Abstract

Jelly candies are soft confectionery products primarily composed of sucrose, corn syrup and gelling agents. This study investigates the impact of six different corn syrup, all used at constant amount (46.22%), on the physicochemical (moisture content, pH, Colour), texture and sensory properties of gelatin-based jelly samples. The Moisture content, pH, colour, and texture properties of samples were analysed at 0th, 15th, 30th, 45th, and 60th day during storage. Before storage moisture content of the candiesranged from21.03 to 22.57% whereas after 60 days, it was found between 19.31 and 20.72%. Sample JF42 exhibited the least moisture rate loss. The type of corn syrup did not significantly affect the pH of the samples. Samples with higher fructose content in the corn syrup had the lowest hardness, whereas the sample with the highest maltose content exhibited the highest hardness. Changes in gumminess and chewiness paralleled variations in hardness results. Hardness and gumminess were found suitable to follow up gelatin-based samples storage using the zero-order kinetics modelling. Corn syrups with high fructose amounts intensified the redness, while those with high glucose levels led to yellowness in the candies. In sensory evaluation, products made with G40, G60, and M50 corn syrups received higher general Understanding how various types of corn syrup impact the candies quality helps producers optimize their formulation. This information enables producers to mitigate quality deterioration during storage, ensuring that their candies maintain at the desired level and appeal to consumers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Since 1922, when Hans Riegel first introduced gelatin-based jellies to the confectionery market, the jelly confectionary industry has been developed and various functional ingredients as innovative fillings, and exotic flavours in confectionery products have been launched by the producers [13, 38]. Global market of confectionery products was 240 billion US dollars in 2019 and is expected to reach 419.76 billion US dollars by 2023 [30]. Chocolate products dominate the majority of the market with 58.01% ratio and the remaining 41.99% accounts for the soft and hard candies, and chewing gum (Önder, 2022). The Europe confectionery market size was valued at 86.40 billion US dollars in 2022 and is estimated to reach around 151.11 billion US dollars by 2032 [30]. Various confectionery products are enormously popular among the global population ranging from kids to seniors due to their unique texture and chewability characteristics [30],Gunes et al., 2020). The Constantly evolving consumer tastes and preferences have encouraged the manufacturers to indulge in the production of new and innovative confectioneries [13]. Marketing strategies of the producers targeted the adult and a wide population in order to expand their business [19, 30].

Different types of confectionery are produced by varying the amount of water in the products, cooking them in different ways, and using practices to control or prevent crystal formation. Confectionery can be divided into two main groups: hard candies and soft (gummy or jellies) candies [16]. Hard candies are products obtained by highly concentrating sucrose by cooking it with glucose syrup and/or invert sugar, consisting of a glassy and amorphous supersaturated sugar mass, and also containing colouring and flavouring substances [21]. Jelly candies are obtained by adding gelling ingredients (such as gelatin, pectin, starch carrageenan or agar gum), sucrose, invert sugar, corn syrup [9], acid, flavourings and colourants, and by cooking them at a certain temperature and evaporating their moisture [2, 25]. Corn syrups are crucial raw materials in candies for controlling crystallization, sweetness, moisture content, viscosity, and color formation [16]. To obtain the most suitable chewability and physical structure for jelly candies, the balance of sucrose and corn syrup in the formulation must be finely adjusted [14]. Role od corn syrup can be classified mainly as:

-

Prevents Crystallization: Corn syrup prevents sugar from crystallizing, making candies, frostings, and fondants smooth and creamy.

-

Maintains Moisture: Corn syrup helps products stay soft and fresh for longer.

-

Acidic Stability: High-fructose corn syrup (HFCS) is an inexpensive liquid that remains stable under acidic conditions in foods and beverages

Corn syrups are widely used in instant drinks with sugar, chocolates, cakes, biscuits, confectionery, jams, marmalade and other jelly-type foods.

Jelly candies are produced in different structures and textures depending on the gelling agent used in the formulation. The texture can range from soft, medium toelastic and easy to cut [16]. Quality properties of jelly canides can be influenced by–the pH value, cooking temperature and use of other ingredients. It is also crucial to understand the inverse relationship between glass transition temperature (Tg) and moisture content, as well as their interaction with other ingredients. The more moisture present in the final product, the lower the Tg can be measured. For example; the Tg value of water is − 134 °C, and the Tg value of sucrose ranges between 65 and 70 °C and for corn syrup with 42 dextrose equivalent (DE) is 79 °C [9].

