Abstract

Hydraulic coupling triaxial test and acoustic emission test were carried out for Xiluodu basalt. The test results show that the peak strength of basalt increases with the increase of confining pressure, showing a typical hard brittle behavior. When the confining pressure remains unchanged, the peak strength decreases gradually with the increase of initial water pressure, and the hard brittleness decreases; Increasing the initial water pressure can promote the propagation of rock cracks, and the cumulative count of acoustic emission increases significantly with the increase of water pressure. Under the combined action of water pressure in the hole and external stress, the tensile failure occurs first and mainly in the internal cracks of basalt. Further, the functional relationship among crack initiation stress, confining pressure and water pressure is obtained through theoretical derivation and three-dimensional spatial data fitting. On this basis, the empirical relationship between critical water pressure, confining pressure and water pressure is established. The correlation is consistent with the test results, which has a good reference value for the study of critical water pressure of basalt crack propagation under hydraulic coupling.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

In the hydropower projects under construction and built in China, the Underground Powerhouse Caverns, headrace tunnels or dam foundation slopes often face the combined action of high ground stress and strong osmotic pressure. Therefore, the research on the mechanical properties of rock mass or rock under hydraulic coupling has always been one of the hot issues in the field of geotechnical engineering. For example, Zhu Zhende et al. [1], Yu Jin et al. [2], Xu Jiang et al. [3] carried out stress seepage coupling indoor triaxial tests on limestone, sandstone and granite, studied the relationship between rock permeability, stress, strain and pore water pressure, and discussed the influence of pore water pressure on rock strength characteristics Deformation law and damage evolution. In addition, Li Junping [4], Zhao Xingdong [5] analyzed the acoustic emission characteristics in the whole process of rock fracture under hydraulic coupling by collecting the acoustic emission signals in the test process.

The above studies show that the pore water pressure in the micro crack in the rock has a great influence on the fracture process under the hydraulic coupling effect. When the pore water pressure reaches the critical value, it will lead to the initiation, propagation and penetration of internal cracks in rock (also known as hydraulic fracturing), which is also an important factor inducing a series of engineering accidents such as tunnel water gushing, rock slope landslide, reservoir earthquake and so on. K. S. min [6] and others successfully simulated the crack initiation and propagation under hydraulic fracturing by using vmib model, establishing equilibrium equation and introducing Weber Distribution Considering Rock heterogeneity; Tang Liansheng [7] derived a new fracture strength criterion of rock mass considering closed and open cracks under dynamic, hydrostatic pressure and hydrochemical damage based on the strength factor of crack tip; Bian Kang [8] combined the stress analysis of hydraulic tunnel with the crack propagation of surrounding rock from the macro and micro perspectives by using the propagation criterion of fracture mechanics, and deduced the calculation formula of critical water pressure for crack propagation of surrounding rock of hydraulic tunnel under tension shear and compression shear conditions; Sheng Jinchang [9] and others further studied the pressure shear crack propagation mechanism of the surrounding rock crack of the hydraulic tunnel on the basis of the mode I tensile failure of the crack; In addition, Cui Shaoying [10] also gave two methods to calculate the critical pore water pressure of hydraulic fracturing, and determined the critical pore water pressure in case of instability failure of surrounding rock. However, most of the above studies on critical pore water pressure are based on the analytical solution of fracture mechanics theory, which has insufficient adaptability to the popularization and application of engineering. In addition, more in-depth research is needed on the relationship between critical pore water pressure and external hydraulic conditions.

Critical pore water pressure is one of the important breakthroughs in the study of rock fracture mechanism under hydraulic coupling. Taking Xiluodu basalt as the research object, through hydraulic coupling indoor triaxial test and acoustic emission test, this paper studies the relationship between critical pore water pressure, confining pressure and initial water pressure of basalt, and puts forward an empirical calculation formula of critical pore water pressure during hydraulic fracture of basalt, The related research has important reference value and significance for rock fracture behavior and mechanism under hydraulic coupling and related engineering practice.

2 Test Principle and Method

The riverbed bedrock in the dam site area of Xiluodu hydropower station is Emeishan basalt of Upper Permian system. The color of basalt specimen is dark cyan, its particle composition is fine and uniform, and there are no obvious macro cracks and holes in the appearance. The cylindrical standard specimen with diameter of 50mm and height of 100mm is uniformly made by drilling, cutting and grinding. The test was carried out on mts815.04 electro-hydraulic servo stiffness testing machine of Wuhan Institute of geotechnical mechanics, Chinese Academy of Sciences. Acoustic emission acquisition system is a PC-II acoustic emission (AE) three-dimensional positioning real-time monitoring and display system developed by physical acoustics company. The sampling frequency is 5 MHz and the data recording threshold is 45 dB.

