Abstract

Large-scale geological sequestration of CO2 is one of the most effective strategies to limit global warming to below 2 °C, as recommended by the Intergovernmental Panel on Climate Change (IPCC). Therefore, identifying and characterizing high-quality storage units is crucial. The Surma Basin, with its four-way dip closed structures, high-quality reservoirs, and thick regional cap rocks, is an ideal location for CO2 storage. This study focuses on the Bokabil Formation, the most prominent reservoir unit in the Surma Basin. Detailed petrographic, petrophysical, XRD, and SEM analyses, along with mapping, have been conducted to evaluate the properties of the reservoir and cap rock within this formation. The Upper Bokabil Sandstone in the Surma Basin ranges from 270 to 350 m in thickness and consists of fine- to medium-grained subarkosic sandstones composed of 70–85% quartz and 5–12% feldspar, with good pore connectivity. Petrophysical analysis of data from four gas fields indicates that this unit has a total porosity of 21–27.4% and a low shale volume of 15–27%. Cross plots and outcrop observations suggest that most of the shales are laminated within the reservoir. The regional cap rock, known as the Upper Marine Shale (UMS), ranges in thickness from 40 to 190 m and contains 10–40 nm nano-type pores. A higher proportion of ductile materials with a significant percentage of quartz in the UMS indicates higher capillary entry pressures, enhancing its capacity to hold CO2. Using the CSLF method with a 6% cut-off of the available pore volume, it is estimated that 103 Mt, 110 Mt, 205 Mt, and 164 Mt of CO2 can be effectively stored in the Sylhet, Kailashtila, Habiganj, and Fenchuganj structures, respectively. Due to the shallow depth of the storage unit and the thick cap rock, the southern Surma Basin is the optimal location for CO2 injection.

Similar content being viewed by others

Introduction

In the last decades, the growing concern over climate change and its impacts have centered on the escalating levels of carbon dioxide (CO2) in the atmosphere1,2,3,4,5. From 1870 to 2015, the cumulative release of anthropogenic CO2 into the atmosphere was approximately 2035 ± 205 Gigatonnes6. The concentration of CO2 in the pre-industrial revolution was about 280 ppmv (part per million by volume) and at present it increased to 395 ppmv7. These increased concentrations of CO2 are the driving force behind climate change8,9,10,11,12. To mitigate catastrophic climate changes and limit global temperature rise to below 2 °C, an 80% reduction in greenhouse gas emissions by 2050 is imperative13,14,15. Achieving this goal necessitates significant reductions in CO2 emissions and the capture and sequestration of CO2 from point sources. Therefore, a collective effort is needed from all participating countries and do their part for CO2 emission reductions as a commitment to the Paris agreement 201516.

Bangladesh is one of the most rapidly developing countries in the world and at the same time one of the most vulnerable countries to the climate change due to the geographic location and low elevation17,18,19. Because of the increasing demand of energy to power the growth in the economy several new coal-based powerplants and industries are being developed and they will inevitably contribute to the emissions of CO2 in the atmosphere. In 1946, Bangladesh annually released approximately 0.12 Mt of CO2 into the atmosphere20. After 40 years, in 1986, this emission surged to 11.46 Mt, nearly 100 times of the 1946 level20. By 2000, the annual emission reached 26.52 Mt, and in 2021, it soared to 93.18 Mt20. Specifically, in 2019, 39.48 Mt of CO2 were released from the electricity and heat production sector, 24.93 Mt from the manufacturing and construction sector, 11.66 Mt from transportation, and 9.8 Mt from buildings21. Recently, Bangladesh has been completing three large coal-based power plant projects, namely the 1320 MW Rampal Power Station, 1200 MW Matarbari Power Station, and 1320 MW Payra Thermal Power Plant. Approximately 1023.758 kg of CO2 is produced to generate 1 MW of electricity from a coal-based power plant22. Therefore, a significant amount of CO2 will be released annually into the atmosphere from these three coal-based power plants and consequently contribute to global warming. To achieve the net zero emission target, it is imperative to capture these CO2 and inject in the subsurface.

Being one of the thickest sedimentary basins in the world, the Bengal Basin boast of having some of the most laterally extensive reservoirs. The Miocene aged fluvio-deltaic Bokabil Formation is one of them and considered as the most prolific reservoirs in the Bengal Basin. In the Bangladesh part of the Bengal Basin, 28 gas fields have been discovered thus far, estimated to possess a total recoverable gas reserve of 838.405 BCM (29.608 TCF)23,24. Among these fields, 11 are situated in the Surma Basin, containing an estimated total recoverable gas reserve of about 304.916 BCM (10.768 TCF)23,25. As of 2021, approximately 541.135 BCM (19.11 TCF) of the gas reserves have been extracted in the Bengal Basin24. Presently, Bangladesh consumes around 28.317 BCM (1 TCF) of natural gas annually, and the production rate from existing gas fields is approximately 25.485 BCM (900 BCF) per year, suggesting that commercial natural gas production in existing fields will continue for the next 10 years, after which the reservoirs will deplete and be abandoned at some point24. These gas fields, along with the existing infrastructure, present significant opportunities to contribute to the journey toward achieving net-zero emissions and create potential for CO2 trading in Bangladesh. Globally, many efforts are ongoing to develop fluvio-deltaic reservoirs as CO2 storage unit such as Bunter Sandstone Formation in the UK26,27,28,29, the Buntsandstein sandstone unit in the Netherlands30,31, Dupuy and Katnook Formation in Australia32,33,34. The findings from this study will be applicable in other places with similar geological setting.

The objective of this study is to characterize the Bokabil Formation within the Surma basin regarding its CO2 storage capacity in four gas fields. Additionally, the regional seal rock known as the Upper Marine Shale (UMS) within the Bengal Basin is part of this formation and remains uncharacterized to date. Here, we integrated detailed sedimentological and subsurface geophysical data, and used well-established reservoir characterization workflows to characterize the Bokabil reservoir and identify how much CO2 can be stored in this formation in the studied four gas fields. Based on the available pore volume and cap rock integrity the most optimal location for storing CO2 has been identified.

Regional geology and stratigraphy

Bangladesh, located in the eastern south Asia occupies a large portion of the Bengal Basin, and the basin is bounded in the north by Shillong plateau, in the east by Indo-Burman ranges, in the west by Indian shield and in the south open to Bay of Bengal. The Bengal basin is a well-known sedimentary basin for almost 22 km Cretaceous to Holocene thickest sedimentary succession with prolific hydrocarbon bearing and potential hydrocarbon generation, accumulation in the world35,36,37. The Bengal Basin initiated its development during early Cretaceous time by the breakup of Gondwana supercontinent and the evolved Indian plate started to move northward with an Atlantic type passive margin in the eastern margin of the plate. After the rift tectonic phase, the Indian plate collided with the Eurasian plate in the north and the Burma plate in the east and started to subduct beneath those plates since the late Eocene time38. The continuous interaction through Eocene to Holocene time among the Indian plate, Eurasian plate, and Burma plate resulted the current configuration of the Bengal Basin38,39,40. The Bengal basin as well as Bangladesh containing 6 major tectonic features, such as: Chittagong-Tripura Fold belt, Bengal Foredeep, Calcutta-Mymenshing Hing zone, Bogra Shelf, Rangpur Platform and Sub-Himalayan Foredeep41. The studied wells are located and scatted in the Surma Basin and the Surma Basin covering a large portion of Bengal Foredeep and a portion of northern Chittagong-Tripura Fold belt.

The Surma Basin covers the north eastern part of Bangladesh with an area about 13,500 km2 and located at the Junction of Indian plate, Eurasian plate, and Burma plate41. The stratigraphy of Surma Basin is almost analogous to Assam stratigraphy of India42,43. The Surma Basin stratigraphy (Fig. 1) comprised with a few major formations, such as: Tura sandstone, Sylhet limestone, Kopili shale, Jenum, Renji, Bhuban, Bokabil, Tipam and Dupi Tila, Dihing and Alluvium Formation43,44,45,46. The Sylhet Limestone, Kopili shale and Jenum formations are the potential major source rocks of the Surma Basin47,48,49. The studied Upper Bokabil Sandstone unit of Bokabil Formation in Surma Basin is the most significant hydrocarbon bearing unit in the Surma Basin as well as Bengal Basin23,50,51,52, which comprises medium to fine grained, moderately sorted, trough cross bedded sandstone with a few isolated mud drapes and defined the depositional environment as a braided fluvial system53. The regionally extensive Upper Marine Shale unit of Bokabil Formation is the main top seal unit which comprises predominantly dark gray to black shale with a little amount silt and indicating marine transgression over Sylhet as well as other parts of the Bengal Basin54,55.

