Abstract

Purpose

Construction and demolition waste (CDW) is increasing due to rapid urbanization. An estimated 35% of CDW is disposed of in landfills worldwide. Thus all available strategies for minimizing the environmental and economic impacts of CDW are explored. This study reviews the use of recycled construction and demolition waste as substitutes for primary materials as well as strategies for the reuse of materials that lead to the circular economy. The aim of this study is to analyse previous literature on CDW that use life cycle analysis and contribute to the circular economy.

Methodology

A bibliometric analysis and systematic critical review is presented to investigate the contribution of construction materials to life cycle sustainability assessment (LCSA). The Scopus database was the main source of data reviewed. The geographical distribution, main research sources, and keywords co-occurrence were analyzed for 69 peer-reviewed articles and conference papers.

Findings

Most studies compared the life cycle assessment (LCA) and life cycle cost (LCC) of alternative concrete recycling methods or using waste instead of aggregates in concrete. Recycling or reuse of concrete, bricks, wood, gypsum, and steel are the most common materials studied in previous research. A knowledge gap is proposed for future research.

Originality

The knowledge gaps identified focus on wood waste and concrete. Currently it is not clear which of the options proposed is the most sustainable.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Approximately a third of greenhouse gas (GHG) emissions come from the construction and building industries. This is due to the energy used in the manufacture of materials as well as the construction processes involved [1, 2]. Additionally, construction processes release a considerable amount of air pollution, negatively impacting human health [3]. The Environmental Protection Agency department from United States claimed that only 38% of 169 million tons of construction and demolition waste was recycled during the 2014 [4]. This low recycling rate has a negative impact on the environment and economy, as construction and demolition waste (CDW) contains valuable resources that can be re-used. Additionally, it adds to the growing problem of landfills and other waste sites. The European union (EU) target is to recover 70% of CDW, and many countries around the EU have achieved these goals. However, the rate of waste recovery varies from country to country with some countries having recovery rates of less than 10%, such as Luxembourg [5]. This emphasizes the urgent need to recover CDW by considering alternative approaches such as Life Cycle Analysis (LCA) and Life Cycle Cost (LCC). Due to difficulties deconstructing buildings at the end-of-life, and to the complexity of recovering materials for reuse, current waste management practices present major drawbacks. Waste management is a critical component of circular practices. Analyzing the implementation of the circular economy cannot be accomplished without incorporating waste management practices [6]. The circular economy is recognized as a standard and proven approach to achieving efficient waste management [7]. However, waste management has broader applications that extend beyond the scope of the current study. These applications include sustainable product design and business models, which, while important, are not the focus of this research.

The rate of recycling CDW varies from country to country. Some have a high recycling rate such as Japan (97%), Netherlands (90%), Germany (90%) [8]. Other countries, such as China, recycle less than 10% [9]. The aim of this study is to review life cycle analyses of building material waste to determine directions of future research. This allows for a comprehensive examination of building material waste management within the context of circular economy practices.

CDW also presents opportunities to businesses to reduce their environmental impact and create value [10, 11]. The circular economy (CE) has become popular in many countries, particularly in the construction sector. Many stakeholders choose alternative strategies to achieve circularity, such as using smaller quantities of raw materials, using more durable materials, or recycling waste [12]. However, CE practices are still in their infancy with respect to managing CDW [1, 13, 14]. The goal of the CE is to increase the societal value of materials, resources and products over time [15]. However, the environmental, economic and social sustainability consequences of the CE need to be evaluated [16]. In practice, different metrics are used to assess the LCA and LCC of construction materials and buildings. Some studies suggest using multiple-criteria decision-making (MCDM) to alleviate the common contradictions between circularity metrics [15]; Balasbaneh, Yeoh, et al. [17]a). Construction and demolition waste management is a significant issue because of its direct environmental and economic impacts. CDW is estimated to be disposed of in landfills worldwide at a rate of 35% [18]. The linear economy as applied to the construction industry is where virgin raw materials are extracted for construction and end up as trash at the end of the life of buildings [10]; Tighnavard et al. [19]). Interest in the CE has burgeoned as an innovative solution to reduce waste and move away from the linear economy. This trend has become more critical in the construction industry since this sector uses at least 40% of all raw resources worldwide [20]. To fully realize the potential of the circular economy (CE), current Life Cycle Assessment (LCA) practices need to incorporate post-construction and demolition waste (CDW) impact categories in their main framework [21]. Additionally, the Life Cycle Sustainability Assessment (LCSA) framework, which can assess CDW, is complex, time-consuming, and challenging to implement [22]. This complexity arises because it considers the three pillars of sustainability: environmental, economic, and social categories. CDW is a crucial contributor transiting to circularity due to its significant potential for resource recovery, reuse, and recycling. By effectively managing CDW, the construction industry can make substantial progress in adopting circular economy principles and reducing its environmental impact.

Some LCA studies of CDW have been conducted. For example, Ferronato et al. [23] applied LCA for CDW in developing countries where most waste is sent to landfills. They found that transportation has an essential role in controlling waste emissions. Limiting the distance that CDW has to be sent to recycling facilities to 40 km was found to be beneficial for all environmental impact categories. Ferronato et al. [24] evaluated the LCA of CDW by considering recycling as the best option for mitigating environmental footprint. Their results showed that CDW contributes more than 60% to freshwater aquatic ecotoxicity. Some studies evaluated the alternative materials. For example [25], used LCA to examine refurbishing traditional buildings compared to demolishing them. They found that reinforced concrete presented the worst performance, whilst timber structures had better environmental performance for reconstruction scenarios. The waste of materials places an unavoidable burden on the environment, economy, and society, specifically at the CDW disposal stage. Some researchers have explored the life cycle inventory database and life cycle impact assessment as applied to the demolition stage by focusing on the concept of circular economy [26]. Peixoto et al. [27] analysed the LCA of CDW, avoiding impacts from recovered materials, such as plastics, glass, steel, and recycling. Another study has proposed a model to justify all CDW impact categories being combined into one quantitative indicator [21]. Other researchers have noted that there are still some issues with managing CDW effectively around the world. For example, Alite et al. [28] reported that the absence of approved storage strategies for construction waste and an underdeveloped market for recycling and reuse are among the most essential issues that hinder progress to adopting the CE. Alternative scenarios for CDW have been considered in different studies. Some consider recycling concrete waste at the end-of-life of buildings [10, 16, 29].

This study is divided into three sections. Firstly, bibliometric analysis was conducted to reveal information rates of publication about CE, the main sources of research, most productive journals, and also geographical distribution. Additionally, alternative scenarios for CDW building materials were evaluated along with their respective case studies. These assessed LCSA in all three sustainability pillars: LCA, economic cost analysis, and social life cycle assessment. Thus, the results provide a comprehensive review of research on specific materials. Finally, gaps in knowledge are identified for future research. These gaps can inform effective policies for sustainable building materials.