In the triaxial compression test of basalt, the confining pressure is selected as three different confining pressure values of 20 MPa, 25 MPa and 30 MPa. Under different confining pressures, the initial water pressure P increases according to the gradient, which are 5 MPa, 10 MPa and 15 MPa respectively. During the test, the initial water pressure remains unchanged. In order to carry out the test smoothly and keep the basalt sample in a closed state under water force coupling, it is necessary to ensure that the initial water pressure P is less than the confining pressure. Before the test, according to the test requirements, the sample shall be soaked freely to reach the saturation state, and the soaking time shall not be less than 48h. The overall test method is as follows:

-

(1)

In the initial stage, the axial pressure and confining pressure are applied by controlling the load rate. Apply axial pressure and confining pressure at the same time until the predetermined confining pressure value, and keep the confining pressure value unchanged in the subsequent test process.

-

(2)

Apply pressurized water. Apply pressurized water at the port at the rate of 1 MPa/min and gradually reach the predetermined water pressure. The water outlet at the top of the sample is connected with the atmosphere to ensure that the water pressure at both ends of the sample is the same. Throughout the test, the end water pressure of the sample remains unchanged.

-

(3)

Keep the confining pressure and water pressure unchanged, and load the axial pressure at a constant loading rate. When the sample enters the unstable expansion stage, the axial pressure control mode is changed to circumferential strain rate control until the sample is damaged.

3 Test Results and Analysis

3.1 Typical Stress-Strain Curve

Figure 1 shows the whole process curves of stress-strain under different water pressures when the confining pressure is 20 MPa. The analysis shows that the phenomenon of stress drop behind the peak of basaltic rock is very obvious, showing typical hard brittle behaviour; With the increase of water pressure, the peak strength of rock gradually decreases and the stress drop gradually weakens, indicating that water pressure will weaken the compressive strength of rock and weaken its hard brittleness to a certain extent.

3.2 Analysis of Acoustic Emission Results

3.2.1 Acoustic Emission Event Rate Characteristics

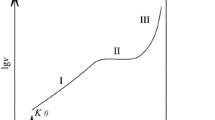

According to the characteristics of the rock failure process, the rock failure process can generally be divided into four stages [11]. Since basalt is a hard brittle rock, the compaction section of the stress-strain curve in Fig. 2 is not obvious or even visible. It can be considered that basalt mainly displays three stages in the compression failure process, namely elastic stage (I) and crack stable propagation stage (II) And the unstable crack growth stage (III).

Figure 2 shows the whole process curve of basalt stress time and the change curve of acoustic emission event rate under 5 MPa water pressure and 20 MPa confining pressure. The analysis shows that in the elastic stage, the rock sample is mainly elastic deformation, and there is almost no acoustic emission activity.When entering the stable crack growth stage, acoustic emission events occur, indicating that the pressurized seepage has entered the rock and led to the crack to begin to crack. Therefore, this paper takes the time when the initial acoustic emission event occurs as the boundary between stage I and stage II, and considers this time as the time point of crack initiation; In the unstable crack growth stage, the AE event rate increases sharply and reaches the peak.

3.2.2 Ra-Af Value Characteristics

The Japanese concrete AE monitoring code introduces a fracture type discrimination method based on AE parameters. In this method, the ratio of ring count to duration is defined as average frequency AF (unit kHz), and the ratio of rise time to maximum amplitude is defined as RA (unit MS/V). RA value and AF value are usually used as reference methods to judge rock failure types. High RA value and low AF value indicate shear failure of rock, and low RA value and high AF value indicate tensile failure of rock [12].

In order to study the characteristics of rock fracture behaviour in different time domains, taking basalt samples under 20 MPa confining pressure and 15 MPa initial water pressure as an example, Fig. 3 shows the distribution of RA-AF values of basalt at different stages. It can be seen from the figure that the basalt is dominated by crack tension failure in stage II, the AF value of acoustic emission is high and increases rapidly, and the RA value is small and basically unchanged; In the third stage, there are two failure modes of shear and tension in the internal cracks of basalt. The acoustic emission signals with high RA value and low AF value are significantly increased, and the acoustic emission signals with low RA value and high AF value are more dense, indicating that the crack failure at this stage is mainly shear failure.

