Abstract

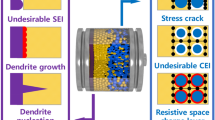

Lithium metal is considered a highly promising anode material because of its low reduction potential and high theoretical specific capacity. However, lithium metal is prone to irreversible side reactions with liquid electrolytes, resulting in the consumption of metallic lithium and electrolytes due to the high reactivity of lithium metal. The uneven plating/stripping of lithium ions leads to the growth of lithium dendrites and battery safety risks, hindering the further development and commercial application of lithium metal batteries (LMBs). Constructing solid-state electrolyte (SSE) systems with high mechanical strength and low flammability is among the most effective strategies for suppressing dendrite growth and improving the safety of LMBs. However, the structural defects, intrinsic ionic conductivity, redox potential and solid-solid contacts of SSEs can cause new electrochemical problems and solid-phase dendrite growth drawbacks in the application of solid-state batteries (SSBs). In this review, the mechanisms of lithium dendrite growth in SSEs are comprehensively summarized. Strategies to suppress lithium dendrite growth, stabilize the interface, and enhance ion transport in organic, inorganic and composite SSEs are emphasized. We conclude with not only relevant experimental findings but also computational predictions to qualitatively and quantitatively characterize the ionic conductivity, interfacial stability and other properties of SSEs based on both chemical and physical principles. The development direction and urgent problems of SSEs are summarized and discussed.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Lithium-ion batteries (LIBs) with high energy densities, high output voltages, and long lifespans are widely used in electric vehicles, mobile wearable devices, smart power grids and so forth. To date, traditional nonaqueous LIBs are based on flammable and explosive organic solvents, which pose a great safety hazard for practical applications. Furthermore, the limited specific capacity of widely used graphite anodes (theoretical specific capacity: 372 mAh g−1) cannot effectively support the step-forward development of energy-dense rechargeable batteries. In addition to LIBs, lithium metals with a high theoretical specific capacity (3 860 mAh g−1), extremely low reduction potential (− 3.04 V vs. a standard hydrogen electrode) [1,2,3,4,5,6] and excellent mechanical flexibility are acknowledged as ideal anode materials to meet the requirements of high energy density batteries. However, the practical application of lithium metal anodes is greatly hindered by the dramatic growth of dendrites and the cascade thermal runaway process. The dendrite filaments formed during electrochemical deposition can penetrate through the separator and induce short circuits in cells. Dendritic lithium is prone to detach from lithium electrodes and becomes a well-known “dead Li”, causing electrical departure, the loss of active materials and shortening of the cycle lifespan of lithium metal batteries (LMBs). Due to the high reactivity of lithium metals, side reactions continuously occur to deplete the organic electrolyte and compromise interfacial stability. Such interface problems increase the resistance and reduce the Coulombic efficiency and the cycle stability. Furthermore, the repeated lithium deposition/stripping process causes a large volume variation with infinite volume expansion, which destroys the solid-electrolyte interface (SEI), thickens the SEI layer, lowers the Coulombic efficiency and exaggerates the interfacial issues. Due to the inherent thermodynamic instability of lithium metal anodes in organic electrolytes, SSEs and SSBs have been highlighted to eliminate the drawbacks of lithium deposition in liquid electrolytes and can potentially be the ultimate solution. SSEs permit a high lithium ion transference number, a wide electrochemically stable voltage window (up to 5 V), thermal stability and separator-free cell stacking, which allow for a higher energy density and better safety than those of their liquid counterparts. However, issues of dendrite growth and interfacial instability in conjunction with lithium metal anodes remain challenging in SSBs, limiting the development of LMBs.

In recent years, a great deal of attention has been given to deepen the understanding of the fading mechanism of lithium metal anodes and better inhibit the growth of lithium dendrites in SSBs. This paper summarizes recent studies on the mechanism of lithium dendrite growth in SSEs and SSBs. Various approaches developed to solve key challenges in organic, inorganic, and composite SSEs are reviewed and discussed, as are the advances and improvements for inhibiting lithium dendrite growth (Figs. 1, 2). An outlook for an in-depth understanding of the dendrite problem in solid-state lithium metal batteries and the development of practical batteries is essentially provided.

1.1 Growth Mechanisms and Strategies for the Suppression of Lithium Dendrites

Dendritic filament formation during the electrodeposition of lithium metals is a result of multiple factors, and a step-by-step understanding of dendrite growth mechanisms is accompanied by parallel explorations among liquid-based, semisolid-state and all-solid-state LIBs, which can be traced back to the 1990s (Fig. 3). Due to its high reactivity, lithium metal undoubtedly undergoes a series of side reactions with liquid electrolytes, which irreversibly consume lithium and electrolytes, reducing battery utilization [7]. Different from the interstitial intercalation mechanism, lithium ions are continuously plated/stripped onto a lithium metal anode substrate during the charging and discharging processes. An ideal Li plating/exfoliation process should be uniform, consistent and preferably two-dimensional. As expected, such plating/stripping processes are affected by various factors [8]. The deposition of lithium ions at the interface is often uneven, which is the root of lithium dendrite growth and electrochemical performance deterioration (capacity fading, lower Coulomb efficiency, etc.), and the main reason hindering the overall application of lithium metal anodes. Due to the “tip effect”, once a lithium dendrite is generated, more charges accumulate at the tip, which triggers selective lithium deposition at the tip and results in continuous dendrite growth. The morphologies of dendrites generally include needle-like, mossy, dendritic, fibrous, granular, and amorphous structures. On the one hand, when lithium dendrites break from the surface of lithium metal, the electron transport pathway is cut off and an isolated “dead lithium” structure is formed, which makes it difficult to participate in subsequent charge-discharge reactions, reducing the Coulomb efficiency, specific capacity, reversibility and other electrochemical properties of batteries [9]. On the other hand, the spreading growth of dendrites may penetrate into separators, causing short circuits inside batteries and triggering cascade thermal runaway behavior, which greatly decreases the safety and lifespan of LMBs [10, 11].

(1) Reproduced with permission from Ref. [15]. Copyright © 1998, Elsevier. (2) Reproduced with permission from Ref. [16]. Copyright © 2002, IOP Publishing. (3) Reproduced with permission from Ref. [17]. Copyright © 2003, IOP Publishing. (4) Reproduced with permission from Ref. [18]. Copyright © 2013, IOP Publishing. (5) Reproduced with permission from Ref. [14]. Copyright © 2015, arXiv. (6) Reproduced with permission from Ref. [19]. Copyright © 2015, IOP Publishing. (7) Reproduced with permission from Ref. [20]. Copyright © 2015, Elsevier. (8) Reproduced with permission from Ref. [21]. Copyright © 2018, American Chemical Society. (9) Reproduced with permission from Ref. [22]. Copyright © 2018, Elsevier. (10) Reproduced with permission from Ref. [23]. Copyright © 2017, Elsevier. (11) Reproduced with permission from Ref. [24]. Copyright © 2019, American Association for the Advancement of Science. (12) Reproduced with permission from Ref. [25]. Copyright © 2019, Elsevier. (13) Reproduced with permission from Ref. [26]. Copyright © 2020, Elsevier. (14) Reproduced with permission from Ref. [27]. Copyright © 2020, John Wiley and Sons. (15) Reproduced with permission from Ref. [28]. Copyright © 2021, The Royal Society of Chemistry. (16) Reproduced with permission from Ref. [29]. Copyright © 2021, John Wiley and Sons. (17) Reproduced with permission from Ref. [30]. Copyright © 2023, Springer Nature. (18) Reproduced with permission from Ref. [31]. Copyright © 2023, Springer Nature. (19) Reproduced with permission from Ref. [32]. Copyright © 2024, John Wiley and Sons. (20) Reproduced with permission from Ref. [33]. Copyright © 2024, American Chemical Society

Chronology of critical achievements toward understanding the growth mechanisms and suppression strategies for lithium metal dendrites.

1.1.1 Models for Lithium Dendrite Formation

Understanding and clarifying the mechanism of lithium dendrite growth are particularly valuable to effectively suppress the growth of lithium dendrites during battery operation. A long period of development underlies a variety of mechanisms and models for lithium dendrite growth, which are insufficient for tackling lithium dendrite issues [12]. Currently, the reason for the insufficient understanding of dendrite growth is not only the complexity of chemical and electrochemical liquid environments but also the significant interface deterioration, corrosive side reactions, dead Li generation and volume expansion during repeated Li+ dissolution/deposition.

-

(a)

Surface nucleation and diffusion model. A prior understanding of the formation of lithium filaments was derived from first-principle calculations by Ling et al. [13], who studied the free energy difference between Mg/Li metals from one- to three-dimensional nucleation. This difference in dimension is more prominent for Mg metals than for lithium metals due to the stronger Mg–Mg bond strength, as a result of which the Mg metal is prone to deposition through a high-dimensional pathway rather than one-dimensional (1D) whiskers. For the same reason, lithium prefers to form a 1D morphology, generating lithium filaments and becoming a well-known obstacle to the implementation of liquid-based LMBs. The surface nucleation and diffusion model was further explained by Ozhabes et al. [14], who performed density functional theory (DFT)-based calculations to determine the surface diffusion barriers and surface energy among several solid-electrolyte interphase (SEI) components [Fig. 3(5)]. From a thermodynamic perspective, an SEI component with a higher surface energy offers greater resistance to dendrite formation, and a component with fast Li+ ion diffusion, for instance, a component with a low diffusion barrier, is less likely to form dendrites. Based on these DFT results, a lithium-halide SEI layer is subsequently suggested, which leads to an improved interface stability with a higher surface energy and a lower surface diffusion barrier, both of which are expected to enable a dendrite-free deposited morphology.

