Abstract

The composition and structure of asphalt mixture have a significant impact on its mechanical performance, and the randomly distributed coarse aggregate impose a significant impact on the stress state of asphalt mortar. However, the traditional method can only evaluate the mechanical properties of asphalt mixture from macro scopic indexes, cannot show the stress state of asphalt mortar in details. Therefore, based on digital image processing technology, a meso-finite element model of asphalt mixture is established, and the stress state of asphalt mortar is analyzed by using finite element method. The correlation between the distance from mortar to aggregate and the stress state is established. Results show that the stress of asphalt mortar basically approaches to the external applied stress or zero when the distance from aggregate surface to mortar exceeds 4 mm. The closer it is to the aggregate surface, the greater the stress of the mortar is. Under compressive conditions, asphalt mortar will be affected by tensile stress in its vertical direction, and the maximum tensile stress is about 0.2–0.25 times of the maximum compressive stress. The results of this paper have a good reference for explaining the complex stress state of asphalt mortar.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

The service life of asphalt pavement closely relates to the material properties of asphalt mixture, and the mixing degree and uniformity of asphalt mixture will affect its performance. In the design of the material composition, the designed asphalt proportion is generally determined according to the macro mechanical parameters of the mixture [1,2,3,4], but the mechanical parameter is essentially the statistical average value which is determined through the test. These mechanical indexes cannot effectively characterize the stress transmission mechanism of different components in the mixture. Moreover, the stress state of asphalt mortar inside of the mixture is very complex due to the random distribution of coarse aggregates, and the stress state of the mortar will affect the travelling performance of asphalt pavement. In traditional research, the stress state of asphalt pavement is generally analyzed from the macro perspective, but it cannot reflect the internal stress state of asphalt mixture. This increases the risk of asphalt pavement damage [5,6,7,8,9]. On the other hand, the random internal structure of asphalt mixture will affect its macro mechanical properties. It takes a lot of money and people to test the performances of asphalt mixture through a lot of experiments, which is not a green and sustainable way. With the development of digital image processing technology, the internal structure of asphalt mixture can be obtained through digital image processing technology, then mesoscopic finite element simulation can be conducted on the mixture to determine the stress state of asphalt mortar. This is expected to become an efficient, green and sustainable research method in the future.

Therefore, digital image processing technology is used to obtain the internal structure of asphalt mixture in this paper, a 2D meso-finite element model of asphalt mixture is established, and the stress state of asphalt mortar is determined by simulation analysis. Moreover, the stress state of asphalt mortar on the surface of asphalt mixture is measured by digital image correlation (DIC) technology, which is compared with the theoretical results finally.

2 Theoretical and Experimental Methods

2.1 Digital Image Processing Method

For the convenience of image acquisition, this work cuts the asphalt mixture sample using the rock cutter, then one scans the section with a scanner and obtains a clear RGB image. After that, the image is denoised and segmented to obtain a binary image of coarse aggregate. The specific processing procedure is shown in Fig. 1.

2.2 Analysis Method on the Distance from Asphalt Mortar to Aggregate Surfac

In this paper, Euclidean distance is used to calculate the nearest distance from mortar to aggregate surface. The calculated result of Euclidean distance between a unit pixel O and its periphery is shown in Fig. 2. In other words, the coarse aggregate is used as the referenced pixel, so the Euclidean distance between the surrounding mortar and the aggregate surface can demonstrate the mortar away from the aggregate.

2.3 Finite Element Modeling Method

Import the binary image processed by MATLAB into software R2V for vectorizing processing. Geometric information of aggregate is saved as dxf file, and then dxf file is imported into ABAQUS to build the geometric sketch of aggregate. Finite element model is built based on the sketch. Finally, the finite element model is established by the default meshing of ABAQUS, the whole modeling process as shown in Fig. 3. Material parameters of aggregate and asphalt mortar in finite element simulation are listed in Table 1.

2.4 Uniaxial Compression Test

In order to verify the simulation results of this paper and determine the feasibility of meso-finite element analysis, Marshall specimen of dense asphalt mixture AC-16 was prepared according to standard for Asphalt and Asphalt Concrete of Highway Engineering (JTG E-20–2011). The cuboid specimen of 75 mm × 60 mm × 25 mm was made by cutting the marshall specimen. the apparent density of the specimen was 2.414 g/cm3, air void percentage is 4.8%. Uniaxial compression test was carried out by electrical universal testing machine at 20℃, and the surface strain of asphalt mixture was tested by DIC technology. The loading rate is 5 mm/min. Test procedure is shown in Fig. 4.

3 Stress State of Asphalt Mortar

3.1 Distribution of the Distance from Asphalt Mortar to Adjacent Aggregate Surface

Due to the random distribution of aggregate and irregular shape, the nearest distance between mortar and aggregate in the mixture also presents a random distributed form. In order to determine this distribution law, this paper makes statistical analysis on the nearest distance between mortar and aggregate of AC-16. Taking the nearest distance between each element of mortar and aggregate edge, and the area of each element as the statistical index. Result is shown in Fig. 5.

It can be seen from Fig. 6. that the statistical value of the nearest distance between mortar and aggregate edge in asphalt mixture shows a negative exponential distribution trend, and its distribution frequency decreases with the increase of the distance to aggregate edge, and the smaller the distance is, the higher the proportion is. According to the changing law of frequency curve, the maximum nearest distance from asphalt mortar to aggregate is about 4 mm.

