Abstract

There is relatively little research on steel deck pavement of bascule bridge at home and abroad, which usually adopts the same paving materials and structures as ordinary steel deck, but it can’t meet the normal application conditions. In order to improve the anti-sliding performance of steel deck pavement of bascule bridge, this paper provides a set of steel deck pavement technology of bascule bridge through theoretical analysis of mechanics of bascule bridge and research of pavement materials. The engineering application research shows that the anti-sliding performance of the pavement back layer is obviously improved. After 7 months of application, the pavement layer has a good overall structure, and the bonding strength is still stable at 3.57 MPa, with good durability and good social benefits.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

With the rapid development of bridge construction, steel deck pavement has become one of the most complicated and critical technical difficulties in road engineering. At present, the main pavement modes of steel bridge deck are asphalt concrete, epoxy asphalt concrete, asphalt concrete and epoxy asphalt concrete double-layer pavement, etc. [1]. With the increase of service life, various diseases, such as cracks, ruts, slipping, etc., have appeared, and the maintenance problem has gradually attracted attention.

The bridge studied in this paper is Zhongshan bascule bridge, and its structural type is bascule bridge. Bascule bridge mainly refers to the bridge whose span structure can move or rotate [2]. According to the mechanical research and analysis report of related literature, the mechanical characteristics of large cantilever box girder structure of bascule bridge are obviously different from those of long-span suspension bridge or cable-stayed bridge. With the change of bridge opening angle, the surface layer is subjected to complex transverse tensile stress and shear stress [3, 4]. The main requirements of bascule bridge for bridge deck pavement are adaptability to deformation, stability of pavement structure and excellent durability, which are reflected in the performance of pavement materials such as good flexibility, thermal stability, waterproof, rutting resistance and high bonding strength with steel bridge deck, and the performance of pavement surface is good service performance. At present, there is relatively little research on steel deck pavement of bascule bridge at home and abroad, which usually adopts the same paving materials and structures as ordinary steel deck, and there is little research on targeted application.

Therefore, this paper aims to provide a steel deck paving technology of bascule bridge through theoretical analysis of mechanics of bascule bridge and research of paving materials. In this paper, taking an bascule bridge in Zhongshan as the research object, through theoretical analysis, combined with the use environment and other factors, the maintenance and reconstruction scheme of steel bridge deck is comprehensively determined, and the performance of paving materials is targeted for research. Finally, the application performance of this paving technology is verified by tracking.

The project relies on bascule bridge in Zhongshan city, which was built in the mid-1990s. The bridge is 95.78 m long and 24 m wide. The main span is an open steel box girder with a span length of 25.9 m. The approach bridge is composed of 5-span reinforced concrete simply supported plate beam, 69.88 m in length, the substructure adopts φ 150 cm bored pile foundation, the pier and the foundation diameter is the same, except the 4# pier, the design load is steam - super 20, the checking load is hanging −100, the design speed is 50 km/h, seismic grade 7°. The opening time of the bridge is from 2 am to 4 am every day, and the maximum opening Angle is 60°.

Midas Civil, a THREE-DIMENSIONAL finite element analysis software, was used to establish the open span model of the open bridge and simulate the stress state when it was opened to 60°, as shown in Fig. 1. According to the mechanical analysis, the stress of the bridge surface varies greatly during the opening process of the bridge, which requires higher mechanical properties of pavement materials.

2 The Choice of Bridge Deck Pavement Scheme

The opening bridge is located in the central business district, with a large traffic flow, and the deck layer is made of patterned steel plate, which is relatively smooth. The bridge is located in subtropical monsoon climate zone, where the temperature is mild in winter, hot and rainy in summer, and the annual average precipitation is higher by about 1700 mm. In rainy days, the anti-sliding performance of the surface layer drops sharply, and there is a great potential safety hazard in driving [5]. In addition, the design life of this bascule bridge is long, and the load of steel deck pavement is not specified in the design, so the pavement layer cannot be overloaded and should not be too thick.

Based on the comprehensive analysis of factors such as steel deck structure, traffic flow and climate environment of bascule bridge, the main engineering characteristics of the steel deck pavement scheme are as follows: the anti-sliding performance of steel deck surface is poor; Heavy traffic, short maintenance time; South China is located in high temperature and rainy area, which requires high weather resistance of materials [6]. In order to meet the performance of steel bridge deck pavement, materials should have excellent anti-sliding performance, aging resistance, deformation coordination, waterproof performance and bonding strength.

According to the comparison and selection of the recommended paving schemes for opening bridges in Table 1, and considering the cost and the requirements of paving schemes comprehensively, the resin anti-sliding thin-layer paving scheme is finally selected. The total design thickness of bridge deck paving is 5 mm, which can greatly reduce the load increase caused by surface paving. The concrete paving structure is shown in Fig. 2, which consists of steel panel + resin adhesive layer (1.5 kg/m2) + anti-sliding aggregate (8 kg/m2, particle size range of 1.18–1).

