Abstract

Contact force for asphalt mixture has a significant effect on mechanical properties, and discrete element method (DEM) is a feasible and efficient numerical simulation approach to investigate on skeleton structure of asphalt mixture from microscopic perspective. A three-dimensional (3D) DEM compaction model which can well describe morphology characteristics of mineral aggregate, compaction temperature, was established to investigate the contact force. It indicates that aggregate–aggregate (A-A) merely exists in contact pressure force, aggregate–mortar (A-M) and mortar–mortar (M-M) exists in contact pressure force and tension force. While contact force of two-dimensional (2D) sections is employed to characterize the contact force of 3D specimens, it needs to investigate rationality of the selected section. The 3D DEM compaction model can be utilized to investigate contact force for asphalt mixture.

You have full access to this open access chapter, Download conference paper PDF

Similar content being viewed by others

Keywords

1 Introduction

Asphalt mixture has been widely regarded as a heterogeneous multiphase granular material consisting of mineral aggregates, asphalt binder and air voids. According to Mohr–Coulomb strength theory, high-temperature stability of asphalt mixture is directly related to aggregate–aggregate (A-A) skeleton structure and adhesion property of asphalt binder [1]. Contact between aggregates, which affects the magnitude and transfer path of force between aggregate particles, and has significant influence on micromechanical properties of asphalt mixture, plays an important role in asphalt mixture gradation. The evaluation index of contact characteristics of A-A is available to measure the internal structure of asphalt mixture at microscopic level, and contact behavior of aggregate to aggregate, asphalt mastic to aggregate and asphalt mastic to asphalt mastic is directly to contact force for each contact types [2]. According to current advances in research of contact property of aggregates, three kinds of prevalent approaches, namely, pure experimental tests, digital image processing (DIP) depending on laboratory tests, and numerical analysis method, have been summarized [3]. However, the first two approaches in rather costly and inefficient, a virtual simulation method, like discrete element method (DEM), has been confirmed that it is feasible to investigated on contact force for asphalt mixture. Liu et al. [4, 5] introduced a user-defined algorithm of coarse aggregate to investigate aggregate movement regulations during compaction with series of evaluation indices, which involved contact force, air voids, coordination number as well as motion angle. Ma. et al. [6, 7] and Xue et al. [8] developed a 3D DEM rutting model of asphalt mixture to describe aggregates movement properties with aggregate translation and rotation, contact number, and contact force.

Most previous studies are confined to contact behavior between aggregates but few published literatures focus on the contact behavior of M-M, A-M, and contact force during compaction, which is critical to disclosing compaction mechanism and controlling compaction quality. In this paper, a 3D DEM simulates experimental compaction, and investigates on contact force for asphalt mixture component including A-A, A-M as well as M-M. The research results can obtain an in-deep understanding compaction mechanism, and provide reference for investigating contact behavior of loose asphalt mixture densification from micro-level.

2 Materials and DEM Compaction Model

2.1 Materials

This paper selects the stone matrix asphalt as research object, namely SMA-13, where SBS asphalt binder content is set to 5%, and the gradation is shown in Table 1. The loose asphalt mixture, whose initial porosity has an important influence on evolution of aggregates as well as contact behavior between aggregate and asphalt mastic, will be tightly packed in the compaction process. Therefore, the number of initial porosity equal to field compaction is 20.5%.

2.2 Experimental Tests

According to the standard specification JTG E20 2011, the laboratory tests involving complex modulus and static compaction were performed to determine 3D DEM model parameters and demonstrate feasibility of the established compaction model, respectively. Moreover, the UTM was used to obtain dynamic modulus at different condition, including temperature: 5, 20 and 30℃, frequencies: 25, 20, 10, 5, 2, 1, 0.5, 0.2, 0.1 and 0.01 Hz.

2.3 DEM Compaction Model

The production of virtual mineral aggregates and asphalt mixture specimen can be introduced in details in the previous study [4, 5], as shown in Fig. 1. The linear contact model is utilized to characterize the particular contact of A-A, and the Burger’s model is to act as the contact model of M-M as well as A-M. The parameters of compaction model can be obtained by performing dynamic modulus tests using UTM. The Burger’s model parameters as following: E1 = 14.256 MPa, E2 = 10.246 MPa, η1 = 629.387 MPa·s, η2 = 1.817 MPa·s.