Method

We conducted a systematic literature review to analyse the CE as it applies to CDW. Using the Scopus database we identified articles published between 2013 and 2023 that discussed all alternative scenarios regarding construction waste towards the CE. These articles dealt with topics including LCSAs, waste management, and CE strategies. The Scopus database was preferred over alternatives such as Google Scholar and Web of Science because it hosts a wide range of academic publications [30, 31]. Scopus is regularly updated and contains the latest research. Furthermore, Scopus offers a more comprehensive search than other databases, allowing users to access relevant results easily [32].

Principles and Procedures

Articles were searched using the “Title” field. Several document types were considered, but only conferences, articles, and chapters were included as these documents undergo rigorous peer-reviewing processes [33]. The titles and abstracts of the documents were scanned, and only those documents deemed relevant were included. Full texts of these documents were then reviewed to determine their eligibility. Finally, the search results were manually verified for accuracy. All these procedures and steps were accomplished based on related previous studies of CE and CDW [34,35,– 36]. Scopus’ title/abstract/keyword fields were searched comprehensively. The investigation was limited to publications in English.

Systematic Literature Review

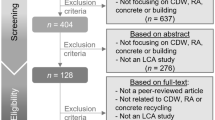

Analysis and research of database data is referred to as bibliometrics. This is a quantitative and objective method [47]. Bibliometric methods may be used to study the growth of scientific fields, to assess the impact of research, and to identify trends in research literature. The workflow diagram for the current study is provided in Fig. 1. Bibliometrics searches were performed using the Scopus database. VOSviewer version 1.6.14 (released on October 31, 2023) was used as a science mapping and content analysis tool for relevant papers located using pre-defined criteria (including research gaps, study scope, highlights, and prominence of LCSA and CE in CDW studies). Based on bibliographic data, VOSviewer is a Java-based program developed by van Eck & Waltman [37], that can visualize node-link maps. Results from VOSviewer were then used to identify trends, clusters, and hot spot areas within the CDW studies. Finally, the findings are discussed, and conclusions are drawn. Systematic Literature Reviews begin by defining a research question that must be answered by literature published in selected databases. In this case, the research question we sought answers for was what studies of CDW have evaluated best practices with respect to LCSA.

A meta-analysis used keywords and exclusion criteria to filter articles that answered this question. It was decided to employ a snowball approach by considering excluded articles that pertain to the subject in general. Qualitative analysis was conducted using other relevant literature [38]. To capture the established and conceptual knowledge outside of the database searches and pre-dating the establishment of CDW related to the CE, a backward snowballing approach was employed.

Figure 1 shows the queries used to interrogate the Scopus database to identify relevant articles. The queries included the terms “construction and demolition waste,” “Circular Economy,” “Life cycle Assessment,” “Social Life cycle Assessment,” and “Life cycle Cost.” The research question was defined as “How can LCSA use knowledge of the CE to manage the CDW of buildings?” The keyword strings shown in Fig. 1 were chosen to locate those used in articles. Date ranges were set to “all years until present” to avoid omission of any relevant papers. Using Scopus, 180 publications were retrieved in May 2023. After removing duplicates and irrelevant articles, we identified and discarded those that contained CE and related keywords without any connection to the study. Inclusion of the remaining articles was determined based on their relevance. After reading the remaining articles, biases and inaccuracies were identified. In total, 69 publications were considered relevant after this final filtering. Following that, a statistical analysis of the dataset was performed to identify trends and determine whether there were any statistically significant relationships between the variables. Based on the results of this analysis, future research recommendations were made.

Results

Bibliometric Data

A bibliometric analysis of the number of publications shows an apparent increase in interest since 2018. A total of 96 articles were considered for further analysis in this study. This indicates a broader and deeper investigation of these topics, which suggests a shift in how society thinks about waste and resource management. This trend is likely to continue in the coming years as more sustainable solutions are searched for. A review of the number of publications per year indicates that this topic is becoming more popular. From 2014 onward, there has been an increase in the number of papers, with most (22) being published in 2022. Since 2014, many researchers have started evaluating waste using LCA. LCA is a powerful tool for estimating the environmental impacts of a product, service, or process. Circular economies aim to reduce their environmental impacts and reduce, reuse, and recycle resources. However, the number of publications was stable at 11 articles per year during 2020 and 2021. As of May of 2023, 13 relevant articles were published. An overview of the number of publications and citations for each year is shown in Fig. 2.

From 2013 to 2017, there was a slow but steady growth in the number of citations per year. Despite this, the citation distribution increased dramatically from 68 in 2018 to 374 in 2022. This can be attributed to the increased popularity of circularity and waste management and the increasing number of researchers working on this topic. This shows that circularity and waste management have become essential to countries and regions. This increase has also led to the development of innovative tools and technologies, which can help to reduce carbon emissions and protect the environment. Additionally, circularity and waste management growth have led to increased collaboration between governments, industry, and academia.

Table 1 lists the journals publishing at least two articles about the CE and CDW based on the number of bibliographic couplings. The Journal of Cleaner Production has the most (16 articles and 422 citations). This journal has the highest total link strength among other journals with 432 links. The Journal of Resources, Conservation and Recycling was second (ten articles and 285 citations). In third to fifth place are the Journals of Waste Management and Science of the Total Environment (5 articles and 195 citations), and the Journal of Building Engineering (3 articles and 46 citations).

Figure 3 shows the most productive journals between 2014 and 2023 based on node link. The node-link maps created by VOSviewer represent bibliometric networks of an object and typically include only one type of object. Objects show the articles and sources of articles with the highest number of publications. Figure 3 shows publications with at least two articles or conferences. To connect these objects in the networks, Scopus database files [72] were used as a source of bibliographic coupling, citations, co-authorships, co-occurrences, or co-citations. The strength of each link is indicated by a positive numerical value. In Table 1, a high total link strength indicates that the link is strong. The Journal of Cleaner Production, and the journal of Waste Management have the highest total link strength of 432 and 318, respectively. Therefore, the articles published in these journals have been cited in several different journals in CE research as applied to building material waste. These maps serve as a visual representation of a discipline’s research published.

Geographical Distribution

Table 2 shows publications by country along with citations. The table shows that most publications are from developed countries such as China, Italy, and Australia. Belgium, Finland, Turkey, and Denmark also contributed with the least number of publications (2). Overall, these publications have been widely cited, indicating that they are influential in this field of research. The following countries have a higher number of contributions based on author affiliation: China (13), Italy (11), Australia (9). In the meantime, Italy (256 citations), China (190), India (191), and Denmark (186 citations) have the highest number of citations. China is among the countries with the highest link strength (393), followed by Australia (393). This statistic represents how closely a given researcher is connected to other researchers regarding co-authorship. On the other hand, India (283) is ranked third for total link strength, with only six documents in this field.

Figure 4 shows the countries or regions where articles on CDW and the CE aligned between 2014 and 2023. The size of the nodes indicates the influence of a country, and the thickness of the links indicates the degree of cooperation among different countries. The colors of the nodes represent different countries, and the size of the nodes and the thickness of the links have been adjusted to reflect the changing dynamics of international relations. The map provides valuable insights into the current state of global cooperation. Statistical data in Table 2 shows that the three most productive countries (China, Italy, and Australia) are the ones that collaborate the most.

