Abstract

The presence of methylene blue (MB) dye in wastewater has raised concern about human health and environmental ecology due to potential carcinogenic, and mutagenic effects. Therefore, this work aims to remove MB dye from wastewater using γ-Al2O3 nanoparticles synthesized from aluminum scrap via simple electrolytic method. The successful synthesis of the adsorbent was confirmed by a range of spectroscopy and microscopy techniques, including XRD, SEM, FTIR, and BET. The central composite design (CCD) of the response surface methodology (RSM) method was used to optimize the processing parameters such as solution pH, contact time, initial MB concentration, and adsorbent dose. The ANOVA results clearly shows that the quadratic model (p < 0.0001) was sufficient to the best predicting of the removal performance of MB dye (R2 = 0.9862). The optimum condition for the maximum MB dye removal (98.91%) was achieved at solution pH of 8.298, initial MB concentration of 31.657 mg/L, adsorbent dose of 0.387 g/L, and contact time of 46.728 min. Nano-γ-Al2O3 was shown to have a good surface area of 59 mg2/g by BET analysis. The adsorption kinetics follows the pseudo-second-order model (R2 = 0.997). With a maximum adsorption capacity of 137.17 mg/g, the Langmuir isotherm model (R2 = 984) provides the best fit to the adsorption isotherm data, indicating a monolayer adsorption process. Furthermore, thermodynamic analysis demonstrated that the adsorption of MB dye was an endothermic and spontaneous process. The reusability study showed that γ-Al2O3 nano-adsorbent retained 85.08% of its original removal efficiency after five cycles. According to the findings of the study, MB dye molecules were taken up by γ-Al2O3 nano-adsorbent via hydrogen bond formation, Van der Waals interaction, and electrostatic attraction. Therefore, γ-Al2O3 nanoparticles can be used as a potentially eco-friendly and low-cost adsorbent for the removal of MB dye from aqueous solutions.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

Water is the most crucial resource for the survival of living organisms1. Currently, only 0.5–1.0% of the total available water resources are considered suitable for drinking2. Despite recent advancements in science and technology, water pollution remains a significant environmental issue worldwide3,4. The global water crisis is a result of industrial globalization, increasing residential and commercial areas, and agricultural lands, leading to significant wastewater production5,6,7. Globally, 1.2 billion people are deficient in accessing safe drinking water, and millions of peoples die from the uncontrolled spread of diseases and chronic illnesses transmitted via unsafe water8. Toxic pollutants such as chemical compounds, dyes, and metal ions, have been released by many sectors, resulting in water contamination. The most significant environmental contaminants among them are synthetic dyes released in to water bodies from industries like textiles, leather, ink, plastics, rubber, and cosmetics because of their high toxicity, carcinogenic qualities, and bright colors9,10. The textile dyeing process is a significant contributor to environmental contamination due to its direct discharge into the body of water without treatment11. Hence, dyes can harm the ecosystem by increasing toxicity, increasing oxygen demand, and delaying photosynthetic processes12. Annually, over 7 × 105 tons of dyes and pigments are produced globally, with 10–15% lost in dye effluents and 17–20% of water pollution resulting from these industries13. One of the popular cationic dye that poses an environmental challenge is methylene blue (MB)14. Long-term exposure to this dye can cause allergic issues, respiratory diseases, eye irritation, and cancer15. Therefore, the removal of MB dye from wastewater is a crucial step before its release into the environment. Technological innovations such as flocculation-coagulation, membrane separation, chemical and electrochemical oxidation, biodegradation, and adsorption are being used to combat global water pollution16. Among these techniques, adsorption is the most widely used method due to its high productivity, accessibility, economic viability, adsorbent recyclability, and large selection of adsorbents17. Adsorption efficiency is primarily determined by the availability, adsorption capacity, reusability, porosity, and specific surface area of the adsorbent18. Zeolites, alumina, silica gel, cellulose-based waste, and activated carbon are commonly used for dye removal from water19. Currently, numerous nanomaterials, including iron and aluminum-based nanoscale adsorbents, have been utilized for the separation of pollutants from the liquid phase20. Aluminum oxide, commonly known as alumina, is used in adsorption-based applications due to its unique properties such as acid–base, high surface area, structural stability, low cost, mechanical and thermal stability, and non-toxic nature21. Nowadays, Al2O3 nanoparticles have been synthesized using various synthetic routes, including metal–organic chemical vapor deposition (MOCVD), polymeric precursors, electrochemical treatment technology, and high-energy milling22. However, these techniques are usually expensive and complicated. Herein, high-purity γ-Al2O3 nanoparticles were synthesized via a simple and cost-effective electrolytic method. The novelty of this work was using aluminum scrap as a cost-effective and easily available starting reagent. Moreover, the research work to analyze the adsorption efficiency of γ-Al2O3 nanoparticles towards MB using the response surface methodology (RSM) is still limited. This study utilized the response surface methodology-based central composite design (RSM-CCD) method to optimize MB adsorption onto γ-Al2O3 nanoparticles. In this regard, various key factors, including initial MB concentration, adsorbent dose, solution pH, and contact time, have been evaluated. Moreover, the adsorption mechanism, isotherms, kinetics, thermodynamics, and reusability were investigated and discussed in details.

Experimental

Chemicals and reagents

All chemicals and reagents were of analytic grade and used without further purification. Methanol (CH3OH, 98%), ethanol (C2H5OH, 99.5%), sodium hydroxide (NaOH, 99%), sodium chloride (NaCl, 99%), potassium bromide (KBr, 99%), and hydrochloric acid (HCl, 37%) were used. The aluminum scraps were collected from the Burka Gibbie metal workshop (Jimma, Ethiopia). Deionized water was used throughout the experiment.

Synthesis of γ-Al2O3 nanoparticles

Figure 1 shows an overall synthesis of γ-Al2O3 nanoparticles from aluminum scraps. First, aluminum scraps were polished with emery paper grade no. 180 to remove any aluminum oxide formed due to oxidation. Then, the scraps were washed with hydrochloric acid (HCl), deionized water (DI), and finally with acetone. Next, scrap metal pieces were cut into 2 cm by 4 cm and used as anode and cathode electrodes in an electrolytic cell, respectively. In doing so, 100 mL of water in a 250 mL glass beaker with a pH of 8 was used as an electrolyte. The electrolysis was done in a simple DC (BK-1502DD, model) power supply and was subjected to electrolysis for 24 h using a voltage of 15.1 V and a current of 0.65 amp. The electrodes interpolar distance were 3 cm. Thereafter, as the electrolysis proceed, hydroxyl ions are generated during the electrolysis and react with the positive electrode, which was aluminum, producing a gel-like precipitates that were deposited on the cathode electrode (aluminum). The precipitates were slightly warmed with methanol to coagulate the colloidal particles. Once the electrolysis was completed, the precipitates were separated by centrifuge and washed thoroughly with deionized water (DI) and ethanol. After this procedure, the aluminum hydroxide precipitates were dried at 100 °C for 24 h and calcined at 600 °C for 4 h with a heating rate of 10 °C/min to produce γ-Al2O3 nanoparticles.

