Highlights

-

The lithium-ion conduction mechanism of organic-inorganic composite solid electrolytes (OICSEs) is thoroughly conducted and concluded from the microscopic perspective based on filler content, type, and system.

-

The classic inorganic filler types, including inert and active fillers, are categorized with special emphasis on the relationship between inorganic filler structure design and the electrochemical performance of OICSEs.

-

Advanced characterization techniques for OICSEs are discussed, and the challenges and prospects for developing superior all-solid-state lithium batteries are highlighted.

Abstract

To address the limitations of contemporary lithium-ion batteries, particularly their low energy density and safety concerns, all-solid-state lithium batteries equipped with solid-state electrolytes have been identified as an up-and-coming alternative. Among the various SEs, organic–inorganic composite solid electrolytes (OICSEs) that combine the advantages of both polymer and inorganic materials demonstrate promising potential for large-scale applications. However, OICSEs still face many challenges in practical applications, such as low ionic conductivity and poor interfacial stability, which severely limit their applications. This review provides a comprehensive overview of recent research advancements in OICSEs. Specifically, the influence of inorganic fillers on the main functional parameters of OICSEs, including ionic conductivity, Li+ transfer number, mechanical strength, electrochemical stability, electronic conductivity, and thermal stability are systematically discussed. The lithium-ion conduction mechanism of OICSE is thoroughly analyzed and concluded from the microscopic perspective. Besides, the classic inorganic filler types, including both inert and active fillers, are categorized with special emphasis on the relationship between inorganic filler structure design and the electrochemical performance of OICSEs. Finally, the advanced characterization techniques relevant to OICSEs are summarized, and the challenges and perspectives on the future development of OICSEs are also highlighted for constructing superior ASSLBs.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Rechargeable lithium-ion batteries (LIBs) are associated with significant safety concerns due to flammable and volatile organic liquid electrolytes, especially in large-scale energy storage applications such as electric vehicles and electronic devices [1,2,3,4,5]. In addition, the energy density of commercial lithium-ion batteries with liquid electrolyte and carbon-based anodes has reached 260 Wh kg−1, which is close to their theoretical limitation [6,7,8]. All-solid-state lithium metal batteries (ASSLBs), with super-high theoretical energy density (> 300 Wh kg−1) and excellent safety, have been widely recognized as one of the most promising next-generation battery technologies [9,10,11]. Solid-state electrolytes (SEs), as an important component of ASSLBs, have presented a rapidly increasing trend of investigations on SEs research in recent years [12,13,14,15].

The physicochemical properties of the SEs, including interfacial reaction kinetics, safety, and durability, are critical to ASSLBs [16,17,18,19,20]. SEs can be divided into inorganic solid electrolytes (ISEs) and organic solid electrolytes (OSEs). ISEs exhibit high ionic conductivity (10−4–10−3 S cm−1), Li+ transference number (~ 1), excellent thermal stability, and ultra-high mechanical strength [21, 22]. However, the inherent fragility and high hardness often result in poor interfacial wettability with both the cathode and anode and significantly increased processing challenges. Therefore, the practical application of ISEs still faces uncertainty [23,24,25]. By contrast, OSEs show higher feasibility with excellent elasticity, well flexibility, superior interface adhesion, and relatively high compatibility [26,27,28,29]. However, the polymer matrix with high crystallinity at room temperature (RT) always results in low ionic conductivity (10−7–10−5 S cm−1), which is unfavorable for achieving high power density. Furthermore, the thermodynamic instability (oxidation potential less than 4 V vs. Li+/Li) restricts the matching with high-voltage cathode materials, while relatively inferior mechanical properties struggle to inhibit the lithium dendrite formation and growth [30,31,32]. In this situation, numerous strategies have been employed to enhance the overall performance of OSEs, such as block/cross-linked copolymerization, incorporation of plasticizers, and addition of inorganic fillers [33,34,35]. Among these approaches, the organic–inorganic composite solid electrolytes (OICSEs), which integrate the advantages of the organic polymer and inorganic fillers, are widely considered the most simple and feasible method to develop high-performance SEs for ASSLBs [36,37,38].

