Abstract

The climate targets set out in the “European Green Deal” call for the consideration and implementation of climate-friendly propulsion concepts and sustainable fuels in future aircraft configurations. This puts the use of very efficient propeller engines into the focus of aircraft design. However, these pose major challenges, especially to cabin acoustics, due to high, tonal sound pressure levels on the fuselage. The design of noise control measures requires the competence to predict the resulting interior noise as early as possible in the design process of the vehicle. This requires a high level of geometric and structural detail regarding the fuselage structure and cabin components. With increasing frequency range, the necessary structural details also increase, which have to be resolved in the simulation models due to the associated decreasing structural wavelength. Especially in the context of aircraft pre-design, there is usually not enough information available for a detailed vibro-acoustic modeling of the fuselage and cabin components, which allows a meaningful prediction of the vibrations and thus the cabin noise. Therefore, the knowledge-based tool Fuselage Geometry Assembler (FUGA) is developed for the targeted enrichment of preliminary design data with knowledge for detailed numerical analyses. This paper describes the knowledge-based geometry and model generation in FUGA, which can consider the necessary (increasing) level of detail for the vibro-acoustic prediction already in the preliminary design. For this purpose, aircraft data sets in the preliminary design data format Common Parametric Aircraft Configuration Schema (CPACS) form the modeling basis. Originating from the aircraft preliminary design, these initially describe the outer shell of the vehicle and are extended by detailed structural information that defines the geometric boundary conditions for component placement in cabin design. For the cabin components, the open-source geometry kernel Open Cascade Technology (OCCT) is used to provide geometries at the level of detail required for subsequent analyses. The geometry models are then discretized in open source (e.g. Gmsh) or commercial meshers and further used for numerical analysis. Finally, the prediction of cabin noise is demonstrated as a Proof of Concept using the example of a short-haul propeller-driven aircraft and the feasibility of the proposed method is indicated by investigating the sensitivity of resulting simulation models to the fuselage skin thickness.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The prediction and evaluation of interior noise for the cabins of novel aircraft concepts is a complex process, which brings together the expertise of different disciplines. Since human hearing covers a wide frequency range, the models and details considered therein must be built according to the principles of the particular method used. Peiffer [1] gives a comprehensive overview in which frequency range which method has to be used for vibro-acoustic simulation. In the low-frequency range, in which the global structural behavior is largely deterministic in nature, the Finite Element Method (FEM) can be used. In the high-frequency range, on the other hand, which can be characterized largely by statistically distributed local vibration modes, the Statistical Energy Analysis (SEA) is applied. The mid-frequency transition region is characterized by a superposition of global structural modes and statistically distributed local modes. This region is especially difficult to characterize with methods of experimental modal analysis [2] as well as to validate simulatively. According to Peiffer, hybrid methods from FEM and SEA are used here in particular. Alternatively, Dynamic Energy Analysis (DEA) operating on the discretized meshes of the FEM offers a promising alternative for use in the high frequency range [3]. In order to generate vibro-acoustic modeling guidelines [4] for the various analysis models and to match and validate them with experimental measurement data, a research platform of a fuselage section with internal cabin equipment [5] was created with the Acoustic Flight-Lab.

Excitation sources of cabin noise can be induced by the flow around the aircraft, generated by the engines, as well as by internal systems and aggregates. A complete calculation chain from engine installation to cabin noise analysis is described by Omais [6]. In particular, the importance of holistic consideration of installation effects on the quality of the cabin noise prediction is emphasized when counter-rotating open rotors are used as sources of noise. Furthermore, imbalances in the engines can also cause vibration, which, for example, transmits through the wing structures into the cabin interior [7]. Blech et al. [8, 9] highlight the need to use a wave-resolving discretization of the relevant structural and acoustic regions even in the presence of broadband excitation by the engine jet.

The objective of the present work is to provide a cabin noise prediction capability from preliminary design data using a novel propeller engine aircraft configuration. A knowledge-based engineering (KBE) design methodology is used to calculate additional design details and generate wave-resolving computational models at the overall aircraft design level.