Stratigraphic succession of the Surma Basin showing all the stratigraphic units23. The stratigraphic succession was created using Adobe Illustrator CC 2021 (https://www.adobe.com/uk/products/illustrator.html).

Data and methodology

Sedimentological analysis

Detailed sedimentological analyses were conducted to identify the contacts of the various stratigraphic units, nature of the reservoir and seal rocks. Petrographic analysis of the collected samples was performed for the identification of texture, mineralogy, and porosity. In total 14 samples were prepared for sieve and petrographic analysis. The samples were collected from the exposed outcrops of the Bokabil Formation along the Shari River cut section53.

Petrophysical analysis

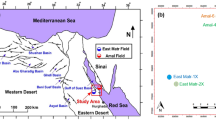

Wells from Sylhet, Kailashtila, Habiganj and Fenchuganj gas fields (Fig. 2) have been selected to study spatial variation of petrophysical properties of Bokabil Formation in the Surma Basin. The petrophysical analysis of the well logs from these gas fields had been carried out by many authors52,56,57,58,59, However those studies were general, brief, and not focused on the Bokabil Formation. Therefore, the qualitative and quantitative analysis have been carried out by the available well logs data in a consistent manner. The used geophysical well logs are caliper (CAL), gamma ray (GR), resistivity shallow (MSFL) and deep (ILD), density (DEN), neutron (NPHI), compressional sonic (DT) and spontaneous potential (SP) logs (Table 1).

Map of Bangladesh in the inset showing the extent of study area. Location of the gas fields within Surma basin and the outcrop location52. The map was created using Adobe Illustrator CC 2021 (https://www.adobe.com/uk/products/illustrator.html).

The Python libraries, namely Numpy, Pandas, and Matplotlib have been used for the various types of well log analysis and visualization including petrophysical and petrographic analysis (Supplementary information). The essential geophysical well logs are de-spiked as well as removed outliers by using OneClassSVM submodule of SVM (Support Vector Machine) module of unsupervised python machine learning techniques. The OpenCV python machine learning library has been used for petrographic analysis by converting color image to gray level image, transforming image from 2 to 1D and then segmenting the image based on 1D histogram.

Volume of Shale (Vsh) determination

Volume of Shale (Vsh) calculation is essential because it helps to differentiate between reservoir and seal rock, to calculate porosity, permeability, fluid content and overall reservoir quality. To calculate the volume of shale of upper gas sand zone of Bokabil Formation from gamma ray log, firstly the gamma ray index has been calculated by using the following equation of Schlumberger60.

where, IGR = gamma ray index, GRlog = gamma ray log reading of the formation, GRmax = maximum gamma ray log reading at shale base line, GRmin = minimum gamma ray log reading at sand base line.

The gamma ray logs of 4 different locations are de-spiked and normalized, then the highest range of gamma values considered shale base line and lowest range of values considered sand base line.

The IGR is a linear responses of gamma ray which is empirically correlated to the fraction or percent of shale volume, where Vsh = IGR and it provides upper limit of shale volume of the formation61. The studied Bokabil Formation of Surma basin in Bangladesh is of Mio-Pliocene age, thus the function of Larionov model for tertiary clastic rocks has been used to calculate more accurate fraction or percent of volume of shale of the formation by using the following formula62,63.

The volume of sand calculated by the following relation,

where, Vqurtz = fraction of quartz volume, Vsh = fraction of shale volume.

Porosity calculation

The total porosity has been calculated from the combination of density porosity and neutron porosity by using the following equations depending on the presence or absence of gas in the formation64,65. First, the density porosity has been calculated from density log by using the following formula.

where, ΦD = fraction or percent of density porosity of the formation, ρma = matrix density of the formation, for pure quartz sand 2.65 g/cm3, ρb = bulk density of the formation from log, ρf = fluid density, usually ranges from 1 to 1.1, but due to gas effect it becomes < 1 which results high porosity.

For gas bearing zone,

For absence of gas in the formation,

where, ΦT = total porosity or accurate porosity of the formation, ΦN = fraction or percent of neutron porosity of the formation.

The effective porosity is calculated by the following equation66,67.

In places with bad boreholes, sonic porosity was used instead of density porosity due to its high depth of penetration. Sonic porosity was calculated from compressional sonic log by using the following equation68.

where, ΦS = fraction or percent of sonic porosity of the formation, Δtlog = interval transit time from log, (μs/ft), Δtma = interval transit of the matrix of the formation, for sandstone 54–56 (μs/ft), Δtf = interval transit time of fluids in the well bore, for mud filtrate 185–190 (μs/ft).

Water saturation

Water saturation was calculated by using Indonesian model, the following equation has been used69.

where, Sw = water saturation, Φe = effective porosity, Rsh = resistivity of shale, Vsh = volume of shale, m = cementation coefficient, n = saturation capacity, Rw = formation water resistivity.

Permeability

Permeability estimation of a reservoir by using well log is one of the useful methods when core data are unavailable. The permeability has been calculated with the help of Timur empirical model based on porosity and irreducible water saturation by using the following equation70.

where, K = permeability of the formation in millidarcies (mD), Φ = total porosity, Swir = Irreducible water saturation.

The irreducible water saturation has been calculated by the following equation.

where, Sw = water saturation of the formation, Φe = effective porosity of the formation.

Results

The Bokabil Formation

The Bokabil Formation is around 1500 m thick in the Surma Basin71,72. Outcrop and subsurface data analysis suggest that there are significant variations in the rock types of this formation. The top most part of the formation is a thick shaly unit, popularly known as the Upper Marine Shale (UMS) (Fig. 3). This represents the last marine transgression and is acting as the regional seal in the Bengal Basin59,73. It has an unconformable contact with the overlying Tipam Sandstone Formation.

Wireline logs of Kailashtila well showing the most part of the Bokabil Formation. Uppermost part of the Bokabil Formation is known as the Upper Marine Shale followed by the Upper Bokabil Sandstones represented by the blocky sandstones (green color) and finally the Middle and Lower Bokabil Sandstones indicated by the coarsening upward cycles (red color).

In the outcrop this unit is characterized by dark gray to black fissile shale, and in the well logs, this unit shows high gamma ray value and high density. Following the Upper Marine Shale, a thick sequence of sandstone unit is identified (Fig. 4).

Outcrop photos of Bokabil Formation. (A) The contact between Bokabil Formation and the overlying Tipam Sandstone Formation, (B) contact between Upper Marine Shale (UMS) and Upper Gas Sand (UGS) within the Bokabil Formation, (C) Dark grey fissile shale is the characteristic lithology of Upper Marine Shale, (D) Yellowish brown, trough cross bedded sandstone is the dominant lithofacies in Upper Bokabil Sandstones.

Log motif analysis shows the Upper Bokabil Sandstones are of blocky pattern and are separated by thin shale units of high gamma ray. Thickness of individual sand unit is in the range of few meters. Overall, this unit consisting with sandstones of blocky pattern, is around 350 m thick in the entire Surma Basin (Figs. 3, 9). Facies at the outcrops suggest this unit is of fluvial origin indicated by large cross beds and channel shaped sandbodies. These moderately consolidated sandstone units are collectively termed as the Upper Bokabil Sandstones53. Below these units are some coarsening upward cycles have been noticed. The outcrop equivalents of these units were not found in the study area. Based on the eletrofacies these are interpreted as the prograding deltaic deposits. Thickness of shale in these coarsening upward cycles decrease upward suggesting gradual shallowing of the basin59,73. The interpretation is consistent with the paleogeography and tectonic evolution of the Bengal Basin73. As the contact between Bokabil Formation and the underlying formation has not been observed in the studied wells, it is believed that significant portion of the Bokabil Formation has not been penetrated by the wells, hence these are termed as the Middle and Lower Bokabil Sandstones.