3 Research on Pavement Material Performance

3.1 High Temperature Stability

The opening bridge is located in the south humid area, and the main problem is that the steel deck absorbs heat and transfers heat quickly. In high temperature summer, the service temperature of steel deck is higher than that of asphalt pavement or cement concrete bridge surface. Therefore, the steel bridge deck pavement is required to have better thermal stability to prevent rutting, pushing, bulging and other diseases [7]. In this paper, the dynamic stability of resin thin layer paving materials is tested, and the data are shown in Table 2. As can be seen from Table 2, the resin mixture prepared from resin pavement binder and aggregate has good high temperature stability. When the test conditions are 60 ℃ and 0.7 MPa, the dynamic stability of resin mixture reaches 29,929 times/mm, and with the increase of test temperature and pressure, the dynamic stability of resin mixture decreases to some extent but still reaches 26,662 times/mm. In addition, in the immersion test, the dynamic stability of the resin mixture is obviously lower than that without water under the same conditions. There are still 18,828 times/mm [8] when immersed in water at 70 ℃ and 0.9 MPa. It can be seen that the resin mixture for steel bridge deck has excellent high temperature stability. This is because resin adhesive is a highly crosslinked three-dimensional network structure after resin and curing agent react, and it still maintains a certain mechanical strength at high temperature. Pure asphalt materials have poor bonding strength at high temperature and are easy to loose, so it is not suitable for steel bridge deck pavement.

3.2 Bonding Performance Between Resin Thin Layer and Steel Base Surface

The bonding performance between resin paving material and steel bridge deck is the key factor to ensure the service performance of thin layer and steel bridge deck after bonding, which mainly includes the function of meeting the vehicle load and the stress function during the cycle of opening and closing the bridge.

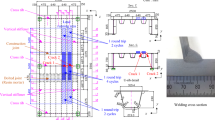

Testing the bonding strength between the resin thin layer and the steel plate surface layer indoors, the main steps are as follows: firstly, pretreating the steel surface, namely, no treatment of the original steel surface, sand blasting treatment and deep grinding treatment; Then, coating the resin anti-sliding layer on the surface of the steel plate, and curing at 40 ℃ for 2 days; The bonding strength of the resin thin layer material was tested by pulling-out. The test results are as shown in Figs. 3 and 4,and the failure locations are all at the anti-sliding surface layer of the planting bar adhesive and resin,As shown in Table 3, the test results of the bonding strength of the three steel plates are 2.85 MPa, 4.46 MPa and 4.47 MPa respectively. From the results, it can be seen that the bonding strength of the surface layer is obviously improved after sand blasting and grinding rough treatment, which shows that the resin anti-sliding layer has a high interfacial bonding strength with the steel base surface.

4 Construction Technology Research

In this paper, the construction technology of steel deck pavement is confirmed through the paving of thin resin pavement on steel deck of bascule bridge. The main construction technology includes the following aspects: base surface treatment-glue mixing-glue spreading-aggregate spreading-maintenance-aggregate cleaning-open traffic.

-

(1)

Base surface treatment

Through modeling and analysis, it can be seen that the different stress in each area of the bridge deck pavement during opening has higher requirements for the bonding strength of pavement materials. Combined with the indoor steel plate treatment methods and test results (Table 3), the steel bridge deck is treated by shot blasting machine in this application project. After shot blasting, the roughness of the surface layer is generally uniform, with an average roughness of 115 μm and a cleanliness of Sa2.5, as shown in Fig. 5. For the anchor bolt of steel plate surface layer, seam leaving treatment can not only facilitate the bolt loosening and welding treatment, but also prevent the surface layer damage caused by the loosening of raised bolts, as shown in Fig. 6.

-

(2)

Resin thin layer bridge deck paving technology

After shot blasting treatment of steel bridge deck, glue mixing, surface paving, curing, aggregate recovery and other steps are carried out, as shown in Fig. 7. In this process, it is necessary to strictly control the proportion of components and the amount of glue used for glue mixing. The glue used for paving the steel bridge surface is controlled to be 1.4–1.5 kg/m2, and the amount of aggregate is 6–8 kg/m2. The curing should be carried out according to the ambient temperature and the recommended time, as shown in Table 4. Finally, the excess aggregate is cleaned and recycled.

-

(3)

Quality control

The technical requirements and indoor test results of the resin adhesive are shown in Table 5. The tensile strength of the resin adhesive reaches 20.3 MPa, the steel-steel bonding strength reaches 19.5 MPa, and the elongation at break reaches 53.5%, which shows that the material has good mechanical properties and ductility, and can adapt to the deformability of the steel bridge deck while ensuring firm bonding with the steel bridge deck.

In addition, on-site pull-out test was carried out on the quality of the layer behind the resin anti-sliding layer pavement, and the test results are shown in Table 6. The results of on-site raw material inspection and pull-out test after on-site paving show that the average bonding strength reaches 4.08 MPa, which fully meets the technical requirements (≥3.0 MPa), indicating that the resin paving thin layer after paving has good mechanical.