Corn syrup and sucrose are the primary ingredients in jelly confectionery, making up approximately 70% of the formulation [25]. Iso-glucose, also known as glucose-fructose syrup or glucose syrup, obtained by enzymatic or acidic hydrolysis of corn sometimes potato or wheat starch [26]. Corn syrup is used in jelly confectionery due to its numerous benefificial properties such as; Appearance and Texture: It imparts a shiny appearance, contributes to the mass and volume, and provides sweetness to the product. Crystallization and Moisture: Corn syrup prevents or delays the crystallization of sucrose and helps preserve moisture, adding solid matter to the product [9, 15]. Cost and Efficiency: It is relatively low-cost, offers a high production yield, and has a good sweetness value. Corn syrup also reduces water activity (aw) and inhibits microbial growth as a result extend the shelf stability of the confectionery products [9]. Corn syrups are differentiated by their dextrose equivalent (DE), which affects their molecular weight, moisture content, and functionality as humectants, sucrose crystallization inhibitors, thickeners, and foam stabilizers. The most commonly used corn syrup in confectionery products is 42 DE [9]. Beside gelling agents, sucrose and corn syrup are not only sweetener but also interacts with water and gelling agents changing the sol to gel transition process. They also promote the brix, flavour and colour by caramelization and/or Maillard reaction [20]. Jelly and gummy candies with generally aw of 0.5–0.7 are likely to harden during shelf life as they lose moisture especially if they are stored at dry conditions [11]. Various corn syrups contain different amounts of glucose, fructose and maltose. Each of these mono and disaccharides have unique properties such as being humectant, heat stability and potential contribution in the maillard reaction and other mentioned functional properties. Therefore, they can affect physicochemical properties of candy products during storage. The evaluation of various types of corn syrups impacts on the final products quality can give a vision and perspective to producers.

Different studies based on replacing (totally or partially) of sucrose/corn syrup in gummy and jelly confectionery products with honey, alcohol-sugars or fruits have been reported [1, 13, 20, 25, 38]. However, no reports considering the effect of using different types of corn syrup on the quality characteristics of jelly confectionery was found. Thus, the perspective of this study was to investigate different corn syrups’ impacts on the quality, textural and sensory characteristics of gelatin-based jelly confectionery products. Shelf life is determined by keeping the food product in the typical storage conditions it is exposed to and measuring the chemical, microbiological and physical changes that occur over a period of time until the food product is unacceptable to consumers [35]. At accelerated shelf-life conditions studies are conducted by storing products in storage cabinets under controlled temperature, RH, and light conditions, which speeds up the deterioration rate to that of normal storage conditions [39]. Therefore, storage study of the samples with different corn syrups were also conducted to improve quality problems occurred during shelf life of these products like hardening, difficulty in chewing or becoming sticky in terms of texture. Moisture content, pH, colour and texture properties of samples at 0th, 15th, 30th, 45th and 60th day of storage under accelerated shelf-life conditions (at 27 °C and 75% RH) were examined.

Materials and methods

Materials

Gelatin (240 bloom), sucrose, corn syrups (G40, G60, F42, M50, F30, F10), citric acid, and natural strawberry flavouring were procured from Elvan Food (Istanbul, Türkiye). Properties of the corn syrups used in the study are given in Table 1. Formulations are given in Table 2, and they were determined by keeping the corn syrup percentage same after initial trials.

Methods

Sample preparation

Figure 1 illustrates the process of preparation gelatin-based jelly candies. Initially, a mixture of sucrose, corn syrup and water was heated to 87°Bx to obtain a pre-syrup. Since different sugar syrups were used in the study, the cooking temperatures of pre-syrups were varied accordingly. Then, a gelatin solution was prepared by dissolving gelatin in water at 90 °C in a beaker. Following cooking process, the gelatin solution was slowly added to the pre-syrup to avoid foaming. Subsequently, citric acid (2%) and natural strawberry flavour (2%) were added to the main syrup. To remove excess moisture and complete gelatinization, main syrup was poured into starch-shaped moulds. The jelly samples were kept at 24 °C and 40% relative humidity (RH) for 24 h in an air-conditioned cabinet. The ielly samples reached the desired gel structure and moisture value after about 24–72 h. They were cleared from the starch moulds by air blowing and afterwards, they were polished with coating agents (carnauba wax and bees wax) in order to prevent sticking them to each other.

The storage study of jelly samples was conducted at 27 °C and 75% RH in an air-conditioning cabinet. Over a period of two months, the samples were evaluated every 15 days for changes in colour, moisture, pH and texture. The conditions in this study was based on previous research by Elvan Food.

Moisture content determination

The moisture content of jelly samples was determined using a Karl Fisher Titrator (Mettler Toledo DL38, Germany), a traditional titration based on volumetric titration. Each mL of Karl Fisher reagent (mg H2O/mL) spent in volumetric Karl Ficher titration corresponds to the mg value of the water in the sample. The samples were weighed at 0.05–0.1 g and dissolved in a previously prepared 20 mL of formamide and 40 mL of methanol mixture in the water bath 53.3 °C.

Colour measurements

The colour values of jelly samples was measured using a Minolta Chroma Meter CR-400 (Minolta, Camera, Osaka, Japan). L* (brightness), a* (± red-green) and b* (± yellow-blue) values of the jelly samples were determined according to the CIE Lab colour measurement scale [28].

pH

The pH values of jelly samples were obtained by diluting 10 g of the sample with 90 mL of distilled water and dissolving it at 50 °C.The pH was then measured at 25 °C using a pH meter (HANNA HI 2211, Romania).