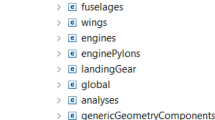

The fundamentals of knowledge-based geometry and model generation in Fuselage Geometry Assembler (FUGA) for cabin noise prediction are described by the authors [10]. As a modeling basis, aircraft concepts in the preliminary design data format Common Parametric Aircraft Configuration Schema (CPACS, www.cpacs.de) [11] are used. These originate from the aircraft pre-design tool openAD [12] and initially describe mostly the geometry of the outer envelope of the vehicle. The pre-designs are then extended in FUGA by detailed structural information that defines the boundary conditions in the cabin design. For the cabin components, the open-source geometry kernel Open Cascade Technology (OCCT) [13] is used to provide geometries at the level of detail required for subsequent analyses. Here, the geometry models are subsequently discretized using the open source meshing library Gmsh [14]. Geometries including material properties can also be exported for meshing in commercial tools [15] and further used for numerical analysis.

For this knowledge-based methodology described in Sect. 2, this paper describes an extension compared to Hesse et al. [10] to include additional, geometric details. These include, for example, the specific assignment of material properties of the various skin field segments, the structural modeling of window geometries and the cargo hold as well as the meshing of interior cavities and the automated setup of fluid–structure interaction (FSI). While the detailed skin properties and window cutouts can be used, for example, to account for structural changes in terms of structural shielding against propeller release, cavity meshing including FSI allows for consideration of insulating materials as well as prediction of the distribution of sound pressure levels in the cabin interior. The calculation of interior noise resulting from these structural measures is performed in Sect. 3. Section 4 concludes the paper with a final discussion.

2 Knowledge-based methodology

In this article, Sect. 2.1 first describes the KBE methodology, which is implemented in FUGA and used for the derivation of multi-fidelity geometries. Subsequently, Sect. 2.2 gives an overview of the rules for fuselage and cabin design, on the basis of which solver-agnostic FE models for the calculation of sound transmission into the cabin interior are generated automatically, as described in Sect. 2.3.

2.1 Fuselage Geometry Assembler

In the FUGA tool implemented in the Python programming language, a knowledge-based design methodology (KBE) is implemented. Since this KBE methodology as well as its graph-based implementation is described very comprehensively in Walther et al. [16], only a brief overview of the main components is given here. The KBE methodology is composed of the following three building blocks:

-

a data repository, which contains the available product data,

-

the knowledge repository, including all design rules,

-

an inference engine, which defines the execution order of the rules.

The role of the data repository in the present work is largely taken over by the description of considered structures in the product model CPACS in its current version 3.5. The detailed definition of the fuselage structure of transport aircraft in CPACS can be taken from Scherer and Kohlgrüber [17] whereas the aircraft cabin and its components are described in Walther et al. [18].

Design rules are implemented in executable Python classes that inherit from a common base class. Each rule returns a value in the data repository, which can contain (CPACS-native or -foreign) data in any form, e.g. numerical values, tables, geometries, but also computational meshes and parameters for finite element models.

In FUGA, a graph-based inference engine based on the Python package NetworkX [19] is used. These building blocks can be used to extend the available design details for the aircraft configuration described within a CPACS dataset and consistently generate additional product data in the form of additional entries in the data repository. This KBE methodology implemented in FUGA is the basis for an automated generation of CAD geometries described in the following section.

2.2 Rulesets for fuselage and cabin design

In this section, an overview of the rule formulation is given for the model generation in coupled fuselage and cabin design. The model setup for cabin noise prediction is divided into CAD-based geometry design and automated meshing as well as property assignment of these geometries.

For the geometric modeling of the primary fuselage structure, the established definition within CPACS is used [17]. The conversion rules of a CPACS data set into geometries are formulated in the form of geometry operations, which are implemented in FUGA on the basis of OCCT. Furthermore, it is possible to enrich the aircraft design with additional cabin- and structure-specific knowledge by means of executing design rules from the knowledge repository for fuselage and cabin design. The fundamentals of knowledge-based fuselage modeling as implemented in FUGA are described by Walther and Ciampa [20]. Rules for the design of internal structural elements such as frames, stringers, as well as floor structures and pressure bulkheads are presented. An initial skin field thickness distribution is also given, although in-flight maneuvering loads are not yet considered for their calculation. Nonetheless this approach provides an efficient methodology for initializing the structure. This initial fuselage design subsequently provides the boundary condition for the placement and connection of the cabin components [21].