Materials characterization

The crystal structure of the synthesized nanoparticles is characterized using Cuka radiation (30 kV, 25 mA, λ = 1.5406 Å) with a 2θ angle ranging from 10° to 80° and a scan rate of 0.02°/s. The surface morphology was determined by scanning electron microscopy (JEOL/EO, JSM-6000 plus) at an accelerating voltage of 15.0 kV. The FTIR spectra of the as-synthesized material was recorded on a Fourier transform infrared spectrophotometer (FTIR) (PerkinElmer, Spectrum Two, USA) to identify the functional groups present on the adsorbent. For recording FTIR spectra, the sample was encapsulated in KBr using a hydraulic pellet press, and the spectra were taken in the wavelength range of 4000–400 cm−1 with a resolution of 4 cm−1. UV–vis spectra were measured using the PerkinElmer Lambda 25 UV–vis spectrophotometer with a wavelength in the range of 200–800 nm. The Brunaur–Emmet–Teller (BET) surface area, pore volume, and pore size distributions of γ-Al2O3 nanoparticles were determined using a Quanta chrome analyzer (Nova Station C, version 11.0, USA) based on the principle of adsorption/desorption of nitrogen at 77.3 K and 60/60 s (ads/des) equilibrium time.

Design of experiments using CCD

In this study, the CCD of RSM was employed to optimize the processing variables estimating the regression model equation23. Four experimental factors with three levels were selected as shown in Table 1. The solution pH, adsorbent dose, initial MB concentration, and contact time were set as factors. Removal efficiency was set as a responsive variable. Based on factorial experimental design, four factors with three level, would give (34) 81 runs. However, the runs were fixed to 30 (Table 2) by Design Expert software version 13 using CCD under the RSM approach.

The total number of experiments can be determined from the following Eq. (1):

where N is the total number of experimental runs, n is the number of factors, and nc is the number of replicates at central point. In this study, N is 30, n is 4 and nc is 6.

The experimental data was analyzed using a second-order polynomial regression model, allowing the response, R (%), to be linked to the independent variables using a quadratic Eq. (2)24,25:

where R (%) is the response and refers to variables (i and j range from 1 to k); ao refers to the coefficient of intercept; aj, ajj, and aij are known to be coefficients of interaction for the variables, respectively, and is the error.

Batch adsorption experiment

The adsorption experiments were performed in batch mode and on a laboratory scale. The effects of adsorbent dose (0.2–0.4 g/L), contact time (30–60 min), solution pH (6–9) and initial MB concentration (20–40 mg/L) on MB removal were investigated. For each adsorption experiment, 100 mL of MB solution with an initial concentration of 50 mg/L was added into the 250 mL Erlenmeyer flasks. The desired pH was set. The pH of the solution was adjusted using 0.1 M NaOH or 0.1 M HCl solutions. 0.3 g of adsorbent dose was added to the flasks and then mixed in a magnetic stirrer at 150 rpm at 25 °C for 2 h26. The residual MB concentrations were centrifuged at 4000 rpm for 10 min and directly measured using a UV–vis spectrophotometer (PerkinElmer model: Lambda 25, USA) at λmax of 664 nm27, as shown in Fig. 2.

The adsorption capacity of the γ-Al2O3 nanoparticle can be calculated according to Eq. (3)28:

The percentage removal of MB adsorbed on the γ-Al2O3 nanoparticles was obtained as follows (4)29,30:

where Co is the initial MB concentration (mg/L), Ce is the equilibrium concentration of MB (mg/L), \(q_{e}\) is the adsorption capacity at equilibrium (mg/g), V is the volume of the solution (L), and M is the amount of adsorbent used (g).

Adsorption isotherm analysis

Adsorption isotherm models were used to describe the interaction between polluting dye molecules and active sites on the adsorbent surface31,32,33. Furthermore, the study investigates the relationship between the mass of the γ-Al2O3 nanoadsorbent and the amount of pollutant absorbed at equilibrium conditions. This study examined dye concentrations ranging from 20 to 40 mg/L while maintaining ideal values of the other three parameters: γ-Al2O3 adsorbent dosage of 0.3 g/100 mL, solution pH of 7.5 and contact time of 45 min34. The adsorption data was analyzed using three adsorption isotherms: the Langmuir, Freundlich, and Temkin models. The adsorption mechanism, favorability of the process and adsorbate-adsorbent affinity can be obtained from crucial information. The Freundlich isotherm35,36 model suggests adsorption occurs on heterogeneity charged surfaces, potentially forming a multilayer of solutes at equilibrium.

The linearized equation can be written as Eq. (5)37:

were \(K_{F}\) and n are the Freundlich constants representing sorption capacity (mg/g) and intensity, respectively. \(K_{F}\) and n can be determined from linear plot of ln\(q_{e}\) against ln\(C_{e}\).

The Langmuir isotherm38 assumes a surface with homogeneous binding sites, equivalent sorption energies, and no interactions between adsorbed species.

The Langmuir isotherm model can be described as in Eq. (6)30,31:

where \(q_{max}\) is the maximum adsorption capacity at monolayer in (mg/g), b (L/mg) is the Langmuir adsorption constant represents the affinity of the binding site.

The Temkin isotherm model predicts that the heat of adsorption will decrease linearly with the surface coverage that results from the interaction of the adsorbate and adsorbent. One way to express the Temkin isotherm is as Eq. (7)30,39:

A plot of qe versus Ln Ce enables the determination of the constants AT and B1. B1 is the heat of sorption, and AT is the equilibrium binding constant, where B1 = RT/b, T is the absolute temperature (K), and R is the universal gas constant [8.314 J/(mol K)].

Kinetic modeling

The nature of adsorption onto the adsorbent surface is described by adsorption kinetics39,40. Additionally, kinetics studies are conducted to determine if chemosorption or physisorption occurs during the interaction between the adsorbent and adsorbate40,41. To study the adsorption of MB on \(\gamma\)-Al2O3 nanoparticles, the four most prevalent kinetic models, pseudo-first-order, pseudo-second-order, intraparticle diffusion, and double constant equation models were used. These models were calculated according to Eq. (8–11), respectively41,42,43,44:

where \(q_{e}\) (mg/g) and qt (mg/g) are the adsorption capacity at equilibrium and at time t (min), respectively; K1 (1/min) is the rate constant of pseudo-first-order; K2 [g/(mg min)] is the rate constant of pseudo-second-order; Ki [mg/(g min0.5)] is the intraparticle diffusion rate constant; and A and B are the double constant equation model constants.

