Abstract

Two centrifuge model tests of a liquefiable sloping deposit subjected to a tapered acceleration input motion were conducted at Rensselaer Polytechnic Institute as part of the Liquefaction Experiments and Analysis Projects (LEAP). The models were built at a consistent relative density Dr = 65%, observing the same methodology of model preparation, but reflected different scaling laws. Model A was designed observing the conventional similitude laws for centrifuge testing, whereas Model B was designed based on the principles of the generalized scaling laws. Albeit the response of the two models was comparable prior to liquefaction, Model B showed a higher propensity for liquefaction and exhibited higher surficial lateral displacements.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

- Liquefaction Experiments and Analysis Project (LEAP-ASIA-2019)

- Generalized scaling law (GSL)

- Centrifuge modelling

- RPI

1 Introduction

Geotechnical centrifuge modeling is a well-established and a validated methodology of reduced-scale testing of geo-systems under static or dynamic conditions (Schofield, 1981; Steedman, 1991). The conventional scaling laws of centrifuge testing (Garnier et al., 2007) are based on equivalent stress conditions between homologous (geometrically analogous) points in the model and the prototype, rendering the geotechnical centrifuge a reliable means of testing. Despite its efficacy, conventional scaling introduces some restrictions in the design of the experimental set up. The selection of the model scaling factor, λ, depends on the available platform size in the centrifuge facility. Additional limitations may stem from the capacity of the shaking table actuators and possibly the capacity (i.e., highest g-ton level) of the centrifuge. These parameters often determine the geometrical dimensions of the model. A frequent trade-off in centrifuge physical modelling is the size of the prototype versus the size of the model. Large prototypes usually require significantly high values of the scaling factor λ, leading to rather small models. Such experimental schemes may prove problematic, due, for example, to inaccuracy in modeling the boundary conditions in small size models. An additional source of uncertainty is the possible interaction between sensors, as a result of the limited space in small models to properly install the instrumentation.

Over the past decades, performance-based design has led to an increased demand for testing larger models (Tobita & Iai, 2011). Large scale models using shaking tables in 1-g conditions have been used to test large soil systems (Tokimatsu et al., 2007; Van Den Einde et al., 2004). In 1-g testing, specific similitude laws, different from the ones for centrifuge testing, are applied. However, challenges remain for unconventionally large geo-systems. The dependence of soil behavior on overburden effective stress, combined with additional accommodations often needed to minimize the effect of the container boundaries on the model, would lead to extremely large soil system being utilized for the model, hence rendering 1-g shake table testing an unrealistic choice (Tobita & Iai, 2011).

In order to overcome these restrictions for large geotechnical prototypes, Iai et al. (2005) introduced an innovative scaling method referred to as “two-stage” scaling. This methodology employs the similitude laws for centrifuge testing and 1-g testing simultaneously, prescribing the scaling in the following two district steps:

-

1.

The prototype is scaled down by a factor of μ under 1g condition. The yielded geometry corresponds to a virtual model, which is to be further scaled down as described in step 2.

-

2.

The virtual model is scaled down by a factor of η, observing the centrifuge scaling laws.

The second scaling leads to the adopted geometry of the physical model, to be tested on the centrifuge. The comparative advantage of the generalized scaling is that unconventionally large prototypes can be tested on the centrifuge, by avoiding very large scaling factors and thus very small geometries. Instead, the unusually large scaling factors are partitioned in two parts: μ and η, corresponding to the 1-g and centrifuge scaling.

As part of the experimental campaign for the Liquefaction Experiments and Analysis Project (Manzari et al., 2014, 2018), a set of centrifuge experiments of a saturated 5° sloping deposit were undertaken in LEAP-2017. The same experimental set up was utilized for the LEAP-Asia2019, and aimed at investigating the response of the same sloping deposit observing the principles of generalized scaling laws.

This article presents and compares two centrifuge model tests (A and B) conducted at Rensselaer Polytechnic Institute (RPI) according to the two scaling methodologies. Model A was tested using the traditional centrifuge similitude laws, and Model B was tested using the laws of generalized scaling. The focus in this article is on the lateral surficial displacements and deformation. Full documentation of these two tests can be found in Korre et al. (2020a, 2021). All dimensions henceforth are presented in prototype units.

