into the environment.

Although bioelectrochemical systems (MFCs and MECs) cannot address all these challenges, they offer an innovative approach with several distinct benefits:

-

Effective treatment of hydroponic water discharged into sensitive receiving streams.

-

Prevention of root exudate buildup in Closed systems.

-

Dual functionality as both hydroponic water treatment systems and plant monitoring tools (biosensors).

-

The unique capability to simultaneously degrade organic matter and produce electricity or chemicals, leading to energy savings.

-

Simple, easy to operate design.

-

Simple operation, including gravitational flow configuration, which further minimizes energy consumption.

Additional information can be found in Table 1.

Recent advancements in the development and scale-up of bioelectrochemical systems, particularly in wastewater treatment, indicate that BES-based systems can be scaled up with relative ease. Initially, MFC and MEC studies employed complex and costly two-compartment designs with proton exchange membranes. However, the development of membraneless MFCs, such as the wetland MFC discussed earlier (Ramírez-Vargas et al. 2018), and flow-through membraneless MECs with granular carbon porous electrodes (Tartakovsky et al. 2018) pave the way for scaling up BES to sizes suitable for large-scale hydroponic operations.

Beyond treating hydroponic effluents prior to discharge into the environment, BESs also hold promise for removing root exudates in Closed hydroponic systems by integrating BESs with hydroponic plant cultivation. Examples of such integrated systems are shown in Fig. 1A, B (MFC—hydroponics configurations) and Fig. 2A, B (MEC-hydroponics configurations). Figures 1A and 2A represent configurations where water treatment is separate from exudate removal, while Fig. 1B and 2B show entirely integrated systems. By separating plant growth and exudate removal steps, better flexibility in hydroponic setup selection can be achieved. However, complete integration of plant growth with exudate removal could lead to a more compact and simpler setup, potentially with lower power consumption due to reduced water transfer requirements.

As discussed extensively earlier, both MFC and MEC systems have demonstrated high efficiencies in removing organic compounds (e.g., exudate removal and electricity production in PMFCs (Khudzari et al. 2018)) and thus are fully expected to successfully remove root exudates in hydroponic systems. However, achieving zero water discharge operation in Closed systems integrated with BESs requires further research to address the partial removal of essential nutrients such as nitrogen and phosphorus. Even with the potential need for partial replenishment of essential nutrients, integrated hydroponic-BES systems are expected to offer significant cost benefits, particularly in remote and Arctic communities where transportation, fuel, and chemical costs are high and ecosystems are fragile. Space exploration is another potential application where the hydroponics-BES concept could be advantageous for plant cultivation. Notably, in all these applications, BES-based exudate removal can be combined with real-time monitoring of plant health using BES-based biosensors, either through miniature biosensors placed at various locations across the hydroponic system (Fig. 3B) or through real-time data analysis of BES output voltage and current used for exudate removal (Fig. 3A).

Overall, despite the numerous potential advantages of BES application in hydroponics, substantial research efforts and practical demonstrations are necessary to realise these advantages. Additionally, studies dedicated to understanding the impact of bioelectrochemical reactions occurring at electrodes on nutrient solution composition, microbial populations, and ultimately, plant growth would aid in selecting the optimal configuration of combined systems.

6 Conclusion

This review discusses traditional and novel approaches in detecting and removing the phytotoxic substances exudated from plant roots. In particular, we investigate the prospects of deploying bioelectrochemical systems such as MFCs and MECs for treating hydroponic wastewater and facilitating its reuse. Several configurations for combining hydroponic plant cultivation with bioelectrochemical treatment of nutrient solution are proposed and potential benefits and challenges of such bioelectrochemical-hydroponic systems are critically discussed.

We conclude that the use of BES for hydroponic wastewater treatment and monitoring as well as for root exudates removal represents a novel and valuable strategy, which potentially can help to overcome limitations of the existing treatment methods and contribute to the advancement of sustainable agriculture.