3.2 Correlation Analysis between Mortar Stress and Distance

In this paper, the correlation between the stress of asphalt mortar and the nearest distance is analyzed. Because the stresses and the nearest distances are discrete, they cannot be fitted by commonly functions. But these data approximately obeys Gaussian distribution. Therefore, a Gaussian function is applied to contain these points as much as possible. The proportion of points falling below the Gaussian function in all points is taken as parameter T instead of coefficient R2. If T belongs to the interval (0.975, 1), it is considered that the Gaussian function can approximately represent the distribution. Gaussian function in this paper has the following form.

where, a, b and c are regression analysis parameters.

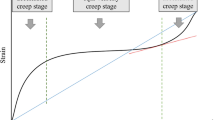

Results of different stresses under the uniaxial compression condition are shown in Fig. 6. σ11 represents the stress perpendicular to the compressive direction, σ22 represents the compressive stress, and τ12 represents the shear stress.

As can be seen from Fig. 6, the distribution of the stress of asphalt mortar to the nearest distance is also approximately in accordance with the Gaussian trend. The maximum amplitude of stress appears at the aggregate edge, this shows that there is a high stress area near the interface between bitumen and aggregate, the maximum compressive stress can reach 1.45Mpa, while the maximum tensile stress and shear stress can reach 0.3Mpa. This shows that tensile stress still exists in its vertical direction even if the mixture is subjected to compression.

3.3 Influence of Loading Mode on Stress Characteristics of Asphalt Mortar

The loading conditions in compressive and shear mode are shown in Table 2. After simulating and analyzing different models, the stress of asphalt mortar is extracted and statistically analyzed. The regression results of σ11 after analysis are listed in Table 3.

As can be seen in Eq. (1) and Table 3, a represents the maximum distance that the stress in asphalt mortar becomes to 0. b represents the stress value corresponding to the maximum value of probability, which determines the position of Gaussian function on the x axis. c reflects the deviation degree of the stress for asphalt mortar away from the average stress. Based on the data in Table 3, it can be seen that the shortest distance for stress to zero is 3.8 mm, and there is a big change, while b = 0 indicates that the horizontal stress is symmetrically distributed, and the value of c gradually decreases with the increase of the compression-shear ratio. It means that the horizontal stress tend to be concentrated, and the horizontal tensile effect caused by pressure is getting weaker and weaker.

3.4 Actual Stress Characteristic of Asphalt Mortar under Uniaxial Compression

Compared with the simulation results as shown in Fig. 7, it can be seen that the stress distance distribution characteristics calculated by finite element model are more concentrated, while those measured by uniaxial compression test are more discrete. This is because there are inevitably fine aggregates and voids in asphalt mixture mortar, which makes the stress transmission mechanism and deformed mechanism extremely complicated, so the stress is more random and discrete, which is different from the theoretical model to some extent. However, the stress and distance distribution characteristics of FE simulation and uniaxial compression test approximate to Gaussian distribution, and it is better to adopt Gaussian function for the next evaluation.

4 Conclusion

The following conclusions can be drawn based on the above analysis of this paper.

-

The nearest distance between mortar and aggregate edge in asphalt mixture is decrease as a negative exponential trend. The stress decrease to zero when this distance reaches 4 mm for the dense asphalt mixture.

-

The distribution of the stress of asphalt mortar to the nearest distance follows Gaussian function, there will be a certain tensile stress in its vertical direction while one direction is compressed. The maximum compressive stress is 4–5 times of the tensile stress.

References

Masad E, Saadeh S, AlRousan T et al (2005) Computations of particle surface characteristics using optical and X-ray CT images. Comput Mater Sci 34(4):406–424

Menapace I, Masad E, Bhasin A (2016) Effect of treatment temperature on the microstructure of asphalt binders: insights on the development of dispersed domains. J Microsc 262(1):12–27

Mahmoud E, Masad E (2010) A probabilistic model for predicting the resistance of aggregates in asphalt mixes to fracture. Road Mater Pave Des 11(11):335–360

Wang LB, Lai JS (2009) Quantification of specific surface area of aggregates using an imaging technique. Int. J Pave Res Technol 2(1):102–106

Wang L, Sun W, Tutumluer E et al (2013) Evaluation of aggregate imaging techniques for quantification of morphological characteristics. Transp Res Rec J Transp Res Board 233(51):39–49

Wang LB, Lane DS, Lu Y et al (2009) Portable image analysis system for characterizing aggregate morphology. Transp Res Rec J Transp Res Board 2104(1):3–11

Khattak MJ, Khattab A, Rizvi HR et al (2015) Imaged-based discrete element modeling of hotmix asphalt mixtures. Mater Struct 48(8):2417–2430

Moon KH, Falchetto AC (2015) Microstructural investigation of hot mix asphalt (HMA)mixtures using digital image processing. J Civ Eng 19(6):1727–1737

Arshadi A, Bahia H (2015) Development of an image based multi scale finite element approach topredict mechanical response of asphalt mixtures. Road Mater Pave Des 16(s2):214–229

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Tan, X., Zhang, Y., Chen, Z., Guo, Q. (2023). Stress State of Asphalt Mortar Based on Meso-Scopic Finite Element Simulation and Verification. In: Feng, G. (eds) Proceedings of the 9th International Conference on Civil Engineering. ICCE 2022. Lecture Notes in Civil Engineering, vol 327. Springer, Singapore. https://doi.org/10.1007/978-981-99-2532-2_18

Download citation

DOI: https://doi.org/10.1007/978-981-99-2532-2_18

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-2531-5

Online ISBN: 978-981-99-2532-2

eBook Packages: EngineeringEngineering (R0)