Abstract

The success and dominance of plastic products used in modern society have improved the quality of life but come with extensive environmental consequences. As a result, the United Nations, European Union, and several industrialized countries have put forth goals and action plans to expedite the recycle and reuse of plastic wastes to minimize their releases to the environment. To keep pace with the world trends of achieving environmental and resource sustainability, Taiwan developed the roadmap in 1997 to reduce the generation of plastic wastes (Phase I). The successful endeavors were further incorporated into the “5 + 2” program in 2019 which underscores the nation’s commitments towards circular economy and environmental awareness (Phase II). As a result, a domestic recycle rate of 51% was attained in 2019. This paper describes the strategy of managing the plastic wastes in Taiwan that has evolved over time. Selected highlights of the efforts involved (the four focal points of green designs, source reductions, recycling enhancements, as well as circulations and regenerations) are discussed. Along with the successful experiences in households and industries, recycle and reuse of plastic wastes has been expanded to the agricultural and fishing sectors as well.

Similar content being viewed by others

1 Introduction

The invention of plastics is pivotal in enhancing the quality of life among the populace in modern society. Plastics are cheap, lightweight, durable, and resistant to chemical corrosions. Moreover, plastics are easy to be molded, extruded, or pressed into different solid shapes. As a result of these characteristics, plastics have replaced metals, wood, and ceramics as the preferred materials for producing a wide variety of household, commercial, and industrial goods in addition to being used as the packaging materials [1].

Worldwide productions of plastics have increased from 2 Mt in 1950 to 15 Mt in 1964, and further increased to 311 Mt in 2016 [2,3,4,5]. It is projected that 1.1 billion t of plastics will be produced globally in 2050. The widespread uses of plastic goods generate a huge quantity of plastic wastes that amounts to 7 billion t in 2015 (cumulative), of which 9% was recycled, 12% incinerated, and the remaining 79% landfilled or discarded back to the environment [6]. Plastics will not easily degrade in landfills because of their durability. Plastic wastes account for about 60 to 80% of marine debris and thereby turning into one of the most prevalent ocean pollution problems. The presence of microplastics within the food chain poses a serious threat to the food safety and public welfare [7]. The incineration of plastic wastes, if not properly controlled and monitored, is likely to produce harmful byproducts, e.g., hydrochloric acid and dioxin [8, 9].

2 Materials and methods

This study, by applying the research method of literature review, is intended to compile the management strategies of plastic wastes developed and applied in Taiwan. With the successful implementation of “the 4-in-1 recycling program” promoted by Taiwan EPA since 1997, four types of stakeholders involved or engaged in the management of plastic wastes include: public community, local authorities (cleaning teams), recycling enterprises, and the recycling fund. The data obtained from various sources such as published literature, government-supported research endeavors, and private sector-sponsored projects are collected. After investigating the actions taken since 1997, the management strategy of plastic wastes in Taiwan can be divided into two phases. That is from waste reduction (Phase I) to circular economy (Phase II). With the discussions on selected highlights of the efforts involved, several focal points of application can therefore be summarized for further expansions.

2.1 Recent international trends in the management of plastic wastes

The impacts of plastic wastes on the environment are exacerbated by the current linear economic system that is built within the hierarchy of take, make, use, and dispose. In contrast, circular economy, which is based on the 6-R concept (i.e., reduce, remanufacture, reuse, recover, recycle, and redesign), is an emerging economic concept that emphasizes the elimination of wastes and repetitive uses of resources [10]. Therefore, circular economy offers a better framework that enables a rational management of plastic waste problems. Table 1 (recycled contents) and 2 (recycle rates) summarize the goals and action plans that the United Nations (UN), the European Union (EU), and several industrialized countries have put forth to expedite the recycle and reuse of the plastics while minimizing their releases to the environment. These goals are consistent with the philosophies of circular economy.

UN has established the goal of attaining 75% recycled contents in the compostable plastics in 2025. To accomplish the goal, producers are encouraged to set the targets of recycled contents and demand incentives on recycled plastics are put in place [2, 3]. Countries such as United Kingdom and the Netherlands have focused on increasing the recycled contents in plastic packaging materials up to 35% in 2025 [11, 12]. Various methodologies such as recycled content labelling, accreditation/certification, and supply chain partnership are employed to ensure the attainment of the stated goals. Through technology innovations and green procurements, Japan attempts to increase the utilizations of bio-based plastics from 0.75 Mt in 2019 to 1.97 Mt in 2030 [13].