Generally, the inorganic materials can be divided into two categories: inert materials [39,40,41,42,43] (e.g., metal oxides (Al2O3, SiO2, BaTiO3, TiO2, and MgO), halloysite nanotubes (HNTs), carbon materials (such as GO)), and active materials [44,45,46] (e.g., sulfide-type (Li10GeP2S12 (LGPS)), garnet-type (Li7La3Zr2O12 (LLZO), and NASICON-type (Li1.3Al0.3Ti1.7(PO4)3 (LATP)), and perovskite-type (Li0.33La0.557TiO3). It has been well confirmed that the functional mechanism of inorganic fillers can be summarized in the following three aspects [47,48,49]: (1) Inorganic fillers can improve the ratio of amorphous regions and enhance the mobility of local chain segments by disrupting the polymer crystallization behavior and reducing the glass transfer temperature (Tg). (2) The special functional groups on the surface of fillers can couple with lithium salt anions or polymer matrix via Lewis acid–base interactions, thereby facilitating the lithium ion transfer behaviors. Several factors, including size, type, concentration, morphology, and surface modifications of fillers, influence the strength of these interactions. (3) The inorganic fillers can increase the Li+ transfer number of OICSE and inhibit the enrichment of anions on the anode side, thus enhancing the electrochemical stability of OICSE. (4) Well-dispersed inorganic fillers can also improve the mechanical strength and thermal stability of OICSEs, effectively improving the reliability and security of the battery system. To improve the electrochemical performance of OICSEs, various inorganic fillers with different dimensions, such as 0D particles, 1D nanowires, 2D nanosheets, and 3D networks, have been specifically designed and widely investigated [50,51,52]. These fillers, exhibiting diverse morphologies, can provide long-range transport channels for lithium ions, resulting in a rapid ion transport pathway between the cathode and anode [53, 54]. Active fillers can directly participate in ion transport compared to inert fillers due to their intrinsic ionic conductivity. Meanwhile, a percolation pathway with fast ionic conductivity between active filler and polymer matrix can be constructed in the OICSEs, which is beneficial to improve the electrochemical performance of the battery system [55, 56].

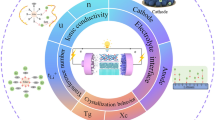

Here, we emphasize the significance of various inorganic filler types and advanced structures in optimizing the performance of OICSEs (Fig. 1). Initially, key parameters such as ionic conductivity, Li+ transference number, mechanical properties, electrochemical stability, electronic conductivity, and thermal stability are extensively investigated. Subsequently, the impacts of the size, content, shape, and arrangement of inorganic fillers on ionic conductivity are analyzed. In addition, the lithium-ion conduction mechanism of OICSE is thoroughly conducted and concluded from the microscopic perspective based on filler content, type, and system. Furthermore, the classic inorganic filler types, including both inert and active fillers, are categorized. Special emphasis is placed on the relationship between inorganic filler structure design and the electrochemical performance of OICSEs. Finally, Advanced characterization techniques for OICSEs like solid-state nuclear magnetic spectroscopy (NMR), magnetic resonance imaging (MRI), time-of-flight secondary ion mass spectrometry (TOF–SIMS), high-angle annular dark field scanning transmission electron microscopy (HAADF-STEM), electron energy loss spectroscopy (EELS), small-angle X-ray scattering (SAXS), X-ray computed tomography (CT), and atomic force microscopy (AFM) are discussed, along with their applications and future challenges. The review concludes with a summary and perspective, offering valuable insights to facilitate the research and development of OICSEs with appreciable overall performance.

2 Key Parameters to Evaluate the Performance of OICSEs

The ionic conductivity, Li+ transference number, mechanical properties, electrochemical stability, electronic conductivity, and thermal stability are essential indicators for evaluating the performance of OICSEs. A common problem of OSEs is low ionic conductivity and insufficient mechanical strength, which restricts their practical application in ASSLBs. To overcome these problems, researchers incorporate inorganic fillers into the polymer matrix. These fillers not only enhance the ionic conductivity but also improve the mechanical strength of the electrolytes, thereby optimizing the overall electrochemical performance of OICSEs in ASSLBs.