Co-occurrence of Keywords

A keyword co-occurrence analysis was used to analyse the 69 papers. A few similar words were initially excluded because they could influence other keyword co-occurrence networks. This is because several words may describe the same concept. Thus, life cycle assessment, life cycle analysis, life-cycle, life-cycle analysis, and LCA were conflated into life cycle assessment. Most occurrences (145) related to life cycle assessment, followed by demolition (47), construction and demolition waste (45), recycling (45), and environmental impact (38). LCA was popular because it is one of the fundamental techniques for addressing the CE.

On the other hand, the total link strength indicated the interrelatedness of the keywords. A total link strength is determined by the total number of references cited between two sources. The strength of the linkage is inversely proportional to the distance between them. This means that items that are closely related are more likely to have stronger linkages than items that are far apart. The strength of a link can also be affected by the number of citations they contain. In comparison, the total link strength of LCA was the highest among keywords (1785) followed by recycling, demolition, construction and demolition waste, global warming, and environmental impact (Table 3).

An analysis of keyword co-occurrence networks for research topics reveals the relationships between keywords and link frames. A keyword co-occurrence network was produced using VOSviewer software (Fig. 5). This shows the network diagram of keywords connected by co-occurrence links, which consists of four clusters. Nodes are sized based on their frequency, and terms are shown in relation to one another in their relative positions in the map. Figure 5 was created for the minimum number of 5 keywords, grouped into four clusters. A different colour highlights each cluster. The map also indicates that terms within the same cluster are closely related. The cluster with the largest node size is most strongly associated with the keyword. The nodes with higher centrality provide more insights into the research topics.

Cluster #1, green in Fig. 5, is the most significant cluster with 21 keywords. This cluster relates to “sustainable development”, “demolition”, “circular economy”, “decision making”, and “sustainability”. The link between demolition and sustainability is challenging for the building industry [39]. This is mainly because unsustainable CDW practices cause serious societal and environmental issues, and lead to resource wastage. Cluster #2 is red in Fig. 5. This cluster focuses on “LCA”, “recycling”, “waste disposal”, and “global warming potential”. Many academic studies discuss legislation for recycling as a beneficial strategy for reducing environmental impacts [40]. Cluster #3, (blue in Fig. 5) mainly discusses “building materials”, “waste”, “waste management”, “cost”, “economic aspects”, and “cost benefit analysis”. The connection between these keyword shows the importance of evaluating the economic cost of waste treatment strategies [41, 42]. Cluster #4, (yellow in Fig. 5) relates to “circular economy”, “CDW”, “decision making”, “demolition”, and “environmental assessment”. There is a correlation between the CE and CDW [43] and strong interactions between the CE and decision-making [34].

Review of Literature

Types of Materials

The CDW analysed in this section include materials such as timber, concrete and bricks. We have identified the end-of-life scenarios for buildings with respect to their constituent materials and highlight future research. This enhances understanding of the different end-of-life scenarios’ potential economic and environmental benefits. A CE perspective also provides insight into best practices for managing and disposing of materials. Finally, it will provide policymakers with insights into developing sustainable strategies for buildings and materials. Figure 6 illustrates the contribution of recycling different materials noted in literature. The majority of studies focused on uses of crushed concrete as aggregates in new concrete and related topics by 61%, followed by brick, wood, gypsum, and steel. The distribution of production shown in Fig. 6.

Tables 4, 5, and 6 present three categories devoted to a different material waste treatment. Wood and concrete waste assessments are presented in Tables 4 and 5, while other materials waste assessments are presented in Table 6. Table 4 presents studies that consider recycling for the end-of-life of buildings to achieve a CE. A previous study showed that one-third of production and construction emissions (CO2) could be recovered by recycling alternative engineering woods such as cross-laminated timber (CLT). However, this depends on how much CLT is sent for recycling. CLT can be recycled multiple times, making it a sustainable and renewable resource. Recycling also reduces the need for timber harvesting, which can harm the environment [44]. Deng et al. [45] investigated the wood that is used for doors by applying a LCA methodology in China. This study compared incineration, landfill, and recycling. Despite the result indicating that recycling was the most environmentally friendly solution for waste disposal of wood, only 20% of waste wood materials are sent for recycling.

The results of Hossain et al. [46] evaluation of the environmental impact of recycling waste indicate that recycling rates of wood waste are an essential factor in reducing GHG emissions. Dahlbo et al. [47] argued that despite the high economic and environmental benefits of energy recovery from wood, wood waste recycling must also remain high. They highlighted the importance of reducing wood waste and preventing it from ending up in landfills. All the studies emphasized how wood waste recycling has a major and positive impact on environmental emissions, and the amount of recycling should be increased to achieve the best result.

Analysis of concrete CDW may be categorized into four sections: (i) mixing CDW as an aggregate replacement to replace natural aggregate, (ii) converting waste into clinker production, (iii) converting CDW recycling using alternative strategies that often considered as sustainable method such as air jig strategy, (iv) used in road and pavements. In addition, if the distance between the production site and the destination site is long, the adverse effects of transportation operations can cancel out any environmental benefits [48]. Table 5 shows the studies related to CDW of cement and concrete. Firstly, Mistri et al. [49], compared four samples of recycled aggregate with different proportions of attached mortar (AM). Using recycled materials in concrete could significantly reduce the cost of concrete. Additionally, using recycled aggregate in concrete reduces the need for natural resources and helps conserve the environment. Recycling waste concrete into lightweight masonry blocks was evaluated by Nežerka et al. [50]. They showed that replacing Portland cement with recycled concrete fines can reduce environmental impact, however, there were some limitations. They suggested that replacing more than 60% could compromise the cementitious matrix’s integrity. Recycling engineering waste to produce lightweight aggregates could reduce carbon emissions by as much as 80%, according to Gao et al. [51]. This material could be used in the construction industry, reducing the amount of cement used in concrete. Some studies focused on autoclaved aerated concrete to produce concrete-like blocks. Volk et al. [29] evaluated the LCA of post-demolition autoclaved aerated concrete. The author claimed that recycled autoclaved aerated concrete could be used for other purposes such as shuttering blocks, lightweight aggregate concrete, and light mortar. Cuenca-Moyano et al. [52] assessed the production of mortar manufactured with alternative amounts of natural fine aggregate recycled from CDW. They showed that recycled fine aggregate could diminish environmental impacts.

The CE and sustainability concepts are becoming increasingly important in the cement and concrete industry due to global warming and irreversible environmental impacts. Some studies have focused on cement production or calcination. For example, Liang et al. [53] evaluated the LCA of domestic waste for clinker production. They found that using domestic waste in cement production is an environmentally friendly approach. The process of calcination derives from burning lime and the decomposition of calcium carbonate to create cement [61]. Zhou et al. [54] showed that calcining engineering sediment waste increased economic performance and decreased environmental impact by 50%. As part of a study conducted by Cassiani et al. [58] the use of auxiliary cementitious materials and recycled concrete aggregates was evaluated to reduce the environmental impacts of Portland cement concrete. One source of recycled concrete aggregates (RCA) was successfully replaced using levels of fly ash (20%), slag (40%), and silica fume (10%).