The recycling of plastic packaging materials is another international effort that attempts to achieve 100% recycle rates by 2030 (Table 2) [2, 15]. Innovative business models, novel technologies, funding mechanisms, quality standards for recycled plastics, etc. are proposed as the tools to ensure that the tasks will meet with success. In Europe, for instance, the landfilling of plastic packaging materials has been reduced from 7.2 Mt in 2006 to 3.4 Mt in 2016. During the same time, the recycling of plastic packaging materials has been increased from 3.9 to 6.8 Mt.

3 Results and discussion

The management of plastic wastes in Taiwan has evolved over time since 1997. The progress of the endeavors can be divided into two phases, namely, Phase I (1997–2018) and Phase II (2019 onward). This section describes the measures taken in the two phases and discusses some observations that can be summarized. Moreover, some important statistics reflecting the efforts taken in 2019 are also incorporated and compared in this section.

3.1 The management of plastic wastes in Taiwan: phase I (1997–2018)

In 1997 the Taiwanese government commenced three action plans to reduce the plastic wastes in the environment: the recycling of plastic containers, the reduced uses of plastic shopping bags, and the restricted uses of plastic cutlery (e.g., tableware, beverage cups, and straws). The following measures have been put in place to support the efforts.

-

(1)

An integrated program that comprises of community-based source separations, municipal collections, private recycling enterprises, and government-subsidized cash incentives has been implemented to encourage the recycle and reuse of plastic wastes (1997 onwards) [20].

-

(2)

A two-phase approach to gradually reduce the uses of plastic shopping bags and plastic cutlery (2002 onwards). The first phase focused on the governmental agencies (including military facilities), public and private schools, governmental-own commercial and industrial enterprises, and public hospitals. The second phase focused on the department stores, shopping malls, supermarkets, franchised convenient stores, and restaurants. The government provided cash incentives to the stores which developed and used multiple-use shopping bags (up to 20% of the development costs or a maximum of NT$200,000). Moreover, the government also encouraged the restaurants to offer discounts to the customers who brought and used their own cutlery [21, 22].

-

(3)

Mandatory separations of household wastes into kitchen wastes, recyclables, and general wastes prior to being collected (2005 onwards). Recyclables are further divided into containers, finished goods, and others. Recyclable materials include aluminum, glass, metal, paper, and plastics (LDPE, HDPE, PET, PP, PS, and PVC). A specific type of recyclables is collected 2 to 3 times per week, whereas food and kitchen wastes are collected 5 times per week. Funds collected from responsible industries, which are based on the principle of extended product responsibility (EPR), play a pivotal role in underwriting these efforts [23, 24].

Figure 1 illustrates the plastic material flow data (i.e., raw materials, products, and wastes) that were documented in 2019 [14, 25]. The data can be used to assess the impacts of the programs that have been put in place since 1997. There were 12.55 Mt of plastic resources (petrol-based raw materials, 83.0%; plastic materials, 10.4%; plastic products, 3.8%; and plastic wastes, 2.8%) imported. Moreover, 0.5 Mt of recycled plastics were domestically produced. As a result, 13.05 Mt of plastic resources were available for both producers and consumers.

About 79.2% of the combined imported and recycled plastic resources (i.e., 10.34 Mt) were used to make finished products and high-quality pellets for the export markets. Of the remaining 2.71 Mt of plastics left in the country, roughly 1.29 Mt were finished products that were either available for sales on the domestic market or already being used. Therefore, 0.92 Mt of plastic wastes were disposed of as follows: incineration (energy recovery), 0.86 Mt; waste export (after sorting): 0.05 Mt; and landfilling: 0.01 Mt. Several observations can be made:

-

(1)

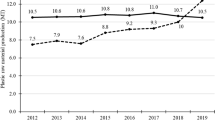

Roughly 7% of the total plastic resources (combined imported and recycled plastic resources) became wastes that required further disposal. This revealed the production efficiency of the plastic industry in Taiwan which primarily focuses on making finished products (including high-quality plastic pellets) for the foreign markets. A plastic overall recycle rate of 35% was attained in 2019. However, the domestic recycle rate increased steadily from 1997, and as of 2019, a recycle rate of 51% was attained (Fig. 2) [26], which is as good as the milestones established by the EU, Korea, and Japan [13, 15, 16, 19]. About 1.14 kg capita− 1 d− 1 domestic wastes were produced in 2019, of which 0.58 kg capita− 1 d− 1 were recycled. It is noteworthy that 97% of the plastic containers (including plastic cup lids) in the domestic solid waste streams produced in 2019 were recycled, and the remaining ones were incinerated together with the general wastes.

