Abstract

Orthodontic adhesive doped with sulfur-modified TiO2 promotes antibacterial effect. The objective of the study was to characterize the physical, mechanical and antibacterial properties of the orthodontic bracket adhesive, doped with modified titanium dioxide nanoparticles. Sulfur-doped TiO2 was synthetized and morphological topography was analyzed with TEM and SEM imaging. The catalytic performance during the degradation of rhodamine B was assessed. Nanomaterial was added at four concentration (1, 3, 6, and 10 wt%) to a commercial orthodontic adhesive. The shear bond strength and microhardness of a resin-based orthodontic adhesive containing S-TiO2 were evaluated. The inhibitory effect of the pure and doped adhesives against Escherichia coli and Streptococcus mutans was examined. As the results, the highest antimicrobial activity and good adhesive properties were noticed for light-cured orthodontic adhesive doped with 3% of S-TiO2. In this case, orthodontic adhesives with strong and long-lasting bactericidal properties can be created through the incorporation of modified TiO2 without negatively influencing microhardnesses, and bonding ability. White spot lesion and demineralization, which occurs very often in patients during orthodontic treatment, can be therefore minimized.

Similar content being viewed by others

Introduction

Orthodontic treatment can be an uncomfortable experience and may have a negative consequences1. The most important one is that orthodontic appliances, especially the brackets, creates new retention areas in addition to blocking plaque-removing shear forces arising from fluid flow and masticatory loads with a resultant undesired effect of accumulation of dental plaque2. In the next step, the white spot lesions (WSL) around the bracket base may appear3, which is an effect of decalcification of the of enamel. Indeed, the brackets and other fixed orthodontic appliances are pointed out as one of the main cause for these undesirable lesions since they facilitate the bacteria accumulation. Indeed, in orthodontic patients enamel demineralization could develop only in just one month4,5. And when it is left untreated, carious lesions may progress and may cause severe infection and pain. Therefore, the various new and modified adhesive systems, with their antibacterial activity are in high demand.

The most commonly used orthodontic adhesive is resin-based composite, which is doped with ion-releasing fillers (such as fluoride compounds, bioglasses, silica or iron fillers) to enhanced the remineralization action of the materials6,7. Al-Eesa et al. reported on reactivity of the orthodontic adhesive containing bioactive glass in response to pH change, which could be consider as a potential clinical benefit against demineralization and promoting remineralization to form more stable fluorapatites8. However, due to the fixed orthodontic appliances which act as biofilm retentive factors that make oral hygiene difficult for patients, the orthodontic materials with antimicrobial properties are desirable.

Nanotechnology has gained importance in recent years due to its ability to enhance material properties, including antimicrobial activity, and durability of orthodontic materials. Indeed, fullerene-like tungsten sulfide nanoparticles were used as self-lubricating coatings for orthodontic stainless steel wires resulted in minimizing the frictional forces between the orthodontic wire and brackets9. Elastomeric ligatures, a support scaffold to deliver nanoparticles, can be anti-cariogenic or anti-inflammatory, which can be effective process against common enamel demineralization around the orthodontic bracket during treatment10. It has been reported, that as the concentration of ZnO nanoparticles increases, the frictional forces between archwires and brackets significantly decreased, and shear bond strength was reduced11,12. On the other hand, the antimicrobial effect of this material was increased. In that case, the additional of various nano-fillers to improve the properties of the orthodontic material are indisputable. However, bonding of brackets to enamel is a critical issue in orthodontics research. The significance of achieving a stable bond between a tooth and its bracket is obvious, and thus, after adding the nano-fillers the physical properties, i.e. shear strength or microhardness of the adhesives must be still acceptable. The antimicrobial properties of silver nanoparticles (AgNPs) have been exploited through the mechanism of joining dental materials or coating the surface to prevent adhesion of microbes to reduce biofilm formation13. However, most silver nanoparticles are toxic to the human body, and it is precisely because of their small particle size that they can penetrate human tissues, therefore, the further research with other nano-fillers is needed14.