Results and discussions

XRD analysis

X-ray powder diffraction was utilized to analyze the as-synthesized γ-Al2O3 nanoparticles to determine their phases and structure. The diffractograms in Fig. 3a–c depict the as-synthesized Al (OH)3 and γ-Al2O3 nanoparticles before and after adsorption. The XRD pattern presented in Fig. 3a indicates that the crystallographic planes (020), (001), (110), (120), (104), (140), (031), (201), (113), (200), (024), (116), (122), (231), and (119) are attributed to the peaks at 2θ values of 13.99°, 18.66°, 20.45°, 27.87°, 34.88°, 36.52°, 37.9°, 40.65°, 45.04°, 47.79°, 53.52°, 57.69°, 63.04°, 64.27°, and 70.74°, respectively. The results were in agreement with standard data for Al (OH)3, which is a mixed phase of boehmite (JCPDS file 00-001-1283) and bayerite (JCPDS file 00-020-0011)44,45,46,47. Crystallographic planes (311), (400), (511), and (440) of the cubic γ-Al2O3 nanostructure in Fig. 3b correspond to diffraction peaks (2θ = 37.35°, 45.60°, 60.03°, and 66.61°). The study shows that high-purity, nanoscale γ-Al2O3 crystallites were formed by peak agreement with JCPDS card no. 02-142047,48,49. Lack of additional peaks associated with impurities proved the high purity of the γ-Al2O3 phase22. The XRD patterns of γ-Al2O3 nanoparticles after adsorption were depicted in Fig. 3c. Two additional peaks, corresponding to the (024) and (120) planes, appear at 2θ = 25.11° and 28.69°, respectively. The small peaks observed in the study were attributed to either Al (OH)3 or the MB dye that adhered to the γ-Al2O3 nanoparticles44. The synthesized γ-Al2O3 nanoparticles had an average crystallite size of 14.02 nm before and 14.34 nm after adsorption, as determined by the Scherrer formula (D = k λ/β cos θ). Where D is the crystal size, k is a constant equal to 0.9, λ is the wavelength of X-ray radiation (λ = 0.15406 nm), β represents the peak width at half maximum intensity of the peak selected, and θ is the Bragg’s angle49,50.

SEM analysis

SEM analysis was used to investigate the structural morphology of the nanoadsorbent. SEM images of γ-Al2O3 nanoparticles before and after adsorption are shown in Fig. 4a and b, respectively. Figure 4a shows the SEM image of γ-Al2O3 nanoparticles before adsorption, in which the surface exhibits a highly irregular shape and inhomogeneous structure with different particle sizes, cavities, and cracks with highly porous internal structures. After MB adsorption (Fig. 4b), the morphological features of γ-Al2O3 nanoparticles became less porous and more compact due to the loading of MB dye molecules on the surface of the nanoparticles, showing a smoother morphology. This may be the result of the adsorption of MB molecules into the particles, forming a thin MB layer covering the pores.

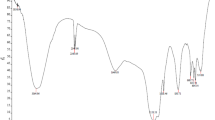

FTIR analysis

The FTIR spectra of all synthesized nanoparticles were plotted in the 400–4000 cm−1 range, as depicted in Fig. 5a–c. Figure 5a reveals a broad peak in the 3400–3700 cm−1 region, with peaks at 3667, 3561, and 3469 cm−1 corresponding to OH stretching vibration in the Al–OH structure. This could suggest the presence of moisture in the KBr powder50,51,52. The 1639 cm−1 peak in the sample confirms the presence of water, as it is determined by the H–O–H bending vibration of H2O molecules21. The peak at 1427 and 1300 cm−1 was attributed to the stretching vibration of C–N in amide (–NH3+) and C=O during the reaction of ammonia from the precursor52,53. The bending vibration of the Al–O bond was confirmed by broader peaks between 1025, 968, and 523 cm−151. The peak at 579 and 855 cm−1 in Fig. 5b corresponds to the Al–O stretching vibrations in an octahedral coordination (AlO6) and a tetrahedral coordination (AlO4) site, respectively53,54. Furthermore, the presence of bending and stretched bands of OH groups at 1639 and 3463 cm−1 were attributed to water molecules55,56. The peaks at 911 and 502 cm−1 in Fig. 5c correspond to the stretching vibration band between Al and O, which is connected tetrahedrally and octahedrally54,56. The peak at 3463 shifted to 3477 cm−1 after adsorption, indicating the binding of dye ions to the absorbent. The new peak at 2339 cm−1 indicates the presence of MB dye molecules on the surface of γ-Al2O3 nanoparticles due to the stretching vibration of N–H bonding. The bands at 1526 and 1420 cm−1 were attributed to the stretching vibrations of the C–N and C=C benzene rings of MB, respectively. The presence of dye on the nanoparticle surface is further supported by this evidence21.

BET analysis

The N2 adsorption–desorption isotherm curve of γ-Al2O3 nanoparticles exhibit type IV, which belongs to a type H3 hysteresis loop for the relative pressure P/Po in the range 0–1.0 according to the IUPAC classification, Fig. 6, demonstrating the mesoporous structural feature. Type IV isotherms were characterized by low adsorption in the low-pressure region and increased adsorption with increasing pressure. The BET surface area, pore volume and average pore diameter were observed to be 59 m2/g, 0.5442 cm3/g, and 6.542 nm, respectively (Table 3).

Central composite design (CCD) and analysis of variance (ANOVA)

CCD based RSM was used to examine the effects of four effective processing parameters on the MB adsorption process such as solution pH, initial MB concentration, adsorbent dose, and contact time57. The CCD designed experimental matrix for investigated parameters, along with the experimental responses, were illustrated in Table 1. The relationship between the independent parameters, and MB removal was expressed by the following quadratic model Eq. (12):

The regression equation optimize process parameters, revealing MB removal (%) influenced by initial MB concentration, adsorbent dose, solution pH, and contact time with positive terms indicate synergistic effect on the response whereas negative terms suggest an antagonistic effect on the process output58,59. ANOVA was conducted statistically to confirm the significance of the effects of the investigated parameters and the quality of the obtained model equation for MB removal. The statistical results given in Table 4 indicate that the smaller p value and the larger F-value were statistically significant for the quadratic model. The model Fisher’s F-value of 76.61 implies the model was significant. There was only a 0.01% chance that an F-value of a model this large could occur due to noise60. p Values less than 0.05 indicate the model terms that are significant23. In this case A, B, C, D, AC, BD, CD, A2, B2, C2, D2 were significant model terms. Values greater than 0.10 indicate the model terms were not significant. The p value was the probability of rejecting a null hypothesis. The higher the Fisher’s F-value, the more significant the individual coefficients and the more adequate the model23,61. The lack of fit F-value of 0.96 entails the lack of fit was not significant relative to the pure error. There was an 37.46% chance that a lack of fit F-value this large possibly will occur due to noise. Non-significant lack of fit was good. Also, the p value of lack of fit was greater than 0.05; this implies that the model fits the experimental data and the independent process variables have a significant effect on the response. On the other hand, the R2 of the model was 0.9862, implying that the obtained model had very high correlation between the response and the investigated parameters61,62,63. The model significance is evident in its high adjusted coefficients of determination (97.33%) and predicted (94.10%), with an adequate precision of 27.6172 > 4, indicating its potential for predicting responses63,64,65. The linear terms, initial MB concentration, γ-Al2O3 adsorbent dose, solution pH, contact time, and square terms of all parameters significantly impacted the process with a p value < 0.0001.