Characterization of Bokabil Sandstone reservoir

Petrographic characterization

Fourteen (14) samples were prepared for the thin section and sieve analysis to study the texture, mineralogy, porosity and diagenetic history of the Upper Bokabil Sandstones.

Texture

The grain sizes are estimated on the basis of Udden–Wentworth scale74,75. The studied samples are fine to medium grained sand, moderately sorted, and sub-angular to sub-rounded in texture. The grain size sieve analysis including various statistical measurements suggest that the Upper Bokabil sandstones are unimodal and fine to medium grained in size, the modal class ranges between 0.125 and 0.0645 mm in grain size (Fig. 5) indicating the predominance of the fine sand. Various statistical parameters76 have been measured for the Upper Bokabil sandstones, where the graphic mean value is 2.23 which indicates fine sand, the graphic standard deviation or the sorting value is 0.78 indicates moderately sorted, the graphic skewness value is 0.95 indicates positive skewed or fine skewed, and the graphic kurtosis value is 1.17 which indicates leptokurtic.

Mineralogy

Thin sections were analyzed using petrographic microscope to study the mineralogical composition of Upper Bokabil Sandstones. Most of the thin sections show that the upper Bokabil Sandstones are composed of quartz, feldspars, rock fragments, and mica. The clay minerals are present as matrix and void spaces are the porosity.

The unsupervised image segmentations using machine learning can effectively separate quartz (Fig. 6C) and mica (Fig. 6D) which helps in measuring amount of various minerals. Quartz is the most abundant mineral in the samples with a percentage of about 65–75 percent (Fig. 6A). Feldspars, mica and rock fragments comprises about 5–12 percent, 3–8 percent, and 2–4 percent, respectively (Fig. 6E,F).

Photomicrographs of the representative thin section under plane (A) and cross (B) polarized light showing the constituent minerals (Q = Quartz, Mi = Mica, Fl = Feldspar, Rf = Rock Fragments). Quartz grains (C) and the Mica and Rock Fragments (D) separated using image segmentation techniques. Photomicrographs under crossed polarized light (E, F) showing Quartz, Feldspar, and Rock Fragments.

Diagenesis

Diagenesis plays a vital role in both enhancing and destroying reservoir quality. The dissolution of fragmental grains including changes in grain shape, contacts, deformation of the soft grains, generation of secondary porosity all are resulted due to physical, chemical and physicochemical changes, which all are involved in the stage of diagenesis of the Upper Bokabil Sandstones in the Surma Basin. Predominance of point and line contacts (Fig. 7) among grains suggest moderate compaction occurred at shallow depth. Some suture contacts and bending of elongated grains also been noticed. The secondary porosities are resulted from dissolution of structural grains. The feldspars are most susceptible for secondary porosity generation by the process of dissolution. In some grains dissolutions of feldspars have removed 70–80% of the grain.

Porosity

The porosity of the samples was measured in thin section by point counting and area coverage. Porosity in the studied samples ranges from 18 to 26% (Fig. 8A) including mostly primary porosity and some secondary porosity. The secondary porosity mainly generated by dissolution of framework grains (Fig. 8C,D) after burial. The dissolutions took place within plagioclase feldspars than other framework grains which supporting the Goldich Weathering Series77. The petrographic analysis by using unsupervised image segmentation with OpenCV reveals a well connected pore network (Fig. 8B) within the thin section of Bokabil Sandstone.

Photomicrograph under plane polarized light (A) showing the primary intergranular porosity (blue dye). Pore networks (red color) extracted using image segmentation technique showing good connectivity among pores (B). Photomicrographs showing the secondary porosity (red arrow) under plane cross polarized light (C, D).

Petrophysical analysis

The petrophysical analysis has been carried out to evaluate reservoir properties and eventually to estimate the storage capacity. The estimated petrophysical properties are volume of shale and their distribution, porosity, permeability, and water saturation. The Upper Bokabil Sandstones in the Surma Basin are observed at different depths at different wells including 1195–1590 m, 2245–2650 m, 1355–1720 m and 1580–1910 m in the Sylhet, Kailashtila, Habiganj and Fenchuganj structures (Fig. 9), respectively. The estimated net reservoir thickness of the Bokabil Formation is about 351 m, 353 m, 271, 332 m in the Sylhet, Kailashtila, Fenchuganj, and Habiganj structures (Fig. 9), respectively.

North–south correlation panel across the studied wells showing the variation in the thickness of Upper Marine Shale (UMS) and Upper Bokabil Sandstone. Thickness of UMS increases from north to south. There is no obvious trend in the Upper Bokabil Sandstone thickness but seem to have a uniform thickness throughout the basin.

Volume of Shale

The volume of shale and distribution of shale and distribution of shale types including dispersed, laminated and structural can affect porosity, permeability and saturation as well as log responses of a reservoir78. The histogram of volume of shale reveals the distribution of volume of shale percentage in the reservoir sands of Bokabil Formation.

The log plots and the histogram for volume of shale (Fig. 10) of reservoir sands reveal that the average volume of shale in the Sylhet structure is about 17.7%. In the Kailashtila, Habiganj and Fenchuganj structures the average volume of shale are about 24%, 15%, and 27%, respectively.

Shale distribution

Density porosity and Neutron porosity crossplot also known as Thomas Stieber cross plot79 was used to identify the shale distribution pattern within the Upper Bokabil Sandstone. The plot shows that most of the points of all four wells fall within the domain of laminated shale. Some are mixed structural and laminated shale (Fig. 11). There is hardly any shale that is dispersed within the sands. In the studied thin sections presence of structural shale could not identified. Observations in the outcrops show prevalence of shale facies alternated with sandstone and siltstone (Fig. 12). These also occur as mud drapes over the foresets in the planar and trough cross bedded sandstone facies.

Porosity

The histogram of porosity (Fig. 13) for Sylhet, Kailashtila, Habiganj and Fenchuganj structures shows the distribution of porosity within the Upper Bokabil Sandstone. The average porosity is about 24.8%, 23.4%, 27.4% and 23.86% in the Sylhet, Kailashtila, Habiganj and Fenchuganj structures, respectively. The Upper Bokabil Sandstone in Kailashtila and Fenchuganj structures shows relatively lower porosity than Sylhet and Habiganj structures due to the position of reservoir sands at greater depth than Sylhet and Habiganj structures. The cross plot of sonic porosity against density porosity shows these are mostly primary intergranular porosity (Fig. 14). Relatively minor secondary porosities could be related to the dissolution of grains as seen in the thin sections (Fig. 8C,D).

Permeability

The histogram of permeability (Fig. 15) of Upper Bokabil Sandstone shows the distribution of permeability in the Sylhet, Kailashtila, Habiganj and Fenchuganj structures. The average permeability is about 241 mD, 209 mD, 857 mD and 140 mD in Sylhet, Kailashtila, Habiganj and Fenchuganj structures, respectively. The Kailashtila and Fenchuganj structures show lower permeability than Sylhet and Habiganj structures due to lower porosity, position at greater depth and higher laminated shale distribution (Fig. 11). The Sylhet structure showing lower permeability than Habiganj structure due to lower porosity and presence of higher proportion of laminated shale.

Water saturation

The histogram of water saturation (Fig. 16) of Upper Bokabil Sandstone shows the distribution of water saturation in Sylhet, Kailashtila, Habiganj and Fenchuganj structures. The average water saturation is about 14.3%, 18.7%, 15.7% and 21% for the Sylhet, Kailashtila, Habiganj and Fenchuganj structures, respectively.

The average petrophysical properties of Upper Bokabil Sandstone in all four gas fields have been summarized in Table 2.