The development of composite materials, such as an orthodontic adhesive, with antimicrobial potential and good mechanical properties may represent a possible alternative for the bonding of brackets to control of the development of white spot lesions. Antimicrobial properties of TiO2 nanoparticles and their application in medicine, dentistry and other science have been widely known15. Usually, the UV irradiation is used for polymerization of light-cured orthodontic adhesive. However, the doping of the resin with extra elements allows sensitizing the material in the visible wavelengths and/or increasing the photoactivity in the ultraviolet spectrum. Indeed, the synthesized sulfur-codoped TiO2 showed excellent photocatalytic performance during the degradation of organic dyes and display visible light absorption16,17.

In this paper, we report on synthesis and characterization of material used as the adhesive for orthodontic treatment (Fig. 1). The objective of the investigation is to make a multifunctional composite material which can be useful for various application, especially for orthopedic and orthodontic curing. Sulfur-doped titanium dioxide nanoparticles were synthetized and characterized for their catalytic activity. The physicomechanical properties of orthodontic adhesive filled with nanomaterials were tested; the shear bond strength (SBS), and microhardness. Finally, the antibacterial potential of the pure or doped adhesive were compared.

The hypothesis of the project is the assumption that the modification of commercially available orthodontic adhesive with sulfur-doped titanium dioxide nanoparticles will create the possibility of a bactericidal effect during orthodontic treatment on the microbial microflora of the surface and interface of the orthodontic appliance due to the photodynamic mechanism of catalysis. The photocatalysis process will be activate with blue lamp, which is alternative to ultraviolet, without critical deterioration of adhesion and microhardness of the adhesive.

Materials and methods

Synthesis, characterization and photocatalytic properties of S-TiO2

The titanium dioxide nanoparticles were prepared according to17, and the optical characterization of the catalysts was performed by spectrophotometer (Cary Series UV–Vis-NIR, Agilent Technologies) in the wavelength range of 200—1200 nm. The hydrodynamic diameter of the nanomaterial was measured by Dynamic Light Scattering (DLS). These measurements were performed with NanoPlus 3 HD analyser (Particulate Systems, Micromeritics, Norcross, GA 30093 US.). Scanning electron microscopy was used to image the TiO2 nanoparticle. The morphology and particles size of prepared nanoparticles were evaluated by a Scanning Electron Microscope (SEM) and Transmission Electron Microscope (TEM). A high-resolution scanning electron microscope Hitachi S-4800 II was used. The JEOL-JEM-1011 TEM microscope was operated at an accelerating voltage of 80 kV with a resolution of 0.2 nm was used. The powder samples were prepared by air-drying a drop of a sonicated suspension onto copper grids. The phase identification of S-TiO2 was carried out by powder X-ray diffraction, using the D8 Advance (BRUKER) diffractometer in the reflection mode with Cu target Kα radiation. Photocatalytic degradation was carried out using a glass photoreactor (Heraeus LRS2, Hanau, Germany) under air conditions. The irradiation was performed with a handmade blue diode lamp as a light source (power density 8.78 W m−2 measured by the Peak Tech 5025 digital lux meter, wavelength 455 nm) immersed in the continuously stirred reaction suspension. The 150 mg of S-TiO2 was added to a glass tube reactor containing 250 mL of 1 × 10−6 M rhodamine B (RhB) water solution (pH = 5.96 ± 0.02). The suspension was stirred for 30 min in the dark to equilibrate adsorption/desorption in the presence of air. The catalytic experiment was conducted in two ways in the absence of H2O2 and the presence of H2O2 (0.3% v/v). As the control experiments, the photolysis of RhB in the absence of H2O2, and the presence of H2O2 (0.3% v/v), was provided. The photocatalytic reaction was performed up to 60 min illumination-time. During the reaction, 5 cm−3 samples were collected from the reactor at regular time-intervals. The concentration of the substrates (after removing the catalyst) was determined by spectrophotometric measurements (VWR UV–VIS 3100 PC spectrophotometer). External standards of five concentration was ranging from 5 × 10−6 to 5 × 10−7 mol dm−3.

