Abstract

Freeze–thaw damage in cold areas is an important reason for the deterioration of durability of concrete structures, and the addition of fiber can effectively improve the frost resistance of concrete. To study the effect of steel fiber and polyvinyl alcohol (PVA) fiber on the frost resistance of concrete, an orthogonal experimental method was applied to analyze the frost resistance of steel-PVA hybrid fiber concrete. The effect of the steel fiber content, PVA fiber content, and steel fiber types were investigated on the mass-loss rate and relative dynamic elastic modulus of fiber concrete, to explore the mechanism of high frost resistance of it. The results show that steel fiber content has a significant effect on the mass-loss rate and relative dynamic elastic modulus of fiber concrete. The influence of PVA fiber content on the relative dynamic elastic modulus is relatively great, and the influence of steel fiber types of the mass-loss rate is the same. The frost resistance of concrete can be improved by adding hybrid fiber in concrete. When 1.0% End-hook steel fibers and 0.3% PVA fibers are added, the concrete specimen has the best frost resistance.

You have full access to this open access chapter, Download chapter PDF

Similar content being viewed by others

Keywords

1 Introduction

Professor Mehta [1] has pointed out that the freeze–thaw cycle is one of the main reasons for the reduction of concrete durability. In northeast and northwest of China, a large number of concrete structures are damaged due to long-term freeze–thaw cycles of varying degrees, seriously affecting the service life and safety performance of concrete structures, and causing certain economic losses [2, 3]. Therefore, improving the frost resistance of concrete material is helpful to improve the durability of concrete structures.

Under the action of freeze–thaw cycle, the micro-cracks and pores in concrete gradually expand under the influence of hydrostatic pressure and osmotic pressure, and finally cause the freeze–thaw damage to concrete. To study the influence of fiber on the frost resistance of concrete, scholars at home and abroad has done a lot of research and found that the addition of fiber can effectively slow down the cracking of concrete and improve its frost resistance [4,5,6,7]. With the deepening of research, the fibers mixed in concrete have gradually developed from single fibers to incorporate fibers of different types and sizes. When two or more fibers were incorporated, they were able to achieve different effects on the concrete [8, 9].

In this paper, the freeze–thaw cycle experiment of steel -PVA hybrid fiber concrete was carried out by orthogonal experiment to study the effects of different steel fiber content, PVA fiber content and steel fiber type on the mass-loss rate and relative dynamic elastic modulus of the specimen, and the mechanism of high frost resistance of steel -PVA fiber concrete was expounded.

2 Experiment

2.1 Raw Materials of Experiment

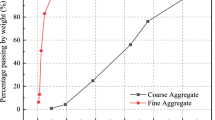

The strength of concrete used in the experiment is C35. The cement is P.O42.5 ordinary Portland cement; the coarse aggregate is crushed stone with 5 ~ 10 mm continuous gradation, and the fine aggregate is natural medium sand with fineness modulus of 2.54. The water reducing agent is polycarboxylate superplasticizer with a water-reducing rate of ≥ 10%; Three types of steel fibers are selected: end hook type with a length of 30 mm, a diameter of 0.6 mm, an aspect ratio of 50, indentation type with a length of 32 mm, a diameter of 0.7–1.2 mm, an aspect ratio of 45.7–26.2, and high-strength ultra-fine steel fiber with a length of 13 mm, a diameter of 0.18–0.25 mm and an aspect ratio of 72.2–52. The PVA fiber is 12 mm in length, 14 μm in diameter and 845 in length-diameter ratio.

2.2 Design of Mix Proportion

To study the influence of steel fiber content, PVA fiber content and steel fiber types on the frost resistance of concrete, the experiment was designed by orthogonal test method, each influencing factor was selected at three levels, and the L9(33) orthogonal table was used to design the orthogonal test with three factors and three levels, as shown in Table 1.

According to the orthogonal factor table, 9 groups of mix proportion are designed, as shown in Table 2.

3 Experimental Results and Analysis

3.1 Experimental Results

The mass-loss rate and relative dynamic elastic modulus of steel -PVA fiber concrete during freeze–thaw cycles are tested, and the specific test results are shown in Table 3.

3.2 Range Analysis

To investigate the influence of three factors on the mass-loss rate and relative dynamic elastic modulus of steel -PVA fiber concrete, the range analysis of each test result is carried out, and the analysis results are shown in Fig. 1.

It can be seen from Fig. 1a that with the increase of freeze–thaw cycles, the influences of three factors on the mass-loss rate of concrete gradually increase. When the number of freeze–thaw cycles is the same, the steel fiber content has the greatest influence on the mass-loss rate of concrete, followed by the type of steel fiber, and the PVA fiber content has the smallest influence on it.

It can be seen from Fig. 1b that with the increase of freeze–thaw cycles, the influence of three factors on the relative dynamic elastic modulus of concrete gradually increases. When the number of freeze–thaw cycles is the same, the steel fiber content has the greatest influence on the relative dynamic elastic modulus of concrete, and the PVA fiber content and the type of steel fiber have similar influences on it.

3.3 Factor-Index Analysis

According to the orthogonal experimental method, the mass-loss rate and relative dynamic elastic modulus are called indexes. Combined with Tables 2 and 3, the average values of the three factors at each level can be obtained, as shown in Figs. 2 and 3.

It can be seen from Fig. 2 that the greater the steel fiber content, the greater the mass-loss rate of concrete; With the increase of freeze–thaw cycles, the mass-loss rate of concrete gradually decreases, but the PVA fiber content has no obvious relationship with the mass-loss rate. With the increase of freeze–thaw cycles, different types of steel fibers have different effects on the mass-loss rate of concrete; generally speaking, the end hook steel fiber has the largest mass-loss rate, followed by indentation steel fiber and superfine steel fiber.

