Abstract

Supercritical carbon dioxide (ScCO2) fracturing to transform geothermal reservoirs is a new technology in geothermal development, with great prospects. In this paper, the current laboratory test methods and test results of ScCO2 fracturing granite are reviewed, and the breakdown pressure and fracture parameters are discussed, and the existing problems and suggestions are given. The results show that the breakdown pressure of ScCO2 is 19.26–26.99% lower than that of water. The breakdown pressure is positively correlated with confining pressure and injection flow rate, and negatively correlated with temperature. ScCO2 tends to form shear fractures, induce more fracture branches and more complex fracture morphology than other fracturing fluids. Compared with water, the density of fracture branches increased by 17.82–60.54%, and the complexity of fracture morphology increased by about 4%. Existing studies have shown that ScCO2 has the advantages of low breakdown pressure, good fracture formation effect, no pollution and water resource saving. It is suggested that further research should be carried out regarding fracturing fluid properties, laboratory tests, theoretical derivation and engineering application in the future, to accelerate the application process of ScCO2 in deep geothermal development.

Highlights

-

The breakdown pressure of ScCO2 fracturing granite is about 20–27% lower than hydraulic fracturing in laboratory tests.

-

The breakdown pressure of ScCO2 fracturing granite is positively correlated with confining pressure and injection rate, but negatively related to temperature.

-

ScCO2 fracturing granite tends to form more shear cracks, fracture branches and complex fracture morphology than other fluids fracturing.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

With the continuous increase of the world's energy demand and the increasingly prominent environmental problems such as haze, hot dry rock (HDR) geothermal has attracted the attention of various countries due to its large energy reserves, wide distribution and stable operation (Rohde et al. 2013; Aghahosseini and Breyer 2020; Watanabe et al. 2020). The distribution of global hot dry rock development projects is shown in Fig. 1 (Mao et al. 2019). At present, the exploitation of hot dry rock is mainly realized by enhanced geothermal systems (EGS) (Xu et al. 2018), as shown in Fig. 2. The hot dry rock reservoir is mainly hosted by granite with dense properties and extremely poor permeability (Liu et al. 2015), at a depth of 3–10 km (actual mining is mainly concentrated at 1.25–5 km (Kang et al. 2022)), a temperature higher than 180 ℃, and no or only a small amount of fluid in the rock mass (Mao et al. 2019). The reservoir has low porosity, poor permeability, large burial depth and high temperature (Kumari and Ranjith 2019), which makes it difficult to exploit hot dry rock (Sun et al. 2022). Therefore, reservoir reconstruction is the key to EGS (Kong et al. 2017; Zhou et al. 2018a).

Hydraulic fracturing, as the most common and effective method (Gong et al. 2022), has been widely used in EGS reservoir reconstruction (Pang 2009; Zhang et al. 2019b), which has made some progress in laboratory and field tests (Pang 2009; Kong et al. 2017). However, hydraulic fracturing of the reservoir consumes a lot of water, which is easy to leak, resulting in low recovery rate (Scanlon et al. 2015). Usually, various solvents are added to enhance the performance of fracturing fluid, which causes certain pollution to the environment and groundwater (Middleton et al. 2015). The hot dry rock reservoir is dense in nature, with extremely high fracturing pressure (Kraft et al. 2009), and excessive pumping pressure can easily induce earthquakes (Majer et al. 2007; Zhou et al. 2018c). Therefore, how to protect the environment and effectively stimulate the fracture network of hot dry rock while reducing the fracturing pressure and the risk of inducing earthquake is an important problem that needs to be solved urgently.

At present, with the continuous improvement of environmental protection requirements, CO2 anhydrous fracturing technology is developing rapidly (Chen et al. 2021a; Zhang et al. 2022a). At the same time, carbon capture, utilization and storage (CCUS) is one of the key technologies to cope with global climate change (Zhong et al. 2011; Xie et al. 2012; Zhang et al. 2013), which has been increasingly researched and developed by countries around the world, and some progress has been made in CO2 flooding (Qin and Cheng 2010). In view of the above problems in the excitation of HDR reservoirs, supercritical carbon dioxide (ScCO2) fracturing technology has attracted scholars' attention. CO2 is in the supercritical phase when CO2 reaches the critical temperature (31.1 ℃) and the critical pressure (7.38 MPa) (Brown 2000). The phase diagram is shown in Fig. 3a. ScCO2 fluid has the characteristics of low viscosity, extremely low surface tension and strong fluidity (Verdon et al. 2010). For the fracturing construction of hot dry rock reservoirs, the construction conditions fully meet the temperature and pressure requirements of ScCO2 (Chen et al. 2018), as shown in Fig. 3b. Brown (2000) first proposed to use ScCO2 for reservoir fracturing and heat extraction in thermal exploitation in 2000, which can achieve the purpose of CO2 geological storage at the same time (Xie et al. 2014). Relevant studies show that it is safe and feasible to use ScCO2 for reservoir reconstruction (Pei 2013).

a Phase diagram of CO2 modified after Yang et al. (2018); b ScCO2 phase diagram under HDR reservoir conditions modified after Zhou and Zhang (2020) (Geothermal gradient is 20–60 °C\km (Pang et al. 2020), geothermal stress is 16 MPa/km (Bijay and Ghazanfari 2021), depth is 1.25–5 km (Kang et al. 2022), and surface temperature is 20 °C

Schematic diagram of ScCO2 fracturing equipment modified after Zhang et al. (2022b)

Laboratory tests are the basis of field tests. To explore the fracturing characteristics of ScCO2, scholars have carried out a series of fracturing tests and fracture observation studies. Ishida et al. (2012, 2016) conducted fracturing tests using granite, analyzed the advantages of ScCO2 fracturing, and found that ScCO2 has lower breakdown pressure and more complex fracture morphology, which is consistent with the results of Kizaki et al. (2013), Chen et al. (2015) and Ha et al. (2021). Using acoustic emission monitoring, Inui et al. (2013) found that ScCO2 tends to induce shear-dominant fracture. Isaka et al. (2019) explored the influence of confining pressure and temperature on ScCO2 fracturing cylindrical granite. ScCO2 fracturing is a relatively advanced technology with a little research. At present, there are a wide range of ways to obtain CO2 (Thonemann 2020) which has lower fracture breakdown pressure (Verdon et al. 2010) and the fractures formed by fracturing have more advantages in terms of seepage and heat exchange than water (Zhang et al. 2020). However, due to construction technology and cost, CO2 fracturing has not been applied to the field on a large scale. CO2 fracturing has high requirements for field equipment, so it is still at the laboratory test and exploration stage.