-

(b)

Heterogeneous nucleation model. The heterogeneous nucleation model describes the lithium plating behavior at the initial stage [12]. In this regard, Ely et al. [18] systematically analyzed the heterogeneous nucleation and growth of electrodeposited lithium metal anodes and defined five regimes, including the nucleation suppression, short incubation time, long incubation time, early growth, and late growth regimes [Fig. 3(4)]. Embryos in the nucleation suppression regime are thermodynamically unstable. They thus were redissolved into the electrolyte. Thermodynamically favored embryos persist and grow after thermal fluctuations in the long incubation time regime, which results in a kinetically favorable growth process. Above a critical overpotential, a short incubation time regime induces a narrow size distribution of embryos. In the early and late growth regimes, thermodynamically and kinetically stable nuclei grow and shape gradually [34].

-

(c)

Space charge model. The heterogeneous nucleation theory is no longer applicable after the initial heterogeneous nucleation, where homogeneous lithium deposition dominates the surface behavior. Therefore, Chazalievl [35] proposed the space charge model in 1990, which describes surface cation and anion migration in low-concentration electrolytes or under fast lithium deposition conditions. As expected, electric fields push directional anion and cation migration toward the positive and negative electrodes, respectively. However, when lithium ions are rapidly deposited, the anion concentration on the anode surface decreases rapidly, and this drastic concentration change creates a large electric field and space charge at the interface between the anode and the electrolyte, which induces dendrite growth [12, 36, 37]. The calculation of the Li+ ion concentration gradient based on the polarization of binary polymer Li symmetric cells was simulated by Rosso et al. [38]:

$$\frac{\partial C}{\partial x}\left(x\right)=\frac{J{\mu }_{\text{a}}}{De\left({\mu }_{\text{a}}+{\mu }_{\text{c}}\right)}$$(1)where \({\mu }_{\text{a}}\) and \({\mu }_{\text{c}}\) represent the anionic and cationic mobility, respectively; \(e\) is the elementary charge; \(D\) represents the ambipolar diffusion constant, \(D=\left({\mu }_{\text{a}}{D}_{\text{c}}+{\mu }_{\text{c}}{D}_{\text{a}}\right)/\left({\mu }_{\text{a}}+{\mu }_{\text{c}}\right)\); and \(J\) is the current density. According to Eq. (1), different lithium deposition conditions can be predicted by the interelectrode distance \(l\), initial concentration \({C}_{0}\), diffusion coefficient \(D\) and current density \(J\): when \(\text{d}c/\text{d}x<2{C}_{0}/l\), the ion concentration distribution near the negative electrode is in a stable state and exhibits a flat lithium deposition morphology; when \(\text{d}c/\text{d}x>2{C}_{0}/l\), the negative electrode ion concentration drops to zero at a particular moment (Sand’s time \({\tau }_{\text{S}}\)), while the potential tends to diverge, and the local space charge causes instability at the lithium anode to generate dendrites.

-

(d)

Solid-electrolyte interface (SEI) model. The formation of nanoscale SEI layers passivates the surface from continuous parasitic reactions, and they compete with lithium metal deposition to consume the Faradaic current, which directly impacts the root vs. tip growth mechanism. Kushima et al. [23] separated the SEI model process into four distinct stages (stage 1: hindered surface growth; stage 2: fast root growth; stage 3: hindered root growth; and stage 4: fast root growth) based on a quantitative TEM analysis [Fig. 3(10)]. They noted that a denser and thicker initial SEI was also conducive to an increase in stress, as the SEI patches tended to connect together and completely passivate the electron-donating surfaces, accelerating the root growth mode-dominated lithium deposition. Once the breakdown of the initial SEI occurs in stages 1–2, a hole forms, similar to the “fumarole” of a volcano, and the kinetics facilitate the direct deposition of lithium metal at the root, thus causing fast lithium deposition at the fumarole.

-

(e)

Sand’s time model. The initiation time of lithium dendrites in dilute solutions is usually defined as Sand’s time (\({\tau }_{\text{S}}\)). In Sand’s early studies, when a cell was polarized with a binary electrolyte at a high current density, the ionic concentration near the anode tended toward zero at Sand’s time (\({\tau }_{\text{S}}\)) [39]. Rosso et al. [38] have related Sand’s time to parameters in cells. The Sand’s time varies as follows:

$${\tau }_{\text{S}}=\uppi D{\left(\frac{{Z}_{\text{c}}e{C}_{\text{c}0}}{2J}\right)}^{2}{\left(\frac{{\mu }_{\text{a}}+{\mu }_{\text{c}}}{{\mu }_{\text{a}}}\right)}^{2}$$(2)where \({\mu }_{\text{a}}\) and \({\mu }_{\text{c}}\) represent the anionic and cationic mobility, respectively; \(e\) is the elementary charge; \(D\) is the ambipolar diffusion constant, \(D=\left({\mu }_{\text{a}}{D}_{\text{c}}+{\mu }_{\text{c}}{D}_{\text{a}}\right)/\left({\mu }_{\text{a}}+{\mu }_{\text{c}}\right)\); \({D}_{\text{a}}\) and \({D}_{\text{c}}\) are the anionic and cationic diffusion constants, respectively; \({C}_{\text{c}0}\) represents the initial cationic concentration; \(J\) is the current density; and \({Z}_{\text{c}}\) is the cationic charge number. Sand’s time model shows better predictability under a larger current density.

1.1.2 Strategies for Suppressing Lithium Dendrite Growth

Due to their inherent advantages, extensive investigations in the past few decades have been devoted to solving the problem of “how to suppress the growth of lithium dendrites” for the sake of lithium anode recovery. In this study, we have briefly summarized dendrite suppression strategies into three categories.

-

(i)

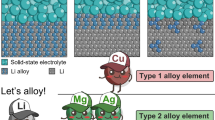

Li alloy structures. The adoption of alloying structures, such as LiAl, LiB, LiSi, LiSn and LiC [40,41,42,43], constrains the deposition and exfoliation behavior of lithium ions, thus not only reducing lithium metal side reactions but also effectively suppressing the generation of lithium dendrites [46]. Combined with nanostructure manipulation, the surface geometry configuration and charge state of lithium metal anodes are regulated and strengthened to promote an even better distribution and diffusion of lithium ions [47].

-

(ii)

Reformulating electrolytes. By changing the formula of lithium salts [40, 48], organic solvents [49, 50], and electrolyte additives [51,52,53], the interface can be modulated to some degree to form a component-favorable and electrochemistry-stable SEI layer [54,55,56], thus stabilizing the deposition and exfoliation behavior of lithium ions. One problem that should be carefully addressed is that once the additives are fully consumed, the cells will expire. Therefore, developing electrolytes to achieve an in situ self-healable SEI is critical for extending the long-term operational lifespan of LMBs.

-

(iii)

Implementing SSEs for LMBs. Taking advantage of the high Young’s modulus [57, 58], the growth and penetration of lithium dendrites can be theoretically suppressed in SSEs [59, 60]. However, recent investigations have suggested that the growth of dendrites can also occur in SSE LMB systems. Therefore, clarifying the dendrite growth mechanism, regulating the electrolyte composition and structure, and improving the ionic conductivity at room temperature and at solid-solid contacts are urgent problems that need to be solved.

1.2 Lithium Dendrite Growth Mechanisms in Solid-State LMBs

Although extensive efforts are still underway to fully understand the fundamental mechanism of lithium dendrite formation in solid electrolytes (SEs), we are attempting to provide a panoramic survey of the key parameters that determine solid-state dendrite growth (Fig. 4). Because of these inherent differences, dendrite growth in organic electrolytes is not entirely analogous to that in inorganic SEs; therefore, we discuss them separately. In solid polymer electrolytes (SPEs), the inherently low room-temperature ionic conductivity and poor mechanical properties are the main reasons for dendrite growth and penetration. Three principles to explain dendrite issues are summarized below [61].

-

(i)

Spiry or lateral dendrite growth. The electric field near the protruding spherical tip is the strongest on the electrode surface [62]. According to the constitutive model established by Monroe, lithium ions are inclined to deposit at the dendrite tip due to the effects of the surface energy and tip curvature [Fig. 3(3)] [17], and these dendrites in turn penetrate the polymer electrolyte and eventually lead to short circuits in the cell. A scheme ascribed to tip-induced dendrite growth was proposed by Dolle et al. in 2002 [Fig. 3(2)] [16]. As a supplement tip-induced dendrite growth, Dolle et al. [16] also reported that lithium dendrites can laterally propagate [Fig. 3(2)]. As deposition continues, the dendrites can even penetrate into the SEI layer and separate from both the electrode and the SE. As a result, delamination between the electrode and polymer electrolyte occurs due to the lateral growth of lithium dendrites. Poor electrolyte-electrode contact is considered the primary reason for such lateral growth of dendrites.