Some studies have evaluated recycling coarse aggregate from CDW. For example, Waskow et al. [57] analysed the RCA from CDW by comparing current and air jig strategies. They found that both recycling strategies provided environmental benefits compared to natural aggregate. Colangelo et al. [60] produced five mixtures of concrete with similar mechanical properties using recycled aggregates from CDW. They showed that mixtures formed using RCA have improved environmental impacts. Some researchers have also focused on providing a life cycle inventory of CDW for concrete. Paz et al. [55] showed that 1 m3 of recycled aggregates produces 0.53–15.35 kgCO2/m3. Finally, some studies proposed using recycled materials as pavements or road structures. For example, Santolini et al. [48] evaluated different applications for recycled aggregates for rural roads and pavements. Recycled aggregates are reported to be clearly less environmentally damaging than virgin aggregates. Tefa et al. [56] assessed the implementation of CDW materials as substitutes for primary natural aggregate for road pavements. They showed that constructing pavements using CDW for the subbase reduces environmental impact.

Table 5 shows that investigators used various software to evaluate waste and recycling methods, such as Gabi, OpenLCA, and SimaPro. However, the functional units they used differed from one study to another. For example, those studies that evaluated the recycled aggregates from CDW [48] considered 1 m3 of the final product. Meanwhile other studies [53] analyzed cement production using domestic waste using the functional unit as 1 t of clinker. Table 6 shows an analysis of CDW converted into other materials such as brick and gypsum.

Table 6 also identifies studies on recycling or reusing single building materials. For example, Gencel et al. [62] evaluated brick production using waste materials. They found that incorporating concrete waste and water treatment sludge as primarily materials could reduce the environmental impact. Gencel et al. [62] claimed that the new brick could be recycled in the manufacture of other building materials, which is in line with the CE. Liang G. et al. [63] evaluated the reuse of waste red brick powder into other products, such as eco-friendly binders. They found that reusing waste red brick powder could significantly reduce both carbon dioxide (CO2) emissions and energy consumption during the manufacturing stage. The last study of brick waste using the CE concept is that of Veiga Simão et al. [64]. They used mine waste to manufacture facing bricks.

LCA showed that facing bricks manufactured from mine waste could improve environmental performance 40% more than standard bricks. The seminal study by Vares et al. [65] evaluated the environmental impacts and costs of reusing steel materials from buildings. LCA at the product stage determined that GHG emissions from re-used steel structures are approximately 188 kg CO2e/m2, as opposed to 375 kg CO2e/m2 when steel is used for the first time. Other studies evaluated the recycling of gypsum.

Suárez et al. [67] evaluated the environmental impact of recycled gypsum as a replacement for natural gypsum in ordinary Portland cement. They found that recycled gypsum had environmental benefits when the gypsum waste was transported less than 30 km to a recycling site. The above shows that most waste analyses focus on cement and concrete and support the CE concept. A few studies focused on steel, wood and gypsum (Vares et al. [65]; Suárez et al. [46, 67]. Figure 7 presents the strategies researchers have used to incorporate CDW in the CE based on the studies mentioned above.

Life Cycle Sustainability Analysis

LCA Evaluation of CDW

LCA is one of the most applicable methods for analysing waste and recycling [68]. One of the first studies that considered LCA for recycling CDW was conducted by Hu et al. [69]. Almusaed et al. [70] indicated reuse can save up to 40% of GHG emissions in constructing new buildings by using materials from previous buildings such as steel, gypsum, wood, concrete, etc. Table 7 shows the studies that considered the LCA of CDW for whole buildings rather than specific waste or recycling processes.

Wang et al. [72] Used LCA to evaluate landfill, reuse, and recycling, showing that reuse and recycling significantly impact on environmental load. Jain et al. [73] conducted a LCA study of CDW and found that due to greater material recovery, integrated wet recycling is more environmentally sound than landfilling. Ram et al. [74] administered an LCA study and showed that recycling remains beneficial compared to landfilling. Vitale & Arena [75], found that recycling of steel, glass and plastic has a positive environmental impact. In terms of carbon, energy, and water footprints, only recycling of construction materials was beneficial for the environment. The use of incineration as a secondary strategy after recycling is a better option for reducing water and energy footprints. When carbon footprint was taken as the main focus for main comparisons, landfilling was found to be a slightly better option [76].

Considering LCA, LCC & SLCA of CDW

Some studies considered both the environmental impact and economic cost of CDW (Table 8). For example, Khan & Ali [77], tried to identify the best types of concrete mixtures to partially replace cement by considering LCA and LCC. Khan & Ali [77], recommended the use of CDW in constructing concrete components due to its affordable price and low emissions. Yu et al. [78] conducted studies on LCA and LCC and showed that recycled coarse aggregates generated from reject prefabricated concrete components provided economic and environmental benefits over conventional self-compacting concrete. Alberto López Ruiz et al. [10] studied using recycled coarse aggregates in preference to traditional concrete and found that these had environmental and economic advantages. Wittocx et al. [42] focused on the CE concept to suggest alternative repair methods to maintain the value of products, materials and resources for as long as possible. Wittocx et al. [42] conducted LCA and LCC studies of repairing concrete including patch repairs, conventional repairs, galvanic cathodic protection, (iv) impressed current cathodic protection and (v) total replacement of elements.

Tavares et al. [41] found end-of-life impacts of prefabricated lightweight steel frames (LSF) to be lower than those of concrete and timber due to recycling options. Qiao et al. [79] claimed that manufacturing of masonry bricks contributed to lower economic costs and CO2 emissions compared to permeable bricks and thermal insulation blocks made from CDW. Boateng et al. [4] found that a 75% reduction in the CDW sent to the landfill could reduce the environmental burden by 35%. Design Vares et al. [65] completed LCA and LCC studies of new and reused steel in constructing a new building. They found the emissions due to the reuse steel to be lower than where steel structures were used for the first time by 188 kg CO2e/m2 versus 375 kg CO2e/m2.

The impact on the environment and economy of different concrete types was assessed by [77]. They showed that the carbon dioxide from specimen mixes with 10% CDW and ordinary concrete was 181 CO2Kg versus 285 CO2Kg. However, the cost of 1 m3 of concrete was 20,302 Pakistani rupees (PKR) and 21,747 PKR for concrete mix with CDW and ordinary concrete, respectively. By replacing traditional building materials with construction waste, CDW recycled products can produce significant environmental and carbon reduction benefits. These decrease the environmental impact of each functional unit (1 ton of CDW utilisation) by at least 1.3 kg and 15.6 kg of CO2e [79].

One of the main foci of sustainability criteria in national building codes is waste recovery from construction demolition (Vares et al. [65]). Most of the research reviewed claimed that using waste materials at the end of a building’s life is more economically advantageous than using raw materials [10]. However, another study found the opposite and claimed that using demolition waste might burden industry more. For example, Illankoon & Lu [81], discovered that to obtain construction waste management-related credits, one needs to pay a higher overall cost ranging from 0.4 to 6% more than a conventional building. As previously mentioned, LCSA comprises three pillars and social is one of them. The social impacts of CDW and related topics have rarely been investigated in literature [82]. Wu et al. [80] found that when waste was transported to another region for recycling, the impact on the original region and district of waste generation and the cost of receiving the waste at the destination are both negatively impacted.