In the current CPACS definition for structures of the cabin lining, these are described as purchased parts [18]. Since no separate parametric description is provided for them, they are generated in FUGA with internal parameters. Geometry models calculated automatically in OCCT are shown in Fig. 1a–c using the example of a fuselage barrel. It is apparent here, that the arrangement of the sidewall panels is based, for example, on the frame spacing. Since structural details such as the window geometries are constructed from the central CPACS definition, consistency between the fuselage structure and the generated sidewall can be automatically ensured.

An essential philosophy of modeling is the constraint that resulting geometries are generated in a watertight way. If this condition is met, the interiors can be generated as solids for further processing. These solids are in turn used in the subsequent generation for the modeling of the air in the passenger cabin and cargo hold as well as the acoustic and thermal insulation. An example of the internal solids is shown in Fig. 1c, with the insulation cavity shown in beige and the passenger cavity in blue. Red, orange and gray describe other air-filled areas in the cargo hold and underfloor areas, respectively.

In addition to the presented fuselage barrel with equally distributed structural regions, special parts such as the wing-fuselage transition can also be defined and considered as geometries in the modeling for FE models. The generation of FE models from the presented geometries is described in the following chapter.

2.3 Rulesets for finite element model generation

Based on the geometry modeling for the fuselage and cabin design described in the previous section, the rules of model generation for the FEM are presented in this section. Based on the geometries generated with OCCT, wave-resolving discrete meshes for noise prediction are to be created. For this purpose, the library Gmsh is used, which provides various algorithms for meshing and is also based on geometry descriptions using OCCT.

The model generation within FUGA is performed using Gmsh as follows: All structural components are first individually meshed using shell elements with linear or quadratic shape functions under specification of a maximum element size. Subsequently, structural connections are created using rivets or vibration isolators via corresponding spring or fastener elements. Figure 1d–f gives an overview of exemplary FE computational meshes, which were calculated with the previously presented approach. The assigned property IDs are plotted in color. Finally, the cavity solids are discretized and the FSI is defined at selected surfaces. Currently, linear as well as quadratic tetrahedra are supported for fluid meshing. Since structural components and cavities are meshed independently, the FSI-definition at interaction surfaces is formulated using non-conformal meshes. On the structure side, the fuselage surface, floor panels as well as the cabin linings are currently considered for coupling to the air cavities. The model creation is not tailored to a specific FE software, but solver-agnostic and the models can be exported for calculation in Nastran and Ansys.

3 Prediction of cabin noise

In this chapter, cabin noise prediction is performed in cruise flight condition and the sensitivity to the fuselage skin thickness is investigated. For this purpose, first in Sect. 3.1, the considered aircraft configurations are presented and in Sect. 3.2, the acoustic excitation generated by the propellers is described. In Sect. 3.3, the simulated results of the configurations are presented and compared for two different fuselage thickness distributions.

3.1 Aircraft configuration

The DLR project EXACT (Exploration of Electric Aircraft Concepts and Technologies) has set itself the task of investigating aircraft concepts that can significantly reduce the environmental impact of future air traffic [22]. The reductions in greenhouse gas emissions should not come at the expense of noise emissions into the cabin. Therefore, the ability to evaluate cabin acoustics from the preliminary aircraft design for as many different configurations as possible is needed to assess potentials of a multitude of aircraft configurations as early as possible. Due to high efficiency potentials, the targeted emission reduction puts the focus on the use of liquid hydrogen fueled propeller engines as propulsion systems [23, 24]. The short-haul aircraft configuration from the EXACT project considered here can accommodate 240 passengers according to the cabin plan shown in Fig. 2. Furthermore, it is equipped with two hydrogen tanks in the unpressurised part of the fuselage behind the rear pressure bulkhead containing the fuel for the powertrain. Since a high propeller radius is beneficial for the propeller efficiency and cruise efficiency decreases with increasing blade number, a high radius propeller with a low number of blades is considered for the aircraft. This leads to very low blade passing frequencies, where the traditional passive noise reduction does not yield high reductions of the noise transmission into the cabin. For more details on the aircraft configuration with an assumed entry into service of 2040, the reader is referred to Burschyk et al. [25]. The aircraft features a 7-bladed propeller with a radius of 3.2 m and a rotation frequency of \(\approx 8.8\) Hz in cruise conditions.