-

(ii)

Impurities cause uneven deposition. Inhomogeneities at local surfaces in SEs play an important role in the formation of dendritic lithium as well. The impurity particles in the electrolyte or at the interface could cause irregular Li deposition and the generation of voids. Harry et al. [19] noted that the particles are electronically insulating, preventing the deposition of lithium metal on top of these impurities. In turn, the SEI is interrupted at the edges of these impurities, leading to the deposition of lithium metal at the corners of the particles [Fig. 3(6a)]. These impurities deactivate local lithium deposition and thereafter generate voids at interface and induce inhomogeneous lithium deposition nearby [Fig. 3(6b)].

-

(iii)

Space charge layer. The potential difference between the electrolyte and electrode leads to the redistribution of lithium ions [63], and this space charge layer creates additional interfacial impedance [35]. Due to the low lithium ion transference number (\({t}_{{\text{Li}}^{+}}\)) of polymer electrolytes, anions in the electrolyte are consumed rapidly. These anions in dual-ion SPEs can move freely and then away from lithium electrodes, which leads to a large electric field and subsequently induces the growth of dendrites. In comparison, Cao et al. [25] prepared a solid-state single-ion polymer electrolyte with high ionic conductivity for dendrite-free LMBs [Fig. 3(12)]. Anions are immobilized in single-ion SPEs, effectively eliminating the electric field caused by charge redistribution and thus minimizing dendrite growth.

Reproduced with permission from Refs. [19,20,21, 25, 44, 45]. Copyright © 2015, IOP Publishing. Copyright © 2015, Elsevier. Copyright © 2018, American Chemical Society. Copyright © 2019, Elsevier. Copyright © 2022, John Wiley and Sons. Copyright © 2023, Springer Nature

Overview diagram of the factors influencing lithium metal dendrites in solid electrolytes.

Dendrite growth in inorganic SSEs is dominantly induced by undesirable wettability, unstable electrode/electrolyte interfaces, defects in grain boundaries and voids, and the unacceptable electronic conductivity of SSEs. The growth mechanisms of lithium dendrites in inorganic solid ceramic electrolytes can be summarized into four categories.

-

(i)

Poor interface wetting. Despite the promise of a high mechanical strength and a high Li+ ion transference number (close to 1), inorganic SEs suffer from poor wettability with lithium metal anodes, and point-to-point contacts are accompanied by distinct interface voids [Fig. 3(8)] [21, 64], which results in uneven Li+ ion flexibility and greatly disrupts the plating/stripping process, as well as the critical current density. Earlier studies [65, 66] have shown nonwetting behavior on a contaminated LLZO surface due to the presence of LiOH and Li2CO3, which results in inhomogeneous electrodeposition and the subsequent penetration of lithium metal into SEs.

-

(ii)

Grain boundary. Most inorganic ceramic SSEs are polycrystalline, and their grain boundaries cannot be ignored during Li+ ion transfer due to their significant ion transport resistance, low shear modulus, and different phase compositions [67]. A locally excessive Li+ ion resistivity and irregular interface shape at the grain boundaries hinder the migration of lithium ions and promote the growth of lithium dendrites [Fig. 3(8)] [21]. Manipulating the grain size of ceramic SEs is recognized as an efficient method to regulate the number of grain boundaries and mitigate interfacial resistance [68]. The grain boundary energy can be quantified using Eq. (12). One study [69] showed that more compact boundaries allow for fast diffusion, while higher-energy grain boundaries with less compact structures decrease the Li+ ion conductivity to a greater degree.

-

(iii)

High electronic conductivity. An ideal SSE should provide a high ionic conductivity and an extremely low electronic conductivity, fully ensuring the requirement of lithium ion permeability but electron inhibition. Driven by the electric potential, Li+ ions are reduced to metallic lithium only at the lithium-electrolyte interface [70]. However, the electronic conductivity of SSEs is excessively high, resulting in a strong local electric field. Li+ ions tend to be deposited in the presence of a strong electric field and are reduced to metallic lithium, thus forming lithium dendrites inside the SE [Fig. 3(9)] [22, 71].

-

(iv)

Interphase effect. Wendel et al. [20] distinguished three types of lithium metal/SE interface formations in detail [Fig. 3(7)]. In the first case [Fig. 3(7a)], a thermodynamically stable interface is formed, and the lithium metal and SE in contact are in thermodynamic equilibrium without any parasitic reaction. In the other two cases [Fig. 3(7b, c)], chemical reactions occur between the SE and lithium metal, and both materials form a thermodynamically unstable interface. In Fig. 3(7b), the final reaction products are mixed ionic and electronic conductors, allowing undesirable electron transport and finally resulting in battery self-discharging. In contrast to the case shown in Fig. 3(7c), a stable interphase is generated when the reaction products are ionically conducting but electronically insulating.

Based on the analysis of the growth mechanism of lithium dendrites in organic and inorganic SSEs, dendrite formation in SE can be suppressed by increasing the ionic conductivity, electrochemical stability window, \({t}_{{\text{Li}}^{+}}\), mechanical strength, interfacial contact and stability of SEs, further protecting the lithium anode and stabilizing the interface. Here, the ion conductivities and electrochemical windows of representative SEs for LMBs are thoroughly summarized in Fig. 5, which is helpful for obtaining an overall understanding of organic, inorganic, and hybrid SEs (more data are summarized in Tables 1, 3, 4, and 6, respectively). Specifically, Fig. 6 summarizes their ionic conductivities at room temperature, and the ionic conductivities of ISEs are generally higher than those of SPEs but are still far from those of liquid electrolytes. Figure 7 shows their electrochemical stability windows. Only if the electrochemical stability window is above the operating voltage range of the cathode material is it possible for the assembled full battery to function properly. Clearly, the low electrochemical window of ISEs cannot match that of some typical cathode materials commonly used today. We will discuss these issues in more detail in subsequent sections (Fig. 7).

2 Challenges Facing Organic SSEs

Polymers have been pioneered as SEs dating back to the 1970s and are still a class of active candidates for application in SSBs. SPEs conduct Li+ ions through segmental relaxation within noncrystallized regions and a free volume above the glass transition temperature (Tg). Subdiffusive motion, intersegmental hopping, and entire chain movements are three main Li+ ion diffusion pathways that contribute to the overall ionic conductivity. The major benefit of SPEs is the easily tangled interface solid-solid contact, which stems from the flexibility and processability of polymer chains. Fenton et al. [72] discovered the ability of poly(ethylene oxide) (PEO) to complex with alkali metal salts through oxygen atoms along the backbone. This discovery has provided an opportunity for PEO-based commercial batteries to achieve greater safety and a higher energy density practically in the absence of separators and liquid electrolytes, which are typically employed in conventional Li ion cells. More recent studies have shown that although polymer chain movement is necessary for ion migration, crystalline domains are also reported to be capable of ion conduction or are even better than those in amorphous regions. Instead of undergoing chain relaxation, polymers may fold into cylindrical tunnels that conduct Li+ ions through hopping routes while anions are fixed outside tunnels. Depending on their heteroatomic organic functional groups, SPEs can be categorized into polyethers, polyesters, polyamides, etc., and the structural formulas of their repeating units are shown in Fig. 8a–c. Additionally, lithium metal salts of different solubilities and stabilities affect the ionic conductivity of SPEs, and the structural formulas of common lithium salt anions are summarized in Fig. 8d. In addition, some polymers with specific functionalities are also a key direction of current research. Here, as shown in Fig. 9, we summarize the representative structures of reported single-ion polymers and self-healing polymers, which will also be discussed in detail in Sects. 2.1.1 and 2.3.1.

At present, widely studied polymer electrolytes include PEO [73], poly(acrylonitrile) (PAN) [74], poly(methyl methacrylate) (PMMA) [75], and poly(vinylidene fluoride) (PVDF) [76]. However, polymer electrolytes still suffer from well-known challenges, such as sluggish chain segment motion, low room-temperature ionic conductivity, insufficient stable potential windows and insufficient ionic conductivity (10−4 S cm−1), even under high-temperature conditions. With respect to LMBs, the mechanical properties of SPEs are greatly deteriorated at high temperature, which renders the protection of lithium metal anodes difficult. Moreover, the contact and stability of electrode-electrolyte interfaces must be improved. As a target, we have focused on studies on refining the ionic conductivity, mechanical properties, electrochemical performance, and thermal stability of organic SEs through polymer cross-linking, copolymerization, grafting, the formation of heterogeneous structures, and the preparation of self-healing and single-ion conducting polymer electrolytes. Table 1 provides a detailed summary of the ionic conductivity and electrochemical window of basic SPEs.