Discussion and Research Gaps

Figure 8 shows the knowledge gaps identified for future research. The current study focused on life cycle sustainability assessment with LCA, LCC and SLCA [83]. Based on a previous review study by Lovrenčić Butković et al. [12], LCA is the most common methodology for evaluating the CE in the construction industry. Despite considering many strategies, some countries still need to apply new methods to manage CDW. This lack of progress may be caused by not fully evaluating the environmental impacts and costs of alternative strategies. The most effective strategy for CDW is upcycling which refers to recycling with a higher or equal quality than the original resource. However, other strategies such as down-cycling (turning the CDW into crushed material for road filling) are also considered as movements towards the CE. Building structures are rarely reused, and regulations are not overwhelmingly supportive of the practice. Vares et al. [65] reported that material recovery for reuse at the end of the life of a building is complex and challenging due to the fact that the building stock is not designed for deconstruction. Thus, more research is needed to evaluate the impact of reuse on the CE and the possibility of reusing alternative CDW.

Some attempts have been made to propose knowledge gaps for future research for CDW [30]. Wood waste needs to be evalauted for both environmental and economic costs. Some studies have compared wood waste in the demolition stage. For example, wood waste used in cement-bonded particleboard [46] and also as a replacement for heavy fuel oil Dahlbo et al. [47]. Future studies need to compare these two senarios in a single study for both LCA and LCC. This should demonstrate the best scenaro for wood waste, thereby showcasing steps to greaner production for industry. Comparing alternative recycling methods for steel waste and identifying the optimum mix of alternative machines for upcycling this waste needs further investigation. Meanwhile, alternative materials need to be evaluated with respect to their LCA and LCC as replacments for cement including quarry dust, glass powder, ceramic dust, coal dust, and tire rubber [85]. In particular, waste issues related to cement, such as water absorption and interfacial transition zone need to be addressed in future research. Such studies will inform decisions about which materials are the most sustainable replacements for cement. These studies also need to consider potential environmental and health impacts of the material replacements. Additionally, the cost-effectiveness of these replacements should be evaluated.

SLCA is a methodology that assesses the social impacts associated with the life cycle of a product or a service. It considers the social aspects of sustainability, including impacts on human well-being, labour conditions, community development, and other social dimensions. The social performance of alternative waste methods are currently absent from literature. For example, several methods could be applied for concrete in the demolition phase but it is not clear which the extent to which these satisfy the social aspect. For example, Yıldız-Geyhan et al. [86] evaluated the SLCA of packaging waste systems and a similar study is needed in the CDW industry. The social aspects of waste management are highly context-dependent, and specific social issues may vary across regions and communities. This is largely due to the fact that most research focuses on the technical aspects of these solutions. However, the social aspects of waste management, such as public opinion, are also important and should be taken into account. Further research is needed to assess the social performance of alternative waste methods. Despite different evaluations of various waste materials, few determine optimal end-of-life scenarios. Further research is needed in this area to definitively identify the best solutions. For example, previous studies have separately examined waste wood for recycling, for cement-bonded particleboard, and as a replacement for heavy fuel oil. Future research could analyze these scenarios in a single study, providing a more holistic understanding of waste wood utilization options.

Conclusion

Based on CE principles and sustainable development goals, this study aimed to review literature to reveal the previous areas of studies and the future gap. The review was conducted to identify the main research themes, gaps, and future research directions. The findings will help to identify opportunities for future research and policy making in the field of the CE and sustainable development. A life cycle sustainability assessment evaluates construction and demolition waste towards a CE. Life cycle analysis can be represented in three ways: environmentally, economically, and socially. It also informs decision-making about reducing the environmental impact of CDW. The keyword search revealed 69 publications relevant to the topic. The most cited keyword was “Life cycle assessment, LCA, Life cycle analysis, etc.” with an occurrence of 145, with total link strength of 1785. The highest number of evolutions among the waste was dedicated to the cement and concrete. This study categorizes construction materials waste into separate categories, including wood waste, cement and concrete waste, brick waste, steel waste, and gypsum waste. This facilitates evaluation by others, allowing them to investigate all waste analyses conducted to date using life cycle assessment, life cycle cost analysis, and social life cycle assessment methodologies. All waste scenarios have been presented as comprehensive diagrams. This visual representation provides both the academic and industry sectors with a holistic view of current waste management practices in the building industry. The proposed knowledge gaps shows that future research is required to include studies on different aspects of social LCA. As a result, the social impact of alternative recycling materials on society and workers has been neglected for the past few years. Meanwhile, the LCA and LCC of alternative waste materials as alternatives to aggregate, such as quarry dust and coal dust in concrete, require more research.

Data Availability

The datasets used and analysed during the current study are available from the corresponding author on reasonable request.

References

Balasbaneh AT, Yeoh D, Juki MI, Gohari A, Abidin ARZ, Marsono AK, Bin (2021) Applying three pillar indicator assessments on alternative floor systems: life cycle study. Int J Life Cycle Assess 26(12):0123456789. https://doi.org/10.1007/s11367-021-01881-6

Ness DA, Xing K (2017) Toward a resource-efficient built environment: a literature review and conceptual model. J Ind Ecol 21(3):572–592. https://doi.org/10.1111/jiec.12586

Nußholz JLK, Nygaard Rasmussen F, Milios L (2019) Circular building materials: Carbon saving potential and the role of business model innovation and public policy. Resour Conserv Recycl 141(March 2018):308–316. https://doi.org/10.1016/j.resconrec.2018.10.036

Boateng SB, Banawi AA, Asa E, Yu Y, Ahiable C (2023) Environmental and economic outlook of construction and demolition waste management practices in a mid-sized city. J Mater Cycles Waste Manage 0123456789. https://doi.org/10.1007/s10163-023-01667-y

Bogoviku L, Waldmann D (2021) Modelling of mineral construction and demolition waste dynamics through a combination of geospatial and image analysis. J Environ Manage 282. https://doi.org/10.1016/j.jenvman.2020.111879

Kirchherr J, Reike D, Hekkert M (2017) Conceptualizing the circular economy: an analysis of 114 definitions. Resour Conserv Recycl 127(September):221–232. https://doi.org/10.1016/j.resconrec.2017.09.005

Dixit A, Dutta P (2024) Critical success factors for the adoption of circular economy in sustainable healthcare waste management. Clean Technol Environ Policy 26(7):2181–2201. https://doi.org/10.1007/s10098-023-02712-y

Kieu T, Nguyen L, Hao H, Guo W, Le T, Nguyen H, Woong S (2021) Science of the total Environment Environmental impacts and greenhouse gas emissions assessment for energy recovery and material recycle of the wastewater treatment plant. Sci Total Environ 784:147135. https://doi.org/10.1016/j.scitotenv.2021.147135