The correlation between the normal % probability vs. externally studetized residuals, residuals vs. run number, residual vs. predicted value and predicted response versus Experimental data were examined in Fig. 7a–d in order to evaluate the agreement between the optimization model and the experimental data29,30,32. The normal probability plot of residuals in Fig. 7a shows that the errors follow a normal distribution, confirming the assumptions of the empirical model10,65,66. As can be seen in Fig. 7b, most of the data points are uniformly distributed over the range of − 3.87982 to + 3.87982 studentized residuals, falling between the lower and upper bounds of outlier detection. A homogeneous distribution around the basic lines is shown by the residuals versus expected values in Fig. 7c, with almost half of the residuals falling below and the other half above the basic line. This distribution shows that the residual values were dispersed randomly with no discernible trend and that the average residual value is very near to zero. The actual and expected values of the response have a significant correlation, as seen in Fig. 7d, suggesting excellent agreement between the two. This implies that the statistical model applied effectively represents the relationship between the four elements examined in the MB removal process10,29,30,64,66,67.

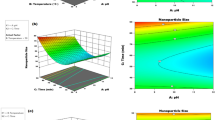

Interaction effect of selected variables on the removal of MB

Three-dimensional (3D) response surface plots against any two independent process variables were created, keeping the other process variables at their central (0) level in order to examine the interaction between the various process variables and their corresponding effects on the response (MB removal efficiency). Figure 8a–c displays 3D surface plots illustrating the interactions between process variables and their corresponding output responses. Out of the six interactions, only three were statistically significant, namely AC (the interaction effect of initial B concentration and solution pH), BD (the interaction effect of adsorbent dose and contact time) and CD (the interaction effect of solution pH and contact time).

Initial MB concentration and solution pH

Figure 8a displays the combined effect between initial MB concentration and solution pH on MB dye removal uptake for a contact time of 45 min and adsorbent dose of 0.3 g. As displayed in Fig. 8a, the removal efficiency increased with increasing solution pH from 6 to 9. On the other hand, at a pH of 6.5, the adsorption capacity decrease from 96.47 to 90% with increasing the initial MB concentration from 20 to 40 mg/L (p value of 0.0086). This observation might be due to the prompt saturation of the active sites in the adsorbent, eventually, the MB dye molecules tends to form aggregate on the outer surface of the γ-Al2O3 nanoparticles and decreases the surface area.

Adsorbent dose and contact time

The interaction effect of adsorbent dose and contact time on MB removal at constant initial MB concentration (30 mg/L) and solution pH (7.5) was presented in the form of three-dimensional (3D) surface plots as shown in Fig. 8b. It was revealed that the removal efficiency of MB dye rapidly increased at early stage from 92 to 96.06% and optimum dose of 0.27 g, while it increased with an increase in contact time until 46 min and then slightly decreased in the later stage. At the beginning of adsorption, the high rate of adsorption of MB dye on the adsorbent was due to the availability of an abundance of adsorption sites and the presence of enough time for the adsorption process, respectively. However, MB dye removal efficiency declined when an adsorbent dose and contact time increased further. The decrease in adsorption capacity can be attributed to the unavailability of the active sites and the slow pore diffusion of the adsorbate molecules in to the bulk of the adsorbent. The interaction effect has significantly impacted the MB adsorption with a p value of 0. 0001.

Solution pH and contact time

Figure 8c shows the response surface plot of MB dye removal efficiency as a function of pH of the solution and contact time. The removal efficiency of the adsorbate increased with an increase in solution pH and contact time. The effect of the solution pH was carried out to evaluate the maximum percentage of MB dye molecules onto the adsorbent γ-Al2O3 nanoparticles in an aqueous solution. The results showed that as the pH of MB increase from 6 to 9, the percentage removal also increases from 92 to 96.02%. In general, the interaction of pH of the solution and contact time had a significant effect on its MB dye removal with a p value of 0.0004 (Table 4). Meanwhile, it was revealed by the result obtained that contact time highly interact with other variables.

Optimization process and validation of the model

Using CCD-RSM approaches, the highest removal efficiency was prioritized as a desirable aim while optimizing the operational variables. The optimal parameters of solution pH = 8.298, contact time = 46.728 min, initial MB concentration = 31.657 mg/L, adsorbent dose = 0.387 g/L, and optimization results are shown in Table 5, where the maximum removal efficiency achieved was 98.91%. The calculated function can accurately describe the experimental model and the intended conditions when the desirability value is 1.00.

Adsorption isotherm

The graphical representations of the Freundlich, Langmuir, and Temkin isotherms were depicted in Fig. 9a–c. According to the results of the isotherm equation in Table 6, the coefficient of determination values for Temkin, Freundlich, and Langmuir isotherms for MB were 0.97959, 0.96015, and 0.98404, respectively. This indicate that the adsorption process on the synthesized γ-Al2O3 nanoparticles adsorbent follow the calculated isotherm with the strongest relates to the Langmuir isotherm model, revealing a homogeneous and monolayer adsorption process on the adsorbent’s active site. Furthermore, the Langmuir isotherm's Qmax was found to be 137.17 mg/g, and that was significantly higher compared to other adsorbents for MB removal from aqueous solutions, as shown in Table 7. The investigation reveals a high Qmax value for the adsorption method efficacy, with Freundlich isothermal constants (1/n) of 0.562, indicating favorable adsorption processes. The values of AT and B1, the Temkin isotherm constants, are found to be 1.83 L/g and 26.49 J/mol, respectively. The adsorption isotherm was a crucial tool for understanding the adsorption mechanism, describing the distribution of adsorbed molecules across the adsorbent contact.

Adsorption kinetics

The desired kinetic model, which in turn depends on the correlation coefficient (R2) value for the linear mode of various kinetic equations, determined the adsorption mechanism and rate66,67,68. It is also helpful in determining which pseudo-first-order, pseudo-second-order, intraparticle diffusion, or double constant equation model best matches the data. This is employed to assess the physicochemical interaction between the adsorbent and adsorbate at the rate-determining stage of surface adsorption68. The combined plots Fig. 10 was used to evaluate the kinetic parameters of the four models, and the results are shown in Table 8. The double constant equation (R2 = 0.57404) and intraparticle diffusion (R2 = 0.52994) models' low R2 values in this table suggest that they did not well describe the adsorption process. The pseudo-second-order model had a higher correlation coefficient (R2) than the pseudo-first-order model. This implies that the process of MB adsorption on γ-Al2O3 nanoparticles was chemisorption23,65.