A special characteristic of using open rotors or propellers as opposed to shrouded engines is that additional measures must be taken in the event of rotor blade release [26]. Otherwise, they could potentially damage the fuselage at the rotor plane and injure the passengers inside. One such measure is a structural shielding in the form of thickening of the fuselage skin in the vicinity of the rotors [24]. Such a structural alteration also affects the sound transmission into the cabin, since the latter is essentially driven by the mass per unit area of the structural skin panels [27]. Here, a transmission reduction into the passenger cabin is expected due to the targeted introduction of additional mass in the area of the propeller plane, where a particularly high acoustic excitation is generated. The knowledge-based engineering approach presented in the preceding chapter allows to create simulation models to investigate the influence of such a measure introduced in the early design stages of an aircraft.

The two considered aircraft configurations are shown in Fig. 3, where configuration \(\mathbb {B}\) has additional shielding against the release of a propeller blade compared to configuration \(\mathbb {A}\). Configuration \(\mathbb {B}\) is additionally shown in Fig. 4 in a side view. The dimensioning of the additional thickening was based on the work of Ritter [24]. In the dark gray skin area, the full thickening is considered; in the gray skin area above, the thickening is \(70\%\) of the maximum thickness. In addition, no windows are present in the shielding region thus yielding a reduced passenger comfort but counteracting an additional structural weakening.

It should be noted at this point that the configuration \(\mathbb {A}\) does not seem to make much sense in this form, since a safety precaution such as a shielding according to [26] must be present in any case. Nevertheless, a comparison of the resulting sound pressures in the cabin for both configurations allows for an evaluation of the influence, which results from an additional shielding.

3.2 Propeller excitation

The noise field generated by the propellers on the outer skin of the fuselage is to be used as an excitation for the cabin noise prediction. The cabin noise is calculated in the form of a harmonic analysis in the frequency domain. Accordingly, the excitation is imposed as pressure fluctuations in the harmonic frequencies corresponding to the integer multiples of the blade passing frequency (BPF). As the most dominant excitation is provided in the first three harmonic frequencies of the BPF, these are investigated in the following section. A comprehensive overview of calculation methods for propeller noise in the frequency domain is given by Kotwicz Herniczek et al. [28].

In the present work, the sound pressure distribution on the fuselage skin is calculated according to [29]. This empirical method is characterized by a fast calculation, which is based on the global design data from the propeller and does not require a detailed design of the blade geometry. The resulting excitation of the left-sided propeller in the flight direction on the fuselage surface at the BPF is shown in Fig. 5. Due to the solver-agnostic generation of the FE models using FUGA according to Sect. 2.3, the excitation can be applied to both Nastran and Ansys models. For Nastran it is exported in the form of PLOAD4 entries; for Ansys, on the other hand, additional SURF154 elements are generated on the hull surface, on which the pressurization is defined.

3.3 Vibro-acoustic evaluation

The resulting cabin noise is calculated under the excitation described at the previous chapter. For this purpose, the simulation models created in FUGA of the two aircraft configurations presented in Sect. 3.1 are used. The simulation model of the fuselage structure of configuration \(\mathbb {A}\) is shown in Fig. 6. In addition to the FE models presented in Sect. 2.3 on a fuselage barrel, additional structures are shown here on the whole fuselage level, such as the pressure bulkheads, the wing box including the keelbeam, and the hydrogen tanks placed in the aft fuselage segment. The respective property ids with unique materials and skin thicknesses of the FE model are depicted here by the different colours, showcasing e.g. the realisation of the panel segmentation as well as the window layout shown in Fig. 3. The cabin lining and fluid are defined analogously to Fig. 1 over the entire cabin area. In the air-filled cargo cavity, there is an additional cutout from the wing box.

In the present work, the calculation is performed using SOL 108 in Nastran. With a number of \(\approx 16.4\cdot 10^6\) degrees of freedom, the solution takes about 7600 s per frequency on a CPU of the type Intel™ Xeon™ Gold 5120 CPU @ 2.20GHz. The influence of the additional fuselage shielding on the interior noise is shown in Fig. 7. This shows the sound pressure level reduction \(\Delta L_p\), which is defined as

in the listening plane of the passengers in the cabin. This listening plane was assumed to be at 1.3 m above floor level at which the FE model was cut and the sound pressure was evaluated at the remaining nodes. It becomes evident in Fig. 7, that a lot of local effects occur regarding the reduction or increase of sound pressure. This is due to the resonant behaviour of the fuselage structure, the cabin linings and the acoustic cavities in the low-frequency regime.