In general, it can be considered that there is pressurized seepage in the internal cracks of the rock. When the pore pressure in the crack reaches a critical state, the crack will firstly undergo tension failure, and then gradually expand and extend, due to the asymmetry and bending characteristics of the crack When entering the unsteady growth stage of cracks, under the continuous hydraulic-mechanical coupling action, the crack gap gradually becomes larger, and frictional slippage occurs at the upper and lower interfaces of the crack, and then the shear failure is the main form and the tension failure is supplemented. The fracture surface is partially sheared and finally penetrated to form a macro fracture surface, which is similar to the conclusion of T. Backers [13].

3.3 Crack Initiation Stress and Critical Water Pressure

According to the characteristic values of RA-AF, under the condition of hydraulic coupling, the internal crack of basalt mainly occurs tensile failure under the combined action of internal water pressure and external stress. This failure mode shows that when the initial water pressure fills the pores in the rock and reaches a certain threshold, the tensile failure will occur around the pores first. In order to facilitate the research, the vertical load borne by the rock at this time is called crack initiation stress, and the corresponding pore water pressure is called critical water pressure.

Figure 4 shows the relationship curve between crack initiation stress, confining pressure and initial water pressure. The analysis shows that when the initial water pressure is constant, the crack initiation stress increases with the increase of confining pressure; When the confining pressure is constant, the crack initiation stress decreases with the increase of initial water pressure. At the same time, the variation law of crack initiation stress with initial water pressure and confining pressure is approximately linear.

4 Calculation Formula of Critical Pore Water Pressure

At present, the research on critical water pressure of rock under hydraulic coupling conditions is mainly based on theoretical analytical methods. The relevant analytical formulas are difficult to verify through experimental test data, which restricts the promotion and application of these theoretical formulas. This article assumes that the original internal cracks in basalt are circular pores. For cracks filled with water, the mechanical model of the crack under pseudo triaxial test conditions is shown in Fig. 5. The infinite body with circular cracks in Fig. 5 bears bidirectional uniform compressive stress and the initial water pressure is completely filled inside the pores, that is the pore water pressure is equal to the initial water pressure.

According to the relevant theories of elasticity and considering the initial water pressure P and critical water pressure Pi, the stress around the circular crack can be expressed as [14]:

In formula (1): σ1 and σ3 represent the maximum and minimum compressive stress respectively. σr and σθ represent the radial normal stress and the tangential normal stress at the distance r from the hole centre and the angle θ with the σ3 direction. R is the radius of the circular crack.

Let r = R to get the stress state on the circular hole wall:

The surface of a circular crack will generate tangential stress under the action of pore water pressure. It can be seen from Eq. (2) that σθ is a function of θ, that is σθ = f(θ).Taking the derivative to get θ = 0° and σθ has a minimum. It means that the hole wall tension failure will occur in the direction parallel to σ1. At this time, σθ reaches the tensile strength T of basalt:

In this paper, the compressive stress is positive, the tensile stress is negative, and the tensile strength T is changed. When the circular crack hole wall undergoes tensile failure, the corresponding σ1 is the initiation stress σci, then the formula (3) can be expressed as:

Equation (4) gives the functional relationship between σci, σ3 and P. However, it is inconsistent with the linear relationship with σci, σ3 and P in Fig. 4. Author believes that this inconsistency is mainly related to Pi. Since σci is a physical quantity related to σ3 and P. Pi is the pore water pressure inside the crack when the axial stress reaches the initiation stress σci. Therefore, it can be considered that Pi in Eq. (4) is also a variable related to σ3 and P. To suppose Pi = f(σ3,P), at the same time, in order to simplify the research, the paper assumes that the tensile strength T is a constant.

The relationship between σci, σ3 and P in Fig. 4 is plane fitted in three-dimensional space.The plane equation is obtained as shown in Eq. (5):

Combining Eq. (4), the relationship between critical water pressure Pi, σ3 and P is obtained.

It can be seen from the empirical relationship of Eq. (6), Under the same initial water pressure, the critical water pressure Pi increases with the increase of the confining pressure. Under the same confining pressure, the greater the initial water pressure, the critical water pressure Pi decreases, which shows this empirical relationship is consistent with the experimental test results, indicating that formula (6) describes the relationship between Pi, σ3 and P is accurate.

5 Conclusion

Taking Xiluodu basalt as the research object, the hydraulic coupling triaxial test and acoustic emission test are carried out, and the following conclusions are obtained.

-

(1)

The hydraulic coupling triaxial test shows that when the initial water pressure is constant, the post peak stress drop phenomenon of basaltic rock is obvious, and the peak strength increases with the increase of confining pressure, showing a typical hard brittle behavior; When the confining pressure remains unchanged, its peak strength decreases gradually with the increase of initial water pressure, and the stress drop decreases gradually, indicating that the water pressure will weaken the compressive strength of rock and weaken its hard brittleness to a certain extent.