This paper summarizes the existing laboratory test research results, analysis and summarizes the characteristics of ScCO2 fracturing based on the characteristics of ScCO2, and expounds on the stimulation mechanism of ScCO2 fracturing, to provide a theoretical basis and reference for subsequent laboratory tests and field fracturing. The test methods of ScCO2 fracturing granite are summarized in Section 1. The results of ScCO2 fracturing granite are summarized in Scetion 2. Section 3 discusses and analyzes ScCO2 fracturing granite. Section 4 describes the problems and suggestions of ScCO2 fracturing granite.

2 Test methods of ScCO2 fracturing granite

2.1 Equipment of fracturing test

Many scholars generally used ScCO2 laboratory fracturing test equipments by conventional hydraulic fracturing plant modification. The fracturing test device mainly comprises an injection system, sample holder, pressure loading system, temperature control system, and computer monitoring system. The schematic diagram of the fracturing device is shown in Fig. 4. This section sorts out the fracturing equipment parameters used by different scholars, as shown in Table 1. The main operation process of fracturing equipment is as follows:

-

1.

Instrument installation. Put the rock sample in the holder, fix and seal the device, and connect the inlet and outlet pipelines, temperature and pressure sensors.

-

2.

Equipment connecting. Power on the instrument, open the control panel, and connect the computer equipment for data recording and collection.

-

3.

Stress loading. The rock sample is stressed to the set value by the pressure pump.

-

4.

Sample heating and insulation. The sample is heated by the temperature control system and kept for a certain time to ensure that the rock sample is evenly heated.

-

5.

Fracturing fluid injection. After cooling the CO2 in the gas cylinder, the injection system uses a booster pump to pressurize it to more than 7.38 MPa, stores the compressed CO2 in the intermediate container, and then pushes out the CO2 in the intermediate container at a certain flow rate through the injection pump. The CO2 flows through the heating device (heating the CO2 to more than 31.1 ℃) and enters the rock sample in an over-critical state until the rock sample is destroyed.

-

6.

Close the test system and all valves, remove the stress of the pressure pump, take out the rock sample after cooling to normal temperature, and conduct follow-up observation.

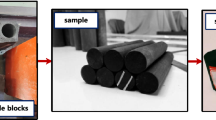

2.2 Test conditions of fracturing test

At present, the shape of the laboratory test rock samples can be divided into cylindrical samples and cubic samples. A borehole with a certain length and diameter is set in the center of the rock sample, and the fracturing fluid is passed into the borehole to make the rock samples fractured and destroyed under the set conditions. The size of the cylindrical sample is smaller than that of the cubic sample, and its height to diameter ratio is generally around 2. The stress loading conditions are axial pressure along the axis and radial confining pressure uniformly applied on the cylindrical surface, and a certain deviatoric stress is generally set during the test, as shown in Fig. 5a. The stress loading condition of the cubic sample is triaxial stress condition, which can be changed according to the experiment, as shown in Fig. 5b, to truly reduce the true triaxial stress environment of the rock sample in the reservoir.

The origin of rock samples for different ScCO2 laboratory fracturing tests is different. The minerals of rock samples are mainly quartz, feldspar and mica. The maximum test temperature is 300 ℃, the maximum applied stress is 40 MPa (Isaka et al. 2019), and the maximum ScCO2 injection rate is 150 mL/min (Kizaki et al. 2013). The types of fracturing fluids used are water, oil, liquid carbon dioxide (L-CO2) and ScCO2. This section summarizes the properties, dimensions and test conditions of granite samples in different fracturing tests, as shown in Table 2.

2.3 Observation methods of fracture

ScCO2 can create more complex fracture network in the fracturing process because of its low viscosity. In order to further study the propagation of the fracture induced by ScCO2 and analyze the breakdown mechanism and fracture characteristics, scholars use image scanners, optical microscopes, X-ray CT and other methods to monitor and observe fractures. This paper summarizes the fracture observation methods which provide a reference for subsequent research, as shown in Table 3.

3 Test results of ScCO2 fracturing granite

Scholars used the above fracturing equipment to carry out laboratory tests. In order to reveal the characteristics of ScCO2 fracturing in terms of test loading conditions, breakdown pressure and fracture parameters, this section summarized the existing results of different scholars, as shown in Tables 4 and 5.

4 Discussion and analysis of ScCO2 fracturing granite

4.1 Analysis of sensitive factors of breakdown pressure

Fracture breakdown pressure is an important parameter for reservoir reconstruction (Ishida et al. 2004; Guo et al. 2020), which is closely related to the engineering geological stability of reservoir rock mass (Guo and Qi 2015; Guo et al. 2017; Li and Einstein 2019). The following analysis will be conducted from four perspectives: flow rate, fracturing fluid type, pressure and temperature.

4.1.1 The effect of flow rate

As shown in Table 4, to explore the influence of flow rate on fracture breakdown pressure, the test results of fracture breakdown pressure acquired by Kizaki et al. (2013) under different flow conditions were summarized in this section. We found the fracture breakdown pressure increases linearly with the increase of injection flow rate for the cubic sample with the size of 150 × 150 × 150 mm3 under a temperature condition of 40 ℃ and a stress condition of σv/σh/σH = 1/3/5 MPa, which is consistent with the results of Cheng et al. (2021). The relationship between fracture breakdown pressure and injection flow rate is shown in Fig. 6.

We mainly explain the above rules from the microscopic point of view. ScCO2 is injected into the rock sample at the beginning of the test. Due to its low viscosity, ScCO2 can enter the tiny pores in the rock sample. The crack starts to expand from the tiny intergranular crack when the pressure increases (Zhang et al. 2017), as shown in Fig. 7a. However, ScCO2 with a high flow rate has just entered the borehole and has not completely entered the tiny fissure of the rock sample, as shown in Fig. 7b. At this time, the pressure in the hole increases rapidly and the rock sample is fractured because it has reached the fracture stress condition. Therefore, the increase of the flow rate will lead to an increase in the breakdown pressure. The increase of flow rate can shorten the time of inducing rock fracture, but requires an increase in the power of the syringe pump and will lead to greater fracture breakdown pressure, which is detrimental to fracturing.