-

(2)

Incineration was by far the most prevalent technology employed for the disposal of plastic wastes that were not recycled. There are 23 incineration and energy recovery facilities on the island, all of which take plastic wastes as the feeds [27]. Roughly 10,000 t of plastic wastes were disposed of in landfills that was less than 1% of the total plastics consumed.

-

(3)

The lower heating value (25 °C) of typical plastics is about 35.7 MJ kg− 1 [28, 29]. As a result, the maximum rate of heat energy recoverable by burning 0.86 Mt of plastic wastes would be 973.55 MW (25 °C). It is noteworthy that a typical household consumes between 10,000 and 12,000 kWh of electricity [28].

The progress of domestic recycling in Taiwan (1997–2019) [26]

Table 3 summarizes the quantities of various recyclables collected from 2017 and 2019 [26]. Quantities of recycled aluminum containers, paper containers, paper cutlery, and bio-based plastics have significantly increased between 2017 and 2019, whereas the quantities of recycled plastic containers were largely unchanged, which could be the result of the durability of plastic goods that reduces the frequency of replacements. Moreover, the easy accessibility of online shopping and food delivery in Taiwan as well as the fondness for road-side food vendors by the populace might be key to producing large amounts of recycled paper containers and cutlery.

3.2 The management of plastic wastes in Taiwan: phase II (2019 onwards)

In order to keep pace with the world trends of achieving environmental and resource sustainability, Taiwan government introduced “the circular economy” industry and projects in the “5+2 innovative industries plan” in 2019. In short, the “5 + 2” plan covers seven industries and projects [30]: Intelligent machinery, Asia Silicon Valley, Green energy, Biomedicine, National defense and aerospace, New agriculture and The circular economy. This section discusses the management strategies of plastic wastes in line with the circular economy program which cane be classified as the Phase II efforts.

Seeking to advance the transformation and upgrade of Taiwan’s industry, the circular economy program emphasizes green designs; source reductions; enhanced recycling; and redesigns and remanufacture. The program underscores the commitment of the government to shift Taiwan towards circular economy to preserve its competitiveness as well as to improve its records in environmental sustainability [14, 21, 22, 31, 32]. The recycling and reuse of plastic wastes have been incorporated as an integral part of the circular economy program [14, 32]. Table 4 summarizes the updated and expanded action plans [31, 32]. Selected highlights of the Phase II efforts are discussed as follows.

-

(1)

Green design: The strategy of bottle to bottle, fiber, and other packaging is implemented successfully at local and MOE industries. Based on the quality of the recycled PET, it is used to manufacture a variety of plastic products including bottles, clothes, and packaging material. The shampoo bottle and the dispenser with 100% traceable recycled PE and PP individually were first on market by a brand company in 2018 and with good sale. It is expected that more will follow.

-

(2)

Source reductions

-

Environmentally friendly online food delivery services. Online food delivery allows customers to order food and then received the food products at the doorstep. The convenience provided by the online food delivery services is pivotal to their popularity and success in Taiwan. However, the extensive uses of nonreusable plastic bags and paper products (e.g., containers, plates, and cups) in such services produce large quantities of plastic and paper wastes that are expensive and problematic to manage. Taiwan EPA has proposed a new approach that is designed to change the current operation mode of the online food delivery (Fig. 3) [32]. In essence, plastic food containers and cutlery will replace the items currently used. These items will then be reused in a close-loop mode to minimize the production of wastes (Fig. 3). When consumers finish the food products they ordered, they will deposit the empty containers and used cutlery at the pickup sites set up by the collection service firms. Once collected, the firms will clean and sanitize the items to ensure their safety and hygiene prior to being sent back to the online food delivery companies for reuses. Consumers who participate in the program will receive discounts on their orders.