Adsorption thermodynamics

The thermodynamic study of the adsorption process requires the study of three major thermodynamic parameters of Gibbs free energy (ΔG°), enthalpy (ΔH°) and entropy (ΔS°), which have a significant effect on adsorption behaviors. To calculate the thermodynamic parameters, the Van't Hoff plot for adsorption MB pollutant on the adsorbent was investigated; that describe the feasibility, spontaneity, and the type of adsorbate-adsorbent interactions on the adsorption of MB onto γ-Al2O3 nanoparticles adsorbent42,65,68,69,70.

where Kf (L/g) is equilibrium constant, qe (mg/g) is the equilibrium adsorption capacity, Ce (mg/L) is the equilibrium concentration of the solution, T(K) is the absolute temperature, and R is the universal gas constant (8.314 J/mol K); Fig. 11 shows a linear plot of \(lnK_{f}\) versus 1/T, from which ΔH° and ΔS° can be calculated.

As shown in Table 9, the amount of ΔG° is negative for the adsorbent studied at different temperatures, and this indicates the spontaneous nature of the adsorption process for this adsorbent, which has favorable thermodynamic conditions. In reality, increasing the temperature increases the amount of ΔG°, indicating effective adsorption at lower temperatures. Besides, ΔG° helps to understand whether the adsorption of MB contaminant on γ-Al2O3 nanoparticles was a chemical or physical adsorbent71. Furthermore, the enthalpy change, ΔH°, was positive (endothermic) due to the increase in adsorption with successive increases in temperature. The ΔH° values obtained for the absorption of MB onto γ-Al2O3 nanoparticles were also found to be less than 40 kJ/mol, indicating that the reaction between MB ions and γ-Al2O3 nanoparticles can be considered as a physical mechanism. Positive ΔS° indicates that during the adsorption process, there is a tendency to increase the balance disturbance between the adsorbent-adsorbed. Moreover, the positive value of ΔS° indicates that there has been a significant change in system irregularities in the process of adsorption of MB and that the adsorbent collisions and pollutant ions were in line with system irregularities72.

The point of zero charge of γ-Al2O3 nanoparticles

The point of zero charge is the pH at which the total surface charge of the adsorbent is neutral73,74. In this study, the pH of the 0.01 M NaCl was adjusted to a value between 2 and 10 using 0.1 M HCl or 0.1 M NaOH. An adsorbent (0.05 g) was added to 20 mL of the pH-adjusted solution and agitated at 120 rpm for 24 h on a shaker. Then, the pH of each solution was measured, and the diagram of the initial pH versus the final pH was plotted in Fig. 12. The pH where the two curves intersect is called pHpzc, which is equal to 6.85 for γ-Al2O3 nanoparticles15,70,75.

Adsorption of a real wastewater effluent

In this work, the efficiency of the as-synthesized γ-Al2O3 nano-adsorbent was also evaluated on a wastewater effluent obtained from the KADISCO paint and adhesive industry, Akaki, Debre Zeit Road, Addis Ababa, and Mohamed general garage (automobile service station and car wash) in the city of Jimma, Ethiopia. Adsorption of the wastewater effluents was performed according to MB dye adsorption experiment procedures, except that the solution pH of the wastewater samples was carried out at 9 for KADISCO paint industry and 5 for garage wastewater. The maximum removal efficiencies of both sites were 73.29% (KADISCO paint industry) and 58.69% (garage wastewater), respectively. As can be seen from the results, the removal efficiency of garage wastewater was comparatively lower than that of the KADISCO paint and adhesive industry and the synthetic solution. This might be due to the presence of oil and grease, turbidity, suspended solids, detergents, phosphates, and other contaminants. Therefore, this nanoadsorbent was promising for wastewater treatment, leading to a cheap and cost-effective technology for developing countries.

Adsorption mechanism

XRD and FTIR measurements were conducted on γ-Al2O3 nanoparticles before and after MB adsorption in order to determine the adsorption mechanism for MB removal using γ-Al2O3 nano-adsorbent. The XRD patterns of the pure γ-Al2O3 nanoparticles and the MB-adsorbed onto γ-Al2O3 nanoparticles were recorded and compared (Fig. 3b,c). The XRD patterns of γ-Al2O3 nanoparticles that have been adsorbed by MB exhibit new peaks at positions (024) and (120) in the diffraction plane. These correspond to the replacement of oxygen ions by nitrate ions of MB molecules at 2θ positions 25.11° and 28.69°, respectively. This indicates that more MB molecules are adsorbed onto the surface of γ-Al2O3 nanoparticles.

After adsorption, from FT-IR analysis, the mechanisms underlying the adsorption of MB ions onto γ-Al2O3 nanoparticles can be deduced from Fig. 5c. Following the adsorption of MB, the O–H absorption bands of γ-Al2O3 nanoparticles were shifted from 3463 to 3477 cm−1, indicating the formation of hydrogen bonds between the nitrogen of MB ions and OH groups on the surface of γ-Al2O3 nanoparticles. As a result, MB ions can be removed by complexation with hydroxyl groups. The MB dye molecules stretching vibration of the N–H bonding is represented by the new peak that appears at 2339 cm−1. The stretching vibrations of the benzene ring of MB C–N and C=C may be responsible for the bands seen at 1526 cm−1 and 1420 cm−1, respectively. Therefore, we deduce that MB was adsorbed onto the γ-Al2O3 nanoparticles surface. Van der Waals forces, hydrogen bonds, and electrostatic interactions were all potential adsorption processes. Additionally, Fig. 13 provides a schematic explanation of the potential adsorption mechanism of MB dye onto the γ-Al2O3 nanoparticles.

Recyclability of nano-adsorbent

Figure 14 shows the results of the γ-Al2O3 nanoparticles reusability test that was conducted. To explore the stability tests, five cycles of 0.35 g of γ-Al2O3 NPs were mixed with 100 mL of MB solution (50 mg/L) for 120 min. Following each cycle, the γ-Al2O3 powder underwent multiple thorough washings before being calcined for 4 h at 600 °C. For five consecutive cycles, the regenerated γ-Al2O3 nanoparticles displayed dye removal efficiencies of 98.91%, 95.75%, 91.84%, 88.13%, and 85.08%. Therefore, it may be concluded that γ-Al2O3 nanoparticles may have promise as an adsorbent for the total removal of organic dyes from wastewater that has been contaminated.