2 Scaling Methodology

The tested Models A and B simulated a 5° mildly sloping deposit, pluviated dry using Ottawa F-65 sand, manufactured by U. S. Silica. Both models reflected the same prototype and had the same dimensions, but they were built observing different scaling principles and they were tested at different centrifugal gravitational fields. Model A, observing the traditional scaling laws for centrifuge testing, was scaled by a factor of λ = 23 and tested under a 23g gravitational field (Fig. 12.1).

Model B was scaled following the methodology of generalized scaling (Iai et al., 2005):

-

1.

The prototype was scaled to a theoretical prototype based on the similitude laws for 1g testing, using a scaling factor of:

$$ \mu =0.50 $$(12.1)Thus, the virtual model is twice as large as the prototype. This unconventional approach was adopted in order to avoid performing the centrifuge experiment at a low gravitational acceleration when using a μ larger than one. Such a case would lead to erroneous results associated with the centrifuge capabilities at Rensselaer.

-

2.

The theoretical prototype was scaled down to the centrifuge model dimensions using a scaling factor of:

$$ \eta =46.0 $$(12.2)Model B was therefore tested under a 46g level.

-

3.

From steps 1 and 2, the global or “partitioned” factor (Iai et al., 2005) for Model B is:

$$ \lambda =\mu \eta $$(12.3)

This factor dictates the scaling factors for Model B as presented in Table 12.1.

Figure 12.1 presents the concept of the two applied scaling methods and the g-level employed in Model A and Model B. Observe that both models reflected the same prototype and had the same dimensions.

3 Model Construction

Both models were prepared in a rigid container with a plexiglass window as shown in Fig. 12.1, observing the same experimental procedure. Dry air pluviation of Ottawa F-65 sand was used and performed at a constant drop-height and velocity to achieve relatively uniform relative density with depth. In both models the achieved mass density was found to be approximately 1.65g/cm3, corresponding to Dr = 65%, based on the maximum and minimum mass densities reported in Carey et al. (2020). Observing the methodology described in Korre et al. (2020b), Models A and B were saturated on the centrifuge beam with methylcellulose solution of 23cP and 27cP viscosity respectively (Table 12.1).

The employed instrumentation in Model A and Model B is shown schematically in Fig. 12.2. Three rows of accelerometers and pore pressure transducers were embedded in specified depths in the two models, along the longitudinal axis of symmetry of the model (Korre et al., 2021). The as-built coordinates of the utilized sensors, with reference to the intersection of the axes of symmetry of the container base (Kutter et al., 2020), are presented in Tables 12.2 and 12.3 showing repeatability in the majority of the achieved sensors’ locations within a range of approximately 10%.

A Phantom v5.1 HI-G high-speed camera manufactured by Vision Research with a capacity to record up to 1200 frames per second at a resolution of 1024 × 1024 pixels (Kokkali et al., 2018) has been utilized in the LEAP experiments performed at the RPI geotechnical centrifuge facilities, to monitor the surficial soil response in terms of permanent lateral displacements and associated lateral spreading (Korre et al., 2020a, b, 2021; Kokkali et al., 2018; Abdoun et al., 2018).

To this end cable tie heads were cut and driven into the soil surface in a grid of 1.15 m × 1.15 m as shown in Fig. 12.3. As shown in Table 12.4, the as-built target locations on the slope surface were highly repeatable for Models A and B. To ensure clear view of the targets while on flight, the camera’s focus was adjusted at the center of the sloping surface. In this way only the targets within the dashed frame shown in Fig. 12.3 were visible during tracking.

Grid of the targets for high-speed tracking. The dashed frame marks the tracked region on the slope surface in the high-speed recording. (Korre et al., 2021)

4 Dynamic Response

Models A and B were subjected to a sinusoidal input acceleration with ramp-up and ramp-down phases and a peak amplitude of 0.15g as shown in Fig. 12.4. The applied input motion was highly repeatable between the two models and compared with high fidelity to the theoretical target. Figure 12.4 shows also the recorded vertical acceleration response of the rigid container, which had minimal amplitude compared to the horizontal one.