In PEO-based SPEs, at the polymeric chain level, Li+ ions are transferred from interchain diffusion, shift, or intrachain diffusion, and the latter contributes to the majority of Li+ ion conductivity [109]. Theoretical evidence suggests that ion transfer in polymers is intrinsically linked to polymer motion [110,111,112,113]. The diffusion coefficients can be calculated by evaluating the ions’ mean squared displacement of the corresponding particles [110, 113,114,115]:

where \({x}_{i}\left(t\right)\) is the instantaneous position of particle i at time \(t\), \({t}^{\prime}\) is the lag time, and < ··· > denotes an ensemble average over the particles. The diffusivity of the polymer is calculated by averaging the diffusivities of O, N, S, etc., atoms in the polymer chains. The ionic conductivity and transference number of the entire polymer electrolyte were calculated using the cluster Nernst-Einstein (cNE) approach to obtain values closer to the exact fully interactive approach [110, 113,114,115]:

where \({z}_{ij}\), \({\alpha }_{ij}\), and \({D}_{ij}\) are the charge number, population, and diffusion coefficient of a cluster composed of i cations and j anions, respectively. Finally, one can also define a transference number for the cation as follows [110, 113, 114]:

Based on the understanding above, Xie et al. [110] conducted an amorphous polymer electrolyte screen and accelerated the calculation by machine learning to reduce errors in molecular dynamics. They achieved relatively accurate predictions of the ionic conductivity and \({t}_{{\text{Li}}^{+}}\) of SPEs and screened up to 6 247 polymers (Fig. 10a–c). Finally, they extracted several design principles and provided an open dataset for the community. Similarly, France-Lanord et al. [113] constructed polymers by alternating ethylene oxide monomers and secondary sites (Fig. 10). The authors investigated the relationship between secondary sites and the ion transport properties of polymer electrolytes via theoretical calculations. Two different secondary sites were considered, including a carbonate group (CAR) and a sulfonyl group (SUL). The investigation suggested that the carbonate groups in PEO backbones can significantly restrain ion pairing due to the enhanced interaction with Li+ ions, while a sulfonyl secondary site improves the cation transference number due to its strong affinity with TFSI− (Fig. 10d–i).

Reproduced with permission from Ref. [110]. Copyright © 2022, Springer Nature. d–i Transport properties of the three investigated polymer electrolytes. Left column: chemical structures. Time evolution of the mean squared displacement for (d) Li+ and (e) TFSI− ions. (f) Conductivity results for the Nernst-Einstein (NE) and cluster NE (cNE) approximations. (g) Haven ratio. (h) Cation transference number as defined in both approximations. (i) Ionic diffusion coefficients. Reproduced with permission from Ref. [113]. Copyright © 2019, American Chemical Society

a–c Screening of polymer electrolytes. (a) Distribution of the conductivities of the top 50 polymers after each iteration, showing the quartiles of the conductivity distributions. (b) Predictions of 50 ns and 5 ns conductivities for 6 247 polymers in the search space. The green line denotes the top 50 conductivities from both predictions. (c) CPU hours that were actually used, required to screen the entire 6 247 search space, and required to screen the 53 362 candidate space.

2.1 Single-Ion Conducting Design

In most dual-ion conducting polymer electrolytes (DIC-PEs), both Li+ ions and anions move freely. Due to the Lewis coordination between Li+ ions and polymer chains, Li+ ions move much slower than anions, resulting in a low \({t}_{{\text{Li}}^{+}}\) (typically below 0.5) [116]. A lower \({t}_{\text{Li}^{+}}\) induces stronger concentration polarization, as a result of which Li+ ions are depleted at the surface of the lithium metal electrode and thereafter begin to deposit and grow in the form of dendrites.

Therefore, pursuing \({t}_{{\text{Li}}^{+}}\) values of up to unity can lessen such concentration polarization and suppress one route of dendrite growth, which is the initial target for developing single-ion conducting polymer electrolytes (SIC-PEs) [117]. In response, several strategies have been applied for anion immobilization: (1) chemically linking anions into the polymer backbone; (2) attaching anions to the inorganic backbone; and (3) introducing anion-trapping agents in DIC-PEs. SIC-PEs can be solid-state or gel-type polymers (containing large amounts of plasticizers). Li+ ions are mainly transported through the amorphous region via an interchain or intrachain hopping process in SIC-SSPEs [116]. Generally, because of their high \({t}_{{\text{Li}}^{+}}\), SIC-PEs homogenize the ion concentration distribution and indeed achieve uniform lithium deposition in the absence of lithium dendrites [118].

Various anion acceptors, such as carboxylates, sulfonates [118], tetrahedral borates [119, 120], bis(sulfonyl)imides [117, 121,122,123], other neutral anion acceptors or even a set of hydrogen bonds [124], have been utilized as anchoring groups through interactions between the anion acceptor and the target small anion to realize optimized SIC-PE configurations. Some representative structures of reported SIC-PEs with ionic conductivity at room temperature are summarized in Fig. 9a, and \({t}_{{\text{Li}}^{+}}\) is shown in Table 2.

-

(i)

Carbonate-based and sulfonate-based SIC-PEs have been developed due to their easy synthesis process and moderate negative charge distribution. However, one problem of sulfonate-based SIC-PEs is the strong attraction between Li+ ions and carboxylates or sulfonates, which results in a low concentration of free Li+ ions [117]. Recent investigations have suggested the incorporation of nitrogen atoms into sulfonate to reduce the anion-cation binding energy and thus favor ionic dissociation. For instance, by covalently attaching propylsulfonate motifs to nitrogen atoms in linear poly(ethyleneimine) (LPEI), Doyle et al. [118] generated PEG-grafted lithium solvating matrices and propylsulfonate-bearing linear poly(ethyleneimine) (LPEI) as single-ion lithium conductors, which promoted ion pair dissociation, stabilized the macromolecular mixture and succeeded in improving the dissociation of polymer-bound lithium salts (Fig. 11a). The prepared PEI-based SSPEs exhibited decent ionic conductivity (4 × 10−4 S cm−1) and showed no electrochemical degradation in the ± 5 V potential range.

-

(ii)

Tetrahedral borate-based lithium salts enable high ionic conductivity, facile preparation, thermal stability, cost effectiveness, environmental friendliness and favorable SE interfaces. Inspired by these advantages, various boron-based SIC-PEs have been carefully designed. Recently, Liu et al. [119] proposed a Li-containing boron-centered fluorinated single-ion conducting gel polymer electrolyte (LiBFSIE). In the LiBFSIE design, Li+ ions were anchored on the delocalized borate anion centers (Fig. 11b). Anion immobilization endows the polymer electrolyte with a high \({t}_{{\text{Li}}^{+}}\) (0.93).

-

(iii)

Bis(sulfonyl)imides are acknowledged as versatile anions in SIC-PEs due to their high degree of Li+ ion dissociation and stability. Meziane et al. [121] synthesized and studied two types of single-ion lithium poly(4-styrenesulfonyl(trifluoromethylsulfonyl)imide) (PSTFSI) associated with CF3–SO2–N− − SO2 anionic groups (Fig. 11c). When mixed with PEO, the polymers formed an electrolyte membrane to achieve improved Li+ ion solvation without any addition of extra lithium salts. The ionic conductivity of PSTFSI/PEO is approximately ten times higher than that of PEO. In these polymers, \({t}_{{\text{Li}}^{+}}\) was at unity, while the ionic conductivity was maintained at a high level. However, the presence of sulfonate groups is suggested to decrease the conductivity.

However, preparing SSPEs that can offer both mS cm–1-level ionic conductivity and high \({t}_{{\text{Li}}^{+}}\) (> 0.8) under ambient conditions remains arduous and is currently limited by (1) the strong Li–O− interactions between lithium salts and polymer backbones and (2) the low dissociation of lithium salts in polymer electrolytes. Therefore, methods to address this trade-off and achieve a balanced enhancement of the ionic conductivity and \({t}_{{\text{Li}}^{+}}\) for SSPEs are urgently needed. In response to this issue, Sun et al. [122] reported a polyamide-based single-ion gel-polymer electrolyte (LiPA) using bis(4-carboxy phenyl sulfonyl)imide and 2,4-diamino-benzene sulfonic acid precursors (Fig. 11d). The PVDF-LiPA membrane has an ionic conductivity of 3.8 × 10−4 S cm−1, which chiefly arises from channels provided by the bis(sulfonyl)imide anions in the polymer chains and moderate interfacial resistance. The high \({t}_{{\text{Li}}^{+}}\) of the membrane (0.88) significantly reduces the polarization potential of the battery, which enhances the electrochemical stability of the electrolyte membrane. Borzutzki et al. [123] studied a polysulfonylamide homopolymer tailored by a –C(CF3)2 functional group. An optimized gel-type polymer electrolyte membrane was produced as a 1:3 blend of PVDF-HFP and SIC polymers, which exhibited a high ionic conductivity of 5.2 × 10−4 S cm−1, corresponding \({t}_{{\text{Li}}^{+}}\) of 0.9, a 7Li self-diffusion coefficient of 4.6 × 10−11 m2 s−1 and an electrochemically stable voltage window up to 4.6 V vs. Li/Li+.