Textural characteristics

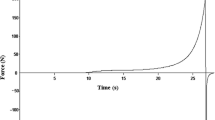

The textural properties of the jelly samples were analysed using a texture analyser (CT3, Brookfield) equipped with 5 kg load cell. The force required to break the jelly samples (25 × 12 × 12 mm) at room temperature was determined using a 4 mm diameter cylinder (TA44) probe, with a test speed of 51.2 mm/s. Hardness, springiness, gumminess, chewiness, and cohesiveness of the jelly samples were evaluated using the time versus force curve.

Sensory analysis

The sensory attributes of the jelly samples, including colour, taste, transparency, hardness, springiness, chewiness and general liking were evaluated by 10 trained panelists from Elvan Food (Istanbul, Türkiye) using a hedonic scale from 1 (disliked extremely) to 9 (liked extremely) [10].

Statistical analysis

Statistical analysis of the experimental data was performed using IBM SPSS (Statistics 24) software (Chicago, IL, USA).A one-way analysis of variance (ANOVA) was conducted, and the Tukey multiple comparison test was used to determine the significant difference among the means, with a significance level set at p < 0.05. Modelling of the texture parameters was carried out using curve Expert Professional 2.7.3.

Results and discussion

Moisture content

Moisture content is a critical parameter in controlling the shelf life and texture as of confectionery products [11, 21]. In this study, the concentration of the corn syrup was kept constant at 46.22%, which is the highest ingredient amount in the recipes. As variations in the moisture content of different corn syrups, cooking temperatures were adjusted accordingly to obtain a similar dry matter value after the heat treatment, which was 87°Bx. Since the moisture content of the corn syrup used in JF42 sample was the highest, the cooking temperature of the confectionery was the highest (Table 3).

The cooking temperatures of the JG60 and JM50 samples were the same because the moisture content of the corn syrups used were similar. On the other hand, the cooking temperature of JF10 was differedt from JM50 although the moisture content of the corn syrup in the recipe was similar (Table 3). This difference can be explained with the main type of the carbohydrate source in the corn syrup: fructose in JF10 and maltose in JM50. Fructose is an excellent humectant that absorbs the water [18] in compared to maltose in JM50 [15]. Therefore, the types of corn syrup is an important parameter in determining the cooking temperature of confectionery. The boiling point of a solution depends on the number of the molecules in the mixture. Although the water content of the corn syrup used in JG60 sample was lower than that in JG40, the cooking temperature was the opposite (higher) (Table 3). This can be explained by the difference in DE among the corn syrups. The effects of the glucose syrup on boiling point elevation depend on the specific saccharide composition [27, 31]. Thus, the boiling point of glucose syrup increases with its DE value [16].

Moisture content affects the shelf life of candy products especially in terms of sensory and microbiological properties. Candies tend to harden over time as they lose moisture to the atmosphere [2, 6]. The moisture content of gelatin-based confectionery samples stored at 27 °C and 75% RH for two months is shown Fig. 2. The used of different corn syrups with different carbohydrate profiles had a significant effect on the moisture content of the confectionery samples during storage (p < 0.05). Before storage, the moisture content was found to be the lowest in the JF42 sample and the highest in JG60 sample, with a value of 21.03 ± 0.061 (%) and 22.57 ± 0.078 (%), respectively. A similar trend was observed after 60 days of storage (Fig. 2). This can be explained with the hygroscopicity property of the corn syrup because JF42 contained corn syrup with the highest fructose content, while JG60 contained corn syrup with the highest glucose content. These are because of the differences in the crystal morphology of fructose and glucose [37].

pH

It is crucial to control pH as a quality parameter to ensure stability since pH and ionic force have a significant effect on gel formation in soft jelly candies [14]. The pH of the confectionery samples measured before and after acid addition and just after moulding. The optimum pH range for candies was reported to be 3.35–3.39 and 3.65–4.29 for [25]. For a good gel structure, pH of the samples was adjusted with citric acid in the experiments, and it was seen that the pH value of the confectionery samples varied only between 3.2 and 3.3 after moulding (Table 4). No significant difference was observed in pH of the confectionery samples. Similarly, Pereira et al. [29] mentioned no difference in pH of gummy candies formulated with different starches. On the other hand, Renaldi et al. [33] reported significant differences in pH of gummy jellies with different pectin and gelatin amounts. Since the only difference between the recipes was the type of the corn syrup and the amounts of the ingredients were similar, similar pH values were measured in this study. Therefore, the use of different corn syrups with different carbohydrate profiles did not affect the pH value of the products.

Colour

The visual appearance of a product is one of the main sensory parameters that the consumers notice. That’s why the food industry aims to optimize the colour of their products so that they can attract the consumers’ attention till the last day of the shelf life. Therefore, it is important to follow the colour of the confectionery during storage. The colour characteristics of the samples prepared with different corn syrups during at 27 °C and 75% relative humidity storage are shown in Table 5 and Fig. 3. In colour analysis, the a* value indicates redness at positive values and greenness at negative values. It was seen that the samples JG40, JG60 and JM50 showed negative values, while JF42, JF30 and JF10 showed positive values when the samples were fresh (Table 5). Examining the change in the a* value of JF42, JF30 and JF10 fresh samples, and comparing with the product visuals, it was observed that the redness was higher in these samples, particularly in the JF42 sample, whichwas closer to a dark brown colour (Fig. 3). This change was thought to occur directly as a Maillard reaction, depending on the fructose-based composition of the samples, the amount of fructose and the cooking temperature of the corn syrup (Table 3). Maillard reaction is known to affect colour [41]. Maltose syrup, with its lower dextrose content, is less prone to participate in the Maillard reaction, resulting in lighter-coloured confections [15].