Sample preparation

Fifteen extracted pig teeth were collected from a local slaughterhouse without ethical approval being required. The teeth were extracted by one of the investigators under the supervision of the workplace veterinary within 1 days after the animals were slaughtered and stored in 0.5% chloramine solution for disinfection. Teeth with cracks and damaged enamel surfaces were rejected (therefore the number for one tested group is n = 3). Teeth used for the study were mechanically cleaned with a dental brush, disinfected, rinsed with water, air-dried and then etched with acid. Acid etching of teeth is a process that removes impurities from the surface layer of the tooth. The use of the etching process has a positive effect on the bond strength of the adhesive due to the formation of microstructures on the irregularly shaped tooth surface where the adhesive can anchor. The teeth were etched with 37% phosphoric acid gel (Concac37, FGM Dental Group) for 30 s, rinsed for 15 s and then dried with stream of air for 30 s. The brackets (Elite Optimum, Trachem) were bonded to the etched enamel using light cure adhesive (Orthocem UV Trace, FGM Dental Group). The brackets were placed parallel to the long axis of the tooth and pressed against the enamel for final positioning, and the excess material was removed. The orthodontic adhesive was hardened using an LED (405 nm) for 180 s. Four types of modified light-cured adhesive were prepared, with various concentration of S-TiO2: 1%, 3%, 6%, and 10%.

Shear bond strength assessment

The bonded specimens were stored in distilled water at 37 °C for 24 h, until the specimens underwent the shear bonding test. The SBS was measured by shearing of the bonded specimens on an Instron universal testing machine (Instron E10000). A non-stretchable tungsten cable was attached on one side to the upper clamping jig of the machine and on the other side anchored to the orthodontic bracket, which enabled the creation of a shear force at the tooth-orthodontic bracket interface. The readings was recorded using a computer connected to a testing machine and the results were subjected to statistical analysis.

Vickers hardness

For measuring Vickers hardness (with the Digital Micro Vickers Hardness Tester (HVS-1000), disc specimens of 5 mm in diameter and 4 mm in length were fabricated in an aluminium mould. The pure or S-TiO2 doped orthodontic adhesive were poured into the mould carefully and the samples were cured using a light-curing unit 80 s on each side. The samples were then removed from the mould and polished. Vickers hardness was measured by applying 0.245 N load for 15 s.

Antibacterial action

Bacteria strains. Escherichia coli PCM 2209 and Streptococcus mutans PCM 2502, were precultured in nutrient broth or brain–heart infusion broth (BTL, Poland) at 37 °C with overnight shaking (150 rpm), before being sub-cultured into fresh, pre-warmed medium and grown to early exponential phase. Pure and modified with S-TiO2 nanoparticles orthodontic adhesive (80 µg) were placed in the 24-well plate, sterilized in absolute ethanol, washed in dH2O and dried prior to inoculation with bacterial suspensions (105 cells/mL). The negative (pure medium) and positive (pure medium with bacteria) controls were maintained. The microtiter plates were incubated for 24 h at 37 °C with shaking (250 rpm, Biosan PST-60HL-4). The growth was monitored through the absorbance measurements (at OD600) of the aliquots after 8 and 24 h.

Statistical analysis

The displayed values for SSB analysis and antibacterial activity represent the mean and SD from two or three independent experiments. All statistical tests were performed using GraphPad Prism software.

Results and discussion

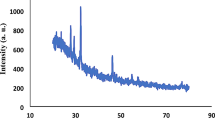

UV–Vis diffuse reflectance spectra of sulfur doped TiO2 have been used to study the effect of doping on the optical properties of the catalyst (Fig. 2A). There is a strong intrinsic absorption band in TiO2 anatase which originates from the band gap excitation of electrons, which allows TiO2 to show only the photoresponse in the UV region (the absorption edge for pure anatase TiO2 is approximately 400 nm)18. For S-doped TiO2, it is extended to the visible light region19,20,21,22. The gradual red shift of the absorption edge suggests the existence of intraband levels introduced by dopants into the bandgap of the catalyst, causing absorption in the visible range. Indeed, it is in agreement with the data reported that sulfur-doped TiO2 shows a strong absorption in the visible light20,21,23,24. The XRD patterns of TiO2:S is presented in Fig. 2B. The well-defined sharp Bragg peaks indicate a highly crystalline nature of the material. The Bragg diffraction peaks indexed as (101), (112), (200), (105), (211), (204), (116), and (220) are correspond to anatase phase TiO2 with tetragonal arrangement. The determined average crystallite size of the catalyst was 19 nm. DLS measurement suggests the catalyst does not exist in its isolated primary particle size form, but as aggregates, hence the hydrodynamic particle size is ca. 358.8 ± 8.57 nm (Fig. 2C). The TEM and SEM images confirmed the flaky morphology of single nanoparticles with sizes in the range of 10–50 nm (Fig. 2D,E). Small particle size can shorten the route for an electron migration from the interior of TiO2 to the surface, which can reduce the recombination of h + and e−. The aggregated form of the catalyst is the reason for its large specific surface area, containing more active sites on the surface, which results in a greater probability of substrate adsorption and improves photocatalytic activity.