4.1 Accelerations

The acceleration response of Models A and B is presented in Fig. 12.5, for the central and side arrays. In the central array, the conditions resembled the ones of a shear beam (Zeghal et al., 2018), whereas in the side arrays the results may have been affected somewhat from the proximity to the side boundaries.

Along the central array (Fig. 12.5), the acceleration response of Models A and B showed reasonable agreement until approximately t = 7 s. Subsequently, Model B liquefied, as shown by the de-amplification in the upslope acceleration amplitude (corresponding to positive acceleration values) and the strong dilative peaks in the downslope direction (corresponding to negative acceleration values). In Model A these characteristics appeared approximately 4 s later (at about t = 11 s).

Similarly, along the upslope and downslope arrays (Fig. 12.5), accelerations compared satisfactorily until t ≈ 7 s for Models A and B. Thereafter, liquefaction was triggered for Model B as revealed by the strong dilation peaks and de-amplification of the positive acceleration values. About 4 s later, similar behavior was also observed for Model A. In general, Model B seemed to exhibit milder dilative response compared to Model A. The locations sustaining the highest dilation peaks were as expected in the upslope array for both models. However, particularly in locations AH7 and AH6 at a depth z ≤ 1.00 m (Fig. 12.5), Model B exhibited significantly lower dilation than Model A.

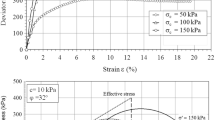

4.2 Pore Water Pressure (PWP)

Figure 12.6 illustrates the pore water pressure build up during the input motion and dissipation, in Models A and B, along the central, upslope, and downslope arrays. The excess pore water pressure ratio, Ru, is determined as the ratio of the excess PWP to the initial effective stress in each corresponding location. Sensors P3, P9 malfunctioned for Model A and sensors P2, P5 for Model B.

The Ru response (Fig. 12.6) corroborated the acceleration results along the central array, revealing overall earlier liquefaction conditions (Ru = 1.0) for Model B compared to Model A (the onset of liquefaction for Model B was approximately at t = 7 s for Model B and at t = 11 s for Model A). Overall, both models developed comparable time histories of excess pore water pressure (EPWP) buildup, but slightly different rates of EPWP buildup and dissipation.

Higher rate and amplitude of EPWP generation and earlier liquefaction in Model B compared to Model A was also observed along the upslope and downslope arrays (Fig. 12.6). Overall Model B exhibited higher susceptibility to EPWP generation than Model A. This trend was consistently evident at all instrumented locations in Model B, even though both models were built with comparable relative densities (Korre et al., 2021). Soil sample tests have revealed reduction in the cyclic resistance to liquefaction as a result of increased confinement (Vaid et al., 2011). The higher confinement in Model B is presumed to be a contributing factor to the observed difference in behavior; however, more research is needed to fully assess the reasons.

5 Lateral Surficial Displacements

The surficial lateral displacements were evaluated by means of image analysis of the high-speed camera recordings. The recordings were processed with the image analysis software TEMA Automotive Lite 3.5-016 by Image Systems. The geometrical relation between engineering length units in the model and pixels in the recording was facilitated by providing in the software the length between two stationary points on the model, thus introducing the geometrical scale in the recording. Based on color contrast between a tracked point and its surrounding points, the software compared in every time increment the relative location of each tracked point and the absolute displacement time history was in this way evaluated. Through differentiation of the displacement, the software produced also the velocity and acceleration response of the tracked points.

The image analysis methodology was validated against the experimental data, by comparing for Model B the acceleration response of the rigid container as recorded by accelerometers AH11-AH12 and the acceleration response of AH4 and the target E0, which was installed closest to that sensor (Fig. 12.7). Even though the accelerometers AH11-AH12 were mounted at the base of the rigid container, whereas the tracked points were at the top of the container, the comparison in Fig. 12.7a revealed good agreement between the two measuring methodologies, reaffirming in this way the high rigidity of the container. Figure 12.7b also showed satisfactory comparison between the embedded sensor and the target adjacent to it, revealing the capabilities of image analysis to capture accurately the soil response, including, for instance, the details of the dilative phase of the soil response. Tracking of the targets after the end of the input motion (t ≈ 16s) was visually compromised, due to light reflections on the free-standing water waves. That part of the response is illustrated with dashed line (Figs. 12.7b, 12.8, and 12.12). The validation of the image analysis for Model A is presented in Korre et al. (2020a).