References

Abdel-Raouf N, Al-Homaidan A, Ibraheem I (2012) Microalgae and wastewater treatment. Saudi J Biol Sci 19(3):257–275

Adekunle A, Raghavan V, Tartakovsky B (2019) A comparison of microbial fuel cell and microbial electrolysis cell biosensors for real-time environmental monitoring. Bioelectrochemistry 126:105–112

Adekunle A, Bambace S, Tanguay-Rioux F, Tartakovsky B (2023) Microbial fuel cell biosensor with capillary carbon source delivery for real-time toxicity detection. Sensors 23:7065

Ahmed MJ, Hameed BH, Khan MA (2023) Recent advances on activated carbon-based materials for nitrate adsorption: a review. J Anal Appl Pyrol 169:105856

Alhamed YA (2006) Activated carbon from dates’ stone by ZnCl2 activation. JKAU Eng Sci 17(2):5–100

Almanassra IW, Kochkodan V, Mckay G, Atieh MA, Al-Ansari T (2021) Review of phosphate removal from water by carbonaceous sorbents. J Environ Manage 287:112245

Al-Sahari M, Al-Gheethi A, Mohamed RMSR, Noman E, Naushad M, Rizuan MB, Vo D-VN, Ismail N (2021) Green approach and strategies for wastewater treatment using bioelectrochemical systems: a critical review of fundamental concepts, applications, mechanism, and future trends. Chemosphere 285:131373

Asaduzzaman M, Asao T (2012) Autotoxicity in beans and their allelochemicals. Sci Hortic 134:26–31

Asaduzzaman M, Asao T (2020) Autotoxicity in strawberry under recycled hydroponics and its mitigation methods. Hortic J 89(2):124–137

Asaduzzaman M, Kobayashi Y, Isogami K, Tokura M, Tokumasa K, Asao T (2012) Growth and yield recovery in strawberry plants under autotoxicity through electrodegradation. Eur J Hortic Sci 77(2):58

Asao T, Umeyama M, Ohta K, Hosoki T, Ito N, Ueda H (1998) Decrease of yield of cucumber by non-renewal of the nutrient hydroponic solution and its reversal by supplementation of activated charcoal. J Jpn Soc Hortic Sci 67(1):99–105

Asao T, Pramanik MH, Tomita K, Ohba Y, Ohta K, Hosoki T, Matsui Y (1999) Influences of phenolics isolated from the nutrient solution nourishing growing cucumber (Cucumis sativus L.) plants on fruit yield. J Jpn Soc Hortic Sci 68(4):847–853

Asao T, Hasegawa K, Sueda Y, Tomita K, Taniguchi K, T. H, Pramanik M H R, Matsui Y, (2003) Autotoxicity of root exudates from taro. Sci Hortic 97:389–396

Asao T, Kitazawa H, Tomita K, Suyama K, Yamamoto H, Hosoki T, Pramanik M (2004) Mitigation of cucumber autotoxicity in hydroponic culture using microbial strain. Sci Hortic 99(3–4):207–214

Asao T, Kitazawa H, Ban T, Pramanik MHR, Tokumasa K (2008) Electrodegradation of root exudates to mitigate autotoxicity in hydroponically grown strawberry (Fragaria× ananassa Duch.) plants. HortScience 43(7):2034–2038

Babel S, Kurniawan TA (2003) Low-cost adsorbents for heavy metals uptake from contaminated water: a review. J Hazard Mater 97(1–3):219–243

Bajracharya S, Sharma M, Mohanakrishna G, Benneton XD, Strik DP, Sarma PM, Pant D (2016) An overview on emerging bioelectrochemical systems (BESs): technology for sustainable electricity, waste remediation, resource recovery, chemical production and beyond. Renewab Energy 98:153–170

Bajracharya S, Srikanth S, Mohanakrishna G, Zacharia R, Strik DP, Pant D (2017) Biotransformation of carbon dioxide in bioelectrochemical systems: state of the art and future prospects. J Power Sourc 356:256–273

Barbosa GL, Gadelha FDA, Kublik N, Proctor A, Reichelm L, Weissinger E, Wohlleb GM, Halden RU (2015) Comparison of land, water, and energy requirements of lettuce grown using hydroponic vs. conventional agricultural methods. Int J Environ Res Public Health 12(6):6879–6891

Baysan A, Beighton D (2007) Assessment of the ozone-mediated killing of bacteria in infected dentine associated with non-cavitated occlusal carious lesions. Caries Res 41(5):337–341

Bhandari VM, Yonemoto T, Juvekar VA (2000) Investigating the differences in acid separation behaviour on weak base ion exchange resins. Chem Eng Sci 55(24):6197–6208

Biffinger JC, Pietron J, Bretschger O, Nadeau LJ, Johnson GR, Williams CC, Nealson KH, Ringeisen BR (2008) The influence of acidity on microbial fuel cells containing Shewanella oneidensis. Biosens Bioelectron 24(4):900–905