Flow barriers and the Kv/Kh

The outcrop of Upper Bokabil sandstone exhibits various permeability barriers (Fig. 12) that might play a crucial role in controlling vertical permeability. These barriers are present at different scales, ranging from the smallest to the largest. The smallest-scale barriers are mud laminae that alternate with sand laminae (Fig. 12). In addition, mud drapes along the foresets of cross-bedded sandstone units can also impede flow. At the largest scale, the most significant barriers are floodplain mudstones, which alternate with channel deposits53. These barriers are laterally discontinuous. Such flow barriers can influence the injectivity and connectivity during the CO2 sequestration process80,81,82. Their effect on the vertical permeability has been described by many authors83,84,85. Here, the impact of discontinuous shale/mudstone on vertical permeability of the Bokabil Sandstone has been evaluated. The first-order influence of the discontinuous mudstones on vertical permeability has been evaluated by applying the equation developed by Begg and King83 to account for the effect of stochastically distributed, laterally discontinuous impermeable barriers (Fig. 12).

where, Kvs is the effective vertical permeability, K is the effective vertical permeability in the absence of barriers, Fr is the fraction of barrier within the unit, s is the barrier density, and l is the mean barrier length. Considering Kv = Kh in the case of homogeneous sandstone, this equation can be rearranged to

Based on outcrop analysis (Fig. 12), s = 0.5 m−1, Fr = 0.15, and l = 8 m. By inputting these values to Eq. (13), the Kvs/Kh ratio equals 0.094, which suggests these mud layers have a significant impact on effective vertical permeability.

Characterization of the Bokabil Caprock

The Upper Marine Shale unit of Mio-Pliocene age marked as Transgressive System Tract (TST) overlying the Bokabil reservoir units by 80–350 m thick impermeable rock unit as a cap rock succession59,73. The XRD analysis (Fig. 17A) reveals that the cap rock unit is mineralogically composed of quartz, albite, mica, illite, carbonate, kaolinite, smectite, chlorite, serpentine and a very few contaminations (Table 3). The percentages of abundant minerals quartz, feldspars, mica, illite and kaolinite in UMS are approximately 34%, 8%, 20%, 14% and 18%, respectively.

SEM images show the abundance of flaky minerals (Fig. 17B,C) which are identified as the clay minerals. The SEM images also reveal the nano type pore with very small diameters, in the range of 10–40 nm (Fig. 17B,C). This very small pore throat diameter results very high capillary entry pressure approximately 5–20 MPa based on the Washburn equation, where considering the interfacial tension for CO2–water and CO2–gas–water multiphase system is about 0.05 N/m based on the pendant drop technique and water wet condition for the contact angle (θ = 0°) between solid and fluid86.

Effective storage capacity of Bokabil reservoirs

Effective storage capacity has been calculated to estimate total volume of CO2 that can be injected. The reservoir temperature and thermal gradient data (Table 4) are collected from87. The structural area (Table 4) calculated from the top to spill point on a seismic section. The average density of CO2 (Table 4) is estimated based on the depth-density cross plot88.

To calculate the theoretical CO2 storage capacity of the Sylhet, Kailashtila, Habiganj and Fenchuganj structures, the CSLF (Carbon Sequestration Leadership Forum) method has been used in this research paper89. The upper portion of the Upper Bokabil Sandstone is a gas reservoir while the lower portion a saline aquifer (Fig. 9). Therefore, Eq. (14) has been used for the brine aquifer portion of the reservoir and Eq. (15) has been used for the gas reservoir to calculate the total volume of CO2 can be stored in the studied geological structures using the CSLF method,

The equation for the brine aquifer:

The equation for the gas reservoir:

where, MCSLF (brine) = CO2 storage capacity (kg) for the brine aquifer, MCSLF (gas) = CO2 storage capacity (kg) for the gas reservoir, ρCO2 = average density of CO2 under reservoir conditions (kg/m3), A = area of the structure (m2), h = average thickness of the structure (m), Φ = average porosity of the structure, Swirr = irreducible water saturation, the average irreducible water saturation assumed 25% for all structures, Sw = water saturation using from Table 2, Rf = recovery factor (average recovery factor about 85% based on production data of Petrobangla).

To estimate the theoretical storage capacity, the required values of variables for Eqs. (14) and (15) are taken from Tables 2 and 4 through log analyses. Three different cases have been considered for volumetric calculations. Petrophysical properties were varied by 2 standard deviations from the mean for the minimum and maximum cases. The standard deviations for porosity in the Sylhet, Kailashtila, Habiganj, and Fenchuganj structures are 0.022, 0.028, 0.029, and 0.0277, respectively. For water saturation, the standard deviations are 0.04, 0.07, 0.11, and 0.12 for the same structures, respectively. The areal coverage was also varied as a function of the height of the structural closure. Thickness was varied based on the observations in the studied wells.

The storage efficiency for CO2 storage defines the ratio of substantive amount of CO2 stored to the available theoratical storage, that reveals the actual effective storage capacity90. By using multiphase flow theory and empirical site data, Ringrose et al. suggested the the actual effective storage capacity for CO2 injection is less than 6% of the theoratical storage capacity91. In case of Sleipner CO2 storage project, the storage efficiency was approximately 5.2%92. Therfore, 6% cut-off has been used to the theoretical storage capacity to estimate the actual effective storage capacity for CO2 injection (Fig. 18).

Discussion

This study aimed at characterizing the Upper Bokabil Sandstones as a potential CO2 storage unit and the Upper Marine Shale as a regional seal by integrating subsurface data from four gas fields along with their outcrop analogues. Thin section petrography, SEM, XRD analysis, petrophysical analysis were performed to estimate the reservoir and seal characteristics.

The Upper Marine Shale (UMS), lying above the Upper Bokabil Sandstone is regionally extensive (Fig. 9) and effectively trapped the hydrocarbons below it in the Bengal Basin25,72,93. High percentage of quartz in the UMS (Fig. 17A) suggest its high mechanical strength and the relatively high fraction of micas and clay minerals indicates its thermal stability. The high percentage of quartz and a low percentage of feldspars also an indicator of its chemical stability94. The higher amount of ductile minerals such as illite and kaolinite are suggestive of low brittleness index and affirms its integrity to hold CO295. The SEM images show pore throat diameters are in the range of 10–40 nm. The capillary entry pressure is inversely proportional to the pore throat diameter; therefore, to flow through these very narrow pore throats, high capillary entry pressure approximately 5–20 MPa will be required96,97,98.

The petrographic and sieve analysis of the Upper Bokabil Sandstone in the Surma Basin suggest that, it is fine to medium grained sand, moderately sorted, fine skewed, leptokurtic and sub arkosic in composition with 18–26% porosity. The abundance of the point contacts along with little line and suture contacts are suggestive of lack of significant diagenesis in the Upper Bokabil Sandstone (Fig. 6). The microscopic image segmentation (Fig. 8B) shows a well-connected pore network.

The petrophysical analysis shows the volume of shale in the Upper Bokabil Sandstones ranges from 17 to 27% which again suggests good reservoir quality. The Thomas Stieber cross plot shows that these shales are distributed predominantly in a laminated manner (Fig. 11). The porosity of the reservoir unit ranges in 23–27% with high permeability 140–860 mD and water saturation ranges from 14 to 21%.

The differences in the porosity and permeability in the Upper Bokabil Sandstone in the gas fields are mainly due to the consolidation of the sandstones. Velocity-porosity crossplot shows Upper Bokabil Sandstone units of the four structures are soft in nature (Fig. 19). The soft sands are highly porous and exhibit good connectivity among pores99. The relative petrophysical analysis among these four structures suggest that, the southern portion of the basin is better on the basis of net reservoir thickness, high effective porosity, low volume of shale, and low water saturation (Table 2). Sandstones in the Kailashtila structure are comparatively stiffer than Sylhet, Habiganj and Fenchuganj structures (Fig. 19) due to the higher burial depth. Hence, they experienced higher burial pressure and compaction, which reduced the primary porosity of the Upper Bokabil Sandstone unit in Kailashtila. The higher burial pressure and compaction lead to diagenetic changes, where feldspars are converted to clay minerals and affect the porosity and permeability100,101.

Storage capacity estimated using CLSF method shows that the theoretical storage capacity ranges between 1399–2057 Mt, 1380–2334 Mt, 2624–4285 Mt and 1878–3733 Mt in Sylhet, Kailashtila, Habiganj and Fenchuganj structures, respectively (Fig. 20). The effective storage capacity was estimated by applying the 6% cut off91, the effective storage capacity ranges between 84–123 Mt, 83–140 Mt, 157–257 Mt and 113–224 Mt in Sylhet, Kailashtila, Habiganj and Fenchuganj structures, respectively (Fig. 18). These numbers are well above some of the industry scale ongoing CO2 projects such as the Sleipner in Norway, In Salah in Algeria, Salt Creek in USA, and Weyburn in Canada. These projects have an effective storage capacity for CO2 of 20 Mt, 20 Mt, 27 Mt, and 35 Mt, respectively102,103,104,105.