Schematic diagram of granite fracturing modified after Wang et al. (2018) a ScCO2 fracturing at normal flow rate; b ScCO2 high flow rate fracturing; c hydraulic fracturing

4.1.2 The effect of fracturing fluid type

As shown in Tables 4 and 5, to explore the influence of fracturing fluid type on fracturing breakdown pressure, we summarized the fracture breakdown pressure by Ishida et al. (2012), Kizaki et al. (2013), Chen et al. (2015), Ishida et al. (2016), Isaka et al. (2019), Xu et al. (2019) and Ha et al. (2021) under different fracturing fluids in this section. It can be found that the breakdown pressure of ScCO2 fracturing was lower than that of other fracturing fluids. The breakdown pressure of ScCO2 is 59.98% lower than that of oil when the temperature is 25–100 ℃ and the flow rate is 10–100 mL/min (Fig. 8). Compared with water, the ScCO2 breakdown pressure is decreased by 19.26%-26.99%. Compared with L-CO2, the ScCO2 breakdown pressure is reduced by 17.81%-19.55%.

This is mainly due to the unique physical properties of ScCO2 including low viscosity, high diffusion, zero surface tension and other factors (He et al. 2018), which make it easier for ScCO2 to enter the tiny pores inside the rock sample, transfer the quasi-static pressure of the fluid to the deep part of the rock and establish fluid pressure systems of different sizes (Wang and Liang 2019), as shown in Fig. 7a. Thus, the effective stress at the fracturing site around the hole is reduced, leading to the destruction of the rock sample along the internal weak points more easily (Zhang et al. 2017).

4.1.3 The effect of pressure

As shown in Table 5, to explore the influence of stress on the fracture breakdown pressure, we summarized the fracture breakdown pressure by Isaka et al. (2019) under different stress conditions and found that the fracture breakdown pressure of the cylindrical sample with the size of φ22.5 × 45 mm increased linearly with the confining pressure when the test temperature was 100 ℃ and the flow rate was 30 mL/min. This is consistent with the conclusion of other scholars' research (Maneth Wanniarachchi et al. 2017). The experimental results align closely with the theoretical results, displaying only a minor deviation. The relationship between pressure and confining pressure is shown in Fig. 9.

The above changes can be analyzed from the following two aspects:

-

1.

Theoretical perspective of pore elasticity

Considering that ScCO2 fluid has significant pore pressure in rock pores and microfractures (Kang et al. 2011; Kumar et al. 2016), Haimson and Fairhurst modified the H-W (Hubbert and Willis) criterion according to the theory of pore elasticity. The H-F (Haimson and Fairhurst) criterion (Hubbert and Willis 1957; Haimson and Charles 1967) was proposed, and Isaka et al. (Isaka et al. 2019) proposed the equation for calculating the breakdown pressure of ScCO2 fracturing considering the thermoelastic stress:

where \(P_{b}\) is the breakdown pressure, MPa; \(\sigma_{3}\) is the confining pressure, MPa; \(\sigma_{t}\) is the tensile strength of the rock specimen, MPa; \(\alpha_{T}\) is the coefficient of thermo-elasticity; \(E\) is the Young’s modulus; \(\Delta T\) is the temperature gradient; \(v\) is the Poisson’s ratio of the rock specimen; \(\alpha\) is the Biot’s coefficient.

By Eq. (3.1), we found the breakdown pressure is positively correlated with confining pressure. The theoretical values of breakdown pressure under different confining pressure at 100 ℃ were calculated and compared with the test results in Fig. 9b. It can be seen that the variation trend of the experimental value for breakdown pressure with confining pressure is basically consistent with that of the theoretical calculation value. Moreover, the test value is about 14% higher than the theoretical value.

-

2.

Theoretical perspective of fracture mechanics

The breakdown pressure increases linearly with the increase of confining pressure, because the energy required to induce tensile fracture increases (Isaka et al. 2019). In online elastic fracture mechanics (LEFM) (Ito and Hayashi 1991), fracture toughness (KIC) or fracture energy (GIC) is the control parameter for tensile fracture initiation (Hashida et al. 1993). Relevant studies have shown that fracture toughness KIC increases with the increase of confining pressure (Al-Shayea et al. 2000), that is, when confining pressure increases, fracture propagation resistance increases, and in the process of fracturing, greater stress is required to generate and expand fractures (Lockner and Byerlee 1977; Atkinson and Meredith 1987; Roegiers and Zhao 1991). Therefore, with the increase of confining pressure, the stress required to form cracks in the borehole wall increases, and the injection stress of ScCO2 increases, which is finally reflected in the increase of the breakdown pressure of rock samples.

4.1.4 The effect of temperature

As shown in Table 5, to explore the influence of temperature on breakdown pressure, we summarized and analyzed the breakdown pressure by Isaka et al. (2019) under different temperature conditions and found that the fracture breakdown pressure of the cylindrical sample with the size of φ22.5 × 45 mm decreased linearly with the temperature when the test confining pressure of 30 MPa/40 MPa and the flow rate was 30 mL/min. Under 30 MPa confining pressure, compared with 50 ℃, the breakdown at 100 ℃, 200 ℃ and 300 ℃ decreases by 3.75%, 6.09% and 14.05%. Under the confining pressure of 40 MPa, the breakdown pressure at 100 ℃, 200 ℃ and 300 ℃ decreased by 1.69%, 4.33% and 10.17%, compared with that at 50 ℃. At the same pressure, the temperature increases and the breakdown pressure decreases. At the same temperature, the percentage reduction of the breakdown pressure at 40 MPa is lower than that at 30 MPa. The relationship between breakdown pressure and temperature is shown in Fig. 10.

The relationship between breakdown pressure and temperature modified after Isaka et al. (2019) a breakdown pressure–time curves of ScCO2 at different temperatures under confining pressure of 30 MPa; b breakdown pressure–time curves of ScCO2 at different temperatures under confining pressure of 40 MPa

The above changes can be analyzed from the following two aspects:

-

1.