Blum U, Shafer SR, Lehman ME (1999) Evidence for inhibitory allelopathic interactions involving phenolic acids in field soils: concepts vs. an experimental model. Crit Rev Plant Sci 18(5):673–693

Bolognesi S, Cecconet D, Callegari A, Capodaglio AG (2021) Combined microalgal photobioreactor/microbial fuel cell system: Performance analysis under different process conditions. Environ Res 192:110263

Brunelli D, Tosato P, Rossi M (2016) Flora health wireless monitoring with plant-microbial fuel cell. Procedia Eng 168:1646–1650

Bull CT, Weller DM, Thomashow LS (1991) Relationship between root colonization and suppression of Gaeumannomyces graminis var tritici by Pseudomonas fluorescens strain. Phytopathology 81(9):954–959

Buyanovsky G, Gale J, Degani N (1981) Ultra-violet radiation for the inactivation of microorganisms in hydroponics. Plant Soil 60:131–136

Carmassi G, Incrocci L, Maggini R, Malorgio F, Tognoni F, Pardossi A (2005) Modeling salinity build-up in recirculating nutrient solution culture. J Plant Nutr 28(3):431–445

Chatterton S, Sutton J, Boland G (2004) Timing Pseudomonas chlororaphis applications to control Pythium aphanidermatum, Pythium dissotocum, and root rot in hydroponic peppers. Biol Control 30(2):360–373

Chen J (2007) Rapid urbanization in China: a real challenge to soil protection and food security. CATENA 69(1):1–15

Chen CY, Chen TY, Chung YC (2014) A comparison of bioelectricity in microbial fuel cells with aerobic and anaerobic anodes. Environ Technol 35:286–293

Chiranjeevi P, Yeruva D K, Kumar A K, Mohan S V, Varjani S (2019). Microbial electrochemical technology. In: Mohan SV, Varjani S, Pandey A (eds), Elsevier, 549–564

Chouler J, Di Lorenzo M (2015) Water quality monitoring in developing countries; can microbial fuel cells be the answer? Biosensors 5(3):450–470

Comninellis C, Pulgarin C (1991) Anodic oxidation of phenol for waste water treatment. J Appl Electrochem 21:703–708

Curl E, Truelove B (1986) The Rhizosphere Springer-Verlag. Google Scholar, Berlin, p 288

De Freitas J, Gupta V, Germida J (1993) Influence of Pseudomonas syringae R25 and P. putida R105 on the growth and N 2 fixation (acetylene reduction activity) of pea (Pisum sativum L.) and field bean (Phaseolus vulgaris L.). Biol Fertil Soils 16:215–220

Del Campo AG, Perez JF, Cañizares P, Rodrigo MA, Fernandez FJ, Lobato J (2015) Characterization of light/dark cycle and long-term performance test in a photosynthetic microbial fuel cell. Fuel 140:209–216

Dos Santos JD, Da Silva ALL, Da Luz CJ, Scheidt GN, Novak AC, Sydney EB, Soccol CR (2013) Development of a vinasse nutritive solution for hydroponics. J Environ Manage 114:8–12

Ehret D, Alsanius B, Wohanka W, Menzies J, Utkhede R (2001) Disinfestation of recirculating nutrient solutions in greenhouse horticulture. Agronomie 21(4):323–339

Ewart J, Chrimes J (1979). Effects of chlorine and ultra-violet light in disease control in NFT, 317–324

Feng Y, Harper WF Jr (2013) Biosensing with microbial fuel cells and artificial neural networks: laboratory and field investigations. J Environ Manage 130:369–374

Feng Y, Li XY (2003) Electro-catalytic oxidation of phenol on several metal-oxide electrodes in aqueous solution. Water Res 37(10):2399–2407

Feng Q, Xu L, Xu Y, Liu C, Lu Y, Wang H, Wu T, Wang R, Chen Y, Cheng Y (2020) Treatment of aged landfill leachate by a self-sustained microbial fuel cell-microbial electrolysis cell system. Int J Electrochem Sci 15(1):1022–1033

Fleszar BW, Po̵Szyńska J, (1985) An attempt to define benzene and phenol electrochemical oxidation mechanism. Electrochim Acta 30(1):31–42

Fujiwara K, Fujii T (2002) Effects of spraying ozonated water on the severity of powdery mildew infection on cucumber leaves. Ozone Sci Eng 24(6):463–469