The b* value in color measurement represents yellowness at positive values and blueness at negative values. In the experiments, all confectionery samples had positive b* values (Table 5). The sample with the highest b* value was JF10 when the samples were fresh, indicating higher yellowness compared to the other samples (Fig. 3). For JF42 and JF30 samples, the b* value was less meaningful due to the more prominent redness. In general, the a* value of the jelly candies made with corn syrup containing higher fructose was found to be higher than the jelly samples using other types of syrups (Table 5).

It was observed that the storage time did not significantly affect the degree of brightness of the jelly samples (Table 5). The a* value of the JG40 sample remained unchanged throughout storage, and it changed for that of JG60 on the 15th day, however it was stable during the rest of the storage (Table 5). The a* value indicates redness with positive values, and it was observed that the redness of the JM50 sample increased since the a* value approached zero during storage. Visual observation also confirmed these changes,, yet the colour change of the JM50 sample was not red, but yellow (Fig. 3), indicating browning of the product. The b* value of JM50 sample, representing yellowness, increased till the day 30th, after which it remained stable. But b* value of JM50 did not show a significant change after 30 days (Table 5). For the JG40 and JG60 samples, the b* value changed on the 15th day but it was stable after day 15 until the end of the storage period. The yellowness values of the JG40, JG60 and JM50 samples were similar at the end of the storage (Table 5).

The a* values of the samples prepared with corn syrups (JF42, JF30 and JF10) were higher than the other samples and changed only on the day 15, with no significant changes afterwards till the end of the storage (Table 5). In these samples, it was thought that non-enzymatic browning reaction continued until the 15th day in the package and it was insignificant after 15th day. This is likely because the initial steps of the Maillard reaction occur more quicker with fructose compared to glucose [7]. Since the colours were already close to brown due to the Maillard reaction (Fig. 3), the b* values of these samples did not change significantly during storage (Table 5).

Texture

Uncontrolled changes in the moisture content of confectionery products can lead to quality defects such as excessive stickiness or hardness, loss of chewiness, or crusting, which can reduce consumer acceptability [11]. In confectionery technology, controlling sugar crystallization is critical to stabilization of texture. The presence of sugar crystals is desired in some type of confectionery like fondant, toffee, and fudge, but not in jelly products. The choice of syrup type can affect the texture and shelf-life of confectionery samples [16]. There are no accepted texture parameters in the literature or the market. Each company sets its textural parameters based on their customers preferences for jellies [34]. Additionally, differences in taste and flavour releases of confectionery with different textural characteristics [38]. Texture Profile Analysis (TPA) is involved in confectionery plants to assess texture properties to handle the gummy jellies without deformation and the purpose of TPA testing is to mimic the movement of the teeth and tongue [3]. Therefore, the texture stability of the confectionery samples prepared with different corn syrups was investigated using the texture parameters of hardness, springiness, gumminess, chewiness, and cohesiveness of samples during storage at 27 °C and 75% RH for 60 days (Fig. 4).

The maximal force necessary to compress a food between the molar teeth is the sensory definition of hardness [4]. Depending on the different carbohydrate profile, moisture and cooking temperature, the samples JM50 and JF10 showed the highest hardness values of 192.50 g and 185.85 g respectively, while the JF30 samples showed the lowest hardness of 133.25 g before storage (Fig. 4.A). The high hardness values of these samples can be attributed to increased covalent cross-links within the protein network in the presence of reducing sugars via Maillard reactions, causing an increase in stiffness of the protein gel network (Steffe, 1996) due to the fructose content of JF10 and the high amount of maltose in JM50. The use of high maltose corn syrups can also result in products that are tough but also highly viscous [35].

Due to the moisture loss of the samples during storage (Fig. 2), the hardness of all samples increased over the 2-month storage period (Fig. 4A). Corn syrups inhibit crystallization in jelly confectionery by controlling the rotation of sucrose in the product and improving the sucrose solubility. The increase in crystallization causes an increase in hardness parameter of the product [14]. The hardness values of samples prepared with JG40 and JM50 were measured close to each other, at 271.90 g and 272.90 g, respectively. The increase in hardness of these samples was higher than the other samples (Fig. 4A). Besides moisture loss, this change in hardness value was due to the differences of carbohydrate profile of the corn syrup used. JG40 and JM50 samples had the highest moisture loss (Fig. 2) and completed 60 days of storage as the hardest samples (Fig. 4.A). This change in hardness may negatively affect consumer perception.