Photocatalytic activity of S-TiO2 were studied in the degradation reaction of aqueous solution of RhB. The degradation reaction was performed under weak acidic conditions (pH of reaction mixture 5.96). The Fig. 3A presents the degradation efficiency of RhB in photocatalytic and photolytic processes. The apparent degradation rate constant (kapp) may be determined according to Eq. 1, assuming that the reactions occurring were of pseudo-first order.

where C0 and Ct are the initial concentration and the concentration at time t, respectively. The dependence of ln(Ct/C0) on time is represented by straight lines, as shown in Fig. 3B, therefore, the degradation kinetics are consistent with the pseudo first-order kinetic model (R2 > 0.95). Photolytic degradation of RhB, both in the presence and absence of hydrogen peroxide, is at the level of 3–5%, which seems to be a negligible value. The value of the apparent rate constant for these reactions is 0.6 × 10−3 and 1 × 10−3 min−1, respectively. The introduction of a photocatalyst into the system causes a significant increase in RhB degradation up to approximately 34% in the presence of the catalyst alone, and 54% in the presence of the catalyst and H2O2. Introducing of H2O2 in the 0.3% v/v concentration to the photocatalytic system significantly improved the efficiency of photocatalytic degradation of RhB (Fig. 3A), apparent rate constant values for photocatalysis in the absence and presence of H2O2 were much higher than for photolysis and amounted to 0.67 × 10−2 and 1.26 × 10−2 min, respectively. It indicates the high ability of the catalyst to generate hydroxyl radicals. Also noteworthy is the very low concentration of hydrogen peroxide used to improve the efficiency of the photocatalytic reaction. Vu et al. reported on preparation and photocatalytic properties of S-doped TiO2 synthesized by a supercritical method25. Its photocatalytic activity was evaluated in reaction of RhB degradation. The observed RhB degradation was 50% during 1 h. Ma et al. also synthesized S-doped TiO2 and studied its photocatalytic properties26. Photocatalyst showed RhB conversion of 70% after 60 min. Sharotri and co-workers in their recent work synthesized sulfur-doped TiO2 nanoparticles and used them for the degradation of Rhodamine 6G27. The degradation efficiency was calculated as 91.7% within four hours (it is impossible to determine the degradation efficiency after 60 min from the data presented in the article). Since the experimental conditions of various research groups were different, it seems that the only parameter that can be compared is the degradation efficiency (in a fixed time). The presented photocatalytic activity of S-TiO2 obtained by other researchers seems to be higher than ours. However, the observed higher degradation efficiency may be due to differences in the methodology of photocatalytic experiments (differences in solution concentrations, light intensity, environmental pH, etc.).

An adequate shear bond strength for orthodontic bonding is required to maintain a good bond between metal brackets and enamel during orthodontic treatment. It is important to remember that high bond strength values are potentially dangerous, as they may cause enamel fractures during debonding28. There is a great variety of orthodontic brackets in the market, however, there is a wide variation in methods and results of shear bond strength tests in the literature, simultaneously. Therefore, the specific properties of new or modified adhesive should be each time evaluated separately. The bond strength obtained with the pure or S-TiO2 doped adhesives used in the study differed between groups (P < 0.001) (Table. 1). The results for shear bond strength found in this study ranged from 4.49 ± 0.25 MPa to 1.11 ± 0.27 MPa. The highest shear bond value was recorded for conventional adhesive, without doping its, compared to all other types of sample. Decreasing of the SBS values were noticed according to the increasing of S-TiO2 concentration. Bond strength of orthodontic brackets depends on many variables, such as: material and surface structure of the bracket, type of bonding agent used and quality of the enamel. Additionally, some aspects of the29 experimental condition can also play a significant role28. Therefore, the result should be compare to the values obtained for pure, non-doped adhesive, not to the other result reported by researchers. Type of preparation and the pigs teeth, employed here, will have an impact on the final values of SBS. A literature search did not identify any comparable studies. Some research showed that adding up to 1% of TiO2 to orthodontic adhesive is acceptable, because exceeding this limit cause the decreasing the shear bond strength values. Indeed, they showed similar results of the decreasing of the SBS after added of the dioxide nanoparticles.