The increase in temperature leads to the deterioration of the microstructure of the rock sample itself (Xu and Liu 2000; Zhou et al. 2017)

Granite is mainly composed of quartz, feldspar and biotite, etc. Due to the different thermal expansion coefficients of different minerals, the expansion of minerals is different when heated (Zhang et al. 2016), which makes it easy to produce microcracks among particles. ScCO2 is more likely to enter into smaller pores or microcracks due to its low viscosity (Zhang et al. 2016). In addition, microcracks along grain boundaries caused by temperature rise reduce the bond strength between mineral particles, such as tensile strength (Kumari et al. 2019; Qi et al. 2020a), which makes crack development and expansion possible with lower pore pressure, resulting in the reduction of breakdown pressure of ScCO2 fracturing granite.

-

2.

The increase in temperature leads to the change in ScCO2 fluid properties (Zhang et al. 2016)

The variation trend of ScCO2 viscosity with temperature and pressure is shown in Fig. 11. The higher the temperature, the lower the viscosity of ScCO2, which indicates that ScCO2 has enhanced fluidity and is more likely to enter small fractures to induce cracks. At the same time, when the rock sample is heated and then injected with fracturing fluid at a constant temperature during the test, there is a temperature difference between the fracturing fluid and the hole wall, which will produce thermal shock effect. The higher the temperature of the rock sample, the stronger the thermal shock effect will be, and the greater the tensile stress on the cooling surface will be (Kim and Kemeny 2009; Zuo et al. 2017). Therefore, the higher the temperature, the lower the breakdown pressure will be.

Variation trend of ScCO2 viscosity with temperature and pressure modified after Yang et al. (2008)

4.2 Analysis of sensitive factors of fracture parameters

Fracture parameters are very important in fracturing (Ishida et al. 2016; Zheng et al. 2020a, b). Fracture, namely structural plane, is a key factor to control the geomechanical behavior of the reservoir rock mass (Zheng and Qi 2016; Qi et al. 2020b; Zheng et al. 2021). The following will be analyzed from the perspectives of fracture number, fracture morphology and fracture type.

4.2.1 Number of fractures

As can be seen from Table 4, to analyze the characteristics of the number of fractures fractured by ScCO2, we sorted out the results of the number of fracture branches by Kizaki et al. (2013), Chen et al. (2015) and Ishida et al. (2016), as shown in Fig. 12. It is found that CO2 fracturing granite can produce more fracture branches and form a complex fracture network (Jia et al. 2020) and ScCO2 has the most significant fracture augmenting effect (Hu et al. 2019), as shown in Fig. 7a. In order to further analyze the fracture propagation of ScCO2 fracturing granite, the fracture branches within unit length were arranged, and the density of fracture branches of Chen et al. (2015) and Ishida et al. (2016) were calculated. As shown in Fig. 12, the density of fracture branches generated by ScCO2 fracturing is the largest. Compared with water, the density of fracture branches generated by ScCO2 fracturing increases by 17.82%-60.54%.

The density of fracture branches in Fig. 12 is the average of the number of the fracture branches along the direction of the main fracture, which does not reflect the distribution law of fracture branch density. However, Ha et al. (2021) found that new fractures are constantly generated along the direction of the main fracture when the fracture expands, and the largest number of fracture branches are generated at the initial position of the fracture, that is, the closer the distance from the borehole, the greater the fracture density. This is because fluid surface tension plays an important role in fracture propagation. Under the action of pump pressure, ScCO2 can enter any pore smaller than ScCO2 molecule (Jia et al. 2018) and form tiny fractures because of its low surface tension and viscosity (Zhou et al. 2015). Therefore, in the area close to drilling holes and main fractures, ScCO2 fracture density is significantly higher than that of hydraulic fracturing. Although the fracture length formed by ScCO2 is shorter and the aperture is smaller, the fracture volume (Zhang et al. 2017) and the fracture area (Chen et al. 2021b) are still larger than hydraulic fracturing in general.

4.2.2 Morphology of fracture

According to Table 4, to analyze the fracture morphological characteristics of ScCO2 fracturing, we analyzed the fracture morphological characteristics by Ishida et al. (2012), Chen et al. (2015) and Ishida et al. (2016) under different fracturing fluids and the results are shown in Fig. 13. Compared with other fracturing fluids, the fracture morphology formed by ScCO2 is more complex. Compared with water, the fracture tortuosity of ScCO2 increases by 1.28%-2.73%, the fractal dimension increases by 4.33%, and the Lav increases by 34.29%, which indicates that ScCO2 fracturing forms meander fractures with more secondary branches and increases the fracture roughness. Three-dimensional fractures are induced (Li et al. 2016).

The fracture morphology of ScCO2 is mainly due to the formation of transgranular fractures in ScCO2. Chen et al. (2015) and Ishida et al. (2016) used fluorescent resin to mark fractures and observed induced fractures through optical microscopy, and found that the fracture propagation mode induced by ScCO2 fracturing was different from that of other fracturing fluids. Fractures created by fluids with greater viscosity, such as oil, extend across mineral particles (yellow arrows), as shown in Fig. 14a, while ScCO2 fractures propagate between or within particles along crystalline particle boundaries (yellow arrows), as shown in Fig. 14b. This is due to the lower viscosity of ScCO2 around the fracture tip, which makes it easier than high viscosity fluids to penetrate hidden weak parts such as natural fractures and grain boundaries (Martin 1996) to resulting in the aperture and dislocating discontinuities. As a result, fractures are randomly oriented as they expand (Chen et al. 2019), eventually penetrating the grain boundary and spreading along the crystal boundary (Zhou et al. 2018b), which leads to the high tortuosity of fractures and complex fracture topography.

a Fracture cutting across the mineral grain observed in the specimen fractured by oil injection; b fracture propagating along the grain boundaries observed in the specimen fractured by ScCO2 injection (Chen et al. 2015)

4.2.3 Type of fracture

As shown in Table 4, Inui et al. (2013), Chen et al. (2015) and Ishida et al. (2016) and observed the fracture failure type through microscopic observation and acoustic emission monitoring. Inui et al. (2013) judged the fracture as a tensile or shear failure according to the initial motion type of longitudinal wave. The results show that high-viscosity fluids tend to induce tensile fractures, and ScCO2 tends to induce shear fractures, which is also proved by the research of other scholars (Deng et al. 2018). The formation of shear fractures can not only increase the reservoir volume of unconventional oil and gas and enhanced geothermal systems (EGS) (McClure and Horne 2014), but also improve fracture conductivity (Zhang et al. 2017).