Gadkari S, Gu S, Sadhukhan J (2018) Towards automated design of bioelectrochemical systems: a comprehensive review of mathematical models. Chem Eng J 343:303–316

Gagnon V, Maltais-Landry G, Puigagut J, Chazarenc F, Brisson J (2010) Treatment of hydroponics wastewater using constructed wetlands in winter conditions. Water Air Soil Pollut 212:483–490

Gao L, Zheng S, Zhang Q (2002) Nano TiO2 photocatalytic materials and application. Chemical Industry Press, Beijing

Gaskins M, Albrecht S, Hubbell D (1985) Rhizosphere bacteria and their use to increase plant productivity: a review. Agr Ecosyst Environ 12(2):99–116

Gouveia L, Neves C, Sebastião D, Nobre BP, Matos CT (2014) Effect of light on the production of bioelectricity and added-value microalgae biomass in a photosynthetic alga microbial fuel cell. Biores Technol 154:171–177

Graham T, Zhang P, Zheng Y, Dixon MA (2009) Phytotoxicity of aqueous ozone on five container-grown nursery species. HortScience 44(3):774–780

Grattieri M, Hasan K, Minteer SD (2017) Bioelectrochemical systems as a multipurpose biosensing tool: present perspective and future outlook. ChemElectroChem 4(4):834–842

Gude VG (2016) Wastewater treatment in microbial fuel cells–an overview. J Clean Prod 122:287–307

Guo Z, Wang Q (2017) Efficacy of ozonated water against Erwinia carotovora subsp carotovora in Brassica campestris ssp. chinensis. Ozone Sci Eng 39(2):127–136

Gupta S, Nayak A, Roy C, Yadav AK (2021) An algal assisted constructed wetland-microbial fuel cell integrated with sand filter for efficient wastewater treatment and electricity production. Chemosphere 263:128132

Han U, Lee Y-G, Byeon J, Chon K, Cho S-K (2023) Mitigation of benzoic acid-driven autotoxicity in waste nutrient solution using O3 and O3/H2O2 treatments: seed germination and root growth of Lactuca sativa L. Environ Pollut 331:121930

Hao Z, Wang Q, Christie P, Li X (2007) Allelopathic potential of watermelon tissues and root exudates. Sci Hortic 112(3):315–320

Hibar K, Daami-Remadi M, Hamada W, El-Mahjoub M (2006) Bio-fungicides as an alternative for tomato Fusarium crown and root rot control. Tunis J Plant Prot 1:19–29

Hickman DT, Rasmussen A, Ritz K, Birkett MA, Neve P (2021) Review: Allelochemicals as multi-kingdom plant defence compounds: towards an integrated approach. Pest Manag Sci 77:1121–1131

Hijnen W, Beerendonk E, Medema GJ (2006) Inactivation credit of UV radiation for viruses, bacteria and protozoan (oo) cysts in water: a review. Water Res 40(1):3–22

Hinsinger P, Plassard C, Jaillard B (2006) Rhizosphere: a new frontier for soil biogeochemistry. J Geochem Explor 88(1–3):210–213

Hoang AT, Nižetić S, Ng KH, Papadopoulos AM, Le AT, Kumar S, Hadiyanto H (2022) Microbial fuel cells for bioelectricity production from waste as sustainable prospect of future energy sector. Chemosphere 287:132285

Hong CX, Moorman GW (2005) Plant pathogens in irrigation water: challenges and opportunities. Crit Rev Plant Sci 24:189–208

Hosseinzadeh S, Bonarrigo G, Verheust Y, Roccaro P, Van Hulle S (2017a) Water reuse in closed hydroponic systems: comparison of GAC adsorption, ion exchange and ozonation processes to treat recycled nutrient solution. Aquacult Eng 78:190–195

Hosseinzadeh S, Verheust Y, Bonarrigo G, Van Hulle S (2017b) Closed hydroponic systems: operational parameters, root exudates occurrence and related water treatment. Rev Environ Sci Bio/technol 16:59–79

Hosseinzadeh S, Liu Z, De Graeve J, Bkheet M, Libbrecht W, De Clercq J, Van Hulle S (2019) Recirculating water treatment in closed hydroponic systems: assessment of granular activated carbon and soft templated mesoporous carbon for adsorptive removal of root exudates. Environ Process 6(1):1–23