Reproduced with permission from Ref. [118]. Copyright © 2014, American Chemical Society. b Synthesis of the single-ion polymer electrolyte LiBFSIE. Reproduced with permission from Ref. [119]. Copyright © 2020, American Chemical Society. c Synthesis of PSTFSI. Reproduced with permission from Ref. [121] Copyright © 2011, Elsevier. d Schematic of the synthesis of EG-P[SSPSILi-alt-MA]. Reproduced with permission from Ref. [117]. Copyright © 2019, American Chemical Society. e Schematic illustration of anion immobilization by boron in 3D-BGPE. Reproduced with permission from Ref. [126]. Copyright © 2019, The Royal Society of Chemistry. f Chemical structure of the anion acceptor CBP. Reproduced with permission from Ref. [127]. Copyright © 2010, John Wiley and Sons

a Synthesis of homopolymers and the single-ion transport mechanism of PEI-based SSPEs.

-

(iv)

Another possible solution for partial anionic immobilization to improve \({t}_{{\text{Li}}^{+}}\) is to use neutral anion acceptors. Anion acceptors are mainly Lewis acids, which can react with counter anions via Lewis acid-base interactions and promote electron delocalization. Thus, they not only immobilize the counter anions but also enhance the dissociation of Li+ ions. Specifically, the anion acceptor may interact with anions via hydrogen bonds. Dai et al. [126] obtained a cross-linked SIC-PE (3D-BGPE) through the in situ polymerization of both linear and branched cross-linkers (Fig. 11e). Lewis acid boron esters in 3D-BGPE act as anion acceptors. The 3D-BGPE exhibited high ionic conductivity (8.4 × 10−4 S cm−1) and near-single-ion conduction (\({t}_{{\text{Li}}^{+}}\) of 0.76). Moreover, Stephan et al. [127] proposed a new anion-trapping component, calix[2]-p-benzo[4]pyrrole (CBP), with hydrogen bonds (Fig. 11f). The \({t}_{{\text{Li}}^{+}}\) increased from 0.23 to 0.78 upon the incorporation of CBP in the polymer electrolyte. Although the CBP did not play a significant role in the ionic conductivity, it improved the interfacial properties significantly.

2.2 Molecular Structure Modification

In response to most polymers that are highly crystalline and unavailable for Li+ ion transfer, methods based on copolymerization [94, 128,129,130], cross-linking [131,132,133], hyperbranching [84, 134], and adding ionic liquids [135,136,137] for molecular structure design are often reported to increase the room-temperature ionic conductivity of polymer electrolytes.

Quasisolid star brush block copolymer electrolytes (SBBCEs) were proposed by Gang et al. [128] and were designed with a BAB-repeating structure composed of a 2-arm star polymer of (poly[poly(ethylene glycol) methyl ether acrylate]b-polystyrene)2 [(PPEGMEA-b-PS)2] (Fig. 12a). CH3O-PEG-PC, which contains a carbonate terminal group that is highly dissociative to lithium salts, results in SBBCEs with ionic conductivities up to 2.1 × 10−4 S cm−1 at room temperature. Combining LiBF2C2O4 (LiODFB) as an additive, Fu et al. [131] designed ultrathin double-salt PEO-based gel polymer electrolytes (DPPEs) by introducing tetraethylene glycol dimethyl ether (TEGDME). By generating a cross-linked network under UV irradiation, the DPPEs showed a superior ionic conductivity of 0.57 mS cm−1 (30 °C) (Fig. 12b). Zhang et al. [84] designed a novel ion-dipole-reinforced polyether electrolyte (PHMP) through the cationic ring-opening polymerization (CROP) of 3-hydroxymethyl-3′-methyloxetane (HMO). The original PHMP was characterized by unique ion solvation cages composed of regionally condensed hyperbranched ether groups with enhanced chain segmental movements (Fig. 12c). First-principle simulations characterized seven representative ion solvation cage configurations, which were assembled with different ether group numbers (n = 3–5) and types (linear, binary, or ternary). The binding energy between the Li+ ions and ion solvation cages varied from − 4.47 to − 5.66 eV, and the Li+ ion transfer energy among the different ion solvation cages ranged from 0.1–0.4 eV. Therefore, such a hyperbranched structure restrained the dehydrogenation reaction of ether-based SEs, broadening the stable potential window to ~ 4.7 V. Therefore, such “ion-dipole” configurations not only enhanced salt dissociation and ion conduction but also restrained the proton-initiated decomposition process at high voltage, which synergistically achieved high ion conduction (1.26 × 10−4 S cm−1 at 25 °C) and high compatibility with high-voltage cathodes. Zhou et al. [135] proposed a novel cross-linked gel polymer electrolyte (GPE) consisting of an ionic liquid with a fluorinated alkyl side chain (F-IL), di-pentaerythritol penta-/hexa-acrylate (DPEPA) and poly(ethylene glycol) methacrylate (PEGMA) (Fig. 12d). PEGMA achieves high ionic conductivity through glycol chains; DPEPA is able to generate a highly cross-linked gel network through abundant acrylate functional groups. The side chain of F-IL can effectively immobilize the lithium salt anion and thus reduce the affinity of Li+ for oxygen atoms on the ethylene glycol chain and improve the electrochemical stability of cross-linked gel polymer electrolytes (CGPEs).

Reproduced with permission from Ref. [128]. Copyright © 2019, American Chemical Society. b Schematic diagram of DPPE chain interconnections. Reproduced with permission from Ref. [131]. Copyright © 2022, Elsevier. c Synthetic scheme of the PHMP solid electrolyte and uniform Li+ diffusion and deposition enabled by PHMP. Reproduced with permission from Ref. [84]. Copyright © 2021, John Wiley and Sons. d Schematic representation of the synthesis of gel polymer electrolytes containing ionic liquid end groups. Reproduced with permission from Ref. [135]. Copyright © 2021, John Wiley and Sons

a Schematic of the synthesis of SBBCEs.

2.3 Mechanical Strength

Grazioli et al. [138] quantitatively expressed the stress-strain relation of SPE, which is defined as:

where \({\varvec{u}}({\varvec{x}}, t)\) is the displacement vector. The stress tensor \({\varvec{\sigma}}\) is defined as the sum of its deviatoric component and pressure.

The constant G represents the bulk modulus, \(\mathbf 1\) represents the identity tensor, and \({\varvec{p}}\) is the pressure. The effects of the ionic concentration and electrostatic forces on the mechanical properties of the material are neglected in the above equation.

A fundamental understanding indicates that the mechanical properties of polymer electrolytes play critical roles in resisting dissolution and preventing punctures, thus increasing overall battery safety. The inferior mechanical strength of SPEs is among the primary causes of the growth and penetration of lithium dendrites. Chen et al. [107] synthesized a new microporous gel polymer electrolyte by blending superior rigid PVDF with PEO to enhance the mechanical strength of GPEs. The composite electrolyte presented a mechanical strength up to 30 MPa and favorable liquid absorption capacity with a room-temperature ionic conductivity of 1.96 × 10−3 S cm−1. Zhang et al. [102] prepared a flexible PEO-based SPE (PTT) via a UV-derived dual reaction. An SPE with a high ionic conductivity of 2.7 × 10−4 S cm−1 and enhanced mechanical strength was obtained. A study of Li//Li symmetrical cells revealed the suppression of dendrites with lithium and a stable voltage profile for over 400 h. Bouchet et al. [103] reported a new SIC-PE based on self-assembled polyanionic “BAB”-type triblock copolymers [P(STFSILi)-PEO-P(STFSILi)] with finely tuned mechanical properties, ionic conductivity and \({t}_{{\text{Li}}^{+}}\). This SIC-PE exhibited unprecedented performance for LMBs in terms of ionic conductivity (1.3 × 10−5 S cm−1 at 60 °C), \({t}_{{\text{Li}}^{+}}\) > 0.85 and improved mechanical strength (10 MPa at 40 °C). Kimura et al. [104] developed an ambient temperature-operating highly concentrated PEC-based composite polymer electrolyte (PI-PEC-LiFSI) by employing a “pore-filling” technique. The highly concentrated poly(ethylene carbonate) (PEC) electrolyte was filled into a three-dimensionally ordered microporous (3D-OM) polyimide (PI) matrix to support the electrolyte and ensure its mechanical stability so that the problem where PEC cannot independently self-support film formation was solved. The 3D porous structure and high concentration of PEC jointly promoted the transport of lithium ions inside the electrolyte, including a reasonable conductivity of 1.6 × 10−4 S cm−1 and a high Li transference number greater than 0.5, while ensuring its mechanical strength. Cyanoethyl polyvinyl alcohol (PVA-CN) is a polymer compound with a high dielectric constant and good adhesion. Using a nitrile material (SEN), Zhou et al. [105] prepared a hierarchical SSE through the in situ polymerization of PVA-CN in a succinonitrile (SN)-based SE. The crosslinked PVA-CN polymer framework strongly enhanced the mechanical strength of the composite electrolyte. The obtained SEN electrolyte exhibited excellent favorable mechanical strength (15.31 MPa).