-

Reusable online shopping bags. Analogous to the one proposed for the online food delivery services, this program is designed to make the online shopping bags reusable (Fig. 4) [32]. Customers may choose to return the used shopping bags directly back to the online retailers for reuses once the orders placed have been delivered, or they can deposit the used bags at the pickup sites. The online retailers can collect the used bags directly from the sites, or third parties can collect the used bags and then offer them to the online retailers. Post offices and private delivery service companies are encouraged to participate in this endeavor to enable expeditious and frequent pickups/deliveries. These efforts offer certain novelty because of the easy accessibility of online shopping and food delivery in Taiwan. Moreover, the fondness for road-side food vendors by the Taiwanese populace also renders these efforts efficacious in handling large amounts of recycled paper containers and cutlery produced [21, 22].

-

-

(3)

Recycling enhancements

-

Recycling of plastic sheets and meshes used in agriculture and horticulture. Plastic sheets and meshes are extensively used in agriculture and horticulture. Plastic sheets are used on ground in fields to conserve water as well as to collect rainwater. Transparent plastic sheets also are used in greenhouses to maintain adequate temperatures and sunlight exposure as well as to offer protections from weather damages. Plastic meshes are used to prevent insecticidal damages to crops, plants, and vegetables. Ground-covered PE sheets are replaced annually, and roughly 11, 700 t of plastic sheets were replaced in 2019. There is reluctance among farmers to recycle the ground-covered plastic sheets because they are loaded with dirt and crop debris when replaced. On the other hands, plastic sheets used in greenhouses and plastic mashes, which are replaced once every three to five years, are clean and easy to recycle.

-

To address this recycling hesitancy on ground-covered plastic sheets, TEPA has started a pilot project in 2019 that was designed to help farmers to remove dirt from the discarded ground-covered plastic sheets prior to being sent to the pickup sites for recyclers [31]. The efforts are ongoing and being expanded with the agriculture department’s participation especially on providing subsidy for purchasing cleaning equipment [24]. In addition, farmers are encouraged to use degradable sheets that, after the harvesting of crops, can be left in the field to decompose naturally.

-

Recycling of discarded fishing nets. The major types of discarded fishing nets in Taiwan are Seine nets and Trawl nets. Incineration is currently the primary means to dispose of discarded fishing nets [31]. Since fishing nets are made from nylon; PE; or PET, they are a good candidate for recycling. A government-subsidized program is in place that pays fishmen 50 cents to turn in 1 kg discarded fishing nets. 89.1 t of discarded fishing nets were collected in 2020, and 54% of the fishing nets collected were converted to reusable materials. The program is being expanded to increase the recycle and regeneration rates. The program, which is developed with the underlying principle of EPR, will eventually render the fishmen fully responsible for the recycling tasks involved. It is noteworthy that similar programs have been implemented in several countries worldwide, e.g., Norway and Slovenia [2].

-

-

(4)

Circulation and regeneration: A committee formed in 2020 by the government and private companies (i.e., detergent producers, plastic containers manufacturers, and recycle and regeneration companies) established the goal that, by 2025, all newly manufactured plastic containers barring those used for food storages should have 25% recycle contents. Moreover, a scheme that will foster regeneration and reuse of plastic wastes is developed (Fig. 5) [14]. The scheme incorporates the key features of the global recycled standard/ postconsumer resin certification program to increase the recycled contents in plastic products while reducing the environmental impacts of the manufacturing processes. The scheme proposes to utilize third parties to certify the recycled contents in the products as well as to ensure the compliance of the certification processes by the reuse/regeneration service companies. EPA will be responsible for the inspection and monitoring of the scheme.

Scheme that facilitates the reuses and recycling of plastics cutlery in on-line food delivery services in Taiwan [32]

Recycling of shopping bags in online shopping services in Taiwan [32]

Scheme that facilitates the reuses of recyclable plastics in Taiwan [14]

4 Conclusions

Circular economy, which is different from the traditional linear economy, emphasizes the recycling and reuses of waste materials to minimize the exploitation of natural resources as well as to slash the creation of wastes, pollution, and greenhouse gas emissions [33]. Circular economy enables economies and societies to become more sustainable [34, 35]. As a result, it has significant ramifications to the resource-poor countries such as Taiwan.

The management of plastic wastes in Taiwan has evolved over time since 1997. Programs such as source separations (households, commercial establishments, and industries), recycling, and reduced uses of plastic shopping bags and cutlery are well established and executed. For instance, a domestic recycle rate of 51% was attained in 2019. It is noteworthy that 97% of the plastic containers (including plastic cup lids) in the domestic solid waste streams produced in 2019 were recycled, and the remaining ones were incinerated together with the general wastes.