ScCO2 induced the generation of tensile and shear fractures, as shown in Fig. 15. Rock fragments are generated during the generation of tensile fractures, as shown in Fig. 15a. Under the subsequent shear action, the fracture surface is misaligned, and rock fragments can play a supporting role in the fracture, as shown in Fig. 15b. Meanwhile, the convex parts of the fracture surface contact with each other point to form self-support (Barton et al. 2009), as shown in Fig. 15c. Some support points are destroyed under the action of σs and the new rock fragments also play a supporting role, as shown in Fig. 15d. The rock fragments generated in the fracture generation, the raised part of the fracture surface and the debris generated by the failure of the raised part are the main supporting factors in the shear fracture, as shown in Fig. 15b–d. Under subsequent shear action, fractures still play a supporting role in the above three modes.

5 Problems and suggestions of ScCO2 fracturing granite

5.1 Properties of fracturing fluid

Although ScCO2 fracturing can produce complex interconnected fractures, the fracture aperture is small, which is easy to close under the action of crustal stress. In addition, the ability of ScCO2 to carry proppant is weak because the low viscosity. Under the condition of high ground stress, after the fluid pressure decreases, the shear fracture formed by fracturing may be difficult to maintain the fracture aperture to ensure the high heat transfer when the fluid pressure decreases, and the fracture is easy to close. Therefore, it is considered to add an appropriate amount of tackifier to form a composite fracturing fluid, so that the fracturing fluid not only increases the sand carrying capacity to a certain extent which can make the proppant to enter the fractures and play a supporting role, but also ensure that the fracture has a suitable tortuosity, thereby reducing the possibility of sand plugging.

In previous studies, Chen et al. (2021a) used different fracturing fluids combinations to fracture shale and he found that the use of water with 0.5% guar after ScCO2 fracturing has lower breakdown pressure and more complex fracture morphology than ScCO2 fracturing. However, the use of composite fracturing fluid is rare in granite. In the future, it can be modified according to the properties of fracturing fluid. We can add additives in ScCO2 to form composite fracturing fluid and divide different fracturing stages. And then various types of composite fracturing fluids can be used at different stages of the fracturing process in geothermal reservoirs to reduce the breakdown pressure which can decrease the possibility of earthquake occurrence and meet the need to maintain the fracture aperture which can ensure the effective seepage and heat transfer.

5.2 Laboratory test

The experimental temperature and pressure were increased to further simulate the deep geothermal reservoir environment. At present, the test temperature of scholars is mainly concentrated in 15–45 ℃, and the stress is within 6 MPa. Only a few scholars have the temperature as high as 300 ℃ and the stress as high as 40 MPa (Isaka et al. 2019). However, the most projects are located at the depth of 4–5 km, accounting for 26.8% of the total number of projects (Kang et al. 2022), so the temperature should reach 320 ℃ and the pressure should reach 64 to 80 MPa.

The size effect also can be considered. Compared with the cylindrical sample, the cubic sample can be loaded with true triaxial stress at the macroscopic scale of the test. Therefore, the stress state of the rock sample in the reservoir is reduced in the test, and subsequent research can be conducted with the cubic sample. At present, the maximum size of a granite cubic sample is 170 × 170 × 170 mm3, while the maximum size of a laboratory fracturing rock sample (Hu et al. 2019) has reached 300 × 300 × 300 mm3. The influence of size effect on fracture breakdown pressure can be explored later. The influence of different mineral contents and heterogeneity of granite on breakdown pressure and fracture morphology can be studied at the mesoscale and microscale.

5.3 Numerical simulation

At present, there are few numerical simulation studies on ScCO2 fracturing of granite. Subsequent scholars can carry out fracturing research by inserting the new physical and mechanical equations under different conditions based on laboratory test results. At the same time, the influence of the mineral composition, the mineral boundary tortuosity and other factors on fracturing which can’t be controlled easily in laboratory test can be considered.

5.4 Theoretical derivation

Some related tests showed that the breakdown pressure would decrease with the increase of the vertical stress (Zhang et al. 2019a). Subsequent scholars can delve into the influence of the triaxial stress state of rock fracturing and the existing calculation equation will be studied more deeply. In current fracture pressure calculation equations for ScCO2, some scholars have considered the effects of both fluid pore pressure under the influence of viscosity and thermoelastic stress in rock samples under high temperature conditions (Isaka et al. 2019). However, the strong seepage effect (low viscosity) of ScCO2 has not been directly reflected in the equation which can be further studied.

5.5 Engineering application

ScCO2 fracturing transformation is fracturing the reservoir to increase reservoir permeability, but the current test is not of fracturing combined with subsequent seepage heat. In order to make laboratory test and field engineering closely integrated, subsequent tests can be combined with the number of fractures and morphological types to evaluate the variation of permeability and heat transfer efficiency of granite after ScCO2 fracturing, the change rule of granite in the thermal efficiency and permeability ScCO2 fracturing advantage, which will provide reference for geothermal exploitation.

6 Conclusions

This paper summarizes existing ScCO2 fracturing granite test results and analyzes the flow rate, fracturing fluid, stress, temperature and other test conditions on the influence law of breakdown pressure and fracture parameters. It is found that ScCO2 fracturing has the characteristics of low breakdown pressure, many fracture branches and complex morphology. We also prospected the following experimental conditions and research squares, as follows:

-

1.

Compared with other fracturing liquid phases, ScCO2 has a lower breakdown pressure, and the breakdown pressure is positively correlated with confining pressure and flow rate, and negatively correlated with temperature. Compared with oil, the ScCO2 breakdown pressure decreased by 59.98%. Compared with water, the ScCO2 breakdown pressure decreased by 19.26%-26.99%. Compared with L-CO2, the ScCO2 breakdown pressure decreased by 17.81%-19.55%.

-

2.