The hardness of the JG60 and JF30 samples was found to be similar after 60-day storage, although the samples prepared with JG60 was harder than the ones with JF30 before the storage (Fig. 4A). This result might be explained with the combined effects of cooking temperature of the samples and humectant characteristics of the corn syrups used during storage. The cooking temperature of the JF30 sample was 123 °C, while that of JG60 was 117 °C (Table 3). These effects may be balanced by the effects of the components of the corn syrup used since in JF30 contains mainly fructose and JG60 contains mainly glucose, so that their hardness values were similar after the storage. The water activity of the major component may give an idea for the humectant properties. The water activity of glucose is 0.737, and that of fructose is 0.961 (Lewicki, 2009).

The distance or length of the compression cycle during the second bite is the springiness value [36]. It is related to the elasticity of the sample and more mastication energy is needed in the mouth when the springiness is high [4]. Springiness value of the samples was not affected by the corn syrup type and storage time (Fig. 4.B). This parameter is related to the concentration of gelatin [17]. Since the amount of gelatin was kept constant in the study, the change in springiness value was not significant before and after the storage in our study. Sun et al. [36] studied the properties of corn starch in syrup and observed that the springiness of starch gels in glucose, fructose and maltose syrup used between 0 and 25% were similar. Similarly, Marfil et al. [22] found no significant differences in springiness between gummy confections formulated with gelatin, corn starch, maltitol syrup and xylitol.

Gumminess is a property of semi-solid foods that have a low degree of hardness but a high level of cohesiveness. It is a more crucial texture property of semi-solids than solids such as gelatin [4]. In this study, gumminess behavior was seen due to the gelatin amount used in the recipes. Gumminess is calculated by multiplying hardness and cohesiveness and as the hardness increases, the gumminess of a product also increases [32]. In parallel with the hardness values, at time zero, i.e. before storage the gumminess value of the JM50 and JF10 samples was found to be higher with 172.94 g and 173.34 g, respectively, (Fig. 4A and C). However, the change in gumminess of samples during storage was not significant and gumminess values of JG40 and JM50 were higher than the other samples which were 242.45 g and 239.43 g, respectively (Fig. 4C). Both gelation and decrease in moisture level can explain the increases in hardness and gumminess. In a study, total solids content of jellies prepared with 29.5% corn syrup correlated with the gumminess of the samples [6].

Chewiness is a textural measurement for how much energy it takes to masticate a food and it’s usually to describe solid foods. Since mastication requires compressing, shearing, piercing, grinding, tearing, and cutting, as well as appropriate lubrication by saliva at body temperatures, chewiness is the most challenging parameter to evaluate exactly [24]. Chewiness values of samples prepared with different corn syrups followed the same trend as gumminess during storage (Fig. 4C and D). This can be explained as chewiness is calculated as the product of gumminess and springiness values. Similarly, Chandra and Shamasundar [4] found the same trend for gelatin sample gels with 6.67% gelatin concentration.

Cohesiveness refers to the internal bonding and strength of a food material mechanically [42]. Like the springiness parameter, it was seen that the use of corn syrup with different carbohydrate profile did not affect cohesiveness values of the samples before and after the storage significantly (Fig. 4E). Tireki et al. [40] reported that cohesiveness of gummy confections was affected by corn syrup to sucrose ratio and gelatin amount during storage. Based on this study cohesiveness behavior was quite expected because besides constant gelatin amount in the recipes, the quantity of corn syrup in each recipe was also same although the carbohydrate profile of each corn syrup used in the recipes was different. Similarly, DiMonaco and Colleagues [8] mentioned similar cohesiveness values for three of the candy samples involved in fifteen solid food samples examined. On the other hand, it has been reported that the brix value is also effective on the cohesiveness of semi solid systems obtained as a result of gelling sugar syrups [23],this can be meant that moisture content is also an effective factor on the cohesiveness since as the brix increases moisture content decreases generally. However, cohesiveness did not change significantly (Fig. 4E) although there are significant changes in moisture content (Fig. 2) during storage.

Moisture and fat concentration, as well as the types and the amounts of structural carbohydrates such as starches and cellulose, hydrocolloids such as gelatin and proteins present, impact the texture of foods [12], which is an important quality parameter for the consumers of confectionery. Studies investigating the texture of these products with different formulations are scarce, and different textural parameters are evaluated in different studies. Therefore, a lean approach is needed to evaluate the texture quality of gelatin-based confectionery. In this study, hardness, gumminess, and chewiness values showed the most significant changes during storage of two months at 27 °C (Fig. 4. These changes can be modelled with a common equation given below derived from zero-order kinetics;

where texture value is hardness(g) or gumminess (g) or chewiness (mj), t shows storage time in days and k is the equation constant.

Texture value (t = 0) shows the initial value, which means before storage. Parameters for the above equation are given in Table 6 and fitted models are shown in Figs. 5, 6 and 7. It was seen that R2 (coefficient of determination) values of equations varied between 0.5374 and 0.9478 for hardness parameter and approach was found convenient for most of the samples namely JM50, JG40, JF30 and JG60, whose R2 is above 0.8000 (Table 6, Fig. 5). The R2 values of the gumminess equations were between 0.2838 and 0.9446 and like hardness, coefficient of determination of JM50, JG40 and JF30 samples were higher than 0.8000 (Table 6, Fig. 6). When the chewiness models were analyzed, it was observed that the R2 values were between 0.0164 and 0.7790, all of them were less than 0.8000 and the highest value was found for the JG40 sample (Table 6, Fig. 7). According to these findings, hardness and gumminess parameters are the best reliable indicators to monitor during storage studies of gelatin based confectionery products with different corn syrup in the recipes.