Along with good petrophysical properties, the other parameters that dictate how CO2 will migrate and trap within the reservoirs are sedimentological heterogeneity80,106,107. The presence of small-scale heterogeneity in the form of lithological and facies variability is very important in the CO2 storage and trapping as they have significant impact on fluid saturation and relative permeability106,108,109,110,111,112,113. The Upper Bokabil Sandstone unit shows heterogeneity in the lamina scale as well as in the lithofacies scale53 (Fig. 12). The presence of mud drapes along the foresets in the crossbedded sandstone and the alternating mudstone and sandstone laminae (Fig. 12) will create capillary equilibrium which might lead to trapping of CO2 across the capillary pressure boundary106,114,115. Ashraf showed that the mud drapes within sandstone facies act as barriers for CO2 plume migration108.

To determine the effect of meter scale mud layers (Fig. 12) in the fluid flow through Upper Bokabil Sandstones, the modified equation of Begg and King were utilized to determine the vertical effective permeability53,83. Results show that, the effective vertical permeability of the unit can decrease significantly due to presence of discontinuous mud layers within the Upper Bokabil Sandstones. These mud layers will restrict the vertical flow and force the injected fluids to move laterally beneath the barriers80,107. This process will lead to localized trapping of CO2 within the reservoir known as local capillary trapping115,116. Hovorka et al. performed a series of numerical simulations and suggested in a homogenous reservoir due to the buoyancy of CO2, CO2 does not disperse and bypass most of reservoir volume which reduces storage capacity117. Whereas, stratigraphic heterogeneity can increase CO2 sequestration capacity due to dispersive flow network, results distribution of CO2 in the whole reservoir117. This stratigraphic heterogeneity will enhance the sequestration effectiveness by distributing CO2 in the whole reservoir and shortening the height of buoyant CO2 plume, which will lead to reduced risk of leakage and seal failure107,118,119. The pore volume will be better utilized and the upward migrated CO2 will be smaller which will make monitoring of the CO2 plume easy and cost effective81,107. Therefore, dispersive flow network due to heterogeneity, high horizontal permeability, capability of distribution of CO2 in the whole reservoir make the Upper Bokabil Sandstones ideal for carbon storage.

Since the lithological characteristics of any deposits, their porosity, permeability, net reservoir thickness, heterogeneity is controlled by depositional system, the findings from this study can be utilized to better understand the braided fluvial reservoirs in the other basins where they are being developed for CO2 storage. Some of the notable ones are Bunter Sandstone Formation in the UK, Buntsandstein Formation in the Netherlands, Utsira Formation in Sleipner field in Norway120,121,122.

The aforementioned characteristics suggest that, the Upper Bokabil Sandstone has good reservoir properties capped by the regional seal rock known as Upper Marine Shale. The high thickness and well connectivity among pores (Fig. 8B) will allow high injectivity of CO2. The shallower depth of the Upper Bokabil Sandstones and good petrophysical properties suggest Sylhet and Habiganj structures are more well suited for the initial phase of injection.

Conclusion

Large scale implementation of Carbon Capture and Storage (CCS) will be required to keep the global warming under control. For this to be successful, identification of good quality storage unit with thick top seals are crucial. This study characterized the Bokabil Formation in the Surma Basin as a potential storage unit. Petrographic analysis showed this is a very good reservoir rock. Having a high thickness, basin-wide lateral extent, higher porosity, and well-connected pores indicate this unit has a significant storage capacity. The presence of laminated shale within the Upper Bokabil Sandstone unit will allow capillary trapping of CO2 within the reservoir and regional extent of the top seal Upper Marine Shale offers reliable trapping of CO2 in the subsurface for a long time. The estimated cumulative mean effective storage capacity is about 582 Mt CO2 in the studied fields, which can be significantly increased if other gas fields in the Surma basin are included in the analysis. The Upper Bokabil Sandstone unit is relatively shallow in the northern and southern parts of the Surma Basin, making them more suitable for storage. The findings in this study would also be applicable to hazardous waste injection, hydrogen storage, etc.

Data availability

The datasets used and/or analyzed during the current study available from the corresponding author on reasonable request.

References

Driga, A. M. & Drigas, A. S. Climate change 101: How everyday activities contribute to the ever-growing issue. Int. J. Recent Contrib. Eng. Sci. 7(1), 22–31. https://doi.org/10.3991/ijes.v7i1.10031 (2019).

McMichael, A. J. & Lindgren, E. Climate change: Present and future risks to health, and necessary responses. J. Intern. Med. 270(5), 401–413. https://doi.org/10.1111/j.1365-2796.2011.02415.x (2011).

Van Aalst, M. K. The impacts of climate change on the risk of natural disasters. Disasters 30(1), 5–18. https://doi.org/10.1111/j.1467-9523.2006.00303.x (2006).

Yoro, K. O., & Daramola, M. O. CO2 emission sources, greenhouse gases, and the global warming effect. in Advances in Carbon Capture, 3–28. (Woodhead Publishing, 2020). https://doi.org/10.1016/B978-0-12-819657-1.00001-3.

Letcher, T. M. Global warming: A complex situation. in Climate Change, 3–17. (Elsevier, 2021). https://doi.org/10.1016/B978-0-12-821575-3.00001-3.

Le Quéré, C. et al. Global carbon budget 2016. Earth Syst. Sci. Data 8(2), 605–649. https://doi.org/10.5194/essd-8-605-2016 (2016).

Hoegh-Guldberg, O. et al. Impacts of 1.5 C global warming on natural and human systems. Global warming of 1.5°C. (2018). https://tuhat.helsinki.fi/ws/portalfiles/portal/130632298/SR15_Approval_Chapter_3.pdf.

Quadrelli, R. & Peterson, S. The energy–climate challenge: Recent trends in CO2 emissions from fuel combustion. Energy Policy 35(11), 5938–5952. https://doi.org/10.1016/j.enpol.2007.07.001 (2007).

Raupach, M. R. et al. Global and regional drivers of accelerating CO2 emissions. Proc. Natl. Acad. Sci. 104(24), 10288–10293. https://doi.org/10.1073/pnas.0700609104 (2007).

Yoro, K. O. & Daramola, M. O. CO2 emission sources, greenhouse gases, and the global warming effect. in Advances in Carbon Capture, 3–28. (Woodhead Publishing, 2020). https://doi.org/10.1016/B978-0-12-819657-1.00001-3.

Singh, P. & Yadav, D. Link between air pollution and global climate change. in Global Climate Change, 79–108. (Elsevier, 2021). https://doi.org/10.1016/B978-0-12-822928-6.00009-5.

Masson-Delmotte, V. et al. Climate change 2021: the physical science basis. in Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change, 2(1), 2391. (2021). https://doi.org/10.1017/9781009157896.

IPCC. Summary for policymakers. in Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. (Stocker, T. F. et al. eds) (Cambridge University Press, 2013). https://boris.unibe.ch/id/eprint/71453.

IPCC Summary for policymakers. In Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C Above Pre-industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty (eds Masson-Delmotte, V. et al.) (World Meteorological Organization, 2018).

Voll, D., Wauschkuhn, A., Hartel, R., Genoese, M. & Fichtner, W. Cost estimation of fossil power plants with carbon dioxide capture and storage. Energy Procedia 23, 333–342. https://doi.org/10.1016/j.egypro.2012.06.038 (2012).

UNFCCC. Paris agreement. in Report of the Conference of the Parties to the United Nations Framework Convention on Climate Change (21st Session, 2015: Paris), vol. 4, 2017). (2015). https://unfccc.int/resource/docs/2015/cop21/eng/10a01.pdf.

Agrawala, S., Ota, T., Ahmed, A. U., Smith, J. & Van Aalst, M. Development and Climate Change in Bangladesh: Focus on Coastal Flooding and the Sundarbans 1–49 (OECD, 2003).