For a global comparison of both configurations, the acoustic potential energy (APE) \(E_{pot}\) is considered, which is calculated as

Through the volume integral of all sound pressure squares, it thus represents a global measure for the radiated interior noise. A qualitative comparison of the APE level (\(L = 10 \log (E_{pot}/E_0)\,\text{dB, reference $E_0 = 10^{-12}\,$J}\) dB) is depicted in Fig. 8. In the BPF, an increase of 2.1 dB can be observed in the passenger cabin, whereas in the second harmonic of the BPF, a reduction of 1.5 dB results. Thereby, according to Fig. 7b, a strong reduction of the sound pressure levels is especially noticeable in the vicinity of the propeller plane. In the third harmonic of the BPF, the APE is reduced slightly by 0.6 dB. Analysis of additional metrics, such as structural and acoustic intensity [30] and modal characteristics of the primary structure, respectively, may provide further insight into the mechanisms of the sound reduction.

It is also noticeable in Fig. 8, that although the noise is increased in the fundamental BPF, there is an overall reduction in cabin noise with additional thickening. In the low-frequency regime, the structural modes dominate the sound radiation into the aircraft cabin. Therefore, the added mass shifts a modal eigenfrequency of the fuselage structure closer to the fundamental BPF. These results are nonetheless indicative that, as expected, the increase in mass on the primary structure is accompanied by an overall reduction in acoustic radiation into the cabin. This demonstrates the prediction of cabin noise from pre-design aircraft data of a short-haul propeller-driven aircraft and the feasibility of the proposed method as indicated by the sensitivity analysis of resulting simulation models to the fuselage skin thickness.

4 Conclusion

This paper describes the knowledge-based model generation of prediction models for aircraft cabin noise. This represents a decisive step towards estimating the influence of design changes to the fuselage or cabin lining on cabin noise from the aircraft preliminary design. As an exemplary design measure, the shielding against the release of propeller blades was investigated, which results in a reduction of cabin noise especially in the second and third harmonic of the blade passing frequency. Here, significant progress was made in noise prediction at the overall aircraft level from pre-design data through the automated generation of wave-resolving simulation models including the fluid–structure interaction implemented in FUGA.

The modeling for the cabin noise prognosis covers many essential details which are not yet necessarily known in the aircraft preliminary design. For this reason, the prediction models contain many assumptions which must be validated in further work and checked for credibility. To this end, experimental characterizations on realistic aircraft fuselage structures are carried out [30] with the goal to have common modeling guidelines and update parameters and properties of the automatically generated FE models [4, 31]. The equally-distributed thickness (apart from the blade release shielding) of the fuselage skin assumed here is acceptable for the comparative analysis of two configurations. In the future, the thickness distribution of the skin fields should be taken from a panel and beam sizing process taking into account the realistic maneuvering loads; such a sizing process is described by Sinha and Klimmek [32]. With CPACS as a common data basis, the conditions for a consistent consideration of structural design and vibroacoustics are given.

Future work will also add geometrically more sophisticated methods for describing and vibro-acoustically modeling additional systems, the cabin seats, as well as the thermal and acoustic insulation. Furthermore, solver efficiency plays an essential role in large-scale simulations [33, 34] and is a key limitation in the models presented in this work. For this purpose, methods are investigated to provide and solve the simulation models with appropriate fidelity for the problem under consideration. Since the model generator FUGA described in this thesis was implemented solver-agnostically, exporting it to open source computational code like the Elementary Parallel Solver (elPaSo) [35] is also in active development, which will enable further research towards solution efficiency and model order reduction methods.

Data Availability

Selected data sets generated during the current study are available from the corresponding author on reasonable request.

References

Peiffer, A.: Full frequency vibro-acoustic simulation in the aeronautics industry. In: Proceedings (Keynote) of ISMA 2016 Including USD 2016 International Conference on Uncertainty in Structural Dynamics, Leuven, pp. 1–15 (2016)

Biedermann, J., Winter, R., Wandel, M., Böswald, M.: Energy based correlation criteria in the mid-frequency range. J. Sound Vib. 400, 457–480 (2017)

Zettel, S.F., Winter, R., Norambuena, M., Böswald, M., Richter, M., Tanner, G.: Finite element method and dynamical energy analysis in vibroacoustics - a comparative study. In: 50th International Congress and Exposition of Noise Control Engineering, INTER-NOISE 2021, pp. 1–11 (2021). https://elib.dlr.de/144699/