2.1 Ionic Conductivity

2.1.1 Effects of Inorganic Fillers on Ionic Conductivity

(a) Particle Size and Content: The inorganic particle size and content are key factors to improve the ionic conductivity of the OICSEs [57,58,59]. Dissanayake et al. evaluated the thermal and electrical properties of the (PEO)9LiCF3SO3-Al2O3 incorporating alumina filler grains with different specific surface areas [60]. The results indicate that the nano-porous alumina grains with 5.8 nm pore size and 150 m2 g−1 specific area and 15 wt% filler exhibited the maximum ionic conductivity, which is attributed to Lewis acid–base interactions of ionic species with O/OH groups on the filler surface. Generally, incorporating 10–20 wt% of ceramic filler into the polymer matrix is considered the optimal concentration for OICSEs. The particles tend to undergo agglomeration behavior with the increase of content, reducing the volume fraction and disrupting the percolation network at the interface. Zhang et al. investigated that Li-salt-free PEO and LLZTO nanoparticles in size of D50 = 43 nm show the highest ionic conductivity of 2.1 × 10−4 S cm−1 at 30 °C [61], which is nearly two orders of magnitude higher than that of micron-sized LLZTO fillers (Fig. 2a). When the LLZTO size is fixed at 43 nm, and content is 12.7 vol% within different temperature ranges (Fig. 2b), the PEO:12.7 vol% LLZTO membrane achieved the maximum ionic conductivity. Moreover, the result found that as the size of LLZTO particles increased from 40 to 400 nm and 10 mm, the optimal ceramic content also increased from 12.7 to 15.1 vol% and 21.1 vol%, respectively (Fig. 2c). Therefore, it can be concluded that the particle size is related to the percolation of LLZTO particles, and the percolation threshold decreases with the decrease in particle size [62]. Nanoparticles have a larger specific surface area and can increase the area of the polymer electrolyte/filler interface, providing more ion transport pathways, thus significantly increasing the ionic conductivity of the OICSEs [63]. Therefore, nanoparticles are more effective in improving ionic conductivity than micron-sized particles.

a Size distribution of LLZTO nanoparticles determined by a laser particle size analyzer. b Ion conductivities of PEO: LLZTO membranes with different volume fractions of LLZTO in size of D50 = 43 nm. c Ionic conductivity as a function of LLZTO volume fraction for LLZTO particles with different sizes [61], Copyright 2016, Elsevier. d Ion conductivities of PAN/LiClO4, PAN/LiClO4 with LLTO nanowires, and LLTO nanoparticles and the comparison of possible lithium-ion conduction pathway in nanowire-filled and nanoparticle-filled composite electrolytes [64], Copyright 2015, American Chemical Society. e Schematic diagram of garnet nanosheets and comparing composite electrolytes consisting of garnet nanoparticles [66], Copyright 2019, American Chemical Society. f Li-ion conduction pathways in OICSEs with nanoparticles, random nanowires, and aligned nanowires [67], Copyright 2017, Springer Nature Limited. g Ionic conductivity of vertically aligned, random, and polymer [68], Copyright 2017, American Chemical Society. h Schematics of agglomerated nanoparticles and 3D continuous framework. i Ionic conductivity of LLTO framework, LLTO nanoparticle, and silica particle OICSEs [69], Copyright 2018 Wiley

(b) Shape of Inorganic Fillers: The ion conduction mechanism based on the percolation effect has shown that the development of specially shaped ceramic fillers (nanowire fillers) can effectively improve the uniform transport of lithium ions and avoid the decrease of ionic conductivity caused by the agglomeration of fillers. Liu et al. explored the impact of nanoparticles and nanowires on the electrochemical performance of PAN/LiClO4 polymer electrolytes [64]. The 15 wt% LLTO nanowires would increase the ionic conductivity by three orders of magnitude over the same content of LLTO nanoparticles. This is mainly because LLTO nanowires create a longer distance than nanoparticles for the ion transport pathway (Fig. 2d). To improve the transport pathway of LLTO nanoparticles in the polymer matrix, Fu et al. reported a 3D garnet nanofiber network by electrostatic spinning and high-temperature annealing with an ionic conductivity of 2.5 × 10−4 S cm−1 at RT, two orders of magnitude higher than that of PEO-based electrolyte containing LLZO nanoparticles [65]. The increased conductivity can be attributed to the 3D interconnected structure, which offers a continuous transport pathway for Li ions. Compared to nanoparticles, garnet nanosheets also have interconnected Li ion transport pathways. Song et al. introduced 15 wt% garnet nanosheets into the polymer matrix for the first time, the ionic conductivity achieved was 3.6 × 10−4 S cm−1 at RT (Fig. 2e) [66]. Therefore, introducing nanowires and nanosheets into the polymer matrix or constructing a three-dimensional or two-dimensional interconnection network structure can provide a continuous Li-ion transport pathway, thereby obtaining higher ionic conductivity.