2.4 Self-Healing Polymer Electrolytes (SHPEs)

The complex application scenario requires lithium batteries to possess a certain self-healing capability to address volume changes, interface instability or even breakage during utilization [139]. Self-healing materials usually self-repair through interfacial interactions such as covalent bonds (including disulfide bonds [139,140,141], esters [142], imines [143], Diels-Alder reactions [144], etc.) or noncovalent interactions (including hydrogen bonds [141, 145], host-guest interactions [146], metal-ligand interactions [147], etc.). Some representative structures of reported SHPEs are summarized in Fig. 9b. In recent years, research on self-healing electrolytes has received increasing interest. With the self-healing effect of electrolytes, the interfacial stability of the electrode-electrolyte can be effectively improved, and the growth of lithium dendrites arising from electrolyte damage can be prevented, thus realizing the protection of lithium metal anodes. Hence, SHPEs can improve the safety, reliability and cycling life of batteries [143].

Reversible dynamic covalent bonds have a higher bonding energy and thus better stability, which endows SHPEs with good mechanical strength [142]. Sun et al. [139] prepared a rigid-flexible self-healing polymer electrolyte (RFSPE) with a flexible-rigid epoxy resin as the backbone and disulfide bonds as reversible cross-linking points. Figure 13a depicts the self-healing mechanism of RFSPEs, where disulfide bonds, as crosslinking points, undergo an exchange reaction to heal damage. The epoxy resin offered superior mechanical abilities with tensile strength greater than 20 MPa, while the disulfide bonds provided excellent self-healing efficiency (> 95%). In particular, RFSPEs play an essential role in lithium dendrite suppression. Compared to that of the non-self-healing RFCPE, the surface of the lithium metal electrode with RFSPE as the electrolyte was smoother (Fig. 13b), suggesting a stabler interface and stronger inhibition of lithium dendrite growth. With the function of disulfide bonds, the broken molecular chains due to the destruction of the electrolyte by lithium dendrites were reconnected, and the cracks were healed (Fig. 13c). Zhou et al. [143] developed a self-healing polymer electrolyte (IBshPE) cross-linked by two types of synergetic dynamic bonds. Boroxine bonds with B-N coordination and imine bonds can synchronously allow for fast bond exchange reactions, supporting the fast self-healing response of IBshPE, as shown in Fig. 13d. IBshPE showed a high self-healing efficiency of 97% within 4 h and a favorable ionic conductivity of 5.08 × 10−3 S cm−1 at 30 °C. The IBshPE-modified LiFePO4/Li cells exhibited better cycling performance (98.6% capacity retention after 80 cycles) and an improved rate capability, with a specific capacity of 130.5 mAh g−1 at 2 C.

Reproduced with permission from Ref. [139]. Copyright © 2022, Elsevier. d Schematic diagram of the self-healing mechanism of IBshPE. Reproduced with permission from Ref. [143]. Copyright © 2022, Elsevier. e Schematic illustration of self-healing between the cut surfaces of the PP-PU. Reproduced with permission from Ref. [145]. Copyright © 2022, American Chemical Society

a Schematic illustration of the self-healing mechanism of RFSPE-3 and the bond exchange reaction of disulfide bonds. b SEM images of pristine Li metal, Li from Li/RFSPE-3/Li, and Li from Li/RFCPE-3/Li after lithium plating/stripping. c Interfacial self-healing process and lithium dendrite-suppressing mechanism of RFSPE-3.

One supramolecular system containing a quadruple hydrogen-bonded structure of a ureidopyrimidinone structure, the UPy system, has been widely used in the field of SHPEs [145]. Chen et al. [145] proposed a multifunctional gel polymer electrolyte with high ionic conductivity and self-healing ability by incorporating brush-like PEG chains with urea-pyrimidinone (PEG-UPy) into a PVDF-HFP matrix to form an inorganic cross-linked network. When the electrolyte film broke, hydrogen bonds formed between UPy units at the interface rejoined, allowing a return to its pre-damaged condition without external stimulation (Fig. 13e). The electrolyte exhibited a good self-healing capability at 25 °C. The scraping of electrolytes and the puncturing caused by lithium dendrite growth were eliminated during charging and discharging, thus enhancing the safety of LMBs.

2.5 Electrode-Electrolyte Interfacial Contact

A stable lithium metal-electrolyte interface is a prerequisite for long-term cycling of all-solid-state batteries and for suppressing dendrite growth. In situ self-polymerization of electrolytes or polymers is among the most effective approaches for obtaining a stable interface. Huang et al. [85] reported a poly(tetrahydrofuran) (PTHF)-based polymer electrolyte (PTSPE) using boron trifluoride diethyl ether (BF3·OEt2) through the in situ polymerization of THF in a LiFePO4/Li cell (Fig. 14a). The in situ polymerization technique markedly enhanced the contact features and interfacial stability. The in situ formed PTSPE exhibited an ionic conductivity of 2.3 × 10−4 S cm−1 and a 4.5 V electrochemically stable voltage window at 60 °C. The LiFePO4/Li SSBs obtained using this PTSPE showed stable cycling ability and delivered a high discharge capacity of 142.3 mAh g−1 after 100 cycles. Zheng et al. [108] designed a cross-linking gel copolymer electrolyte containing various alkyl acrylates, triethylene glycol dimethacrylate (TEGDMA), and a liquid electrolyte using in situ thermal polymerization, as depicted in Fig. 14b. The as-assembled LiFePO4/Li cell and graphite/Li cell employing this in situ formed GPE revealed that the prepared GPE had good compatibility with the battery cathode and anode materials. The flexibility and liquid absorption rate of the electrolyte were boosted by copolymerization, with a room-temperature ionic conductivity of 5 × 10−3 S cm−1. Moreover, ionic liquids, which act as nonflammable, nonvolatile electrolytes with high ionic conductivity, have been investigated for the preparation of SSEs by in situ polymerization. Zhou et al. [106] fabricated a nesting doll-like hierarchical poly(ionic liquid)-based SE (HPILSE) in situ (Fig. 14c), which provided an excellent ionic conductivity greater than 10−3 S cm−1.

Reproduced with permission from Ref. [85]. Copyright © 2019, Elsevier. b The synthesis of chemically cross-linked GPEs. Reproduced with permission from Ref. [108]. Copyright © 2014, Springer Nature. c Schematic illustration of the in situ synthesis route of nesting doll-like HPILSE. Reproduced with permission from Ref. [106]. Copyright © 2017, Elsevier

a Schematic diagram of the in situ polymerization process of the PTHF electrolyte.

Due to the substantial difference in the electrochemical environments of the cathode and anode, achieving simultaneous stability for both the cathode and anode using a single-component solid-state polymer electrolyte is practically infeasible. For example, the PEO SSE interfaces favorably with the lithium metal anode, but the relatively narrow electrochemical window (3.9 V) renders it unavailable to match with the high-voltage cathode. Constructing a double-layered heterogeneous structure is an ideal treatment for the high-voltage intolerance of PEO. Zhou et al. [78] combined two different functional polymers to constitute a double-layer polymer electrolyte. The PEO-LiTFSI layer was in contact with only the lithium metal anode to prevent dendrite growth, and the poly(N-methyl-malonic amide) (PMA)-LiTFSI layer was used to contact only the cathode to stabilize the cathode interface. A dendrite-free Li-metal anode interface and a stable polymer/oxide cathode interface were produced with 100 charge/discharge cycles at 4 V and 65 °C for an as-assembled all-solid-state LiCoO2/Li cell. The oxidation potential, mechanical properties, Li+ ion conductivity, thickness of the electrolyte membrane, and interpolymer compatibility are identified as the critical considerations for advancing double-layer organic composite SSEs.

3 Challenges Facing Inorganic SSEs

Inorganic SSEs are typically oxides, sulfides, halides, hydrides, and nitrides [148]. In terms of crystallinity, inorganic SSEs are segmented into crystalline and amorphous structures. The dominant crystalline structures include the lithium superionic conductor (LISICON) structure (Li1−xZn1−xGeO4) and its sulfide (thio-LISICON) (Li4−xGe1−xPxS4) [149], sodium superionic conductor (NASICON) structure [Li1−xMxTi2−x(PO4)3, M = Al, Y, In, …] [150], garnet structure [Li7La3Zr2O12 (LLZO)] [151], Li6.4La3Zr1.4Ta0.6O12 (LLZTO) [152], perovskite structure [La2/3−xLi3xTiO3 (LLTO)] [153, 154], anti-perovskite structure (Li3OX, X = Cl, Br) [155], layer-structured hydrides [Li2(NH), Li(BH4)] [156], AlCl3-type halogen compounds (Li3MCl6, M = Mg, Mn, Fe, Cd) [157], and argyrodite structure (Li6PS5X, X = Cl, Br, I) [158, 159]. The amorphous structures predominantly consist of sulfide glasses (Li2S-P2S5 [160] and Li2S-SiS2 [161]) and nitrogenous compounds (Li3N [162] and LiPON [163]). Inorganic SEs suffer from solid–solid contact, dendrite growth, and excessive grain boundaries. Investigators aim to ameliorate these problems by modulating the microstructure (compactness, grain boundaries, grain size, etc.) and enhancing the interfacial contact. The electrochemical properties of some inorganic SSEs that have been studied are shown in Table 3. In this review, we propose that interfacial and dendrite problems, such as interfacial stability, interface contact/wettability and interfacial Li stripping/plating processes, are the main drawbacks of inorganic SSEs in achieving high-performance cells. This section reviews the drawbacks and dominant solutions of inorganic SSEs in practical investigations.