Dastagir, M. R. Modeling recent climate change induced extreme events in Bangladesh: A review. Weather Clim. Extrem. 7, 49–60. https://doi.org/10.1016/j.wace.2014.10.003 (2015).

Islam, M. A. et al. Fourth industrial revolution in developing countries: A case on Bangladesh. J. Manag. Inf. Decis. Sci. (JMIDS) 21(1), 3417813 (2018).

Friedlingstein, P. et al. Global carbon budget 2022. Earth Syst. Sci. Data Discuss. 2022, 1–159. https://doi.org/10.5194/essd-14-4811-2022 (2022).

Ritchie, J. S., & Pratsides, P. The caister fields, block 44/23a, UK north sea. in Geological Society, London, Petroleum Geology Conference Series, Vol. 4, No. 1, 759–769. (The Geological Society of London, 1993).

McGrath, G. Electric power sector CO2 emissions drop as generation mix shifts from coal to natural gas. Today in Energy. U.S. Energy Information Administration. https://www.eia.gov/todayinenergy/detail.php?id=48296. Accessed 9 Jun 2021.

Curiale, J., Covington, G., Shamsuddin, A., Morelos, J. & Shamsuddin, A. Origin of petroleum in Bangladesh. AAPG Bull. 86(4), 625–652. https://doi.org/10.1306/61EEDB66-173E-11D7-8645000102C1865D (2002).

Petrobangla. Annual Report 2021. (2022). http://www.petrobangla.org.bd/sites/default/files/files/petrobangla.portal.gov.bd/annual_reports/3b3b53fd_e70e_48b8_92af_5be5175204b2/2022-10-14-11-22-ca7de68e2252061b00da3dea1375ad9b.pdf.

Shamsuddin, A. H. M. Petroleum Systems of Bangladesh. (2001).

Hossain, S., Hampson, G. J., Jacquemyn, C., Jackson, M. D. & Chiarella, D. Permeability characterisation of sedimentological facies in the Bunter Sandstone Formation, Endurance CO2 storage site, offshore UK. Int. J. Greenhouse Gas Control 135, 104140. https://doi.org/10.1016/j.ijggc.2024.104140 (2024).

Alshakri, J. et al. A Screening Assessment of the Impact of Sedimentological Heterogeneity on CO2 Migration and Stratigraphic-Baffling Potential (Sherwood and Bunter Sandstones, 2023). https://doi.org/10.1144/SP528-2022-34.

Gluyas, J. G. & Bagudu, U. The endurance CO2 storage site, blocks 42/25 and 43/21, UK North Sea. Geol. Soc. 52(1), 163–171. https://doi.org/10.1144/M52-2019-47 (2020).

Heinemann, N., Wilkinson, M., Pickup, G. E., Haszeldine, R. S. & Cutler, N. A. CO2 storage in the offshore UK Bunter Sandstone Formation. Int. J. Greenhouse Gas Control 6, 210–219. https://doi.org/10.1016/j.ijggc.2011.11.002 (2012).

Wildenborg, T., Loeve, D. & Neele, F. Large-scale CO2 transport and storage infrastructure development and cost estimation in the Netherlands offshore. Int. J. Greenhouse Gas Control 118, 103649. https://doi.org/10.1016/j.ijggc.2022.103649 (2022).

Arts, R. J. et al. The feasibility of CO2 storage in the depleted P18–4 gas field offshore the Netherlands (the ROAD project). Int. J. Greenhouse Gas Control 11, S10–S20. https://doi.org/10.1016/j.ijggc.2012.09.010 (2012).

Quinn, M. Carbon capture and storage: A review of Australian projects. APPEA J. 62(1), 334–341. https://doi.org/10.1071/AJ21161 (2022).

Trupp, M. et al. Developing the world’s largest CO2 injection system: A history of the Gorgon carbon dioxide injection system. in Proceedings of the 15th Greenhouse Gas Control Technologies Conference, 15–18. https://doi.org/10.2139/ssrn.3815492.

Gibson-Poole, C. M. Site characterisation for geological storage of carbon dioxide: examples of potential sites from the North West Shelf, Australia (Doctoral dissertation). (2010). https://hdl.handle.net/2440/63078.

Alam, M., Alam, M. M., Curray, J. R., Chowdhury, M. L. R. & Gani, M. R. An overview of the sedimentary geology of the Bengal Basin in relation to the regional tectonic framework and basin-fill history. Sedim. Geol. 155(3–4), 179–208. https://doi.org/10.1016/S0037-0738(02)00180-X (2003).

Curray, J. R. Possible greenschist metamorphism at the base of a 22-km sedimentary section, Bay of Bengal. Geology 19(11), 1097–1100 (1991).

Curray, J. R. & Munasinghe, T. Origin of the Rajmahal Traps and the 85 E Ridge: Preliminary reconstructions of the trace of the Crozet hotspot. Geology 19(12), 1237–1240 (1991).

Curray, J. R., Emmel, F. J., Moore, D. G., & Raitt, R. W. Structure, tectonics, and geological history of the northeastern Indian Ocean. in The Ocean Basins and Margins, 399–450 (Springer, 1982). https://doi.org/10.1007/978-1-4615-8038-6_9.

Alam, M. Geology and depositional history of Cenozoic sediments of the Bengal Basin of Bangladesh. Palaeogeogr. Palaeoclimatol. Palaeoecol. 69, 125–139. https://doi.org/10.1016/0031-0182(89)90159-4 (1989).

Coffin, M. F. & Lawver, L. Atlas of Paleogeographic Reconstructions (University of Texas Institute for Geophysics, 1998).

Alam, M., Hassan, A., Khan, M., & Whitney, J. Geological Map of Bangladesh, Scale 1: 1,000,000. (Government of the Peoples's Republic of Bangladesh, 1990).

Evans, P. Tertiary succession in Assam. Trans. Min. Geol. Inst. India 27(3), 155–260 (1932).

Imam, B. Energy Resources of Bangladesh: Natural Gas, Oil, Coal (University Grants Commission of Bangladesh, 2013).

Khan, F. H. Geology of Bangladesh (Wiley Eastern, 1991).

Hossain, H. M. Z., Roser, B. P. & Kimura, J. I. Petrography and whole-rock geochemistry of the Tertiary Sylhet succession, northeastern Bengal Basin, Bangladesh: Provenance and source area weathering. Sedim. Geol. 228(3–4), 171–183. https://doi.org/10.1016/j.sedgeo.2010.04.009 (2010).

Reimann, K. Geology of Bangladesh (Science Publishers, 1993).

Farhaduzzaman, M. Characterization of Selected Petroleum Source Rocks and Reservoir Rocks of Bengal Basin (Bangladesh) Based on Geochemical Petrographical and Petrophysical Methods (University of Malaya, 2013).

Hiller, K., & Elahi, M. Structural Growth and Hydrocarbon Entrapment in the Surma Basin, Bangladesh. (1989).

Jahan, S., Uddin, A., Pashin, J. C. & Savrda, C. E. Petroleum source-rock evaluation of upper Eocene Kopili Shale, Bengal Basin, Bangladesh. Int. J. Coal Geol. 172, 71–79 (2017).

Hossain, A., Hossain, D. & Abdullah, R. Structural and stratigraphic interpretation of geophysical data of the Fenchuganj gas field in the Surma basin, Bangladesh. J. Geol. Soc. India 86(2), 148–154. https://doi.org/10.1007/s12594-015-0294-4 (2015).

Shah, M. S. et al. Petrophysical evaluation of well log data for reservoir characterization in Titas gas field, Bangladesh: A case study. J. Nat. Gas Sci. Eng. 95, 104129. https://doi.org/10.1016/j.jngse.2021.104129 (2021).

Shreya, S. S., Bhuiyan, M. A. H., Hossain, S. & Sultana, T. Petrophysical reservoir characterization of Habiganj Gas Field, Surma Basin, Bangladesh. Dhaka Univ. J. Earth Environ. Sci. 10(1), 1–10. https://doi.org/10.3329/dujees.v10i1.56275 (2021).

Hossain, S., Shekhar, H. & Rahman, N. Facies and architectural element analysis of the upper Bokabil Sandstone in the Bengal Basin. Sedim. Geol. https://doi.org/10.1016/j.sedgeo.2023.106433 (2023).