Conclusion

The γ-Al2O3 nanoparticles from aluminum scrap was easily synthesized using a simple, cost-effective, eco-friendliness and sustainable simple electrolytic method. The XRD, SEM, FTIR, and BET techniques were used to characterize the γ-Al2O3 nanoparticles. The suitability of γ-Al2O3 nanoparticles for the adsorption-based method of removing MB from aqueous solutions was investigated. Using the RSM-CCD approach, the impact of several process factors, including solution pH, contact time, adsorbent dose, and initial MB concentration, on the MB removal process with γ-Al2O3 nanoparticles were examined. Based on the results of the analysis of variance (ANOVA), it was determined that the quadratic model, which has a high correlation coefficient (R2 = 0.9862), well describes the removal efficiency. Maximum removal effectiveness of 98.91% was achieved at an ideal solution pH of 8.298, a contact time of 46.728 min, an initial MB concentration of 31.657 mg/L, and an adsorbent dose of 0.387 g/L. The Langmuir isotherm model, with a maximum adsorption capacity of 137.17 mg/g, provided the best fit for equilibrium data. The adsorption kinetics followed a pseudo-second-order kinetic model and demonstrated the chemisorption of MB on the nanoparticles surface. The adsorbent's surface area was closely correlated with its adsorption capacity, as evidenced by its specific surface area of 59 m2/g reported by BET. Thermodynamic analysis also demonstrated that MB adsorption was an endothermic, and spontaneous process. According to the findings, MB dye molecules were taken up by γ-Al2O3 nanoparticles via hydrogen bond formation, Van der Waals interactions, and electrostatic interaction. Therefore, γ-Al2O3 nanoparticles can be used as a potentially low-cost adsorbent for the removal of MB from aqueous solutions.

Data availability

The authors declare that the data supporting the findings of this study are available from the corresponding author on reasonable request.

References

Mishra, S., Acharya, R. & Parida, K. Spinel-ferrite-decorated graphene-based nanocomposites for enhanced photocatalytic detoxification of organic dyes in aqueous medium: A review. Water 15(1), 81 (2023).

Shah, A. et al. A review of physicochemical and biological contaminants in drinking water and their impacts on human health. Water Sci. Eng. 16(4), 333–344 (2023).

Khodamorady, M. & Bahrami, K. Fe3O4@BNPs@ ZnO–ZnS as a novel, reusable and efficient photocatalyst for dye removal from synthetic and textile wastewaters. Heliyon 9(6), e16397 (2023).

Mandal, B. et al. MnFe2O4 decorated reduced graphene oxide heterostructures: Nanophotocatalyst for methylene blue dye degradation. Vacuum 173, 109150 (2020).

Sukmana, H. et al. Adsorption and coagulation in wastewater treatment—Review. Prog. Agric. Eng. Sci. 17(1), 49–68 (2021).

Inbaraj, D. J., Chandran, B. & Mangalaraj, C. Synthesis of CoFe2O4 and CoFe2O4/g-C3N4 nanocomposite via honey mediated sol–gel auto combustion method and hydrothermal method with enhanced photocatalytic and efficient Pb+2 adsorption property. Prog. Agric. Eng. Sci. 6(5), 055501 (2019).

Nguyen, L. T. et al. Synthesis, characterization, and application of ZnFe2O4@ZnO nanoparticles for photocatalytic degradation of Rhodamine B under visible-light illumination. Mater. Res. Express 25, 102130 (2022).

Ahuja, P. et al. Transition metal oxides and their composites for photocatalytic dye degradation. J. Compos. Sci. 5(3), 82 (2021).

Adeleke, J. T. et al. Photocatalytic degradation of methylene blue by ZnO/NiFe2O4 nanoparticles. Appl. Surf. Sci. 455, 195–200. https://doi.org/10.1016/j.apsusc.2018.05.184 (2018).

Yılmaz, Ş, Zengin, A. & Şahan, T. A novel material poly(N-acryloyl-L-serine)-brush grafted kaolin for efficient elimination of malachite green dye from aqueous environments. Colloids Surf. A Physicochem. Eng. Asp. 601, 125041. https://doi.org/10.1016/j.colsurfa.2020.125041 (2020).

Desalegn, Y. M. et al. Optimization of adsorption of methyl orange from aqueous solution by magnetic CoFe2O4/ZnAl-layered double hydroxide composite using response surface methodology. Mater. Res. Express 10(1), 015505 (2023).

Zamani, A., Mahjoub, A. R. & SeyedSadjadi, M. Synthesis and characterization of MnFe2O4@ZnO-GO and MnFe2O4@ZnO-rGO nanocomposites with evaluation of improved photocatalytic performance under sun light. J. Nanostruct. 10(3), 581–606 (2020).

Mousavi, S. M. et al. Phenol red dye removal from wastewater using TiO2-FSM-16 and Ni-FSM-16 photocatalysts. Heliyon 9(3), e14488 (2023).

Muthukrishnaraj, A. et al. Enhanced photocatalytic activity of Cu2O Cabbage/RGO nanocomposites under visible light irradiation. Polymers 13(11), 1712 (2021).

Eltaweil, A. S. et al. Efficient removal of toxic methylene blue (MB) dye from aqueous solution using a metal-organic framework (MOF) MIL-101 (Fe): Isotherms, kinetics, and thermodynamic studies. Desalin. Water Treat. 189, 395–407. https://doi.org/10.5004/dwt.2020.25599 (2020).

Rosly, N. Z. et al. Adsorption of methylene blue dye by calix [6] arene-modified lead sulphide (Pbs): Optimisation using response surface methodology. Int. J. Environ. Res. Public Health 18(2), 397 (2021).

Danila, R. et al. CoFe2O4@HaP as magnetic heterostructures for sustainable wastewater treatment. Materials 16(2594), 2023 (2023).

Wang, J. et al. Study on the application of shell-activated carbon for the adsorption of dyes and antibiotics. Water 14(22), 3752 (2022).

Bouchelkia, N. et al. Study and characterization of H3PO4 activated carbons prepared from jujube stones for the treatment of industrial textile effluents. Processes 11(9), 2694 (2023).

Banerjee, S. et al. Adsorption characteristics of alumina nanoparticles for the removal of hazardous dye, Orange G from aqueous solutions. Arab. J. Chem. 12(8), 5339–5354 (2019).

Gholizadeh, Z. et al. High specific surface area γ-Al2O3 nanoparticles synthesized by facile and low-cost co-precipitation method. Sci. Rep. 13(1), 6131 (2023).

Jbara, A. S. et al. Characterization of γ-Al2O3 nanopowders synthesized by Co-precipitation method. Mater. Chem. Phys. 188, 24–29 (2017).

Igwegbe, C. A. et al. Modeling of adsorption of methylene blue dye on Ho-CaWO4 nanoparticles using response surface methodology (RSM) and artificial neural network (ANN) techniques. MethodsX 6, 1779–1797. https://doi.org/10.1016/j.mex.2019.07.016 (2019).

Nure, J. F. et al. Adsorption of black MNN reactive dye from tannery wastewater using activated carbon of Rumex abysinicus. J. Taiwan Inst. Chem. Eng. 151, 10513 (2023).