3.1 Interfacial Chemical/Electrochemical Stability

High interfacial impedance severely hinders the transport of Li+ ions and leads to poor performance of all-solid-state lithium batteries (ASSLMBs). The main reasons for the high interfacial impedance of the cell originate from the decomposition of the SE and the formation of the interfacial phase. The narrow electrochemical window of the electrolyte may lead to redox reactions at the electrolyte/electrode interface when lower or higher voltages are exerted on the SE. The poor chemical stability between the electrolyte and electrode can also cause interfacial side reactions and changes in the chemical structure at the interface. Therefore, the interfacial stability remains decisive for the development of high-energy and high-power density ASSLMBs. Among inorganic SEs, the interfacial stability of sulfide SSEs is particularly problematic. In this section, we attribute the problem of interfacial stability of inorganic SSEs (ISSEs) to two aspects: (1) the electrochemical stability of the ISSE itself and (2) the side reactivity with the lithium metal.

During the operation of LIBs, the low voltage of the anode drives mobile cations into the electrolyte and vice versa for the cathode, inducing the depletion or accumulation of charge carriers (Fig. 15a) [164]. The migration of internally mobile species will inevitably cause a change in the electrochemical potential. The evolution of the electrochemical potential leads to a concentration gradient of the mobile cation, which directly triggers the decomposition of the SE and/or reaction with the electrodes [164]. The applied voltage can be directly converted to a lithium chemical potential \({\mu }_{\text{Li}}\) using Eq. (8) [165], where \({\mu }_{\text{Li}}^{0}\) is the lithium chemical potential in lithium metal and e is the elementary charge.

Reproduced with permission from Ref. [164]. Copyright © 2019, Springer Nature. b Experimental setup of the in situ XPS experiment to monitor the reaction between sulfide and Li. c XPS spectra recorded during deposition of 31 nm Li metal on Li10GeP2S12. Detailed S 2p, Ge 3d, and P 2p/Ge 3p spectra are shown for different deposition states. d S 2p, Ge 3d, and P 2p XPS spectra and model fits for the pristine LGPS sample and the after deposition of 31 nm Li metal. Reproduced with permission from Ref. [169]. Copyright © 2016, American Chemical Society. e Contour plots of operando 7Li NMR spectra and their corresponding charge/discharge curves for LGPS, LPS, LSiPSCl, and LPSCl. Reproduced with permission from Ref. [172]. Copyright © 2023, Springer Nature

a Evolution of the chemical potential across the solid electrolyte in contact with an anode and a cathode.

Energy-dense batteries necessarily have anodes and cathodes with very different \({\mu }_{\text{Li}}\) values. We must consider subjecting the electrolyte to these extreme lithium potentials without other parasitic reactions [166]. The electrochemically stable voltage window is the voltage range that an electrolyte can sustain without redox decomposition. The intrinsic electrochemical stability of most SEs is often lower than that reported. In particular, for some sulfide electrolytes, their low electrochemical stability windows limit further progress [167]. Zhu et al. [168] investigated the electrochemical window and decomposition products of several common inorganic SE materials (Table 4). The electrochemical window for most sulfide electrolytes is very narrow, approximately 1.7–2.1 V, which means that they are extremely susceptible to decomposition during battery operation. Sulfide materials are generally not thermodynamically stable when in contact with lithium anodes, whereas the reduction of most sulfide materials starts at 1.6–1.7 V in the presence of Li+/Li, and even LLZO starts to be reduced at 0.05 V. Wenzel et al. [169] used in situ XPS and electrochemical measurements to observe chemical reactions at the Li/LGPS interface. They confirmed that LGPS decomposed into Li2S, Li3P and Ge metal or Li-Ge alloy when in contact with Li metal (Fig. 15b–d). Similar phenomena were discovered for Li7P3S11 and Li6PS5X (X = Cl, Br, or I) [170, 171]. The authors confirmed that Li7P3S11 decomposed into Li2S and Li3P, and Li6PS5X decomposed into Li2S, Li3P, and LiX. Liang et al. [172] proposed operando in situ NMR measurements for the real-time quantification and evolution tracking of inactive lithium formed in solid-state LMBs with four different sulfide-based SEs, namely, Li10GeP2S12 (LGPS), Li9.54Si1.74P1.44S11.7Cl0.3 (LSiPSCl), Li6PS5Cl (LPSCl) and Li7P3S11 (LPS). They revealed the evolution of dead Li formation and the amount of the Li-containing SEI component via operando NMR spectroscopy. Figure 15e shows the contour plots of operando 7Li NMR spectra and corresponding charge/discharge curves of four sulfide-based SEs. The study indicated that LGPS is prone to react with deposited lithium metals immediately, converting all active lithium into SEI-Li, the formation of which is severer than that of dead Li in LSiPSCl.

Building a protective layer at the Li-electrolyte interface is the most well-recognized method to inhibit side reactions and stabilize the interface [173,174,175]. Ye et al. [176] took advantage of the contraction susceptibility of the lithiation reaction of micron-sized Si at the interface to add a SiG (silicon, graphite, and polytetrafluoroethylene composite) protective layer on the lithium metal anode, and the assembled Li|SiG| Li5.5PS4.5Cl1.5 (LPSCl1.5)-Li10SnP2S12 (LSnPS)-Li5.5PS4.5Cl1.5 (LPSCl1.5)|NMC83 solid-state cell exhibited an 80% capacity retention after 2 000 cycles at a high current density.

In addition, experimental and simulation results indicated that the balance of lithiophobicity, electronic and ionic conductivity, and interlayer porosity are the key factors for the stable deposition/stripping of lithium at high capacity. Therefore, Wang et al. [177] designed a porous lithiophobic ion/electron-conducting L7N2I-CNT interlayer and an electron-conducting gradient L7N2I-Mg interlayer between a Li6PS5Cl (LPSC) electrolyte and a Li metal anode. This configuration enables Li to be deposited on the Li/interlayer interface and reversibly permeate into the porous interlayer. The configured Li4SiO4@NCM811|LPSC|Li full cell maintains 82.4% of its capacity after 350 cycles at 60 °C.

3.2 Interfacial Contact/Wettability

The point-to-point contact between the inorganic SSE particles and the lithium metal anode radically leads to high interfacial resistance, which is highly predisposed to an uneven distribution of Li+ ion flux and provides a gap for lithium dendrite growth. Various coating materials, such as alloying reaction coatings (Au, Si, Al, Ge, Ag, etc.), inactive coatings (ZnO, Al2O3, SiO2, SnO2, SnNx, and Li-C composite), a polymeric interlayer and artificial SEI layer for lithium anode [173, 202,203,204,205,206], have been developed for the electrode/ISSE interface to improve the electrochemical performance of ASSLMBs, to suppress the side reactions, and to stabilize the electrode/o interface.

On the anodic side of lithium metal, alloy coatings such as Au [64] and Ge [207] and inactive coatings such as ZnO [208], Al2O3 [209], and Li-C composites [202] are commonly used as buffer coatings to enhance interfacial contact. For example, based on the Au-Li alloying reaction, Tsai et al. [64] sputtered a Au buffer layer on a polished Al-contaminated Ta-substituted Li7La3Zr2O12 (LLZ:Ta) electrolyte surface. The use of a Au buffer layer improved the contact between LLZ:Ta and the lithium electrode and promoted the homogenization of Li+ ions at the interface, which efficiently prevented lithium dendrite growth (Fig. 16a). The interface resistance decreased dramatically (from 3 000 to 380 Ω cm2). Xu et al. [208] designed a novel all-in-one porous-dense-porous trilayer garnet SSE for lithium-sulfur batteries (Fig. 16b). Both the lithium anode and the sulfur cathode were infiltrated into the porous garnet framework, and a ZnO surface treatment was introduced to achieve seamless contact between the electrolyte and lithium metal anode. The all-in-one battery design provided continuous pathways for Li+ ions and electrons that led to a lower resistance, which effectively inhibited lithium polysulfide shuttling, lithium dendrite penetration, and volume expansion. Han et al. [209] also solved the problem of large interfacial impedance between lithium metal anodes and garnet electrolytes via atomic layer deposition (ALD) with ultrathin Al2O3 to effectively improve the wettability and stability of the interface between the garnet SSE and lithium metal (Fig. 16c), which significantly reduced the interfacial impedance from 1 710 to 1 Ω cm2.