Huang B, Wang X, Kua H, Geng Y, Bleischwitz R, Ren J (2018) Construction and demolition waste management in China through the 3R principle. Resour Conserv Recycl 129(October 2017):36–44. https://doi.org/10.1016/j.resconrec.2017.09.029

Alberto López Ruiz L, Ramon R, Melissa Lara Mercedes X, C., Domingo G (2022) S. Multicriteria analysis of the environmental and economic performance of circularity strategies for concrete waste recycling in Spain. Waste Manag 144:387–400. https://doi.org/10.1016/j.wasman.2022.04.008

Balasbaneh AT, Bin Marsono AK (2017) Proposing of new building scheme and composite towards global warming mitigation for Malaysia. Int J Sustain Eng 10(3). https://doi.org/10.1080/19397038.2017.1293184

Lovrenčić Butković L, Mihić M, Sigmund Z (2021) Assessment methods for evaluating circular economy projects in construction: a review of available tools. Int J Constr Manage 0(0):1–10. https://doi.org/10.1080/15623599.2021.1942770

Khan SAR, Shah ASA, Yu Z, Tanveer M (2022) A systematic literature review on circular economy practices: challenges, opportunities and future trends. J Entrepreneurship Emerg Economies 14(5):754–795. https://doi.org/10.1108/JEEE-09-2021-0349

Patra SP, Wankhede VA, Agrawal R (2023) Circular economy practices in supply chain finance: a state-of-the-art review. Benchmarking 31(7):2197–2216. https://doi.org/10.1108/BIJ-10-2022-0627

Walzberg J, Lonca G, J. Hanes R, L. Eberle A (2021) Do we need a New Sustainability Assessment Method for the Circular Economy? A critical literature review. 1(January):1–20. https://doi.org/10.3389/frsus.2020.620047

Balasbaneh AT, Sher W (2021) Life cycle sustainability assessment analysis of different concrete construction techniques for residential building in Malaysia. Int J Life Cycle Assess 0123456789. https://doi.org/10.1007/s11367-021-01938-6

Balasbaneh AT, Yeoh D, Ramli MZ, Valdi MHT (2022) Different alternative retrofit to improving the sustainability of building in tropical climate: multi-criteria decision-making. Environ Sci Pollut Res 0123456789. https://doi.org/10.1007/s11356-022-18647-8

Kabirifar K, Mojtahedi M, Wang C, Tam VWY (2020) Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: a review. J Clean Prod 263:121265. https://doi.org/10.1016/j.jclepro.2020.121265

Tighnavard Balasbaneh A, Sher W, Yeoh D, Koushfar K (2022a) LCA & LCC analysis of hybrid glued laminated timber–concrete composite floor slab system. J Building Eng 49(January). https://doi.org/10.1016/j.jobe.2022.104005

Balasbaneh AT, Sher W (2022) Economic and environmental life cycle assessment of alternative mass timber walls to evaluate circular economy in building: MCDM method. Environ Dev Sustain 0123456789. https://doi.org/10.1007/s10668-022-02707-7

Gholami Rostam M, Abbasi A (2022) Integrating construction and demolition waste impact categories into building energy optimization through a conceptual sustainability-oriented model. J Clean Prod 378(June):134543. https://doi.org/10.1016/j.jclepro.2022.134543

Quéheille E, Ventura A, Saiyouri N, Taillandier F (2022) A Life Cycle Assessment model of end-of-life scenarios for building deconstruction and waste management. J Clean Prod 339(January). https://doi.org/10.1016/j.jclepro.2022.130694

Ferronato N, Lizarazu G, Gorritty Portillo GE, Moresco MA, Conti L, F., Torretta V (2022) Environmental assessment of construction and demolition waste recycling in Bolivia: Focus on transportation distances and selective collection rates. Waste Manage Res 40(6):793–805. https://doi.org/10.1177/0734242X211029170

Ferronato N, Moresco L, Guisbert Lizarazu GE, Gorritty Portillo MA, Conti F, Torretta V (2023) Comparison of environmental impacts related to municipal solid waste and construction and demolition waste management and recycling in a latin American developing city. Environ Sci Pollut Res 30(4):8548–8562. https://doi.org/10.1007/s11356-021-16968-8

Silva R, Surra E, Quelhas B, Costa AA, Lapa N, Delerue-Matos C (2022) Advantages of structural inspection and diagnosis for traditional buildings’ refurbishment: a Life Cycle Assessment perspective. Build Environ 223(June):109485. https://doi.org/10.1016/j.buildenv.2022.109485

Ivanica R, Risse M, Weber-Blaschke G, Richter K (2022) Development of a life cycle inventory database and life cycle impact assessment of the building demolition stage: a case study in Germany. J Clean Prod 338(August 2021):130631. https://doi.org/10.1016/j.jclepro.2022.130631

Peixoto L, Vitale P, Penteado CSG, Arena U (2019) Life cycle assessment of construction and demolition waste management in a large area of São Paulo State, Brazil. 85, 477–489. https://doi.org/10.1016/j.wasman.2019.01.011

Alite M, Abu-Omar H, Agurcia MT, Jácome M, Kenney J, Tapia A, Siebel M (2023) Construction and demolition waste management in Kosovo: a survey of challenges and opportunities on the road to circular economy. J Mater Cycles Waste Manage 25(2):1191–1203. https://doi.org/10.1007/s10163-022-01577-5

Volk R, Steins JJ, Kreft O, Schultmann F (2023) Life cycle assessment of post-demolition autoclaved aerated concrete (AAC) recycling options. Resour Conserv Recycl 188:106716. https://doi.org/10.1016/j.resconrec.2022.106716

Antwi-Afari MF, Li H, Pärn EA, Edwards DJ (2018) Critical success factors for implementing building information modelling (BIM): a longitudinal review. Autom Constr 91(February):100–110. https://doi.org/10.1016/j.autcon.2018.03.010

Chàfer M, Cabeza LF, Pisello AL, Tan CL, Wong NH (2021) Trends and gaps in global research of greenery systems through a bibliometric analysis. Sustain Cities Soc 65:102608. https://doi.org/10.1016/j.scs.2020.102608

Antwi-afari P, Ng ST, Hossain U (2021) A review of the circularity gap in the construction industry through scientometric analysis. J Clean Prod 298:126870. https://doi.org/10.1016/j.jclepro.2021.126870

Tighnavard A, Sher W, Madun A, Ashour A (2024) Life cycle sustainability assessment of alternative green roofs– A systematic literature review. Build Environ 248(August 2023):111064. https://doi.org/10.1016/j.buildenv.2023.111064

Jiang J, Chu C, Song L, Gao X, Huang B, Zhang Y, Zhang Y, Liu Y, Hou L, Ju M, Cao Z (2023) From prospecting to mining: a review of enabling technologies, LCAs, and LCCAs for improved construction and demolition waste management. Waste Manag 159(September 2022):12–26. https://doi.org/10.1016/j.wasman.2023.01.017

Li Y, Li M, Sang P (2022) A bibliometric review of studies on construction and demolition waste management by using CiteSpace. Energy Build 258:111822. https://doi.org/10.1016/j.enbuild.2021.111822