(c) Arrangement of Inorganic Fillers: To reduce the tortuosity of ion conduction pathway in OICSEs and to obtain larger inorganic particle/polymer interfaces, researchers have employed various methods to create OICSEs with oriented ceramic fillers, including electrostatic spinning, ice-templating-based methods, and 3D printing techniques. Liu and colleagues have developed well-oriented LLTO nanowires by electrospinning and embedding the LLTO nanowires in the PAN-LiClO4 electrolyte (Fig. 2f) [67]. This innovative design has resulted in a remarkable ionic conductivity of 6.05 × 10−5 S cm−1 at 30 °C, ten orders of magnitude higher than previous polymer electrolytes containing randomly arranged nanowires. The exceptional conductivity improvement is attributed to the efficient ion-conducting pathway created by the aligned nanowires. A flexible OICSE composed of vertically aligned and connected LATP NPs has been synthesized through the ice-templating process (Fig. 2g) [68]. The alignment of the nanoparticles creates direct channels for lithium ions, and the OICSEs show an impressive ionic conductivity of 0.52 × 10−4 S cm−1 at RT, which is 3.6 orders of magnitude higher than the PEO electrolyte containing LATP NPs randomly dispersed within the material. It has been discovered that 3D ceramic frameworks can significantly enhance the continuous and integrated ion-conduction network and increase mechanical strength. Bae and colleagues proposed a 3D hydrogel-derived nanostructured LLTO framework as a highly loaded nanofiller (Fig. 2h) [69]. The interconnected structure of the 3D LLTO framework provides a long-range, continuous pathway for Li-ions, which results in an impressive ionic conductivity of 8.8 × 10−5 S cm−1 at RT (Fig. 2i). Although OICSEs exhibit enhanced ionic conductivity, the polymer matrix limits the overall ionic conductivity. There are still many challenges to achieving practical applications at RT. Therefore, we need to improve the ionic conductivity further by designing the ceramic structure and optimizing the polymer matrix composition.

2.2 Mechanical Properties

Mechanical properties are the physical characteristics of a material that it exhibits under the action of various forces, including toughness, hardness, strength, brittleness, and elasticity. Good mechanical properties can effectively hinder the formation and growth of lithium dendrites, which contribute to long cycling life [70]. Inorganic fillers in composite electrolytes usually have adequate strength but lack flexibility. The addition of inorganic fillers increases tensile strength but decreases elongation at break compared to the polymer matrix. For example, the addition of 5 wt% carbon nanotubes to the PEO polymer matrix can increase tensile strength by 160%, improving the mechanical properties of OICSEs significantly [71]. However, due to the presence of inorganic fillers, the polymer flexibility and adhesion in OICSEs decreases, which affects close contact with the electrodes and leads to an increase in interfacial resistance during cycling. Therefore, the balance between mechanical properties and interface contact with the electrode is required when designing OICSEs. The thickness of OICSEs is indeed crucial for the development of high-energy solid-state batteries. Currently, the thickness of the prepared OICSEs membranes is much thicker than that of commercial membranes, and most of the OICSEs are about 100 μm or thicker. It remains challenging to prepare OICSEs using traditional methods that maintain excellent mechanical properties while being ultrathin. Luo et al. [72] prepared ultrathin (4.2 μm) CSEs with a bilayer polymer structure (UFF/PEO/PAN/LiTFSI) by electrospinning, and the hard UFF ceramic scaffolds can maintain the mechanical strength. The elastic moduli of the PEO and PAN sides were measured by nanoindentation to be 298 and 1072 MPa, respectively. The high energy density of 506 Wh kg−1 and 1514 Wh L−1 is achieved based on LiNi0.8Co0.1Mn0.1O2 (NCM811) cathodes with a low N/P ratio and long lifespan over 3000 h. Wang et al. [73] fabricated LLZO layer and metal–organic framework (MOF) layer on both sides of polyethylene (PE) by tape casting and developed an ultrathin (12.6 μm) asymmetric composite solid electrolyte. The Li-symmetric battery has an ultra-long cycle (5000 h) and the assembled pouch cells provided a gravimetric/ volume energy density of 344.0 Wh kg−1/773.1 Wh L−1. However, it should be noted that OICEs inevitably reduce mechanical strength and increase the risk of membrane rupture or lithium dendrite growth, leading to interruption of ionic conduction and cell failure. Meanwhile, excessive hardness or elastic modulus may increase the impedance at the electrode–electrolyte interface, affecting the energy density and power density of the battery. Therefore, when designing and optimizing OICSEs, the above mechanical properties need to be considered to achieve excellent electrochemical performance and long-life battery systems.