Reproduced with permission from Ref. [64]. Copyright © 2016, American Chemical Society. b Schematic diagram of the structure and working principle of an all-in-one solid-state Li-S battery based on a trilayer garnet electrolyte. Reproduced with permission from Ref. [208]. Copyright © 2018, Elsevier. c Schematic diagram of the wetting behavior of a garnet surface with molten Li and SEM images of the garnet solid-state electrolyte/Li metal interface. Reproduced with permission from Ref. [209]. Copyright © 2016, Springer Nature. d Schematic diagram of casting lithium-graphite (Li-C) composites on garnet SSEs. The Li-C composite can spread well on garnet like a paste and provide intimate contact. Reproduced with permission from Ref. [202]. Copyright © 2019, John Wiley and Sons. e Schematic diagram of Li deposition behavior using an LLZTO solid-state electrolyte and an LLZTO-2wt%Li3OCl composite solid-state electrolyte. Reproduced with permission from Ref. [179]. Copyright © 2018, Elsevier. f Schematic illustration of the preparation and role of the PPF40 interlayer. Reproduced with permission from Ref. [216]. Copyright © 2023, John Wiley and Sons. g Schematic diagram of lithium deposition behavior in a cell. Reproduced with permission from Ref. [214]. Copyright © 2021, John Wiley and Sons. h Schematic illustration of dendrite growth in an unmodified Li anode and smooth lithium deposition in a modified LNA-Li anode. Reproduced with permission from Ref. [217]. Copyright © 2023, American Chemical Society. i Schematic representation of the pretreatment process for the formation of a LiF-rich SEI layer between Li metal and LPS solid-state electrolytes. Reproduced with permission from Ref. [218]. Copyright © 2018, American Association for the Advancement of Science

a Schematic diagram of the lithium ion transport process and impedance spectra of Li/LLZ:Ta/Li cells with and without Au buffer layers.

Moreover, temperature also considerably affects the interfacial contact properties of lithium metal. Studies have shown that the interface formed between molten lithium metal and SSE exhibits a rather low interfacial resistance [210]. However, the chemical stability between the SSE and molten lithium requires special attention, as some SSEs will react violently with molten lithium metal at high temperature [211]. Duan et al. [202] achieved an intimate garnet interface by casting a lithium-graphite (Li-C) composite onto a garnet-type SSE. Like a paste, Li-C composites with lower fluidity and higher viscosity can be cast onto garnet and exhibit intimate contact (Fig. 16d). They also found that the Li-C composite and garnet showed a minor interfacial reaction with a small reaction energy, delivering a decreased interfacial resistance from 381 to 11 Ω cm2. The origin of the large interfacial resistance of the garnet electrolyte is intimately related to the Li+-ion-insulating Li2CO3 surface layer on the garnet surface [212]. Li et al. [212] effectively removed the impurity Li2CO3 in the garnet electrolyte Li6.5La3Zr1.5Ta0.5O12 (LLZTO) by reacting the garnet electrolyte with carbon, which enhanced the interfacial wettability.

A similar approach was implemented in garnet electrolytes by Tian et al. [179]. As shown in Fig. 16e, Li3OCl, which has an excellent affinity for lithium metals in the voids and boundaries of Li6.75La3Zr1.75Ta0.25O12 (LLZTO) particles, was introduced using the melting-quenching method. By acting as a binder, amorphous Li3OCl promoted the formation of a stable and dense interfacial layer and continuous ionic conductive network among LLZTO particles, improving surface wetting not only with lithium metal but also among LLZTO particles. The investigation indicated that the interfacial resistance between the composite electrolyte and lithium metal decreased from 1 850 to 90 Ω cm−2.

The current density at which Li penetrates an SSE is often referred to as the critical current density (CCD). Interfacial contact and the electrolyte microstructure (pores, grain boundaries, etc.) are the main factors affecting the CCD of SSE [213]. The CCD of the SSE can be critical for its ability to inhibit the growth of lithium dendrites. Charging batteries at current densities above a critical value can result in lithium-filled cracks, commonly referred to as “dendrites”. Figure 17 and Table 5 summarize representative SEs and the corresponding CCDs, including both organic and inorganic SEs [214, 215]. The CCDs used in most of the studies (\(\leqslant\) 1 mA cm−2, most of which were \(\leqslant\) 0.5 mA cm−2) were far below the practically acceptable values (\(\geqslant\) 3 mA cm−2) [215].

At Li-SSE interfaces with poor electrical contacts or discontinuities, electrochemical currents wind around defects or voids, leading to an increase in the local current density near the edges of defects/voids. If the current density in the defects is sufficiently high, the SSE will rupture due to pressure accumulation at the defects, which further leads to the propagation of Li filaments and the formation of Li dendrites. Therefore, the surface modification of lithium metal or SSE is one of the key methods to improve the CCD of SSE.

Polymers provide favorable safety, chemical stability, and flexibility, and thus using polymers as an anode interface buffer layer may greatly enhance contact. Zheng et al. [216] designed an extensible elastic Li+-conducting polymer interlayer, poly(ethylene glycol methyl ether acrylate) (PEGMEMA), with a poly(vinylidene fluoride)-hexafluoropropylene (PVDF-HFP) elastomeric skeleton formed with perfluoropolyether (PFPE) additives for the lithium/garnet interface (Fig. 16f). The elastic network builds a continuous Li+ transport path, and the good viscoelasticity of the middle layer buffers the change in the lithium volume and results in tight interfacial contact. The PFPE additive is used to promote the formation of LiF-containing SEIs. Due to the specific structural and compositional integration, this strategy endows the lithium symmetric battery with a high CCD (3.6 mA cm−2) and an excellent cycle life (stable for more than 400 h at a current density of 1.0 mA cm−2). Peng et al. [214] combined a liquid lithium metal cathode (Li-Bp-DME), a sulfide SSE (Li7P3S11) and an interfacial protective layer (PEO), resulting in the highest CCD (17.78 mA cm−2) currently available for sulfide solid electrolyte-based batteries (Fig. 16g).

LiF is one of the key components for stabilizing the SEI layer and is the preferred choice for lithium anode protection. Cheng et al. [217] fabricated an artificial SEI layer (consisting of LiF and nano-Ag) through a substitution reaction between AgF and Li (Fig. 16h). On the one hand, LiF can guide the horizontal uniform deposition of Li due to its high surface energy; on the other hand, nano-Ag enables alloying with Li, which compensates for the electronic insulating property and low ionic conductivity of LiF, resulting in uniform and dense lithium deposition. The symmetric cell can be stably cycled for 600 h at 10 mA cm−2 with low and constant voltage hysteresis. Fan et al. [218] infiltrated a drop of highly concentrated 6 mol L−1 LiFSI dimethoxyethane (DME) (~ 20 mL) between the Li metal anode and the SSE of Li3PS4 and then dried it under vacuum overnight at 120 °C to evaporate the DME solvent. A LiF-rich SEI layer was constructed between Li3PS4 and Li metal (Fig. 16i), which successfully suppressed the formation of lithium dendrites and could increase the CCD of Li3PS4 to more than 2 mA cm−2.

Additives in liquid electrolyte systems can serve to improve the SEI film composition and alleviate the generation of dendrites [219,220,221]. SEI components such as LiF, LiI and Li3N are considered to play such important roles. Similarly, this principle has been applied to LMBs. Han et al. [222] incorporated LiI as an additive into the Li2S-P2S5 SSE, which has high ionic conductivity but electronic insulation in the SEI while increasing the lithium ion transference number, promoting the homogeneity of lithium deposition at the interface, and increasing the electrochemical stability of sulfide electrolytes (Fig. 17).

3.3 Microstructure Modulation

Granular inorganic SEs inevitably feature defects, such as inhomogeneities, porosity, cracks, grain boundaries, and impurity precipitation, which are all nucleation sites for dendrite precipitation. An ideal single-crystal SSE is the fundamental remedy for the grain boundary issue. More recent studies have shown that dendrites can penetrate through stiff SSE membranes along grain boundary networks, resulting in unexpected cell failure [69, 210, 243, 244]. This surprising result suggests that microstructural features should be rationally regulated in the design of practical SEs.

Kataoka et al. [232] successfully grew a centimeter-sized single-crystal garnet-type SE Li6.5La3Zr1.5Nb0.5O12 (LLZNb05) without grain boundaries and pores using the floating zone method. Figure 18a shows an optical image of an LLZNb05 single-crystal plate polished on the surface and an SEM image. From the SEM image, only polishing scratches were observed on the crystal surface, and voids or grain boundaries were not observed. The single-crystal SE featured an extremely high lithium ion conductivity of 1.39 × 10−3 S cm−1 at room temperature and a favorable CCD of 0.5 mA cm−2. However, the costly fabrication and complicated synthesis techniques are key issues that hinder the further development and application of single crystals at this stage. The tendency of single-crystal SEs to simplify the synthesis processes and constitute innovative SE interface structures has been demonstrated.

Reproduced with permission from Ref. [232]. Copyright © 2016, Springer Nature. b X-ray tomographic reconstructions of the void phase in the interior of LLZO electrolytes and the changes in pore size distribution between the pristine and failed electrolytes sintered at 1 050, 1 100, and 1 150 °C. Reproduced with permission from Ref. [245]. Copyright © 2018, American Chemical Society. c Proposed mechanism for pore formation in Li metal anodes. Reproduced with permission from Ref. [246]. Copyright © 2018, Elsevier. d, e Schematic of the synthesis process of Li6PS5Cl. Reproduced with permission from Ref. [238]. Copyright © 2020, American Chemical Society

a Optical and SEM images of a polished LLZNb05 single-crystal plate.