5.1 Response Along the Central Region of the Slope

The response along the arrays labelled −1 and 1 in Fig. 12.3 was practically identical to the one along the central array 0. Therefore, the presented results focus on the response along the arrays −2 and 2, as it provides a clearer view of the lateral displacement progression across the slope. The results from tracking arrays −2, 0, and 2 along the slope are presented in Fig. 12.8. Array −2 was located closer to the plexiglass window boundary of the container, whereas array 2 was located closer to the aluminum side wall (Fig. 12.3). Arrays −2 and 2 were placed approximately 8.50 cm in model scale (2 m in prototype scale) away from the side walls of the rigid container.

Before the onset of liquefaction in Model B (t < 7 s), the response was in good agreement with Model A (Fig. 12.8). Consistently with the acceleration and EPWP response (Figs. 12.5 and 12.6), after the onset of liquefaction in Model B (approximately at t ≈7 s), the rate of lateral displacement accumulation became larger in Model B and the associated lateral spreading led to almost three times higher lateral residual surficial displacements (Korre et al., 2021).

5.2 Boundary Effects

The permanent lateral surficial displacement response was affected by the container side walls as well as the container boundary at the bottom of the slope, as illustrated in Figs. 12.9, 12.10, 12.11 and 12.12. Figure 12.9 presents an overhead view of the target grid in Model A and Model B after the end of shaking. The dashed lines show schematically the distribution of residual lateral displacements across the slope, for each one of the tracked rows. The observed trend shows decreased lateral displacements in arrays 2, 3 (close to the aluminum container side) compared to the central arrays −1, 0, and 1. In contrast, the lateral displacements near the plexiglass side (array −3) were larger than along the central arrays. The two models exhibited the same trend, which was however more pronounced in Model B.

Figure 12.10 compares the distribution of ultimate lateral displacement along the slope for arrays −2, 0, and 2 of models A and B. Both models revealed similar lateral displacement trends with values increasing from the top of the slope towards the middle zone and then decreasing values closer to the container boundary at the bottom of the slope. This trend was more pronounced for the side arrays −2 and 2. The ultimate displacements for these arrays were compared to those of central array 0, as shown in Fig. 12.11. This figure illustrates the distribution of the ratio of the ultimate displacement along arrays −2 and 2 to the ultimate displacement in the central array, or \( \frac{{\left({d}_{-2}\right)}_{\mathrm{ult}}}{{\left({d}_0\right)}_{\mathrm{ult}}} \) and \( \frac{{\left({d}_2\right)}_{\mathrm{ult}}}{{\left({d}_0\right)}_{\mathrm{ult}}} \), respectively. Model A exhibited relatively small differences in the residual lateral displacement of the side arrays −2 and 2 compared to the ultimate displacement in the central array. Nevertheless, the array closer to the plexiglass window (−2), for this model, exhibited at the end of shaking residual lateral displacements on average about 1.12 times higher than those of the central array (Figs. 12.8 and 12.11). On the other hand, array 2 of Model A (which is closer to the aluminum side), revealed mostly lower ultimate surficial displacements compared to the central array, leading to a value about 0.94 times the ultimate value in the central array.

The observed trend in Model B is quite similar to that of Model A. The array closer to the plexiglass window (−2) exhibited ultimate lateral displacements about 1.16 times the corresponding displacements of the central array (Figs. 12.8 and 12.11). Also, Model B exhibited lower ultimate lateral displacements in the aluminum side, compared to its central array. However, this effect was significantly more pronounced in Model B, which accumulated residual surficial lateral displacements about 0.75 times the ones in the central array (Figs. 12.8 and 12.11).

To further investigate the effects of the side container boundaries on the lateral displacement response, Fig. 12.12 presents the lateral spreading time histories across the slope for the central row E. Arrays −3 and 3 were located approximately 3.5 cm in model scale (0.81 m in prototype scale) away from the side container walls.