Dewald, R.D., Klimmek, T., Algermissen, S., Hesse, C., Winter, R.: Angepasste Modellierungsvorschriften für vibroakustische Untersuchungen von Flugzeugrümpfen. In: 49. Jahrestagung für Akustik (DAGA) (2023). https://elib.dlr.de/194901/

Wandel, M., Thomas, C., Teschner, M.: Acoustic Flight-Lab–Eine einzigartige Integrationsplattform zur Optimierung vibro-akustischer Maßnahmen an Flugzeugen. 49. Jahrestagung für Akustik (DAGA) (2023)

Omais, M., Biedermann, J., Wandel, M.: From engine integration to cabin noise: drivers to accurate interior noise evaluations. In: INTER-NOISE and NOISE-CON Congress and Conference Proceedings, vol. 253, pp. 4010–4021 (2016). Institute of Noise Control Engineering

Zettel, S.F., Böswald, M., Winter, R.: Jet-engine vibration model for the estimation of pylon-wing interface loads. In: DAGA 2023 (2023). https://elib.dlr.de/194823/

Blech, C., Appel, C.K., Ewert, R., Delfs, J.W., Langer, S.C.: Numerical prediction of passenger cabin noise due to jet noise by an ultra-high-bypass ratio engine. J. Sound Vib. 464, 114960 (2020)

Blech, C.: Wave-resolving Aircraft Cabin Noise Prediction. PhD thesis, TU Braunschweig (2022)

Hesse, C., Walther, J.-N., Allebrodt, P., Wandel, M., Algermissen, S., Dewald, R.D.: Wissensbasierte Modellgenerierung für die Vorhersage von Kabinenlärm im Kontext des Flugzeugvorentwurfs. In: 49. Jahrestagung für Akustik (DAGA) (2023). https://elib.dlr.de/194485/

Alder, M., Moerland, E., Jepsen, J., Nagel, B.: Recent advances in establishing a common language for aircraft design with CPACS. In: Aerospace Europe Conference 2020 (2020). https://elib.dlr.de/134341/

Wöhler, S., Atanasov, G., Silberhorn, D., Fröhler, B., Zill, T.: Preliminary aircraft design within a multidisciplinary and multifidelity design environment. In: Aerospace Europe Conference 2020 (2020). https://elib.dlr.de/185515/

Paviot, T.: Pythonocc. https://github.com/tpaviot/pythonocc-core. https://doi.org/10.5281/zenodo.7471333

Geuzaine, C., Remacle, J.-F.: Gmsh: a 3-D finite element mesh generator with built-in pre-and post-processing facilities. Int. J. Numer. Methods Eng. 79(11), 1309–1331 (2009)

Algermissen, S., Hesse, C., Dewald, R.D.: Automatisierte Modellerstellung zur Berechnung von Innenlärm in Flugzeugen. In: 49. Jahrestagung für Akustik (DAGA), pp. 569–572 (2023). https://elib.dlr.de/194812/

Walther, J.-N., Hesse, C., Biedermann, J., Nagel, B.: Extensible aircraft fuselage model generation for a multidisciplinary, multi-fidelity context. In: ICAS 2022 (2022). https://elib.dlr.de/189459/

Scherer, J., Kohlgrüber, D.: Fuselage structures within the CPACS data format. Aircraft Eng. Aerosp. Technol. 88(2), 294–302 (2016)

Walther, J.-N., Hesse, C., Alder, M., Biedermann, J., Nagel, B.: Expansion of the cabin description within the CPACS air vehicle data schema to support detailed analyses. CEAS Aeronaut. J. 13, 1119–1132 (2022)

Hagberg, A., Swart, P., S Chult, D.: Exploring network structure, dynamics, and function using NetworkX. Technical report (2008)

Walther, J.-N., Petsch, M., Kohlgrüber, D.: Modeling of CPACS-based fuselage structures using Python. Aircraft Eng. Aerosp. Technol. 89(5), 644–653 (2017)

Walther, J.-N., Kocacan, B., Hesse, C., Gindorf, A., Nagel, B.: Automatisierte Kabinenvirtualisierung auf Basis von Flugzeugvorentwurfsdaten. In: DLRK 2020 (2020). https://elib.dlr.de/135956/