Sensory evaluation

Taste, preference and acceptance of foods including confectionery vary widely and depend on a number of factors such as ethnicity, education, age and environment.. Table 7 shows the results of some of the important sensory properties of gelatin-based confectionery samples prepared with different corn syrups. Colour, taste, transparency, hardness, springiness, chewiness and general liking of the samples were scored with a 9-point hedonic scale (Table 7).

The first impression a consumer has of any food product is related to its colour. In the study, the panelists gave the high scores (liked) to the darker samples and the lower (disliked) ones to the lighter samples. JF42 sample was scored as the most liked and JG60 was the most disliked confectionery (Table 7). Considering the colour results, it was also noticed visually by the panelists that the a* value of JF42 was higher than the other samples (Table 5 and Fig. 3). Transparency parameter was rated low/high by the panelists and the transparencies of JG40, JG60, JM50 and JF10 samples were evaluated as the highest and close to each other (Table 7). The use of different corn syrup was not found to be effective on the taste scores (p > 0.05) (Table 7). This result was expected as the amount of gelling agent gelatin in the recipes was constant. Taste evaluation is related to flavour release of the product. This is affected by the chemical bonding and physical entrapment and gelatin captures volatile compounds in a stronger manner [33]. So, having the same amount of gelatin in the samples make senses, as no difference in the taste can be observed.

Food texture sensation has a significant impact on consumer liking and preference for the food items [5]. JM50 and JF10 samples were scored as the liked samples and JF30 sample scored as the lowest one in hardness. JG40, JG60 and JF42 were evaluated as samples having similar preference samples with no significant difference (Table 7). Comparing these sensory findings with the texture measurement part of the study as JM50 and JF10 samples had higher hardness values and JF30 sample had the lowest one (Fig. 4. A), it seems that our panellists liked the hardest samples that soft ones. The springiness and chewiness parameters of the samples were not affected by the use of different corn syrup in the sensory evaluation with no significant differences between samples (p > 0.05) (Table 7).

Textural attributes and colour can be related to the use of polysaccharide sugar amounts [13]. Hardness and colour were the most significant parameters that making a difference in the sample’s sensory evaluation (Table 7) as it was seen that the panelists gave significantly different scores to these parameters. The general liking scores of JG40, JG60 and JM50 samples were higher while their colour scores were lower. In general, it can be concluded that the use of glucose and maltose syrups in gelatin-based confectionery products has led to higher liking scores than the use of fructose syrups in sensory evaluation. It was also observed that fructose syrup had a negative impact on panelist general liking, on the other hand it can gave coloured (from orange to dark red) visual to the prodcut (Fig. 3).

Conclusion

Six different corn syrups were used at a constant ratio of 46.22% in gelatin-based jelly confectionery, and physical, chemical, and sensory properties of the samples were examined during 60-day storage. According to the colour analysis, the change in L* value among the samples was found to be insignificant. It was observed that the use of corn syrup type with high amount of fructose significantly increased the redness of jelly confectionery samples by accelerating Maillard reactions occurring between gelatin and reducing sugar. On the other hand, the colour of these samples became unacceptable by the end of the storage (60th day). Corn syrup type with high amount of glucose led to yellowness in candy. It was found that the use of different corn syrups did not affect the pH of the samples. The samples with corn syrup containing the highest fructose content (F42) had the lowest hardness, while the sample with corn syrup type with highest amount of maltose content (M50) had the highest hardness. The hardness of samples JG60 and JF30 was the similar, with medium hardness, and the change in their hardness during shelf life was found at an acceptable level. Changes in gumminess and chewiness parameters were similar to the hardness. The change in moisture value significantly affected the hardness parameter of the samples during storage. The samples tended to lose moisture resulting in increased hardness, chewiness and gumminess. Due to its composition, G60 (the highest amount of glucose in corn syrup) provides moisture retention and ensures softness of the candy. Hardness increased due to the moisture loss during storage for the samples prepared with M50 and G40 corn syrup. While the colour performance of these samples during storage was appreciated, their textural properties can be improved by adding different humectants to the formulation.

In the sensory evaluation textural and taste parameters of jelly candies play an important role in consumer preference. The most general liking samples at the end of 60th day were the jelly candies containing M50, G40 and G60 corn syrups, which had similar (p > 0.05) taste and transparency but different (p < 0.05) textural (hardness, springiness and chewiness) properties. This study focused on oil-coated gelatin-based candies. Future studies can explore sugar-acid coated candies with different gelling agents like pectin and starch with various corn syrups.

Data availability

The data that support the findings of this study are available on request from the corresponding author.