It can be seen from Fig. 3 that the greater the steel fiber content, the greater the relative dynamic elastic modulus of concrete; The greater the PVA fiber content, the greater the relative dynamic elastic modulus of concrete. The relative dynamic elastic modulus of hook-shaped steel fiber is the largest, and the relative dynamic elastic modulus of indentation steel fiber is close to that of superfine steel fiber.

3.4 Mechanism of High Frost Resistance of Steel—PVA Fiber Concrete

It can be seen from the above analysis that adding PVA fiber based on steel fiber can refine the pore structure, reduce the appearance of initial cracks and inhibit the development of freeze–thaw cracks. This is because the mixture of steel fiber and PVA fiber can play a role in different stages and scales of crack development. The effect model of high frost resistance of steel -PVA fiber concrete is shown in Fig. 4. PVA fibers are evenly dispersed in the concrete to bridge the micro-cracks in the concrete. Hook-shaped steel fiber can bridge the macro-cracks, transfer the stress on both sides of the cracks, reduce the stress at the crack tip, and effectively prevent the macro-cracks from further expanding. Moreover, the interface transition zone between the smooth fiber surface and cement paste has good hydration and compact structure. For indented steel fiber, the hydration effect of cement around it is worse than that around the end hook steel fiber, because of uneven surface curvature and uneven water distribution. The shape of superfine steel fiber is similar to PVA, so it is difficult for them to give full play to the complementary advantages of fiber length in concrete.

To sum up, the frost resistance of end-hooked steel—PVA hybrid fiber concrete is better, mainly because dense hydration products can be formed around the smooth surface of end hook fiber, which reduces the permeability of concrete. PVA fiber has small volume and many elements per unit volume, which can refine pores, reduce connected pores, make the air in the concrete evenly distributed and bridge micro-cracks. Therefore, the end hook steel fiber -PVA fiber hybrid can realize the complementary functions of the two fibers, resist the freeze–thaw damage more effectively, and show the "positive" hybrid effect of fibers.

4 Conclusion

Through the freeze–thaw cycle experiment of steel -PVA hybrid fiber concrete, the mass-loss rate and relative dynamic elastic modulus of the specimen are analyzed, and the frost resistance mechanism is explored, so as to obtain the optimal mix ratio of high frost resistance concrete, which provides a certain reference value for practical projects. The main conclusions are as follows:

-

(1)

Different factors have different effects on the mass-loss rate and relative dynamic elastic modulus of concrete. The steel fiber content has the greatest influence on them, the PVA fiber content has a great influence on the relative dynamic elastic modulus, and the content of steel fiber has a great influence on the mass-loss rate. With the increase of freeze–thaw cycles, the influence of three factors on the frost resistance of concrete gradually increases.

-

(2)

The more steel fiber content, the better frost resistance of concrete. The more PVA fiber content, the better frost resistance of concrete. Steel fiber concrete with end hook has the best frost resistance. When the fiber content is 1.0% end hook steel fiber + 0.3%PVA fiber, the frost resistance of concrete is the best.

-

(3)

The end hook steel fiber and PVA fiber are overlapped and complementary to each other in the concrete to improve the initial strength and permeability resistance of concrete, effectively prevent the development of micro-cracks in concrete, and thus improve the frost resistance of concrete.

At present, there are many studies on the frost resistance of concrete, but the problem of freeze–thaw damage of concrete has not been solved from the root. It is necessary to further study the mechanism and measures of frost resistance of fiber reinforced concrete and do more in-depth research on the frost resistance of concrete.

References

Mehta PK (1991) Concrete durability-fifty year’s progress. In: Proceeding 2nd international conference on concrete durability, American, p 31

Yu X, Zang Y, Yuan S, Dong J, Wang Q (2017) Research progress of frost resistance and durability of concrete. Concrete 4:15–20

Jin S, Li Z, Zhang J, Wang Y (2015) Experimental study on frost resistance of basalt fiber reinforced concrete under corrosive conditions. Eng Mech 5:178–183

Dong Z, Zhao K, Wang Y (2017) Experimental study on frost resistance of high-strength steel fiber reinforced concrete. Concrete 2:63–65

Wang L (2014) Experimental study on frost resistance of basalt fiber reinforced concrete. Inner Mongolia University of Technology, Hohhot

Haiyan M, Hongfa Y, Wei S (2013) Freezing–thawing durability and its improvement of high strength shrinkage compensation concrete with high volume mineral admixtures. Constr Build Mater 39(2):124–128

Richardson AE, Coventry KA, Wilkinson S (2012) Freeze/thaw durability of concrete with synthetic fiber additions. Cold Reg Sci Technol 83–84

Zhang X, Chai Y, Liu J (2014) Experimental study on the proportion optimization of fiber concrete based on freeze-thaw cycle. Bulletin of Silicate 33(8):2021–2026

Niu D, Jiang L, Bai M (2012) Experimental study on frost resistance of steel fiber reinforced concrete. Civ Eng Environ Eng 34(04):80–84+98

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 This is a U.S. government work and not under copyright protection in the U.S.; foreign copyright protection may apply

About this chapter

Cite this chapter

Niu, D., Gong, S., Guo, B., Cao, Z., Wang, Y. (2023). Study on Frost Resistance of Steel-PVA Hybrid Fiber Concrete. In: Yang, Y. (eds) Advances in Frontier Research on Engineering Structures. Lecture Notes in Civil Engineering, vol 286. Springer, Singapore. https://doi.org/10.1007/978-981-19-8657-4_10

Download citation

DOI: https://doi.org/10.1007/978-981-19-8657-4_10

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-8656-7

Online ISBN: 978-981-19-8657-4

eBook Packages: EngineeringEngineering (R0)