Generally, the mechanical strength is described by the equations of Young's modulus of elasticity (E, MPa) and shear modulus (G, MPa). The specific equations are as follows [74, 75]:

where \(\uprho\) is the density, \({\text{V}\upiota }\) is the longitudinal velocity, and \(\upnu\) is Poisson’s ratio, ν = 0.257 [76]. In addition to Young's modulus and shear modulus, other parameters such as maximum stress (MPa) and strain at break (mm/mm) are also helpful in describing the mechanical properties of OICSEs in ASSLBs.

2.3 Li-Ion Transference Number

Li-ion transference number is another important parameter to evaluate the electrochemical performance of OICSEs, which is the contribution of Li-ion transport charge to the total charge, calculated as the ratio of Li-ionic conductivity to total ionic conductivity. In OICSEs, which consist of multiple ions and are referred to as multi-ion conductors, the ionic conductivity is influenced by both Li-ion and anion transport. Lithium ions and anions can move during cycling but move in opposite directions. Consequently, a significant Li-ion concentration gradient is formed from the anode to the cathode, impeding Li-ion transport and resulting in undesired Li deposition. The Li-ion migration number of OICSEs can be obtained by the DC/AC electrochemical method proposed by Bruce [77, 78]. By assembling a Li |OICSEs| Li symmetric cell, an impedance spectrum test is performed before polarization begins, and then a minimal potential is applied for polarization tests, where the Li ions and anions move in opposite directions in response to an electric field. The lithium ions are reduced to Li atoms at the electrode interface, while the anions accumulated at the interface do not participate in the electrochemical reaction. Meanwhile, the anions can diffuse to the low potential electrode under concentration polarization. Finally, the impedance of the symmetric cell is tested after polarization. Based on the impedance change and current response, the Li+ migration number can be obtained using Eq. (3):

where \(\Delta \text{V}\) is the dc polarization voltage, \({I}_{0}\) and \({I}_{s}\) are the initial and steady-state current, respectively. The \({R}_{0}\) and \({R}_{s}\) are the initial and steady-state interfacial impedance, respectively. Most OSEs are multi-ion conductors, so the Li-ion transference number of OSEs is generally low, usually only about 0.1–0.2 [79]. In contrast, ISEs are typically single Li-ion conductors with a migration number roughly equal to 1. Therefore, the ion migration number of composite ion conductors is generally more significant than that of OSEs.