In Model A the residual lateral displacement across the slope showed small variability, and the anticipated boundary effects seemed to have minimal influence on the response. In Model B however, the influence of the boundaries was more pronounced, as shown in the response of the arrays −3 and 3, leading approximately to three times smaller lateral displacement compared to the central array 0 (Fig. 12.12). Observe that in Model B, the response in arrays −2, − 1, 1, and 2 exhibited ultimate displacement similar to the one in array 0 (Fig. 12.12), with minimal boundary effects. As discussed also previously, in both models the targets closer to the plexiglass window (−3, −2) exhibited larger ultimate lateral displacement compared to the ones closer to the aluminum boundary (3, 2) as shown in Figs. 12.8, 12.9, 12.11 and 12.12.

The reduced ultimate displacement values close to the aluminum side boundary of the container may be attributed to the surface of that boundary being rougher than the plexiglass. Moreover, the secured cables on the aluminum side wall may have introduced additional friction with the neighboring soil, thus restricting the lateral displacements in arrays 2, 3

The reason behind the more pronounced boundary effects in Model B may stem from minor variations in the built Models A and B. Nonetheless, such uncertainties did not affect the results sufficiently away from the aluminum boundary, in arrays 0 and - 2, where the trend is consistent with the one observed in Model A.

6 Conclusions

Two centrifuge models (A and B) were tested at Rensselaer Polytechnic Institute as part of the experimental campaign for the LEAP-Asia2019. The models reflected the same prototype and soil conditions were constructed observing the same experimental methodology, but were prepared observing different scaling laws. Model A was designed observing the conventional similitude laws for geotechnical centrifuge testing, whereas Model B observed the generalized scaling laws.

The models were subjected to the same ramped sinusoidal acceleration ground motion, which was repeated in both tests with high fidelity to the theoretical target. Overall, the responses of Model A and Model B were in good agreement, before the onset of liquefaction. Model B exhibited consistently in all instrumented locations conditions of Ru ≈ 1.0 at t ≈ 7 s, approximately 4 s earlier than Model A. This observation was reaffirmed by the acceleration response. In terms of permanent lateral surficial displacements, Model B sustained about three times higher residual surficial displacements compared to Model A. The rates of accumulation of lateral displacements were consistent prior to liquefaction for Models A and B. Lateral surficial deformations in Model B accumulated at a higher rate than Model A after the onset of liquefaction.

Boundary effects led to reduced ultimate surficial lateral displacements in the proximity to the rigid container at the bottom of the slope. Moreover, the aluminum and plexiglass sides of the used model container appeared to have affected the surficial displacement response, in both model tests. Overall, the boundary effects were more pronounced in Model B. Nevertheless, away from the boundaries, both models revealed consistent trends of lateral surficial displacements.

References

Abdoun, T., Kokkali, P., & Zeghal, M. (2018). Physical modeling of soil liquefaction: Repeatability of centrifuge experimentation at RPI. Geotechnical Testing Journal, 41(1), 141–163.

Carey, T. J., Stone, N., & Kutter, B. L. (2020). Grain size analysis and maximum and minimum dry density testing of Ottawa F-65 sand for LEAP-UCD-2017. In Model tests and numerical simulations of liquefaction and lateral spreading: LEAP-UCD-2017 (pp. 31–44). Springer.

Garnier, J., Gaudin, C., Springman, S. M., Culligan, P. J., Goodings, D., Konig, D., et al. (2007). Catalogue of scaling laws and similitude questions in geotechnical centrifuge modelling. International Journal of Physical Modelling in Geotechnics, 7(3), 01–23.

Iai, S., Tobita, T., & Nakahara, T. (2005). Generalised scaling relations for dynamic centrifuge tests. Geotechnique, 55(5), 355–362.

Kokkali, P., Abdoun, T., & Zeghal, M. (2018). Physical modeling of soil liquefaction: Overview of LEAP production test 1 at Rensselaer Polytechnic Institute. Soil Dynamics and Earthquake Engineering, 113, 629–649.