Alam, M. Z., Bari, M. N. & Kawsari, S. Statistical optimization of methylene blue dye removal from a synthetic textile wastewater using indigenous adsorbents. Environ. Sustain. Indic. 14, 100176 (2022).

Rashtbari, Y. et al. Potential of using green adsorbent of humic acid removal from aqueous solutions: Equilibrium, kinetics, thermodynamic and regeneration studies. Int. J. Environ. Anal. Chem. 102(17), 5373–5390 (2022).

Sangor, F. I. M. S. & Al-Ghouti, M. A. Waste-to-value: Synthesis of nano-aluminum oxide (nano-γ-Al2O3) from waste aluminum foils for efficient adsorption of methylene blue dye. Case Stud. Chem. Environ. Eng. 8, 100394 (2023).

Tavassoli, S., Etemadifar, P., Mollahosseini, A., Joodaki, S. & Sedighi, N. Optimization and characterization of silver nanoparticle-modifed lufa for the adsorption of ketoprofen and reactive yellow 15 from aqueous solutions. Sci. Rep. 14(1), 4398 (2024).

Ripanda, A. et al. Removal of lamivudine from synthetic solution using jamun seed (Syzygium cumini) biochar adsorbent. Emerg. Contam. 9(3), 100232 (2023).

Askari, R. et al. Synthesis of activated carbon from walnut wood and magnetized with cobalt ferrite (CoFe2O4) and its application in removal of cephalexin from aqueous solutions. J. Dispers. Sci. Technol. 44(7), 1183–1194. https://doi.org/10.1080/01932691.2021.2008421 (2023).

Ofgea, N. M., Tura, A. M. & Fanta, G. M. Activated carbon from H3PO4-Activated Moringa stenopetale seed husk for removal of methylene blue: Optimization using the response surface method (RSM). Environ. Sustain. Indic. 16, 100214 (2022).

Mohammad, A. K. T., Abdulhameed, A. S. & Jawad, A. H. Box–Behnken design to optimize the synthesis of new crosslinked chitosan-glyoxal/TiO2 nanocomposite: Methyl orange adsorption and mechanism studies. Int. J. Biol. Macromol. 129, 98–109 (2019).

Rashtbari, Y. et al. Efficiency of zeolite coated with zero-valent iron nanoparticles for removal of humic acid from aqueous solutions. Water Air Soil Pollut. 231(10), 514. https://doi.org/10.1007/s11270-020-04872-9 (2020).

Dimbo, D. et al. Methylene blue adsorption from aqueous solution using activated carbon of spathodea campanulata. Results Eng. 21, 101910 (2024).

Ahmad, M. A., Eusoff, M. A., Oladoye, P. O., Adegoke, K. A. & Bello, O. S. Optimization and batch studies on adsorption of methylene blue dye using pomegranate fruit peel based adsorbent. Chem. Data Collect. 32, 100676 (2021).

Verma, M. et al. Fabrication of GO–MnO2 nanocomposite using hydrothermal process for cationic and anionic dyes adsorption: Kinetics, isotherm, and reusability. J. Environ. Chem. Eng. 9(5), 106045 (2021).

Ahmadfazeli, A. et al. Removal of metronidazole antibiotic from aqueous solution by ammonia-modified activated carbon: Adsorption isotherm and kinetic study. J. Water Sanit. Hyg. Dev. 11(6), 1083–1096 (2021).

Al-Rubayee, W. T., Abdul-Rasheed, O. F. & Ali, N. M. Preparation of a modified nanoalumina sorbent for the removal of alizarin yellow R and methylene blue dyes from aqueous solutions. J. Chem. 2016(1), 4683859 (2016).

Jawad, A. H. et al. High surface area and mesoporous activated carbon from KOH-activated dragon fruit peels for methylene blue dye adsorption: Optimization and mechanism study. Chin. J. Chem. Eng. 32, 281–290 (2021).

Aktar, M. S., Shakil, M. S. & Tuj-Zohra, F. Potentials of bio-adsorbent prepared from coconut fibre in mitigation of pollution from tanning effluent. Clean. Eng. Technol. 17, 100687. https://doi.org/10.1016/j.clet.2023.100687 (2023).

Abewaa, M., Adino, E. & Mengistu, A. Preparation of Rumex abyssinicus based biosorbent for the removal of methyl orange from aqueous solution. Heliyon 9(12), e22447 (2023).

Rashtbari, Y. et al. Green synthesis of zinc oxide nanoparticles loaded on activated carbon prepared from walnut peel extract for the removal of Eosin Y and Erythrosine B dyes from aqueous solution: experimental approaches, kinetics models, and thermodynamic studies. Environ. Sci. Pollut. Res. 2022, 1–13. https://doi.org/10.1007/s11356-021-16006-7 (2022).

Ghosh, I. et al. Removal of methylene blue from aqueous solution using Lathyrus sativus husk: Adsorption study. MPR ANN Model. 149, 345–361 (2021).

Houston, R. L., Waclawik, E. R. & Sarina, S. Application of alumina nanofibers as adsorbents for the removal of mercury (II) and lead (II) from aqueous solutions. Minerals 13(5), 654 (2023).

Sadeq, Z. S., Mahdi, Z. F. & Hamza, A. M. Low cost, fast and powerful performance interfacial charge transfer nanostructured Al2O3 capturing of light photocatalyst eco-friendly system using hydrothermal method. Mater. Lett. 254, 120–124 (2019).

Dhawale, V. P., Khobragade, V. & Kulkarni, S. D. Synthesis and characterization of aluminium oxide (Al2O3) nanoparticles and its application in azodye decolourisation. Chemistry 27, 31 (2018).

Barakat, M. et al. Novel Al2O3/GO/halloysite nanotube composite for sequestration of anionic and cationic dyes. RSC Adv. 9(24), 13916–13926 (2019).

Shelke, P. D. & Rajbhoj, A. S. Electrochemical synthesis and their photocatalytic application of mesoporous γ-Al2O3 nanoparticles. Chem. Sin. 8(5), 482–486 (2017).

Ahmed, M. I. et al. Synthesis and characterization of γ-Al2O3 and α-Al2O3 nanoparticles using a facile, inexpensive auto-combustion approach. Egypt. J. Chem. 64(5), 2509–2515 (2021).

Kam, O. R. et al. Low-cost synthesis of alumina nanoparticles and their usage for bisphenol-A removal from aqueous solutions. Processes 9(10), 1709 (2021).

Chu, T. P. M. et al. Synthesis, characterization, and modification of alumina nanoparticles for cationic dye removal. Materials 12(3), 450 (2019).

Rabu, R. et al. Synthesis of metal-oxide (Al2O3) nanoparticles by using autoclave for the efficient absorption of heavy metal ions. J. Nanomater. Mol. Nanotechnol 9(6), 1–6 (2020).

Ali, S. et al. Synthesis of γ-alumina (Al2O3) nanoparticles and their potential for use as an adsorbent in the removal of methylene blue dye from industrial wastewater. Nanoscale Adv. 1(1), 213–218 (2019).