Hou Q, Nie C, Pei H, Hu W, Jiang L, Yang Z (2016) The effect of algae species on the bioelectricity and biodiesel generation through open-air cathode microbial fuel cell with kitchen waste anaerobically digested effluent as substrate. Biores Technol 218:902–908

Hussain A, Iqbal K, Aziem S, Mahato P, Negi A (2014) A review on the science of growing crops without soil (soilless culture)-a novel alternative for growing crops. Int J Agric Crop Sci 7(11):833

Inderjit, Weston L (2003). Root exudates: an overview. Root ecology: 235–255

Ivase TJP, Nyakuma BB, Oladokun O, Abu PT, Hassan MN (2020) Review of the principal mechanisms, prospects, and challenges of bioelectrochemical systems. Environ Prog Sustainable Energy 39(1):13298

Janda T, Szalai G, Tari I, Paldi E (1999) Hydroponic treatment with salicylic acid decreases the effects of chilling injury in maize (Zea mays L.) plants. Planta 208:175–180

Jeon S, Krasnow CS, Bhalsod GD, Harlan BR, Hausbeck MK, Safferman SI, Zhang W (2019) Rapid sand filtration of recycled irrigation water controlled pythium root rot of poinsettia in greenhouse. HortTechnology 29:578–589

Ji L, Liu F, Xu Z, Zheng S, Zhu D (2010) Adsorption of pharmaceutical antibiotics on template-synthesized ordered micro-and mesoporous carbons. Environ Sci Technol 44(8):3116–3122

Jiang Y, Su M, Li D (2014) Removal of sulfide and production of methane from carbon dioxide in microbial fuel cells–microbial electrolysis cell (MFCs–MEC) coupled system. Appl Biochem Biotechnol 172:2720–2731

Jiang Y, Liang P, Liu P, Wang D, Miao B, Huang X (2017) A novel microbial fuel cell sensor with biocathode sensing element. Biosens Bioelectron 94:344–350

Jin X, Angelidaki I, Zhang Y (2016) Microbial electrochemical monitoring of volatile fatty acids during anaerobic digestion. Environ Sci Technol 50(8):4422–4429

Jin X, Li X, Zhao N, Angelidaki I, Zhang Y (2017) Bio-electrolytic sensor for rapid monitoring of volatile fatty acids in anaerobic digestion process. Water Res 111:74–80

Jones JB Jr (2016) Hydroponics: a practical guide for the soilless grower. CRC Press

Jones DL, Nguyen C, Finlay RD (2009) Carbon flow in the rhizosphere: carbon trading at the soil–root interface. Springer, Berlin

Karaca H, Velioglu YS (2007) Ozone applications in fruit and vegetable processing. Food Rev Intl 23(1):91–106

Katuri KP, Ali M, Saikaly PE (2019) The role of microbial electrolysis cell in urban wastewater treatment: integration options, challenges, and prospects. Curr Opin Biotechnol 57:101–110

Ke W, Xiong Z (2008) Difference of growth, copper accumulation and mineral element uptake in two elsholtzia haichowensis populations under copper and mineral nutrition stress, 4704–4708

Khalil S, Alsanius BW (2001) Dynamics of the indigenous microflora inhabiting the root zone and the nutrient solution of tomato in a commercial closed greenhouse system. Gartenbauwissenschaft 66(4):188–198

Khalil S, Alsanius BW (2009) Utilisation of carbon sources by pythium, phytophthora and fusarium species as determined by biolog® microplate assay. Open Microbiol J 3:9

Khalil S, Bååth E, Alsanius B, Englund J-E, Sundin P, Gertsson U, Jensén P (2001) A comparison of sole carbon source utilization patterns and phospholipid fatty acid profiles to detect changes in the root microflora of hydroponically grown crops. Can J Microbiol 47(4):302–308

Khalil S, Alsanius B (2010). Evaluation of biocontrol agents for managing root diseases on hydroponically grown tomato/Bewertung von Antagonisten zur Kontrolle von Wurzelkrankheiten in hydroponischen Tomatenkulturen. J Plant Diseases Protect 214–219

Khan FA (2018) A review on hydroponic greenhouse cultivation for sustainable agriculture. Int J Agric Environ Food Sci 2(2):59–66

Khandelwal A, Vijay A, Dixit A, Chhabra M (2018) Microbial fuel cell powered by lipid extracted algae: a promising system for algal lipids and power generation. Biores Technol 247:520–527