ScCO2 tends to form shear fractures, and induces complex fracture network and fracture morphology. Compared with water, the density of fracture branches induced by ScCO2 is increased by 17.82%-60.54%, tortuosity is increased by 1.28%-2.73%, fractal dimension is increased by 4.33%, and Lav is increased by 34.29%, which is beneficial to the heat transfer of EGS fluid in the later stage.

-

3.

ScCO2 is economically stable for EGS operation. ScCO2 reduces the power required by the wellhead pump to generate higher thermal productivity, while effectively protecting the EGS pipeline and geothermal reservoir for long-term stable EGS operation. The smaller the viscosity of the fracturing fluid and the smaller the injection flow rate, the lower the breakdown pressure of the fractured formation. At the same time, the resulting lower stress of the reservoir and higher temperature are also beneficial to the reservoir fracturing. At the same time, low-viscosity fracturing fluids such as ScCO2 can form a certain self-supporting shear fracture and produce complex fractures, which is beneficial to the seepage and heat transfer of geothermal reservoirs.

Laboratory tests can be optimized from four aspects: fracturing fluid properties, laboratory tests, numerical simulation, theoretical derivation and engineering application, further promoting the guiding significance of laboratory tests for EGS.

Data availability

Data are contained within this manuscript.

References

Aghahosseini A, Breyer C (2020) From hot rock to useful energy: a global estimate of enhanced geothermal systems potential. Appl Energy 279:115769

Al-Shayea NA, Khan K, Abduljauwad SN (2000) Effects of confining pressure and temperature on mixed-mode (I–II) fracture toughness of a limestone rock. Int J Rock Mech Min Sci 37:629–643

Atkinson BK, Meredith PG (1987) Experinmental fracture nmechanics data for rocks and nminerals. Fract Mech rock 477

Barton C, Moos D, Tezuka K (2009) Geomechanical wellbore imaging: Implications for reservoir fracture permeability. Am Assoc Pet Geol Bull 93:1551–1569

Bijay KC, Ghazanfari E (2021) Geothermal reservoir stimulation through hydro-shearing: an experimental study under conditions close to enhanced geothermal systems. Geothermics 96:102200

Brown D (2000) A hot dry rock geothermal energy concept utilizing supercritical CO2 instead of water. Twenty-Fifth Work Geotherm Resevoir Eng 1–6

Chen C, Zhu Y, Zhai L, et al (2018) Research Progress on Supercritical Carbon Dioxide Fracturing Technology. Explor Eng (Rock Soil Drill Tunneling) 45:21–26

Chen H, Hu Y, Kang Y, et al (2019) Fracture initiation and propagation under different perforation orientation angles in supercritical CO2 fracturing. J Pet Sci Eng 183:106403

Chen H, Hu Y, Kang Y, et al (2021a) Advantages of supercritical CO2 compound fracturing in shale on fracture geometry, complexity and width. J Nat Gas Sci Eng 93:104033

Chen H, Hu Y, Liu J, et al (2021b) Surface characteristics analysis of fractures induced by supercritical CO2 and water through three-dimensional scanning and scanning electron micrography. J Rock Mech Geotech Eng 13:1047–1058

Chen Y, Nagaya Y, Ishida T (2015) Observations of fractures induced by hydraulic fracturing in anisotropic granite. Rock Mech Rock Eng 48:1455–1461

Cheng Y, Zhang Y, Yu Z, Hu Z (2021) Investigation on reservoir stimulation characteristics in hot dry rock geothermal formations of China during hydraulic fracturing. Rock Mech Rock Eng 54:3817–3845

Deng B, Yin G, Li M et al (2018) Feature of fractures induced by hydrofracturing treatment using water and L-CO2 as fracturing fluids in laboratory experiments. Fuel 226:35–46

Gong L, Han D, Chen Z et al (2022) Research status and development trend of key technologies for an enhanced geothermal system. Nat Gas Ind 42:135–159

Guo S, Qi S (2015) Numerical study on progressive failure of hard rock samples with an unfilled undulate joint. Eng Geol 193:173–182

Guo S, Qi S, Zhan Z, Zheng B (2017) Plastic-strain-dependent strength model to simulate the cracking process of brittle rocks with an existing non-persistent joint. Eng Geol 231:114–125

Guo S, Qi S, Zhan Z et al (2020) Numerical study on the progressive failure of heterogeneous geomaterials under varied confining stresses. Eng Geol 269:105556

Ha SJ, Kim Y, Yun TS (2021) Development of microcracks in granitic rock by liquid CO2 fracturing. Int J Rock Mech Min Sci 146:104876

Haimson BC, Charles F (1967) Initiation and extension of hydraulic fractures in rocks. SPE J 7:310–318

Hashida T, Oghikubo H, Takahashi H, Shoji T (1993) Numerical simulation with experimental verification of the fracture behavior in granite under confining pressures based on the tension-softening model. Int J Fract 59:227–244

He J, Afolagboye LO, Lin C, Wan X (2018) An experimental investigation of hydraulic fracturing in shale considering anisotropy and using freshwater and supercritical CO2. Energies 11:1–13

Hu Y, Liu F, Hu Y et al (2019) Propagation characteristics of supercritical carbon dioxide induced fractures under true tri-axial stresses. Energies 12:4299

Hubbert MK, Willis DG (1957) Mechanics of Hydraulic Fracturing. Trans AIME 210:153–168

Inui S, Ishida T, Nagaya Y, et al (2013) AE monitoring of hydraulic fracturing experiments conducted using CO2 and water. In: ISRM international symposium - EUROCK 2013 957–962

Isaka BLA, Ranjith PG, Rathnaweera TD et al (2019) Testing the frackability of granite using supercritical carbon dioxide: Insights into geothermal energy systems. J CO2 Util 34:180–197

Ishida T, Aoyagi K, Niwa T, et al (2012) Acoustic emission monitoring of hydraulic fracturing laboratory experiment with supercritical and liquid CO2. Geophys Res Lett 39:1–6

Ishida T, Chen Q, Mizuta Y, Roegiers JC (2004) Influence of fluid viscosity on the hydraulic fracturing mechanism. J Energy Resour Technol Trans ASME 126:190–200

Ishida T, Chen Y, Bennour Z et al (2016) Features of CO2 fracturing deduced from acoustic emission and microscopy in laboratory experiments. J Geophys Res Solid Earth 121:8080–8098