Miloševića, D. L. et al. Structural and surface modification of highly ordered alumina for enhanced removal of Pb2+, Cd2+ and Ni2+ from aqueous solution. Desalin. Water Treat. 178, 220–239 (2019).

Miloševića, D. L. et al. Structural and surface modification of highly ordered alumina for enhanced removal of Pb2+, Cd2+ and Ni2+ from aqueous solution. Desalin. Water Treat. 178, 220–239 (2020).

ShokatiPoursani, A. et al. A novel method for synthesis of nano-γ-Al2O3: Study of adsorption behavior of chromium, nickel, cadmium and lead ions. Int. J. Environ. Sci. Technol. 12, 2003–2014 (2015).

Pourali, P. et al. Dissociation of acid blue 113 dye from aqueous solutions using activated persulfate by zero iron nanoparticle from green synthesis: The optimization process with RSM-BBD model: Mineralization and reaction kinetic study. Biomass Convers. Biorefin. 14(5), 6333–6345 (2024).

Kumari, S. et al. Application of RSM for bioremoval of methylene blue dye from industrial wastewater onto sustainable walnut shell (Juglans regia) biomass. Water 14(22), 3651 (2022).

Shokoohi, R. et al. Optimizing laccase-mediated amoxicillin removal by the use of Box–Behnken design in an aqueous solution. Desalin. Water Treat. 119, 53–63 (2018).

Rashtbari, Y. et al. The optimization of reactive black 5 dye removal in the sono-catalytic process combined with local yellow montmorillonite and hydrogen peroxide using response surface methodology from aqueous solutions. Biomass Convers. Biorefin. 13(7), 6067–6081. https://doi.org/10.1007/s13399-021-01773-7 (2023).

Shokoohi, R. et al. Modeling and optimization of removal of cefalexin from aquatic solutions by enzymatic oxidation using experimental design. Braz. J. Chem. Eng. 35(3), 943–956 (2018).

Yılmaz, Ş et al. Efficient Removal of 2, 4-dichlorophenoxyacetic acid from aqueous medium using polydopamine/polyacrylamide co-deposited magnetic sporopollenin and optimization with response surface methodology approach. J. Polym. Environ. 31(1), 36–49 (2023).

Yılmaz, Ş, Zengin, A., Şahan, T. & Zorer, Ö. S. Utilization of a novel polymer–clay material for high elimination of hazardous radioactive contamination uranium(VI) from aqueous environments. Environ. Technol. Innov. 23, 101631. https://doi.org/10.1016/j.eti.2021.101631 (2021).

Asgari, G. et al. Sonophotocatalytic treatment of AB113 dye and real textile wastewater using ZnO/persulfate: Modeling by response surface methodology and artificial neural network. Environ. Res. 184, 109367 (2020).

Rzig, B., Guesmi, F., Sillanpää, M. & Hamrouni, B. Modelling and optimization of hexavalent chromium removal from aqueous solution by adsorption on low-cost agricultural waste biomass using response surface methodological approach. Water Sci. Technol. 84(3), 552–575. https://doi.org/10.2166/wst.2021.233 (2021).

Dehghani, M. H. et al. Statistical modelling of endocrine disrupting compounds adsorption onto activated carbon prepared from wood using CCD-RSM and DE hybrid evolutionary optimization framework: Comparison of linear vs non-linear isotherm and kinetic parameters. J. Mol. Liq. 302, 112526 (2020).

Omwoyo, F. O. & Otieno, G. Optimization of methylene blue dye adsorption onto coconut husk cellulose using response surface methodology: Adsorption kinetics, isotherms and reusability studies. J. Mater. Sci. Chem. Eng. 12(2), 1–18 (2024).

Desalegn, Y. M., Bekele, E. A. & Olu, F. E. Optimization of Cd (II) removal from aqueous solution by natural hydroxyapatite/bentonite composite using response surface methodology. Sci. Rep. 13(1), 5158. https://doi.org/10.1038/s41598-023-32413-x (2023).

Zadeh, R. J., Sayadi, M. H. & Rezaei, M. R. Synthesis of Thiol modified magMCM-41 nanoparticles with rice husk ash as a robust, high effective, and recycling magnetic sorbent for the removal of herbicides. J. Environ. Chem. Eng. 9(1), 104804 (2021).

Shi, X., Zhang, W. & Li, B. Characteristics of adsorption kinetics and isotherms of Cu (II) by sediment under different hydrodynamic of the Ganjiang river, China. Water Supply 22(2), 1337–1346. https://doi.org/10.2166/ws.2021.350 (2022).

Cundari, L., Utari, A. N. & Septikarini, M. Application of response surface methodology on efficiency of fig leaf activated carbon for removal of methylene blue dye. IOP Conf. Ser. Mater. Sci. Eng. 5, 794–811 (2023).

Cundari, L., Utari, A. & Septikarini, M. Adsorption capacity and isotherm of methylene blue removal in aqueous solution onto regenerated activated carbon. IOP Conf. Ser. Mater. Sci. Eng. 543, 012088. https://doi.org/10.1088/1757-899X/543/1/012088 (2019).

Hashemian, S., Ardakani, M. K. & Salehifar, H. Kinetics and thermodynamics of adsorption methylene blue onto tea waste/CuFe2O4 composite. Am. J. Anal. Chem. 4, 1–7. https://doi.org/10.4236/ajac.2013.47A001 (2013).

Zhang, Z. H., Xu, J. Y. & Yang, X. L. MXene/sodium alginate gel beads for adsorption of methylene blue. Mater. Chem. Phy. 260, 124123. https://doi.org/10.1016/j.matchemphys.2020.124123 (2021).

Sharifi, S. H. & Shoja, H. Optimization of process variables by response surface methodology for methylene blue dye removal using Spruce sawdust/MgO nano-biocomposite. J. Water Environ. Nanotechnol. 3(2), 157–172. https://doi.org/10.22090/jwent.2018.02.007 (2018).

Cundari, L., Sari, K. & Anggraini, L. Characteristic of betel nuts activated carbon and its application to Jumputan wastewater treatment. IOP Conf. Ser. Mater. Sci. Eng. 345, 012041 (2018).

Author information

Authors and Affiliations

Contributions

E.A.B. and Y.M.D. contributed equally to this work. E.A.B.: conceptualization, methodology, investigation, writing—original draft, Y.M.D.: writing—original draft, methodology, validation, formal analysis, supervision. H.K.A.: resources, writing—review and editing.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Bekele, E.A., Korsa, H.A. & Desalegn, Y.M. Electrolytic synthesis of γ-Al2O3 nanoparticle from aluminum scrap for enhanced methylene blue adsorption: experimental and RSM modeling. Sci Rep 14, 16957 (2024). https://doi.org/10.1038/s41598-024-67656-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-67656-9

- Springer Nature Limited