Modification of the composition of the orthodontic adhesives may change the mechanical properties, such as microhardness, which can be explained by the size of the filler, the percentage of filler particles, and the hardness30. To assess the ability to resist plastic deformation of the pure and doped adhesives, the Vickers hardness (HV) of sample was performed. The results of microhardness measurements indicate that the differences between individual adhesive samples are relatively small (Fig. 4). The highest and smallest Vickers hardness were found for adhesive doped with 3% (389 HV) and 10% of S-TiO2 (334 HV), respectively. By increasing the content of titanium dioxide nanoparticles in the orthodontic glue to 10%, the obtained microhardness result was 334 HV. Therefore, it can be concluded that the shrinkage of orthodontic glue (polymerization quality) containing more than 3% titanium dioxide nanoparticles decreases. It does not correlate with the results of Xia et al. who reported that the more the TiO2 filler added, the greater the improvement in microhardness31.

This study only tested one type of bracket bonded with Orthocem UV Trace to pig enamel, and the results cannot be extended to other types of material, such as ceramic brackets, other types of adhesive, different enamel preparations or bonding on different surfaces, such as restorative material28. However, these data show the strong antibacterial effect after doping with nanomaterial, which further may be valuable for other researchers and dental appliance manufacturers.

The antibacterial impact of the adhesive doped with 3% of S-TiO2 was assessed. Figure 5 shows the impact of the pure and NPs-doped material on the bacteria cell populations. After doping the adhesive with 3% of S-TiO2 the inhibition of the growth of bacteria was noticed for two of the tested strains, no matter of the light exposure. While, the pure othodontic adhesive did not exhibit significant decreasing in the growth for E. coli or S. mutans strains. On the contrary, the exponential growth was observed, which was similar to the positive control. In general, the S-TiO2 doped adhesive showed greater inhibiting capacity on E. coli and S. mutans than non-modified material. The reduction of the cell population was in the range of 45–94% compare to the positive control. Several antimicrobial components have been added to dental composite resin and adhesive system to disinfect the area around the adhesive restorations for a prolonged duration such as dodecylamine, bipyridine, tannic acid derivatives, polyhexanide, amphilic lipids, silver32. Degrazia et al. reported on the antibacterial effect after addition of silver nanoaprticles33. However, there has been issues with dispersion and consistency with the mixing of the nanoparticles into the adhesive. What more, the widespread application of nano silver preparations in daily life raises concerns about public health34,35. Therefore, other type of doping material are desired to increase the antimicrobial activity. TiO2 nanoparticles, known as non-toxic, inexpensive, biocompatible, reusable and chemically stable, display also efficient antimicrobial properties36. It was found that sulfur-doped TiO2 exhibits a strong antibacterial effect under visible light, enabling effective inhibition of Micrococcus lylae and most of the Gram-positive bacteria16. Indeed, in this study the higher inhibition of the bacteria growth was indicated after blue-light irradiation of the adhesive resin; 94.3 and 75.6% reduction of bacteria population with or without irradiation, respectively. The irradiated pure adhesive without any nanofiller exhibit no reduction at all.