Ito T, Hayashi K (1991) Physical background to the breakdown pressure in hydraulic fracturing tectonic stress measurements. In: International journal of rock mechanics and mining sciences & geomechanics abstracts. Elsevier, pp 285–293

Jia Y, Lu Y, Elsworth D et al (2018) Surface characteristics and permeability enhancement of shale fractures due to water and supercritical carbon dioxide fracturing. J Pet Sci Eng 165:284–297

Jia Y, Lu Z, Liu H et al (2020) Fracture propagation and morphology due to non-aqueous fracturing: competing roles between fluid characteristics and in situ Stress State. Minerals 10:428

Kang F, Tang C, Li Y, et al (2022) Challenges and opportunities of enhanced geothermal systems: a review. Chinese J Eng 44:1–11

Kang SM, Fathi E, Ambrose RJ, et al (2011) Carbon dioxide storage capacity of organic-rich shales. SPE J 16:842–855

Kim KM, Kemeny J (2009) Effect of thermal shock and rapid unloading on mechanical rock properties. In: 43rd US rock mechanics symposium & 4th US-Canada Rock Mechanics Symposium. OnePetro

Kizaki A, Tanaka H, Ohashi K et al (2013) Hydraulic fracturing in Inada granite and Ogino tuff using super critical carbon dioxide and water as fracturing fluids. J MMIJ 129:461–466

Kong Y, Pang Z, Shao H, Kolditz O (2017) Optimization of well-doublet placement in geothermal reservoirs using numerical simulation and economic analysis. Environ Earth Sci 76:1–7

Kraft T, Mai PM, Wiemer S et al (2009) Enhanced geothermal systems: mitigating risk in urban areas. Eos (washington DC) 90:273–274

Kumar H, Elsworth D, Mathews JP, Marone C (2016) Permeability evolution in sorbing media: analogies between organic-rich shale and coal. Geofluids 16:43–55

Kumari WGP, Beaumont DM, Ranjith PG, et al (2019) An experimental study on tensile characteristics of granite rocks exposed to different high-temperature treatments. Geomech Geophys Geo-Energy Geo-Resour 5:47–64

Kumari WGP, Ranjith PG (2019) Sustainable development of enhanced geothermal systems based on geotechnical research—a review. Earth-Science Rev 199:102955

Li B, Einstein HH (2019) Direct and microseismic observations of hydraulic fracturing in barre granite and opalinus clayshale. J Geophys Res Solid Earth 124:11900–11916

Li X, Feng Z, Han G et al (2016) Breakdown pressure and fracture surface morphology of hydraulic fracturing in shale with H2O, CO2 and N2. Geomech Geophys Geo-Energy Geo-Resour 2:63–76

Liu R, Jiang Y, Li S et al (2015) Study of nonlinear hydraulic characteristics and hydraulic aperture calculation of crossed fracture. Rock Soil Mech 36:1581–1590

Lockner D, Byerlee JD (1977) Hydrofracture in Weber sandstone at high confining pressure and differential stress. J Geophys Res 82:2018–2026

Majer EL, Baria R, Stark M et al (2007) Induced seismicity associated with enhanced geothermal systems. Geothermics 36:185–222

Maneth Wanniarachchi WA, Gamage RP, Perera MSA et al (2017) Investigation of depth and injection pressure effects on breakdown pressure and fracture permeability of shale reservoirs: an experimental study. Appl Sci 7:664

Mao X, Guo D, Luo L, Wang T (2019) The global development process of hot dry rock (enhanced geothermal system) and its geological background. Geol Rev 65:1462–1472

Martin CD (1996) Brittle failure of rock materials: test results and constitutive models. Can Geotech J 33:378–378

McClure MW, Horne RN (2014) An investigation of stimulation mechanisms in enhanced geothermal systems. Int J Rock Mech Min Sci 72:242–260

Middleton RS, Carey JW, Currier RP et al (2015) Shale gas and non-aqueous fracturing fluids: opportunities and challenges for supercritical CO2. Appl Energy 147:500–509

Pang Z (2009) Overview of geothermal energy development in the world. Geotherm Energy 5:15–25

Pang Z, Luo J, Cheng Y et al (2020) Evaluation of geological conditions for the development of deep geothermal energy in China. Earth Sci Front 27:134–151

Pei J (2013) Feasibility study of hot dry rock geothermal energy with CO2 as heating transmission fluid. China University of Petroleum (EastChina)

Qi S, Lan H, Martin D, Huang X (2020a) Factors controlling the difference in Brazilian and direct tensile strengths of the Lac du Bonnet granite. Rock Mech Rock Eng 53:1005–1019

Qi S, Zheng B, Wu F et al (2020b) A new dynamic direct shear testing device on rock joints. Rock Mech Rock Eng 53:4787–4798

Qin T, Cheng H (2010) International law issues on the technology using of carbon capture and sequestration. J China Univ Geosci 10:36–40

Roegiers JC, Zhao XL (1991) Rock fracture tests in simulated downhole conditions. In: The 32nd US symposium on rock mechanics (USRMS). OnePetro

Rohde R, Muller R, Jacobsen R et al (2013) Berkeley earth temperature averaging process. Geoinf Geostat Overv 1:20–100

Scanlon BR, Reedy RC, Nicot JP (2015) Response to comment on “comparison of water use for hydraulic fracturing for unconventional oil and gas versus conventional oil.” Environ Sci Technol 49:6360–6361

Sun M, Wang R, Guan Y, Liu D (2022) Estimation of hot-dry geothermal resources in Guangxi. J Jilin Univ Sci Ed 52:1302–1313

Thonemann MAN (2020) Environmental impacts of CO2-based chemical production: a systematic literature review and meta-analysis. Appl Energy 263:114599

Verdon JP, Kendall JM, Maxwell SC (2010) A comparison of passive seismic monitoring of fracture stimulation from water and CO2 injection. Geophysics 75:1–7

Wang H, Li G, He Z et al (2018) Analysis of mechanisms of supercritical CO2 fracturing. Rock Soil Mech 39:3589–3596

Wang L, Liang W (2019) Experimental study on fracture initiation and growth in coal using hydraulic fracturing with supercritical CO2 and normal water. Chin J Rock Mech Eng 38:2680–2689