Holtrop, J. & Keizer, J. Some aspects of the stratigraphy and correlation of the Surma Basin wells, East Pakistan. ECAFE Miner. Resourc. Dev. Ser. 36, 143–154 (1970).

Rahman, M., Mccann, T., Abdullah, R. & Yeasmin, R. Sandstone diagenesis of the neogene Surma group from the Shahbazpur gas field, southern Bengal basin, Bangladesh. Austrian J. Earth Sci. 104(1), 1–10 (2011).

AbdullahAlFatta, M., Islam, S. & Farhaduzzaman, M. Petrophysical analysis of sylhet gas field using well logs and associated data from Well Sylhet, Bangladesh. Int. J. Pet. Petrochem. Eng. 4(1), 55–69. https://doi.org/10.20431/2454-7980.0401007 (2018).

Ahmed, A. D. & Islam, M. S. International Journal of Petroleum and Geoscience Engineering. (2015).

Islam, M. Petrophysical evaluation of subsurface reservoir sandstones of Bengal Basin, Bangladesh. J. Geol. Soc. India 76(6), 621–631 (2010).

Parvin, A., Rahman, M. J. & Woobaidullah, A. Petroleum prospect analysis and new gas horizon detection at Fenchuganj Gas Field in the Surma Basin, Bangladesh: An application of sequence stratigraphic concept. Mar. Pet. Geol. 102, 786–799. https://doi.org/10.1016/j.marpetgeo.2019.01.033 (2019).

Schlumberger. Log Interpretation. (1974).

Poupon, A. & Gaymard, R. The evaluation of clay content from logs. in Paper Presented at the SPWLA 11th Annual Logging Symposium. (1970).

Atlas, D. Dresser Atlas Log Interpretation Charts (Dresser Atlas Dresser Industries, 1979).

Larionov, V. Radiometry of Boreholes 127 (Nedra, 1969).

Bateman, R. Openhole Log Analysis and Formation Analysis. (1985).

Schlumberger. Log Interpretation. (1972).

Adams, S. J. Quantifying petrophysical uncertainties. in Paper presented at the SPE Asia Pacific Oil and Gas Conference and Exhibition. (2005). https://doi.org/10.2118/93125-MS.

Worthington, P. Conjunctive interpretation of core and log data through association of the effective and total porosity models. Geol. Soc. Lond. Spec. Publ. 136(1), 213–223. https://doi.org/10.1144/GSL.SP.1998.136.01.18 (1998).

Wyllie, M., Gregory, A. & Gardner, G. An experimental investigation of factors affecting elastic wave velocities in porous media. Geophysics 23(3), 459–493 (1958).

Leveaux, J. & Poupon, A. Evaluation of water saturation in shaly formations. Log Anal. 12(04), 1–10 (1971).

Timur, A. An investigation of permeability, porosity, and residual water saturation relationships. in Paper Presented at the SPWLA 9th Annual Logging Symposium. (1968).

Evans, P. The Tectonic Framework of Assam (0974–6889). (1964).

Imam, M. B. & Hussain, M. A review of hydrocarbon habitats in Bangladesh. J. Pet. Geol. 25(1), 31–52. https://doi.org/10.1111/j.1747-5457.2002.tb00098.x (2002).

Gani, M. R. & Alam, M. M. Sedimentation and basin-fill history of the Neogene clastic succession exposed in the southeastern fold belt of the Bengal Basin, Bangladesh: A high-resolution sequence stratigraphic approach. Sedim. Geol. 155(3–4), 227–270. https://doi.org/10.1016/S0037-0738(02)00182-3 (2003).

Wentworth, C. K. A scale of grade and class terms for clastic sediments. J. Geol. 30(5), 377–392 (1922).

Udden, J. A. Mechanical composition of clastic sediments. Bull. Geol. Soc. Am. 25(1), 655–744 (1914).

Folk, R. L. & Ward, W. C. Brazos River bar [Texas]; a study in the significance of grain size parameters. J. Sedim. Res. 27(1), 3–26 (1957).

Goldich, S. S. A study in rock-weathering. J. Geol. 46(1), 17–58 (1938).

Hamada, G. An integrated approach to determine shale volume and hydrocarbon potential in shaly sands in the Gulf of Suez. Log Anal. 40(03), 1–10 (1999).

Thomas, E. & Stieber, U. S. The distribution of shale in sandstones and its effect upon porosity. in Paper Presented at the SPWLA 16th Annual Logging Symposium. (1975).

Ambrose, W. A. et al. Geologic factors controlling CO 2 storage capacity and permanence: Case studies based on experience with heterogeneity in oil and gas reservoirs applied to CO2 storage. Environ. Geol. 54, 1619–1633. https://doi.org/10.1007/s00254-007-0940-2 (2008).

Issautier, B., Viseur, S., Audigane, P. & le Nindre, Y. M. Impacts of fluvial reservoir heterogeneity on connectivity: Implications in estimating geological storage capacity for CO2. Int. J. Greenhouse Gas Control 20, 333–349. https://doi.org/10.1016/j.ijggc.2013.11.009 (2014).

Sun, X. et al. Effects of fluvial sedimentary heterogeneity on CO2 geological storage: Integrating storage capacity, injectivity, distribution and CO2 phases. J. Hydrol. 617, 128936. https://doi.org/10.1016/j.jhydrol.2022.128936 (2023).

Begg, S. H. & King, P. R. Modelling the effects of shales on reservoir performance: Calculation of effective vertical permeability. in SPE Reservoir Simulation Symposium. (OnePetro, 1985).

Green, C. & Slatt, R. M. Complex Braided Stream Depositional Model for the Murdoch Field, Block 44/22 UK Southern North Sea, Braided Rivers: Form, Process and Economic Applications (The Geological Society, 1992).

Wethington, C., Pashin, J., Wethington, J., Esposito, R. & Riestenberg, D. Mudstone baffles and barriers in lower cretaceous strata at a proposed CO2 storage hub in Kemper County, Mississippi, Unites States. Front. Energy Res. 10, 904850. https://doi.org/10.3389/fenrg.2022.904850 (2022).

Washburn, E. W. Note on a method of determining the distribution of pore sizes in a porous material. Proc. Natl. Acad. Sci. 7(4), 115–116. https://doi.org/10.1073/pnas.7.4.115 (1921).

Kabir, S. Subsurface Temperature and Geothermal Gradient in Bangladesh (Department of Geology, Dhaka University, 2008).

Benson, S. M. & Cole, D. R. CO2 sequestration in deep sedimentary formations. Elements 4(5), 325–331. https://doi.org/10.2113/gselements.4.5.325 (2008).

Bachu, S. et al. CO2 storage capacity estimation: Methodology and gaps. Int. J. Greenhouse Gas Control 1(4), 430–443 (2007).

Van der Meer, L. G. H. The CO2 storage efficiency of aquifers. Energy Convers. Manag. 36(6–9), 513–518. https://doi.org/10.1016/0196-8904(95)00056-J (1995).

Ringrose, P. S. et al. Storage of carbon dioxide in saline aquifers: Physicochemical processes, key constraints, and scale-up potential. Annu. Rev. Chem. Biomol. Eng. 12, 471–494 (2021).

Ringrose, P. How to store CO2 underground: Insights from early-mover CCS projects. (2020). https://doi.org/10.1007/978-3-030-33113-9.

Mondal, D., Sarkar, K., Sultan-Ul-Islam, M., Sang, S. & Mostafa, G. Evaluation of petroleum system using 1D modeling technique of well Atgram-1X, Zakiganj, Bengal Basin. Arab. J. Geosci. 14, 1–13. https://doi.org/10.1007/s12517-021-08747-z (2021).

Nesbitt, H. W., Fedo, C. M. & Young, G. M. Quartz and feldspar stability, steady and non-steady-state weathering, and petrogenesis of siliciclastic sands and muds. J. Geol. 105(2), 173–192. https://doi.org/10.1086/515908 (1997).

Zhang, S., Xian, X., Zhou, J. & Zhang, L. Mechanical behaviour of Longmaxi black shale saturated with different fluids: an experimental study. RSC Adv. 7(68), 42946–42955. https://doi.org/10.1039/C7RA07179E (2017).