-

(2)

Acoustic emission test results show that water pressure has a great impact on acoustic emission activities, mainly in the post peak stage of rock. The cumulative acoustic emission count increases with the increase of water pressure, indicating that water pressure will stimulate the generation and propagation of rock cracks to a certain extent. The distribution of RA-AF value of basalt at different stages shows that the tensile failure occurs first and mainly under the combined action of pore water pressure and external stress.

-

(3)

Based on the theoretical derivation of single circular hole and the fitting of three-dimensional spatial data, the functional relationship between σci, σ3 and P is obtained respectively. Through comparative analysis, the empirical relationship between critical water pressure Pi, σ3 and P is established. The correlation is consistent with the test results, which shows that the description of the relationship between Pi, σ3 and P in this paper is accurate.

References

Zhu, Z.D., Zhang, A.J., Xu, W.Y.: Experimental study on seepage characteristics of brittle rock in full stress-strain process. Rock Soil Mech. (05), 555–558+563 (2002)

Yu, J., Li, H., Chen, X., et al.: Triaxial test study on the correlation between permeability and deformation of sandstone under osmotic pressure-stress coupling. Chin. J. Rock Mech. Eng. 32(06), 1203–1213 (2013)

Xu, J., Yang, H.W., Peng, S.J., et al.: Experimental study on the mechanical properties of sandstone under the action of pore water pressure and confining pressure. Chin. J. Rock Mech. Eng. 29(08), 1618–1623 (2010)

Li, J.P., Yu, Z.X., Zhou, C.B., et al.: Experimental study on acoustic emission characteristics of rock under hydraulic coupling. Chin. J. Rock Mech. Eng. 03, 492–498 (2006)

Zhao, X.D., Tang, C.A., Li, Y.H., et al.: Study on acoustic emission characteristics of granite fracture process. Chin. J. Rock Mech. Eng. S2, 3673–3678 (2003)

Min, K.S., Zhang, Z.N., Ghassemi, A.: Hydraulic fracturing propagation in heterogeneous rock using the VMIB method. Geotherm. Reservoir Eng. 35, 1–10 (2010)

Tang, L.S., Zhang, P.C., Wang, Y.: Discussion on the fracture strength of rock mass under water. Chin. J. Rock Mech. Eng. 19, 3337–3341 (2004)

Bian, K., Xiao, M., Hu, T.Q.: Analytical solution of critical water pressure for crack propagation in surrounding rock of hydraulic tunnel. Rock Soil Mech. 33(08), 2429–2436 (2012)

Sheng, J.C., Zhao, J., Su, B.Y.: Hydraulic fracturing analysis of hydraulic pressure tunnel under high water head. Chin. J. Rock Mech. Eng. 7, 1226–1230 (2005)

Cui, S.Y., Bao, T.F., Cui, J.J.: Calculation method of critical pore water pressure for hydraulic fracturing in hydraulic tunnels. Hydropower Energy Sci. 30(05), 62–64+170 (2012)

Eberhardt, E.D.: Brittle rock fracture and progressive damage in uniaxial compression, Ph. D. Thesis. University of Saskatchewan, Saskatoon (1998)

Dimitrios, G.A.: Classification of cracking mode in concrete by acoustic emission parameters. Mech. Res. Commun. 38(3), 153–157 (2011)

Backers, T., Stanchits, S., Dresen, G.: Tensile fracture propagation and acoustic emission activity in sandstone: the effect of loading rate. Int. J. Rock Mech. Min. Sci. 42(7–8), 1094–1101 (2005)

Deng, G.Z., Huang, B.X., Wang, G.D., et al.: Theoretical analysis of pressure parameters of cracks in the wall of a circular hole with hydraulic pressure expansion. J. Xi'an Univ. Sci. Technol. (04), 361–364 (2003)

Acknowledgement

The authors acknowledge the strong support and help by China Three Gorges Corporation.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2022 The Author(s)

About this paper

Cite this paper

Tang, D., Quan, H., Yu, X., Xu, Q., Zhu, Z. (2022). Research on Crack Propagation and Critical Water Pressure of Basalt Under Hydraulic Coupling. In: Feng, G. (eds) Proceedings of the 8th International Conference on Civil Engineering. ICCE 2021. Lecture Notes in Civil Engineering, vol 213. Springer, Singapore. https://doi.org/10.1007/978-981-19-1260-3_36

Download citation

DOI: https://doi.org/10.1007/978-981-19-1260-3_36

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1259-7

Online ISBN: 978-981-19-1260-3

eBook Packages: EngineeringEngineering (R0)