3 Results and Discussion

3.1 Contact Force Distribution Law

The internal contact of asphalt mixture mainly includes the following contact types: A-A, A-M, and M-M. The DEM results can well show the distribution characteristics of contact force of loose asphalt mixture during compaction. The irregular coarse aggregates herein are represented by clump, in which there is no contact force.

The contact force distribution characteristics of asphalt mixture are shown in Fig. 2, where contact pressure and contact tension are indicated by black and red, respectively. The force orientation is consistent with line segment direction, and the magnitude of force is direct proportional to width of line segment. The greater the contact force, the wider the line segment, and vice versa. It should be noted that the ratios of the line segments of Fig. 2 (a), (b) and (c) are not identical. Owing to the chaotic state of contact force in 3D DEM simulation, contact force can be qualitatively compared in the same figure. As shown in Fig. 2 (a), contact pressure is mainly between mineral aggregates, since the aggregates will have a movement, and the extrusion of A-A can form contact pressure force, instead of contact tension force. As plotted in Fig. 2 (b) and (c), both contact pressure force and contact tension force exist in A-M as well as M-M. Meanwhile, the contact tension force is greater than the contact pressure force between M-M. It indicates that asphalt mastic can share most of contact tension force during compaction. Moreover, the contact force distribution of asphalt mixture is disorderly, especially the contact of M-M. The most probable cause may be the contact number of A-A is smaller than those of contact types.

The qualitative analysis of the contact force distribution can’t deeply disclose the mechanism of asphalt mixture during compaction from microscopic perspective, as dis-cussed above. In order to quantitatively analyse the distribution law of internal contact force of asphalt mixture, the internal contact force was extracted by user-defined FISH language programming. The distribution characteristics of contact force of asphalt mixture were obtained with statistical analysis method. It is necessary to introduce a sign convention for contact force. The contact pressure force is positive and the contact tension force is negative.

Figure 3 and Fig. 4 show the distribution of internal contact pressure force and contact tension force at the compaction displacement 7.5 mm. As plotted in Fig. 3, the contact pressure force of A-A, A-M and M-M share the same trend. The ratio of contact pressure force shows a similar with negative exponential tendency, and most of contact pressure force is from zero to a certain value. However, the contact pressure force value of all sorts of contact types are of different sizes. In terms of the A-A, those contact pressure force is about 66% in the interval of zero to 5N, and those ratio of the contact pressure force in the range of 5N to 10N is about 15%. Therefore, the contact pressure force is mainly distributed in the range of zero to 10N. The main range of A-M contact pressure force is from zero to 2N. Furthermore, the M-M contact pressure force is small, and the distribution is mainly concentrated in the section of zero to 0.2N. In summary, it holds that the contact pressure force between A-A is dramatically greater than these of A-M and M-M. The main reason is that modulus value of materials directly affects the contact pressure force value of different contact types, and the mineral aggregate modulus is significantly stronger than that of asphalt mastic.

As plotted in Fig. 4, the contact tension force of A-M and M-M is rather small compared to the contact pressure force of A-A, and the distribution range of these contact tension force has a similar discipline from −0.2N to zero. As stated above, the contact pressure force is directly related to the corresponding modulus, and the materials modulus the greater, the contact pressure forces the greater. However, these rules are inapplicable to the contact tension force distribution. In short, it indicates that there are migration and evolution of mineral aggregates in loose and hot asphalt mixture during compaction. The contact pressure force is more that the contact tension force. They exist in A-M as well as M-M, but there is only contact pressure force in A-A.

3.2 Contact Force Distribution Variability of Two-dimensional Section

It is commonly accepted that the 3D DEM is used to comprehensively and objectively investigate the internal microstructure of asphalt mixture, and a 3D virtual specimen can be easily cut into series of 2D planes to realize the visualization of internal contact force of all kinds of contact types within asphalt mixture. However, the multiphase asphalt mixture is heterogeneous granular material with a large variability in mechanical properties. So, this section will discuss the variability and complexity of contact force at different compaction displacement.

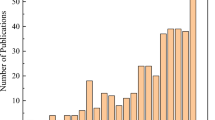

The 3D virtual specimen can be theoretically cut into numerous 2D sections, but too many or too few 2D sections will inevitably have a profound effect on studying the variability of contact force. Therefore, the virtual specimen was divided into 12 2D sections at intervals of 30 degrees in vertical direction, and Fig. 5 shows the maximum contact force distribution under different compaction displacements (7.5 mm, 15 mm and 22.5 mm).