The Taiwanese government commenced the “5 + 2” program in 2019 which underscores the nation’s commitments towards circular economy and environmental sustainability. As an integral part of the circular economy program, the focal points of the updated plastic waste management agenda are: green designs, source reductions; enhanced recycling, and redesigns and remanufactures of plastic products with increased recycled contents. In addition to the programs already put in place for households, commercial establishments, and industries, recycle and reuse of plastic wastes has been expanded to the agricultural and fishing sectors as well. Plastic products built with recyclable parts which are easy to take apart will replace the current ones available on the market. New production and recycling technologies will be developed to expedite the transitions. Voluntariness or regulation enforcements will be employed to embolden circulation and regeneration. By 2025, all newly manufactured plastic containers barring those used for food storages should have 25% recycle contents.

The management of plastic wastes in Taiwan is an integral part of the overall endeavors that underscore the nation’s commitments towards circular economy and environmental awareness. The initial strategies adopted since 1997, which emphasize the recycling of domestic plastic wastes, have been enhanced via a series of program expansions. The most recent version of the strategy has included many new concepts such as novel product designs, advanced recycling technologies, and alternative manufacturing processes that will significantly reduce the uses of virgin plastic materials in final products. The accomplishments achieved thus far since 1997 in Taiwan offer a nice model that can be studies by other resource-poor countries in their efforts to tackle the similar challenges.

Availability of data and materials

All data generated or analyzed during this study were collected in Taiwan EPA reports as listed in the references are also available from the corresponding author on reasonable request.

References

Hoornweg D, Bhada-Tata P. What a waste: a global review of solid waste management. Washington: World Bank; 2012.

EMF. The New Plastics Economy: Rethinking the Future of Plastics. Cowes: Ellen MacArthur Foundation; 2016.

EMF. The Global Commitment 2021 Progress Report. Cowes: Ellen MacArthur Foundation; 2021.

Geyer R, Jambeck JR, Law KL. Production, use, and fate of all plastics ever made. Sci Adv. 2017;3:e1700782.

Ritchie H, Roser M. Plastic Pollution, Our World in Data. London: University of Oxford; 2018. https://ourworldindata.org/plastic-pollution.

Taylor M. Plastic pollution risks near permanent contamination of natural environment. London: The Guardian; 2017.

Barboza LGA, Cunha SC, Monteiro C, Fernandes JO, Guilhermino L. Bisphenol A and its analogs in muscle and liver of fish from the North East Atlantic Ocean in relation to microplastic contamination. Exposure and risk to human consumers. J Hazard Mater. 2020;393:122419.

Li XD, Ma YF, Zhang MM, Zhan MX, Wang PY, Lin XQ, et al. Study on the relationship between waste classification, combustion condition and dioxin emission from waste incineration. Waste Dispos Sustain Energy. 2019;1:91–8.

Wu D, Li Q, Shang XN, Liang YG, Ding X, Sun H, et al. Commodity plastic burning as a source of inhaled toxic aerosols. J Hazard Mater. 2021;416:125820.

Jawahir IS, Bradley R. Technological elements of circular economy and the principles of 6R-based closed-loop material flow in sustainable manufacturing. Procedia CIRP. 2016;40:103–8.

WRAP. A Roadmap to 2025 - The UK Plastics. Banbury: The Waste and Resources Action Programme; 2020.

RVO. Plastics Pact NL 2019-2025: Frontrunners to Do More, with Less Plastic in the Circular Economy. Assen: Ministry of Infrastructure and the Environment; 2019.

Ministry of the Environment, Japan. Resource circulation strategy for plastics. JAPAN Environment Quarterly. 2018;20:3-15. https://www.env.go.jp/en/focus/jeq/issue/pdf/Volume20January2018.pdf.

EPA. The Expanded Promotion of Plastic Resource Circular Economy Model. Taipei: Environmental Protection Administration; 2020. https://epq.epa.gov.tw/project/FileDownload.aspx?proj_id=1080276207.

EC. A European Strategy for Plastics in a Circular Economy. Brussels: European Commission; 2018.

PE. Plastics - The Facts 2020: An Analysis of European Plastics Production, Demand and Waste Data. Brussels: Plastics Europe; 2020.