Conclusions

In this study, modified titanium dioxide nanoparticles were successfully incorporated into an orthodontic adhesive to enhance its functionality. Nanoparticles of titanium dioxide doped with sulfur and carbon in a 3 percent filling improve the microhardness of the adhesive without significant deterioration of adhesion. An important acquired function of the modified adhesive is its photocatalytic property, which provides an antibacterial effect. Doping titanium dioxide with sulfur sensitizes it to the visible region of the spectrum and provides photocatalytic generation of free radicals when excited by the radiation of a standard photopolymerization “blue” LED lamp, which suppresses the growth of pathogenic bacteria. This opens up prospects for interval photodynamic therapy of problem areas in the early stages of complications. Given the long period of orthodontic treatment, such prevention and inhibition of caries is also possible in outpatient settings. The proposed modified adhesive obviously has minimal toxicity for normal hard and soft tooth tissues in the absence of mechanisms of primary and acquired resistance. It should also be noted the possibility of combination with other methods of diagnosis and treatment (for example, “Diagnodent”) and the convenience of use for multiple medical center. Future clinical trials of the developed adhesive will precede its introduction into dental practice.

Data availability

The data sets used and/or analysed during the current study available from the corresponding author on reasonable request.

References

Marques, L. S. et al. Discomfort associated with fixed orthodontic appliances: Determinant factors and influence on quality of life. Dental Press J. Orthod. 19(3), 102–107 (2014).

Metin-Gürsoy, G. The relationship between orthodontic treatment and dental caries. In Dental Caries—Diagnosis, Prevention and Management (ed. Metin-Gürsoy, G.) (InTech, 2018).

Chanachai, S. et al. Physical/mechanical and antibacterial properties of orthodontic adhesives containing calcium phosphate and Nisin. J. Funct. Biomater. 12(4), 73 (2021).

Gorton, J. & Featherstone, J. D. In vivo inhibition of demineralization around orthodontic brackets. Am. J. Orthod. Dentofacial Orthop. 123(1), 10–14 (2003).

O’Reilly, M. M. & Featherstone, J. D. Demineralization and remineralization around orthodontic appliances: An in vivo study. Am. J. Orthod. Dentofacial Orthop. 92(1), 33–40 (1987).

Al Tuma, R. R. & Yassir, Y. A. Evaluation of a newly developed calcium fluoride nanoparticles-containing orthodontic primer: An in-vitro study. J. Mech. Behav. Biomed. Mater. 122, 104691 (2021).

Eliades, T., Panayi, N. & Papageorgiou, S. N. From biomimetics to smart materials and 3D technology: Applications in orthodontic bonding, debonding, and appliance design or fabrication. Jpn Dent. Sci. Rev. 59, 403–411 (2023).

Al-Eesa, N. A. et al. Bioactive glass composite for orthodontic adhesives—Formation and characterisation of apatites using MAS-NMR and SEM. Dent. Mater. 35(4), 597–605 (2019).

Redlich, M. et al. Improved orthodontic stainless steel wires coated with inorganic fullerene-like nanoparticles of WS(2) impregnated in electroless nickel-phosphorous film. Dent. Mater. 24(12), 1640–1646 (2008).

Nalbantgil, D. et al. Prevention of demineralization around orthodontic brackets using two different fluoride varnishes. Eur. J. Dent. 7(1), 41–47 (2013).

Behroozian, A. et al. The effect of ZnO nanoparticle coating on the frictional resistance between orthodontic wires and ceramic brackets. J. Dent. Res. Dent. Clin. Dent. Prospects 10, 106–111 (2016).

Zakrzewski, W. et al. Nanomaterials Application in Orthodontics. Nanomaterials (Basel) 11(2), 337 (2021).

Moolya, N. et al. Orthodontic bracket designs and their impact on microbial profile and periodontal disease: A clinical trial. J. Orthod. Sci. 3, 125–131 (2014).

McShan, D., Ray, P. & Yu, H. Molecular toxicity mechanism of nanosilver. J. Food Drug Anal. 22, 116–127 (2014).

Sodagar, A. et al. Effect of TiO2 nanoparticles incorporation on antibacterial properties and shear bond strength of dental composite used in Orthodontics. Dent. Press J. Orthod. 22, 67–74 (2017).

Yu, J. C. et al. Efficient visible-light-induced photocatalytic disinfection on sulfur-doped nanocrystalline titania. Environ. Sci. Technol. 39(4), 1175–1179 (2005).

Ivanov, S. et al. Synthesis, characterization, and photocatalytic properties of sulfur- and carbon-codoped TiO2 nanoparticles. Nanoscale Res. Lett. https://doi.org/10.1186/s11671-016-1353-5 (2016).