Jennings, J. B. Capillary pressure techniques: Application to exploration and development geology. AAPG Bull. 71(10), 1196–1209. https://doi.org/10.1306/703C8047-1707-11D7-8645000102C1865D (1987).

Jerauld, G. R. & Salter, S. J. The effect of pore-structure on hysteresis in relative permeability and capillary pressure: Pore-level modeling. Transp. Porous Media 5, 103–151. https://doi.org/10.1007/BF00144600 (1990).

Nelson, P. H. Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull. 93(3), 329–340. https://doi.org/10.1306/10240808059 (2009).

Avseth, P., Mukerji, T., Mavko, G. & Dvorkin, J. Rock-physics diagnostics of depositional texture, diagenetic alterations, and reservoir heterogeneity in high-porosity siliciclastic sediments and rocks: A review of selected models and suggested work flows. Geophysics 75(5), 7531–7547. https://doi.org/10.1190/1.3483770 (2010).

Bjørlykke, K. Sandstone diagenesis in relation to preservation, destruction and creation of porosity. Dev. Sedimentol. 41, 555–588. https://doi.org/10.1016/S0070-4571(08)70180-8 (1988).

Worden, R. H. & Morad, S. Clay minerals in sandstones: Controls on formation, distribution and evolution. Clay Miner. Cements Sandstones https://doi.org/10.1002/9781444304336.ch1 (1999).

IPCC IPCC special report on carbon dioxide capture and storage. In Prepared by Working Group III of the Intergovernmental Panel on Climate Change (eds Metz, B. et al.) (Cambridge University Press, 2005).

Kalam, S. et al. Carbon dioxide sequestration in underground formations: Review of experimental, modeling, and field studies. J. Pet. Explor. Prod. 11, 303–325. https://doi.org/10.1007/s13202-020-01028-7 (2021).

Ma, J. et al. Carbon capture and storage: History and the road ahead. Engineering 14, 33–43. https://doi.org/10.1016/j.eng.2021.11.024 (2022).

Torp, T. A. & Gale, J. Demonstrating storage of CO2 in geological reservoirs: The Sleipner and SACS projects. Energy 29(9–10), 1361–1369. https://doi.org/10.1016/j.energy.2004.03.104 (2004).

Jackson, S. J., Agada, S., Reynolds, C. A. & Krevor, S. Characterizing drainage multiphase flow in heterogeneous sandstones. Water Resourc. Res. 54(4), 3139–3161. https://doi.org/10.1029/2017WR022282 (2018).

Jackson, S. J. & Krevor, S. Small-scale capillary heterogeneity linked to rapid plume migration during CO2 storage. Geophys. Res. Lett. 47(18), e2020088616. https://doi.org/10.1029/2020GL088616 (2020).

Ashraf, M., Lie, K. A., Nilsen, H. M. & Skorstad, A. Impact of geological heterogeneity on early-stage CO2 plume migration: sensitivity study. Int. J. Greenhouse Gas Control https://doi.org/10.3997/2214-4609.20145012 (2010).

Ashraf, M. Geological storage of CO2: Heterogeneity Impact on the behavior of pressure. Int. J. Greenhouse Gas Control 28, 356–368. https://doi.org/10.1016/j.ijggc.2014.06.018 (2014).

Bachu, S. CO2 storage in geological media: Role, means, status and barriers to deployment. Progress Energy Combust. Sci. 34(2), 254–273. https://doi.org/10.1016/j.pecs.2007.10.001 (2008).

Issautier, B. et al. Modelling of CO2 injection in fluvial sedimentary heterogeneous reservoirs to assess the impact of geological heterogeneities on CO2 storage capacity and performance. Energy Procedia 37, 5181–5190. https://doi.org/10.1016/j.egypro.2013.06.434 (2013).

Ojo, A. C. & Tse, A. C. Geological characterisation of depleted oil and gas reservoirs for carbon sequestration potentials in a field in the Niger Delta, Nigeria. J. Appl. Sci. Environ. Manag. 20(1), 45. https://doi.org/10.4314/jasem.v20i1.6 (2016).

Zhang, D. & Song, J. Mechanisms for geological carbon sequestration. Procedia IUTAM 10, 319–327. https://doi.org/10.1016/j.piutam.2014.01.027 (2014).

Bandara, U. C., Tartakovsky, A. M. & Palmer, B. J. Pore-scale study of capillary trapping mechanism during CO2 injection in geological formations. Int. J. Greenhouse Gas Control 5(6), 1566–1577. https://doi.org/10.1016/j.ijggc.2011.08.014 (2011).

Gershenzon, N. I., Ritzi, R. W. Jr., Dominic, D. F., Mehnert, E. & Okwen, R. T. Capillary trapping of CO2 in heterogeneous reservoirs during the injection period. Int. J. Greenhouse Gas Control 59, 13–23. https://doi.org/10.1016/j.ijggc.2017.02.002 (2017).

Harris, C., Jackson, S. J., Benham, G. P., Krevor, S. & Muggeridge, A. H. The impact of heterogeneity on the capillary trapping of CO2 in the Captain Sandstone. Int. J. Greenhouse Gas Control 112, 103511. https://doi.org/10.1016/j.ijggc.2021.103511 (2021).

Hovorka, S. D., Doughty, C., Benson, S. M., Pruess, K. & Knox, P. R. The impact of geological heterogeneity on CO2 storage in brine formations: A case study from the Texas Gulf Coast. Geol. Soc. Lond. Spec. Publ. 233(1), 147–163. https://doi.org/10.1144/GSL.SP.2004.233.01.10 (2004).

Krevor, S. C., Pini, R., Li, B. & Benson, S. M. Capillary heterogeneity trapping of CO2 in a sandstone rock at reservoir conditions. Geophys. Res. Lett. https://doi.org/10.1029/2011GL048239 (2011).

Krevor, S. C., Pini, R., Zuo, L. & Benson, S. M. Relative permeability and trapping of CO2 and water in sandstone rocks at reservoir conditions. Water Resourc. Res. https://doi.org/10.1029/2011WR010859 (2012).

Wakefield, O. J., Hough, E. & Peatfield, A. W. Architectural analysis of a Triassic fluvial system: The Sherwood Sandstone of the East Midlands Shelf, UK. Sedim. Geol. 327, 1–13. https://doi.org/10.1016/j.sedgeo.2015.07.006 (2015).

Ramírez, A., Hagedoorn, S., Kramers, L., Wildenborg, T. & Hendriks, C. Screening CO2 storage options in the Netherlands. Int. J. Greenhouse Gas Control 4(2), 367–380. https://doi.org/10.1016/j.ijggc.2009.10.015 (2010).

Hermanrud, C. et al. Storage of CO2 in saline aquifers: Lessons learned from 10 years of injection into the Utsira Formation in the Sleipner area. Energy Procedia 1(1), 1997–2004. https://doi.org/10.1016/j.egypro.2009.01.260 (2009).

Acknowledgements

We extend our gratitude to Imperial College London for generously covering the open access fee through the Imperial College London Open Access Fund. This support has been invaluable in making our research freely accessible to the global community.

Author information

Authors and Affiliations

Contributions

Conceptualization: Shakhawat Hossain Data curation: Shakhawat Hossain, Naymur Rahman Formal analysis: Shakhawat Hossain, Naymur Rahman, Himadri Shekhar Investigation: Shakhawat Hossain, Naymur Rahman, Himadri Shekhar Methodology: Shakhawat Hossain, Naymur Rahman, Himadri Shekhar Software: Shakhawat Hossain, Naymur Rahman Supervision: Shakhawat Hossain Validation: Shakhawat Hossain, Naymur Rahman, Himadri Shekhar Visualization: Shakhawat Hossain, Naymur Rahman Roles/Writing—original draft: Shakhawat Hossain, Naymur Rahman, Himadri Shekhar.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hossain, S., Rahman, N. & Shekhar, H. Sedimentological and petrophysical characterization of the Bokabil Formation in the Surma Basin for CO2 storage capacity estimation. Sci Rep 14, 16416 (2024). https://doi.org/10.1038/s41598-024-66373-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-66373-7

- Springer Nature Limited