It can be seen that the contact force with large compaction displacement contains the contact force curve with small compaction displacement, which shows that the maximum contact force is positively proportional to the magnitude of compaction displacement, namely the larger compaction displacement, the greater maximum contact force. Meanwhile, the maximum contact force fluctuates greatly in different cutting planes, particularly at the 30° cutting plane, and it shows that the 3D virtual specimen is cut into 2D sections which can be employed to evaluate the asphalt mixture variability by selecting ap-propriate indicators. However, it should be noted that the local anomaly of contact force in virtual specimen has a negative and great influence on the operating efficiency and simulation reliability with the 3D DEM. When the abnormal contact force exceeds the maximum allowable contact force of system, the particles will escape at a large speed and cause an interlocking effect on the surrounding particles, even the DEM model is out of equilibrium. Therefore, the escaped particles can be deleted without affecting the simulation results.

The contact force of asphalt mixture from 12 2D planes is utilized to perform statistics analysis to deeply investigate the variability of contact force, as shown in Table 2. Under the same compaction displacement, the maximum contact force of different sections shows a certain volatility, and the coefficient of variation changes from 10 to 30%. Therefore, when the contact force of a 2D section is used to represent the contact force of a 3D virtual specimen, it is necessary to evaluate the rationality of the selected 2D section. In addition, it indicates that the virtual cutting method can be judged to the homogeneity of asphalt mixture to some extent by selecting an appropriate evaluation index, such as contact force, contact number.

4 Conclusions

-

(1)

The contact pressure force of aggregate to aggregate, aggregate to mortar, and mortar to mortar are mainly distributed in ranges of 0-10N, 0-2N and 0–0.2N, respectively.

-

(2)

The absolute value of contact tension force of both aggregate to mortar and mortar to mortar are in range of 0–0.2N, and contact pressure or tension force can meet the regular that with the increase of contact pressure or tension force, the distribution frequency decreases gradually.

-

(3)

The maximum contact force of different sections shows certain fluctuation. When contact force of a 2D section is used to represent the contact force of an asphalt mixture specimen, it needs to investigate rationality of the selected section.

References

Shi LW, Wang DY, Masley J, Zhang SW (2013) Comparison analysis of the aggregate contact characteristics between skeleton-dense and suspended-dense structure asphalt mixture. App. Mech. Mater. 470:889–892

Zhang Y, Ma T, Ling M, Huang X (2019) Mechanistic sieve-size classification of aggregate gradation by characterizing load-carrying capacity of inner structures. Eng Mech 145:04019069

Shi L, Wang D, Jin C, Li B, Liang H (2020) Measurement of coarse aggregates movement characteristics within asphalt mixture using digital image processing methods. Measurement 163:107948

Liu W, Gao Y (2016) Discrete element modeling of migration and evolution rules of coarse aggregates in the static compaction. Southeast Univ 32:85–92

Liu W, Gao Y, Huang X, Li L (2020) Investigation of motion of coarse aggregates in asphalt mixture based on virtual simulation of compaction test. Int J Pavement Eng 21:144–156

Ma T, Zhang D, Zhang Y, Hong J (2016) Micromechanical response of aggregate skeleton within asphalt mixture based on virtual simulation of wheel tracking test. Constr. Build. Mater 111:153–163

Ma T, Zhang D, Zhang Y, Wang S, Huang X (2018) Simulation of wheel tracking test for asphalt mixture using discrete element modelling. Road Mater Pavement 19:367–384

Xue B, Xu J, Pei J, Zhang J, Li R (2020) Investigation on the micromechanical response of asphalt mixture during permanent deformation based on 3d virtual wheel tracking test. Constr Build Mater 267:121031

Acknowledgements

This research was funded by the Guangxi Science and Technology Project (ZY21195043), the Nanning Science and Technology Project (20223039).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Open Access This chapter is licensed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license and indicate if changes were made.

The images or other third party material in this chapter are included in the chapter's Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the chapter's Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder.

Copyright information

© 2023 The Author(s)

About this paper

Cite this paper

Feng, J., Liu, W., Lei, J. (2023). Investigation on Contact Force for Asphalt Mixture During Compaction Using DEM. In: Feng, G. (eds) Proceedings of the 9th International Conference on Civil Engineering. ICCE 2022. Lecture Notes in Civil Engineering, vol 327. Springer, Singapore. https://doi.org/10.1007/978-981-99-2532-2_6

Download citation

DOI: https://doi.org/10.1007/978-981-99-2532-2_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-99-2531-5

Online ISBN: 978-981-99-2532-2

eBook Packages: EngineeringEngineering (R0)