Silberhorn, D., Dahlmann, K., Görtz, A., Linke, F., Zanger, J., Rauch, B., Methling, T., Janzer, C., Hartmann, J.: Climate impact reduction potentials of synthetic kerosene and green hydrogen powered mid-range aircraft concepts. Appl. Sci. 12(12), 5950 (2022)

Atanasov, G., Silberhorn, D., Wassink, P., Hartmann, J., Wöhler, S., Dzikus, N., Fröhler, B., Zill, T., Nagel, B.: Short medium range turboprop-powered aircraft as an enabler for low climate impact. In: Deutscher Luft- und Raumfahrtkongress (DLRK) (2021). https://elib.dlr.de/148094/

Ritter, J.: Design and Assessment of Open Rotor Aircraft Concepts. Institut für Flugzeugbau, Universität Stuttgart, Masterarbeit (2023)

Burschyk, T., Silberhorn, D., Wehrspohn, J., Kühlen, M., Zill, T.: Scenario-based implications of liquid hydrogen storage tank insulation quality for a short-range aircraft concept. In: AIAA AVIATION 2023 Forum, p. 3522 (2023)

Advisory Circular: AC20-128A - Design Considerations for Minimizing Hazards caused by Uncontained Turbine Engine and Auxiliary Power Unit Rotor Failure. Federal Aviation Administration, Boston (1997)

Deutsche Gesellschaft für Akustik: DEGA-Empfehlung ‘Akustische Wellen und Felder’ (2006)

Kotwicz Herniczek, M.T., Feszty, D., Meslioui, S.-A., Park, J., Nitzsche, F.: Evaluation of acoustic frequency methods for the prediction of propeller noise. AIAA J. 57(6), 2465–2478 (2019)

Society of Automotive Engineers, Inc.: AIR1407: Prediction Procedure for Near-Field and FarField Propeller Noise. Warrendale, PA, USA, 1977. https://doi.org/10.4271/AIR1407A.

Winter, R., Biedermann, J., Norambuena, M.: High-resolution vibration measurement and analysis of the Flight-Lab aircraft fuselage demonstrator. In: INTER-NOISE 2018 - 47th International Congress and Exposition on Noise Control Engineering: Impact of Noise Control Engineering (2018). https://elib.dlr.de/122597/

Hesse, C., Dewald, R.D., Allebrodt, P., Winter, R., Biedermann, J.: Sensitivitätsanalyse für die numerische Vorhersage von Kabinenlärm in Flugzeugen. In: DAGA 2024 - 50. Jahrestagung für Akustik (2024). https://elib.dlr.de/204156/

Sinha, K., Klimmek, T.: A framework for the bi-level optimization of a generic transport aircraft fuselage using aeroelastic loads. CEAS Aeronaut. J. 14, 127–137 (2022)

Sreekumar, H., Blech, C., Langer, S.: Large-scale vibroacoustic simulations using parallel direct solvers for high-performance clusters. In: 47. Jahrestagung für Akustik (DAGA) (2021)

Hüpel, Y., Blech, C., Sreekumar, H.K., Langer, S.C.: Efficient solutions of preconditioned large-scale systems for simulative aircraft cabin noise assessment. Proc. Appl. Math. Mech. 23, 202300102 (2023)

Sreekumar, H.K., Blech, C., Langer, S.C.: Sustainable development and deployment of an acoustic FEM research software. In: 49. Jahrestagung für Akustik (DAGA) (2023)

Acknowledgements

The authors would like to thank the Hamburgische Investitions- und Förderbank (IFB Hamburg) for funding the activities in the CATECO project (Cabin Acoustics at the hearT of ECO-responsibility) under the GATE funding program (Green Aviation TEchnologies).

Funding

Open Access funding enabled and organized by Projekt DEAL. This study was funded by Hamburgische Investitions- und Förderbank (IFB Hamburg).

Author information

Authors and Affiliations

Contributions

C.H. wrote the main manuscript text and conducted the analyses. P.A. contributed to the software developed for the study. M.T. provided guidance and the acoustic excitation from the propeller engines. J.B. contributed to the conception and acquisition of the work. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hesse, C., Allebrodt, P., Teschner, M. et al. Knowledge-based model generation for aircraft cabin noise prediction from pre-design data. CEAS Aeronaut J (2024). https://doi.org/10.1007/s13272-024-00769-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13272-024-00769-z