Watanabe N, Saito K, Okamoto A et al (2020) Stabilizing and enhancing permeability for sustainable and profitable energy extraction from superhot geothermal environments. Appl Energy 260:114306

Xie H, Liu H, Wu G (2012) China’s future carbon dioxide emission reduction technology should be developed in the direction of CCU. Chinese Energy Sources 34:15–18

Xie H, Xiong L, Xie L, Hou Z (2014) Preliminary study of CO2 geological sequestration and enhancement of geothermal exploitation integration in China. Chin J Rock Mech Eng 33(S1):3077–3086

Xu C, Bai B, Liu M (2019) Experimental study of the fracture characteristics of granite under CO2 injection condition. Rock Soil Mech 40:1474–1482

Xu T, Hu Z, Li S et al (2018) Enhanced geothermal system: International progresses and research status of China. Acta Geol Sin 92:1936–1947

Xu X, Liu Q (2000) A preliminary study on basic mechanical properties for granite at high temperature. Chin J of Geotech Eng. 22:332–335.

Yang J, Lian H, Liang W et al (2018) Experimental investigation of the effects of supercritical carbon dioxide on fracture toughness of bituminous coals. Int J Rock Mech Min Sci 107:233–242

Yang J, Ma Y, Zeng X, Liu S (2008) Study on the properties of CO2 fluid at supercritical pressure. Fluid Mach 1:53–57

Zhang C, Cheng P, Ranjith PG, et al (2020) A comparative study of fracture surface roughness and flow characteristics between CO2 and water fracturing. J Nat Gas Sci Eng 76:103188

Zhang W, Sun Q, Hao S et al (2016) Experimental study on the variation of physical and mechanical properties of rock after high temperature treatment. Appl Therm Eng 98:1297–1304

Zhang X, Fan J, Wei Y (2013) Technology roadmap study on carbon capture, utilization and storage in China. Energy Policy 59:536–550

Zhang X, Li K, Wei N, et al (2022a) Advances, challenges, and perspectives for CCUS source-sink matching models under carbon neutrality target. Carbon Neutrality 1:1–11

Zhang X, Lu Y, Tang J (2017) Experimental study on fracture initiation and propagation in shale using supercritical carbon dioxide fracturing. Fuel 190:370–378

Zhang X, Zhu W, Xu Z, et al (2022b) A review of experimental apparatus for supercritical CO2 fracturing of shale. J Pet Sci Eng 208:109515

Zhang Y, He J, Li X, Lin C (2022) Experimental study on the supercritical CO2 fracturing of shale considering anisotropic effects. J Pet Sci Eng 173:932–940

Zhang Y, Ma Y, Hu Z, et al (2019b) An experimental investigation into the characteristics of hydraulic fracturing and fracture permeability after hydraulic fracturing in granite. Renew Energy 140:615–624

Zheng B, Qi S (2016) A new index to describe joint roughness coefficient (JRC) under cyclic shear. Eng Geol 212:72–85

Zheng B, Qi S, Guo S, Huang X (2020a) A new shear strength criterion for rock masses with non-persistent discontinuities considering the nonlinear progressive failure process. Materials (basel) 13:4694

Zheng B, Qi S, Huang X, Guo S (2020b) An advanced shear strength criterion for rock discontinuities considering size and low shear rate. Appl Sci 10:4095

Zheng B, Qi S, Luo G et al (2021) Characterization of discontinuity surface morphology based on 3D fractal dimension by integrating laser scanning with ArcGIS. Bull Eng Geol Environ 80:2261–2281

Zhong P, Peng S, Jia L et al (2011) Carbon capture utilization and storage technology development in developed countries and inspirations to China. China Popul Resour Environ 21:41–45

Zhou C, Wan Z, Zhang Y, Gu B (2018a) Experimental study on hydraulic fracturing of granite under thermal shock. Geothermics 71:146–155

Zhou C, Wan Z, Zhang Y, et al (2017) Experimental study on hydraulic fracturing of granite specimens under high temperature. China Min Mag 26:135–141.

Zhou D, Zhang G (2020) A review of mechanisms of induced fractures in SC-CO2 fracturing. Pet Sci Bull 5:239–253

Zhou D, Zhang G, Wang Y, Xing Y (2018b) Experimental investigation on fracture propagation modes in supercritical carbon dioxide fracturing using acoustic emission monitoring. Int J Rock Mech Min Sci 110:111–119

Zhou X, Zhang Q, Liu Q, et al (2015) Densities, isobaric thermal expansion coefficients and isothermal compressibilities of linear alkylbenzene. Phys Scr 90:55701

Zhou Z, Jin Y, Lu Y, Zhou B (2018c) Present challenge and prospects of drilling and hydraulic fracturing technology for hot dry rock geothermal reservoir. Sci Sin Phys Mech Astron 48:97–102

Zuo J, Wang J, Sun Y et al (2017) Effects of thermal treatment on fracture characteristics of granite from Beishan, a possible high-level radioactive waste disposal site in China. Eng Fract Mech 182:425–437

Acknowledgements

This work was funded by the National Natural Science Foundation of China under Grant Nos. 42141009, 41825018, 41888101 and 41902289, Key Research Program of the Institute of Geology and Geophysics, CAS under Grant No. IGGCAS-202201, the Youth Innovation Promotion Association Foundation of the Chinese Academy of Sciences under Grant No. 2023073, the Second Tibetan Plateau Scientific Expedition and Research Program (STEP) under Grant No. 2019QZKK0904.

Author information

Authors and Affiliations

Contributions

BZ, SQ and ZW had the idea and methodology for the manuscript. WL, SG, NL, XY and ZW performed the literature search, data analysis, figures and tables. BZ, SQ and WL drafted the manuscript. All authors critically revised the manuscript.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All the authors have approved the manuscript for submission and publication.

Conflict of interest

I would like to declare that the authors have no competing interests as defined by Springer, or other interests that might be perceived to influence the results and/or discussion reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zheng, B., Qi, S., Lu, W. et al. Laboratory test study on supercritical carbon dioxide fracturing granite: a quantitative review. Geomech. Geophys. Geo-energ. Geo-resour. 9, 98 (2023). https://doi.org/10.1007/s40948-023-00636-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-023-00636-x