References

M.N.N. Anuar, N.H. Zakaria, M. Ibrahim, F.A.A. Majid, Physicochemical, phytochemical, and shelf-life studies of a functional jelly from banana (Musa paradisiaca) and Malaysian stingless bee honey (Trigona sp.). Curr. Res. Nutr. Food Sci. J. 10(2), 698–710 (2022). https://doi.org/10.12944/CRNFSJ.10.2.24

P. Burey, B.R. Bhandari, R.P.G. Rutgers, P.J. Halley, P.J. Torley, Confectionery gels: a review on formulation, rheological and structural aspects. Int. J. Food Prop. 12(1), 176–210 (2009). https://doi.org/10.1080/10942910802223404

L. Cai, J. Feng, J. Regenstein, Y. Lv, J. Li, Confectionery gels: effects of low calorie sweeteners on the rheological properties and microstructure of fish gelatin. Food Hydrocoll 67, 157–165 (2017). https://doi.org/10.1016/j.foodhyd.2016.12.031

M.V. Chandra, B.A. Shamasundar, Texture profile analysis and functional properties of gelatin from the skin of three species of fresh water fish. Int. J. Food Prop. 18(3), 572–584 (2015). https://doi.org/10.1080/10942912.2013.845787

Chen, J., & Rosenthal, A. (Eds.). (2015). Modifying food texture: Novel ingredients and processing techniques. Woodhead Publishing. Pages: 3–24, ISBN 9781782423331, https://doi.org/10.1016/B978-1-78242-333-1.00001-2.

P. Delgado, S. Bañón, Determining the minimum drying time of gummy confections based on their mechanical properties. CyTA-J. Food 13(3), 329–335 (2015). https://doi.org/10.1080/19476337.2014.974676

W.L. Dills Jr., Protein fructosylation: fructose and the maillard reaction. Am. J. Clin. Nutr. 58(5), 779S-787S (1993)

R. DiMonaco, S. Cavella, P. Masi, Predicting sensory cohesiveness, hardness and springiness of solid foods from instrumental measurements. J. Texture Stud. 39(2), 129–149 (2008). https://doi.org/10.1111/j.1745-4603.2008.00134.x

N. Efe, P. Dawson, A review: sugar-based confectionery and the importance of ingredients. European J. Agric. Food Sci. 4(5), 1–8 (2022). https://doi.org/10.24018/ejfood.2022.4.5.552

M. Elia, A procedure for sensory evaluation of bread: protocol developed by a trained panel. J. Sens. Stud. 26(4), 269–277 (2011). https://doi.org/10.1111/j.1745-459X.2011.00342.x

R. Ergun, R. Lietha, R.W. Hartel, Moisture and shelf life in sugar confections. Crit. Rev. Food Sci. Nutr. 50(2), 162–192 (2010). https://doi.org/10.1080/10408390802248833

Fellows, P. J. (2017). Properties of food and principles of processing. Food processing technology, 3–200. Editor(s): P.J. Fellows, In Woodhead Publishing Series in Food Science, Technology and Nutrition, Food Processing Technology (Fourth Edition), Woodhead PublishingISBN 9780081019078, https://doi.org/10.1016/B978-0-08-100522-4.00001-8.

S. Gok, O.S. Toker, I. Palabiyik, N. Konar, Usage possibility of mannitol and soluble wheat fiber in low calorie gummy candies. LWT 128, 109531 (2020). https://doi.org/10.1016/j.lwt.2020.109531

R. Gunes, I. Palabiyik, N. Konar, O.S. Toker, Soft confectionery products: quality parameters, interactions with processing and ingredients. Food Chem. 385, 132735 (2022). https://doi.org/10.1016/j.foodchem.2022.132735

P. Hull, Glucose syrups: technology and applications (John Wiley & Sons, 2010)

R.W. Hartel, J.H. von Elbe, R. Hofberger, Confectionery science and technology, vol. 536 (Springer, Berlin/Heidelberg, Germany, 2018)

Jacobson, B. O. (1991). Rheology and elastohydrodynamic lubrication (Vol. 19). Elsevier.

Johnson, J. M., and Conforti F. D. (2003). Fructose: Encyclopedia of Food Sciencesand Nutrition (Second Edition), Academic press, Pages: 2748–2752. https://doi.org/10.1016/B0-12-227055-X/00529-0

N. Konar, R. Gunes, I. Palabiyik, O.S. Toker, Health conscious consumers and sugar confectionery: present aspects and projections. Trends Food Sci. Technol. 123, 57–68 (2022). https://doi.org/10.1016/j.tifs.2022.02.001

A. Kurt, K. Bursa, O.S. Toker, Gummy candies production with natural sugar source: Effect of molasses types and gelatin ratios. Food Sci. Technol. Int. 28(2), 118–127 (2022). https://doi.org/10.1177/10820132219935

Lees, R. & Jackson, E. B. (1995). Sugar Confectionery and Chocolate Manufacture. Springer, published: Aspen Publishers Inc.,U.S. ; New edition (31 December 1995).