Mi, Y. & Weng, Y. Band alignment and controllable electron migration between rutile and anatase TiO2. Sci. Rep. 5, 11482 (2015).

Kisala, J. et al. Photocatalytic degradation of 4,4′-Isopropylidenebis(2,6-Dibromophenol) on sulfur-doped nano TiO2. Materials 15, 361 (2022).

Zhu, M. et al. New method to synthesize S-doped TiO2 with stable and highly efficient photocatalytic performance under indoor sunlight irradiation. ACS Sustain. Chem. Eng. 3(12), 3123–3129 (2015).

Cravanzola, S. et al. Sulfur-doped TiO2: Structure and surface properties. Catalysts 7(7), 214 (2017).

Bakar, S. A. & Ribeiro, C. Rapid and morphology controlled synthesis of anionic S-doped TiO2 photocatalysts for the visible-light-driven photodegradation of organic pollutants. RSC Adv. 6(43), 36516–36527 (2016).

Piątkowska, A. et al. C-, N- and S-Doped TiO2 photocatalysts: A review. Catalysts 11(1), 144 (2021).

Kisała, J. B. et al. Photocatalytic degradation of 4,4′-Isopropylidenebis(2,6-dibromophenol) on sulfur-doped nano TiO2. Materials 15(1), 361 (2022).

Vu, T. A. et al. Study on photocatalytic activity of TiO2 and non–metal doped TiO2 in Rhodamine B degradation under visible light irradiation. Int. J. Nanotechnol., 2013. 10(3–4), 235–246 (2013).

Ma, D. et al. Fabrication and photocatalytic properties of cationic and anionic S-doped TiO2 nanofibers by electrospinning. Appl. Catal. B Environ. 147, 49–57 (2014).

Sharotri, N., Gupta, S. & Sud, D. Visible light responsive S-Doped TiO2 nanoparticles: Synthesis, characterization and photocatalytic degradation of pollutants. Nanotechnol. Environ. Eng. 7, 503 (2022).

Henkin, F. et al. In vitro analysis of shear bond strength and adhesive remnant index of different metal brackets. Dent. Press J. Orthod. 21, 67–73 (2016).

EL-Awady, A. A. et al. Shear bond strength and antibacterial efficacy of cinnamon and titanium dioxide nanoparticles incorporated experimental orthodontic adhesive—An in vitro comparative study. Appl. Sci. 13(10), 6294 (2023).

Molaasadolah, F. et al. In vitro evaluation of enamel microhardness after application of two types of fluoride varnish. J. Clin. Diag. Res. 11, ZC64–ZC66 (2017).

Xia, Y. et al. Nanoparticle-reinforced resin-based dental composites. J. Dent. 36, 450–455 (2008).

Felemban, N. H. & Ebrahim, M. I. The influence of adding modified zirconium oxide-titanium dioxide nano-particles on mechanical properties of orthodontic adhesive: An in vitro study. BMC Oral Health 17(1), 43 (2017).

Degrazia, F. et al. Effect of silver nanoparticles on the physicochemical and antimicrobial properties of an orthodontic adhesive. J. Appl. Oral Sci. 24, 404–410 (2016).

Zhang, J. et al. Nano silver-induced toxicity and associated mechanisms. Int. J. Nanomed. 17, 1851–1864 (2022).

EFSA Panel on Food Contact Materials. Safety assessment of the substance silver nanoparticles for use in food contact materials. EFSA J. 19(8), e06790 (2021).

Gupta, N. et al. Chapter 7—Use of nanotechnology in antimicrobial therapy. In Methods in Microbiology (eds Gurtler, V. et al.) 143–172 (Academic Press, 2019).

Author information

Authors and Affiliations

Contributions

Conceptualization, AB., YB., and MKL.; methodology, PF., AB., JK., AD., and MKL.; data curation, JK., and MKL.; writing original draft preparation, JK., and MKL.; supervision, MKL.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Barylyak, A., Kisała, J., Fornal, P. et al. Physical, mechanical and antibacterial properties of the orthodontic adhesive doped with S-TiO2. Sci Rep 14, 17862 (2024). https://doi.org/10.1038/s41598-024-68975-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-68975-7

- Springer Nature Limited