Jang YC, Lee G, Kwon Y, Lim JH, Jeong JH. Recycling and management practices of plastic packaging waste towards a circular economy in South Korea. Resour Conserv Recycl. 2020;158:104798.

Shin SK, Um N, Kim YJ, Cho NH, Jeon TW. New policy framework with plastic waste control plan for effective plastic waste management. Sustain-Basel. 2020;12:6049.

Ju MS. Basic plan on resource circulation (2018-2027). In: No. 47 Comprehensive measure of waste recycling. Korea Environ Policy Bull. 2019;16:6–9.

Yan SM, Wei WI. Resource recycling in Taiwan. J Budget Account Stat. 2020;773:56–61 http://www.bas-association.org.tw/catalog/arts/010905056.pdf.

EPA. The Reduction Planning and Promoting Project for Plastic Shopping Bags, Disposable Tableware, Takeaway Beverage Cups, Plastic Straws. Taipei: Environmental Protection Administration; 2019. https://epq.epa.gov.tw/EPQ_resultDetail.aspx?proj_id=1080108481&document_id=9999&KeyWord=Plastic+Shopping+Bags.

EPA. The Planning and Promoting Project for Packaging Reduction and Heavy Metal Source Reduction. Taipei: Environmental Protection Administration; 2019. https://epq.epa.gov.tw/project/FileDownload.aspx?proj_id=1081063306.

Fan KS, Lin CH, Chang TC. Management and performance of Taiwan’s waste recycling fund. J Air Waste Manag Assoc. 2005;55:574–82.

Cheng CP, Lin CH, Wen LC, Chang TC. Determining environmental costs: a challenge in a governmental e-waste recycling scheme. Sustain-Basel. 2019;11:5156.

MOF. Statistics Database Query. Taipei: Ministry of Finance; 2021. https://portal.sw.nat.gov.tw/APGA/GA35E.

EPA. Yearbook of Environmental Protection Statistics. Taipei: Environmental Protection Administration; 2021. https://www.epa.gov.tw/Page/27372777FD92ADDB.

Liu LR, Lee YM. Remedial measures for erroneous environmental policies: assessing infrastructure projects of waste-to-energy incineration in Taiwan with a case study of the Taitung incinerator. Sustain-Basel. 2016;8:1284.

Masters GM. and Ela WP. Introduction to environmental engineering and science. 3rd ed. Essex: Pearson; 2008.

Sharma BK, Moser BR, Vermillion KE, Doll KM, Rajagopalan N. Production, characterization and fuel properties of alternative diesel fuel from pyrolysis of waste plastic grocery bags. Fuel Process Tech. 2014;122:79–90.

NDC. Coordinate and Promote the Industrial Transformation Plan. Taipei: National Development Council; 2016. https://www.ndc.gov.tw/Content_List.aspx?n=9D024A4424DC36B9.

EPA. Construction, Agricultural and Medical Waste Management Project. Taipei: Environmental Protection Administration; 2019. https://epq.epa.gov.tw/EPQ_resultDetail.aspx?proj_id=1080511262&document_id=9999&KeyWord=Construction%2c+agricultural#tab1.

EPA. The Promotion of Plastic Resource Circular Economy Model Project. Taipei: Environmental Protection Administration; 2019. https://epq.epa.gov.tw/EPQ_resultDetail.aspx?proj_id=1080276207&document_id=9999&KeyWord=plastic+resource#tab1.

European Union. Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment. Off J Eur Union. 2019;15:1–19.

Lau WWY, Shiran Y, Bailey RM, Cook E, Stuchtey MR, Koskella J, et al. Evaluating scenarios toward zero plastic pollution. Science. 2020;369:1455–61.

Morseletto P. Targets for a circular economy. Resour Conserv Recycl. 2020;153:104553.

Acknowledgements

The authors would like to express their thanks to the colleague and friends in TEPA, ESTC, and CEITA for their time, effort, and feedback to make this paper valuable.

Funding

Not Applicable.

Author information

Authors and Affiliations

Contributions

Ms. Lai is the first author in charge of data analysis and manuscript writing. Dr. Lee is the corresponding author who initialized the concept and supervised the whole work. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lai, YY., Lee, YM. Management strategy of plastic wastes in Taiwan. Sustain Environ Res 32, 11 (2022). https://doi.org/10.1186/s42834-022-00123-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s42834-022-00123-0