5 Application Performance of Resin Thin Layer After Paving

5.1 Sliding Resistance

Before the bridge deck is paved, the anti-sliding performance of patterned steel plates on the surface is poor, especially in wet weather after rain, and the anti-sliding performance drops rapidly. For specific data, please refer to Table 7. The anti-sliding performance was improved from the friction pendulum value BPN36 to 86 by 139% after the resin anti-sliding thin layer was added on the surface layer. Even after 7 months of use, the friction coefficient remains above 74. In addition, the tracking of the pavement performance of the bridge deck shows that the structural depth of the bridge deck is stable at about 1.4 mm (as shown in Fig. 8) after the anti-sliding reconstruction, and the water permeability of the resin thin layer is 0 ml/min, which plays a good role in protecting the steel plate at the bottom. It can be seen that the resin thin layer added not only obviously improves the anti-sliding performance of the original bridge deck, but also plays a role of waterproof and anti-corrosion.

5.2 Durability

After the completion of the steel deck pavement (January-July), the application performance was tracked and tested, and the overall application effect of the deck pavement of the bascule bridge was good, without falling off and other diseases, as shown in Fig. 9. In addition, the adhesive strength between the resin thin layer and the base surface was tracked and tested, and after 7 months of open traffic, the adhesive strength of the surface layer remained stable above 3.71 MPa, as shown in Fig. 10.

6 Conclusion

-

(1)

Through the stress analysis of the opening bridge and the comprehensive analysis of the use environment factors, the resin anti-sliding thin layer pavement scheme is selected for the steel deck pavement of the opening bridge, with a total thickness of about 5 mm, which has little influence on the original bridge deck load.

-

(2)

In order to ensure the good durability of the resin anti-sliding thin layer, the performance of pavement materials was studied in laboratory. The results show that the resin anti-sliding thin layer has excellent high temperature resistance and mechanical properties. At 60 ℃ and 0.7 MPa, the dynamic stability of the mixture reaches 29,929 times/mm, and the bonding strength between the resin thin layer and the steel plate surface reaches 4.08 MPa.

-

(3)

Through the research on the construction technology of steel deck pavement of bascule bridge, shot blasting of steel deck is beneficial to improve the bonding strength between anti-sliding layer and base surface, thus improving the durability of thin layer.

-

(3)

The tracking application test shows that the anti-sliding performance of the resin thin layer pavement is obviously improved. After 7 months of application, the pavement surface is in good condition as a whole, the structural depth is more than 1.4 mm, and the bonding strength is still stable at 3.71 MPa, with good durability and good social benefits.

References

Wang, C.H., Fu, Y., Chen, Q., Chen, B., Zhou, Q.W.: Research and application progress of epoxy asphalt concrete bridge deck pavement materials. Mater. Guide 17, 2992–3009 (2018)

Shen, C., Wei, J.F., Guo, H.Z., Jiang, K.Q., et al.: Key technologies and difficulties in the research of bridge deck pavement with vertical turning and opening. Highw. Eng. 132–137 (2018)

Yu, L.Q., Guo, H.Z., Sui, H.R., Liu, T.G., et al.: Mechanical response analysis of steel deck pavement of vertical-turn-bascule bridge. Road Traffic Technol. 29–12 (2009)

Wei, P., Liu, Y., Kuang, Y.: Dynamic response analysis of bascule bridge deck pavement considering cantilever structure rotation. J. East China Jiaotong Univ. 15–21 (2020)

Rong, B.S.: Analysis of anti-sliding performance and noise reduction technology of cement concrete pavement in highway tunnel. Shanxi Archit. 106–107 (2019)

Xu, R.H., Zeng, G.D., Huang, H.L.: Research on the whole maintenance scheme of wide epoxy asphalt pavement of Pingsheng Bridge. Chin. Foreign Highw. 62–66 (2020)

Zheng, Y.: Study on the performance of reactive resin mixture and its application in steel bridge deck pavement. Chongqing Jiaodong University (2010)

Yang, Y., Chen, S.T., Yin, C.Y.: Application of resin anti-sliding layer in anti-sliding reconstruction of steel deck of Guangming Bridge in Zhongshan. Highw. Autom. Transp. 160–163 (2014)

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2022 The Author(s)

About this paper

Cite this paper

Wu, D., Han, Y., Jin, X. (2022). Research on Key Technology of Anti-sliding Treatment of Resin Thin Layer of Bascule Bridge Steel Panel. In: Feng, G. (eds) Proceedings of the 8th International Conference on Civil Engineering. ICCE 2021. Lecture Notes in Civil Engineering, vol 213. Springer, Singapore. https://doi.org/10.1007/978-981-19-1260-3_45

Download citation

DOI: https://doi.org/10.1007/978-981-19-1260-3_45

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-1259-7

Online ISBN: 978-981-19-1260-3

eBook Packages: EngineeringEngineering (R0)