Korre, E., Abdoun, T., & Zeghal, M. (2020a). Verification of the repeatability of soil liquefaction centrifuge testing at Rensselaer. In Model tests and numerical simulations of liquefaction and lateral spreading: LEAP-UCD-2017 (pp. 385–400). Springer.

Korre, E., Abdoun, T., & Zeghal, M. (2020b). Liquefaction of a sloping deposit: LEAP-2017 centrifuge tests at Rensselaer Polytechnic Institute. Soil Dynamics and Earthquake Engineering, 134, 106152.

Korre, E., Abdoun, T., Zeghal, M., & Kokkali, P. (2021). Verification of generalized scaling laws: Two centrifuge tests of a liquefiable sloping deposit. Soil Dynamics and Earthquake Engineering, 141, 106480.

Kutter, B. L., Carey, T. J., Stone, N., Bonab, M. H., Manzari, M. T., Zeghal, M., et al. (2020). LEAP-UCD-2017 v. 1.01 model specifications. In Model tests and numerical simulations of liquefaction and lateral spreading: LEAP-UCD-2017 (pp. 3–29). Springer.

Manzari, M. T., Kutter, B. L., Zeghal, M., Iai, S., Tobita, T., Madabhushi, S. P. G., et al. (2014). LEAP projects: Concept and challenges. In Geotechnics for catastrophic flooding events (pp. 109–116). CRC Press.

Manzari, M. T., El Ghoraiby, M., Kutter, B. L., Zeghal, M., Abdoun, T., Arduino, P., et al. (2018). Liquefaction experiment and analysis projects (LEAP): Summary of observations from the planning phase. Soil Dynamics and Earthquake Engineering, 113, 714–743.

Schofield, A. N. (1981). Dynamic and earthquake geotechnical centrifuge modelling. In International conference on recent advances in geotechnical engineering and soil dynamics (pp. 1081–1100).

Steedman, R. S. (1991). Centrifuge modeling for dynamic geotechnical studies. In Proceedings of the 2nd international conference on recent advances in geotechnical earthquake engineering and soil dynamics (pp. 2401–2417).

Tobita, T., & Iai, S. (2011). Application of the generalized scaling law to liquefiable model ground (pp. 225–236). Annuals of Disaster Prevention Research Institute, Kyoto University, No. 54 B.

Tokimatsu, K., Suzuki, H., Tabata, K., & Sato, M. (2007). Three-dimensional shaking table tests on soil-pile-structure models using E-defense facility. In 4th international conference on earthquake engineering, June (pp. 25–28).

Vaid, Y. P., Stedman, J. D., & Sivathayalan, S. (2011). Confining stress and static shear effects in cyclic liquefaction. Canadian Geotechnical Journal, 38(3), 580–591.

Van Den Einde, L., Restrepo, J., Conte, J. P., Luco, E., Seible, F., Filiatrault, A., et al. (2004, August). Development of the George E. Brown Jr. network for earthquake engineering simulation (NEES) large high performance outdoor shake table at the University of California, San Diego. In Proceedings of the 13th world conference on earthquake engineering (pp. 1–6).

Zeghal, M., Goswami, N., Kutter, B. L., Manzari, M. T., Abdoun, T., Arduino, P., et al. (2018). Stress-strain response of the LEAP-2015 centrifuge tests and numerical predictions. Soil Dynamics and Earthquake Engineering, 113, 804–818.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2024 The Author(s)

About this paper

Cite this paper

Korre, E., Abdoun, T., Zeghal, M. (2024). Experimental Evaluation of Lateral Spreading of a Liquefiable Sloping Deposit Using Centrifuge and Generalized Scaling Law Tests at RPI. In: Tobita, T., Ichii, K., Ueda, K. (eds) Model Tests and Numerical Simulations of Liquefaction and Lateral Spreading II. LEAP 2019. Springer, Cham. https://doi.org/10.1007/978-3-031-48821-4_12

Download citation

DOI: https://doi.org/10.1007/978-3-031-48821-4_12

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-031-48820-7

Online ISBN: 978-3-031-48821-4

eBook Packages: EngineeringEngineering (R0)