Sharma N, Kalbar PP, Salman M (2022) Global review of circular economy and life cycle thinking in building demolition Waste Management: a way ahead for India. Build Environ 222(July):109413. https://doi.org/10.1016/j.buildenv.2022.109413

van Eck NJ, Waltman L (2017) Citation-based clustering of publications using CitNetExplorer and VOSviewer. Scientometrics 111(2):1053–1070. https://doi.org/10.1007/s11192-017-2300-7

Tinoco MP, de Mendonça ÉM, Fernandez LIC, Caldas LR, Reales OAM, Toledo Filho RD (2022) Life cycle assessment (LCA) and environmental sustainability of cementitious materials for 3D concrete printing: A systematic literature review. J Build Eng 52:104456. https://doi.org/10.1016/j.jobe.2022.104456

Zhang K, Qing Y, Umer Q, Asmi F (2023) How construction and demolition waste management has addressed sustainable development goals: exploring academic and industrial trends. J Environ Manage 345(March):118823. https://doi.org/10.1016/j.jenvman.2023.118823

Huang Y, Liang Y, Gong Y, Yuan Z (2023) Role of trust-building in online recycling platforms. Int J Prod Econ 263(August 2022):108962. https://doi.org/10.1016/j.ijpe.2023.108962

Tavares V, Soares N, Raposo N, Marques P, Freire F (2021) Prefabricated versus conventional construction: comparing life-cycle impacts of alternative structural materials. J Building Eng 41(May):102705. https://doi.org/10.1016/j.jobe.2021.102705

Wittocx L, Buyle M, Audenaert A, Seuntjens O, Renne N, Craeye B (2022) Revamping corrosion damaged reinforced concrete balconies: life cycle assessment and life cycle cost of life-extending repair methods. J Building Eng 52(March):104436. https://doi.org/10.1016/j.jobe.2022.104436

Bonoli A, Zanni S, Serrano-Bernardo F (2021) Sustainability in building and construction within the framework of circular cities and european new green deal. The contribution of concrete recycling. Sustainability (Switzerland) 13(4):1–16. https://doi.org/10.3390/su13042139

Balasbaneh AT, Sher W, Yeoh D, Yasin MN (2022) Economic and environmental life cycle perspectives on two engineered wood products: comparison of LVL and GLT construction materials. Environ Sci Pollut Res Lcc. https://doi.org/10.1007/s11356-022-24079-1

Deng N, Wang J, Sun J, Cao N (2023) Life cycle assessment and optimization scenario of solid wood composite doors: a case study in the east of China. Sci Total Environ 868(January):161494. https://doi.org/10.1016/j.scitotenv.2023.161494

Hossain MU, Wang L, Yu IKM, Tsang DCW, Poon CS (2018) Environmental and technical feasibility study of upcycling wood waste into cement-bonded particleboard. Constr Build Mater 173:474–480. https://doi.org/10.1016/j.conbuildmat.2018.04.066

Dahlbo H, Bachér J, Lähtinen K, Jouttijärvi T, Suoheimo P, Mattila T, Sironen S, Myllymaa T, Saramäki K (2015) Construction and demolition waste management - A holistic evaluation of environmental performance. J Clean Prod 107:333–341. https://doi.org/10.1016/j.jclepro.2015.02.073

Santolini E, Bovo M, Barbaresi A, Torreggiani D, Tassinari P (2023) LCA of virgin and recycled materials to assess the sustainability of paved surfaces in agricultural environment. J Clean Prod 393(January):136291. https://doi.org/10.1016/j.jclepro.2023.136291

Mistri A, Dhami N, Kumar S, Barai SV, Mukherjee A, Biswas WK (2021) Resources, Conservation & Recycling Environmental implications of the use of bio-cement treated recycled aggregate in concrete. Resour Conserv Recycl 167:105436. https://doi.org/10.1016/j.resconrec.2021.105436

Nežerka V, Prošek Z, Trejbal J, Pešta J, Ferriz-Papi J. A., Tesárek P (2023) Recycling of fines from waste concrete: development of lightweight masonry blocks and assessment of their environmental benefits. J Clean Prod 385(December 2022):135711. https://doi.org/10.1016/j.jclepro.2022.135711

Gao W, Zhang H, Ren Q, Zhong Y, Jiang Z (2023) A low-carbon approach to recycling engineering muck to produce non-sintering lightweight aggregates: physical properties, microstructure, reaction mechanism, and life cycle assessment. J Clean Prod 385(December 2022):135650. https://doi.org/10.1016/j.jclepro.2022.135650

Cuenca-moyano GM, Martín-morales M, Bonoli A (2018) & Valverde-palacios, I. Environmental assessment of masonry mortars made with natural and recycled aggregates

Liang X, Dang W, Yang G, Zhang Y (2023) Environmental feasibility evaluation of cement co-production using classified domestic waste as alternative raw material and fuel: a life cycle perspective. J Environ Manage 326(PA):116726. https://doi.org/10.1016/j.jenvman.2022.116726

Zhou A, Wei H, Guo H, Zhang W, Liu T, Zou D (2023) Mechanical performance and environmental potential of concrete with engineering sediment waste for sustainable built environment. Resources, Conservation and Recycling, 189(September 2021), 106742. https://doi.org/10.1016/j.resconrec.2022.106742

Paz CF, Biela R, Punhagui KRG, Possan E (2023) Life cycle inventory of recycled aggregates derived from construction and demolition waste. J Mater Cycles Waste Manage 25(2):1082–1095. https://doi.org/10.1007/s10163-023-01594-y

Tefa L, Bianco I, Blengini GA, Bassani M (2022) Integrated and comparative Structural-LCA analysis of unbound and cement-stabilized construction and demolition waste aggregate for subbase road pavement layers formation. J Clean Prod 352(April):131599. https://doi.org/10.1016/j.jclepro.2022.131599

Waskow R, Gonçalves V, Tubino R, Passuello A (2021) Environmental performance of construction and demolition waste management strategies for valorization of recycled coarse aggregate. J Environ Manage 295(June):113094. https://doi.org/10.1016/j.jenvman.2021.113094

Cassiani J, Martinez-Arguelles G, Peñabaena-Niebles R, Keßler S, Dugarte M (2021) Sustainable concrete formulations to mitigate alkali-silica reaction in recycled concrete aggregates (RCA) for concrete infrastructure. Constr Build Mater 307(March). https://doi.org/10.1016/j.conbuildmat.2021.124919

Zhou A, Zhang W, Wei H, Liu T, Zou D, Guo H (2021) Resources, Conservation & Recycling A novel approach for recycling engineering sediment waste as sustainable supplementary cementitious materials. Resour Conserv Recycl 167:105435. https://doi.org/10.1016/j.resconrec.2021.105435

Colangelo F, Petrillo A, Farina I (2021) Comparative environmental evaluation of recycled aggregates from construction and demolition wastes in Italy. Sci Total Environ 798:149250. https://doi.org/10.1016/j.scitotenv.2021.149250