P.H. Marfil, A.C. Anhê, V.R. Telis, Texture and microstructure of gelatin/corn starch-based gummy confections. Food Biophys. 7, 236–243 (2012). https://doi.org/10.1007/s11483-012-9262-3

M.P. Molina-Rubio, N.B. Casas-Alencáster, L.P. Martinez-Padilla, Effect of formulation and processing conditions on the rheological and textural properties of a semi-liquid syrup model. Food Res. Int. 43(3), 678–682 (2010). https://doi.org/10.1016/j.foodres.2009.10.023

D. Mihaylova, A. Popova, Z. Goranova, D. Petkova, P. Doykina, A. Lante, The perspective of nectarine fruit as a sugar substituent in puddings prepared with corn and rice starch. Foods 10(11), 2563 (2021). https://doi.org/10.3390/foods10112563

C. Mutlu, S.A. Tontul, M. Erbaş, Production of a minimally processed jelly candy for children using honey instead of sugar. LWT 93, 499–505 (2018). https://doi.org/10.1016/j.lwt.2018.03.064

H. Önder, A.Y. Aydar, Şekerleme üretiminde kullanilan hammaddeler ve fonksiyonel yumuşak şekerleme üretimi. Aydın Gastronomy 6(1), 65–78 (2022)

R.S. Norrish, Selected tables of physical properties of sugar solutions (Wiley-Blackwell. Cham, British food manufacturing industries research association, 1967)

A. Periche, A. Heredia, I. Escriche, A. Andrés, M.L. Castelló, Potential use of isomaltulose to produce healthier marshmallows. LWT-Food Sci. Technol. 62(1), 605–612 (2015)

D.G. Pereira, M.D.T. Benassi, A.D.P. Beleia, Gummy candies produced with acid-thinned cassava starch: physical and sensory evaluation. J. Food Process. Preserv. 46(7), e16661 (2022). https://doi.org/10.1111/jfpp.16661

Precedence research. (2023). Food and beverages-confectionery market. https://www.precedenceresearch.com/confectionery-market. Accessed: 04.01.2024

H.M. Pancoast, W.R. Junk, Handbook of sugars (Publisher, AVI Pub. Co, 1980), p.598

Rao, M. A. (2013). Rheology of fluid, semisolid, and solid foods: principles and applications. Third edition. Springer Science & Business Media.

G. Renaldi, K. Junsara, T. Jannu, N. Sirinupong, R.S. Samakradhamrongthai, Physicochemical, textural, and sensory qualities of pectin/gelatin gummy jelly incorporated with Garcinia atroviridis and its consumer acceptability. Int. J. Gastronomy Food Sci. 28, 100505 (2022). https://doi.org/10.1016/j.ijgfs.2022.100505

M.B. Sudharsan, G.R. Ziegler, J.L. Duda, Modelling diffusion of moisture during stoving of starch-molded confections. Food Bioprod. Process. 82(1), 60–72 (2004). https://doi.org/10.1205/096030804322985335

P. Subramaniam, The stability and shelf life of confectionery products (Woodhead Publishing, In the stability and shelf life of food, 2016). https://doi.org/10.1016/B978-0-08-100435-7.00019-8

Q. Sun, Y. Xing, C. Qiu, L. Xiong, The pasting and gel textural properties of corn starch in glucose, fructose and maltose syrup. PLoS ONE 9(4), e95862 (2014). https://doi.org/10.1371/journal.pone.0095862

G. Sgualdino, G. Vaccari, G. Mantovani, D. Aquilano, Glucose and fructose adsorption on sucrose crystals (Crystal Research and Technology, Their role as habit modifiers, 1997). https://doi.org/10.1002/crat.2170320807

M. Tarahi, S. Tahmouzi, M.R. Kianiani, S. Ezzati, S. Hedayati, M. Niakousari, Current innovations in the development of functional gummy candies. Foods 13(1), 76 (2023). https://doi.org/10.3390/foods13010076

M. Takahashi, M. Iijima, K. Kimura, T. Hatakeyama, H. Hatakeyama, Thermal and viscoelastic properties of xanthan gum/chitosan complexes in aqueous solutions. J. Therm. Anal. Calorim. 85(3), 669–674 (2006)

S. Tireki, G. Sumnu, S. Sahin, Correlation between physical and sensorial properties of gummy confections with different formulations during storage. J. Food Sci. Technol. (2021). https://doi.org/10.1007/s13197-020-04923-3

M.A. Vieira, A.A. Rovaris, M. Maraschin, K.N. De Simas, C.M. Pagliosa, R. Podestá, E.R. Amante, Chemical characterization of candy made of erva-mate (Ilex paraguariensis A. St. Hil.) residue. J. agric. food chem. 56(12), 4637–4642 (2008). https://doi.org/10.1021/jf8011085

Y. Zhang, R. Pandiselvam, H. Zhu, D. Su, H. Wang, Z. Ai, Y. Liu, Impact of radio frequency treatment on textural properties of food products: an updated review. Trends Food Sci. Technol. 124, 154–166 (2022). https://doi.org/10.1016/j.tifs.2022.04.014

Acknowledgements

The authors all authors declare no acknowledgements

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Ethical approval

This article does not contain any studies with animal subjects. The sensory analyses were conducted under the safe food production and with no problem from Food engineering department.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bulca, E.N., Akdeniz, E., Mutlu, Z. et al. Influence of various corn syrup types on the quality and sensory properties of gelatin-based jelly confectionery. Food Measure (2024). https://doi.org/10.1007/s11694-024-02809-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11694-024-02809-y