Ali A, Gheethi A, Memon ZA, Balasbaneh AT, Kutti WA, Al, Mokhtar N, Othman N, Juki MI, Noman EA, Algaifi HA (2022) Critical Analysis for Life Cycle Assessment of Bio - Cementitious Materials Production and Sustainable Solutions

Gencel O, Kizinievic O, Erdogmus E, Kizinievic V, Sutcu M, Muñoz P (2022) Manufacturing of fired bricks derived from wastes: utilization of water treatment sludge and concrete demolition waste. Archives Civil Mech Eng 22(2):1–16. https://doi.org/10.1007/s43452-022-00396-7

Liang G, Luo L, Yao W (2022) Reusing waste red brick powder as partial mineral precursor in eco-friendly binders: reaction kinetics, microstructure and life-cycle assessment. Resour Conserv Recycl 185(March):106523. https://doi.org/10.1016/j.resconrec.2022.106523

Veiga Simão F, Chambart H, Vandemeulebroeke L, Nielsen P, Adrianto LR, Pfister S, Cappuyns V (2022) Mine waste as a sustainable resource for facing bricks. J Clean Prod 368(June). https://doi.org/10.1016/j.jclepro.2022.133118

Design L, Vares S, Hradil P, Sansom M, Ungureanu V (2019) Economic potential and environmental impacts of reused steel structures. Struct Infrastruct Eng 0(0):1–12. https://doi.org/10.1080/15732479.2019.1662064

Pantini S, Giurato M, Rigamonti L (2019) Resources, Conservation & Recycling a LCA study to investigate resource-efficient strategies for managing post-consumer gypsum waste in Lombardy region (Italy). Resour Conserv Recycling 147(April):157–168. https://doi.org/10.1016/j.resconrec.2019.04.019

Suárez S, Roca X, Gasso S (2016) Product-specific life cycle assessment of recycled gypsum as a replacement for natural gypsum in ordinary Portland cement: application to the Spanish context. J Clean Prod 117:150–159. https://doi.org/10.1016/j.jclepro.2016.01.044

Li J, Liang J, Zuo J, Guo H (2020) Environmental impact assessment of mobile recycling of demolition waste in Shenzhen, China. J Clean Prod 263:121371. https://doi.org/10.1016/j.jclepro.2020.121371

Hu M, Kleijn R, Bozhilova-Kisheva KP, Di Maio F (2013) An approach to LCSA: the case of concrete recycling. Int J Life Cycle Assess 18(9):1793–1803. https://doi.org/10.1007/s11367-013-0599-8

Almusaed A, Yitmen I, Myhren JA, Almssad A (2024) Assessing the impact of recycled building materials on environmental sustainability and energy efficiency: a Comprehensive Framework for reducing Greenhouse Gas emissions. Buildings 14(6). https://doi.org/10.3390/buildings14061566

Charlotte L, Eberhardt M, Birgisdottir H (2022) Building the future using the existing building stock: the environmental potential of reuse building the future using the existing building stock: the environmental potential of reuse. https://doi.org/10.1088/1755-1315/1078/1/012020

Wang J, Wei J, Liu Z, Huang C, Du X (2022) Resources, Conservation & Recycling Life cycle assessment of building demolition waste based on building information modeling. Resour Conserv Recycling 178(June 2021):106095. https://doi.org/10.1016/j.resconrec.2021.106095

Jain S, Singhal S, Pandey S (2020) Resources, Conservation & Recycling Environmental life cycle assessment of construction and demolition waste recycling: a case of urban India. Resour Conserv Recycling 155(November 2019):104642. https://doi.org/10.1016/j.resconrec.2019.104642

Ram VG, Kishore KC, Kalidindi SN (2020) Environmental bene fi ts of construction and demolition debris recycling: evidence from an Indian case study using life cycle assessment. J Clean Prod 255:120258. https://doi.org/10.1016/j.jclepro.2020.120258

Vitale P, Arena U (2017) An Attributional Life Cycle Assessment for an Italian residential multifamily an attributional life cycle assessment for an Italian residential multifamily building. Environ Technol 0(0):1–13. https://doi.org/10.1080/09593330.2017.1371252

Kucukvar M, Egilmez G, Tatari O (2014) Evaluating environmental impacts of alternative construction waste management approaches using supply-chain-linked life-cycle analysis. Waste Manage Res 32(6):500–508. https://doi.org/10.1177/0734242X14536457

Khan MW, Ali Y (2020) Sustainable construction lessons learned from life cycle assessment (LCA) and life cycle cost analysis (LCCA). 191–207. https://doi.org/10.1108/CI-05-2019-0040

Yu Y, Zhao X, Xie T, Wang X (2022) Eco-, economic- and mechanical- efficiencies of using precast rejects as coarse aggregates in self-compacting concrete. Case Stud Constr Mater 17(October):e01591. https://doi.org/10.1016/j.cscm.2022.e01591

Qiao L, Tang Y, Li Y, Liu M, Yuan X, Wang Q, Ma Q (2022) Life cycle assessment of three typical recycled products from construction and demolition waste. J Clean Prod 376(March):134139. https://doi.org/10.1016/j.jclepro.2022.134139

Wu H, Zuo J, Yuan H, Zillante G, Wang J (2023) Investigation of the social and economic impacts of cross-regional mobility of construction and demolition waste in Australia. Resources, Conservation and Recycling, 190(November 2022), 106814. https://doi.org/10.1016/j.resconrec.2022.106814

Illankoon IMCS, Lu W (2020) Cost implications of obtaining construction waste management-related credits in green building. Waste Manag 102:722–731. https://doi.org/10.1016/j.wasman.2019.11.024

Carina A, Mendes P, Ribau M (2019) Social life cycle analysis as a tool for sustainable management of illegal waste dumping in municipal services. J Clean Prod 210:1141–1149. https://doi.org/10.1016/j.jclepro.2018.11.042

Larsen VG, Tollin N, Sattrup PA, Birkved M, Holmboe T (2022) What are the challenges in assessing circular economy for the built environment? A literature review on integrating LCA, LCC and S-LCA in life cycle sustainability assessment, LCSA. J Building Eng 50(January):104203. https://doi.org/10.1016/j.jobe.2022.104203

Guimaraes GD, Gu N, Gomes V, Paniagua JO (2020) A conceptual framework for construction and demolition waste prevention in building ’ s design phase. 31–40

Geeta B, Saleem A (2021) Alternatives to Coarse Aggregate in Cement Concrete-A review. Int Res J Eng Technol, June, 8–11. www.irjet.net

Yıldız-Geyhan E, Altun-Çiftçioğlu GA, Kadırgan MAN (2017) Social life cycle assessment of different packaging waste collection system. Resour Conserv Recycl 124(April):1–12. https://doi.org/10.1016/j.resconrec.2017.04.003

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Balasbaneh, A.T., Sher, W., Li, J. et al. Systematic Review of Construction Waste Management Scenarios: Informing Life Cycle Sustainability Analysis. Circ.Econ.Sust. (2024). https://doi.org/10.1007/s43615-024-00424-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43615-024-00424-z