2.4 Electrochemical Stability

The electrochemical window is a vital parameter in evaluating the electrochemical stability of solid-state electrolytes. It determines the range of feasible reversible electrochemical reactions, facilitating controlled electrode potential during electrochemical desorption and adsorption processes and preventing irreversible reactions. The electrochemical window is typically measured by cyclic voltammetry or linear scanning voltammetry, using electrochemical cells containing working and reference electrodes for the configuration. The electrochemical window directly affects the lifetime and performance of the cell. Expanding the electrochemical window can enhance the compatibility of the solid-state electrolyte with both positive and negative electrodes, reduce energy losses and electrolyte degradation, and improve battery capacity retention and cycling stability. Generally, OICSEs offer a wider electrochemical window compared to OSEs. This phenomenon arises from the propensity of the polymer matrix in OSEs to decompose at high voltages, limiting their electrochemical window [80]. The most common oxidize potential of PEO-based polymer electrolytes is about 3.8 V, limiting their application in high energy density battery systems. Zhang et al. [81] developed an anion-immobilized OICSE to protect Li metal anodes by adding 40 wt% LLZTO to PEO (LiTFSI) polymer matrix. Compared to conventional liquid electrolytes with mobile anions, inorganic fillers effectively immobilize anions, resulting in uniform ion distribution and no dendritic lithium deposition. The wide electrochemical window (5.5 V vs. Li+/Li) of OICSE without distinct reaction was measured by LSV using Li|OICSE|SS. This indicates that OICSE has good polarization tolerance and great potential for high-voltage lithium batteries. The improvement of the OICSE electrochemical window is due to the excellent stability of LLZTO and its surface passivation layer towards lithium metal, while finely dispersed ceramic fillers help to remove impurities at the interface. Ding et al.[82] reported the addition of boron nitride (BN) to the PEO-LiTFSI system, BN reduces the crystallinity of PEO, promotes the dissociation of LiTFSI, and improves the ability of the PEO chain segment to transport ions, and the electrochemical stabilization window is increased from 4.43 to 5.16 V versus Li+/Li based on Li|OICSE|SS cell. The improvement in the electrochemical window is due to stronger binding between TFSI−1 and BN, which inhibits TFSI−1 transport and promotes Li+ transport. This slows down the concentration gradient and polarization and improves the stability of the lithium electrodeposition. Zhang et al. [83] prepared a flexible PEO/PEG-3LGPS composite electrolyte through an in situ coupling reaction, in which the ceramic and polymer were tightly bound to each other by strong chemical bonding, and successfully solved the interfacial compatibility problem. The oxidation potential of this PEO/PEG-3LGPS composite electrolyte was increased to 5.1 V versus Li+/Li based on Li|OICSE|SS cell. The enhancement of the electrochemical window was attributed to the higher ionic conductivity reducing the Li+ accumulation at the electrode/electrolyte interface, thus lowering the interfacial over-potential, and ultimately achieving better electrode–electrolyte compatibility.

2.5 Electronic Conductivity

Electronic conductivity is often considered another key criterion for ASSLBs applications. Ideally, the electronic conductivity of a composite electrolyte should be as close to zero as possible, typically in the range of 10−10 S cm−1 or less. A recent study shows that the high electronic conductivity of solid electrolytes allows Li+ to combine with electrons to form lithium dendrites directly inside these SEs when the potential reaches the Li plating potential. Wang et al. [84] investigated the formation mechanism of dendritic grains in LLZO and Li3PS4 using operational neutron depth profiling (NDP), emphasizing the important role of reducing the electronic conductivity of SEs to achieve dendrite-free lithium plating at high current densities. Polymers typically have lower electronic conductivity (10−14 and 10−17 S cm−1) compared to inorganic materials. Therefore, the reduction of the electronic conductivity of electrolytes is favored by inorganic–organic composites. Goodenough et al. reported that CPE-25LZP has a low electronic conductivity of 9.0 × 10–10 S cm−1 at 25 °C [85]. Low electronic conductivity ensures that the electrolyte conducts ions rather than electrons, which avoids self-discharge and internal short-circuit problems in batteries.

2.6 Thermal Stability

High thermal stability prevents OICSEs from decomposing during the thermal runaway of the battery, which plays a critical role in the safety of ASSLBs. Currently, thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC) are commonly used techniques to analyze these properties. The thermal decomposition temperature and mass loss of the composite electrolyte can be measured by TGA, while the thermal stability and phase transition temperature of the material can be analyzed by DSC. Most inorganic electrolytes have high decomposition temperatures, so the addition of inorganic materials to OICSEs can improve the thermal stability of the electrolytes. For example, Ramaswamy et al. [86] investigated the thermogravimetric analysis curves of PVDF-HFP/POEGMA/LLZTO composite electrolytes by TG. The results showed that the weight of PVDF-HFP/POEGMA gradually decreased by about 25% from 240 to 395 °C for the membrane without LLZTO, while the weight of PVDF-HFP/POEGMA/LLZTO only gradually decreased from 245 to 420 °C, indicating that the incorporation of LLZTO filler improved the thermal stability. Meanwhile, the thermal stability of ASSLBs can be improved by introducing inorganic fillers. Cui et al. [87] reported a poly(propylene carbonate) (PPC) and 5 wt% LLZTO CSE. Commercial lithium-ion batteries using organic liquid electrolytes typically suffer severe performance degradation when operating temperatures exceed 60 °C. The solid-state battery of LiFePO4||Li based on the OICSE was operated at 160 °C with excellent rate capability at high rates, indicating that the OICSE can be used in the field of high-temperature lithium batteries. The melting point (Tm), glass transition temperature (Tg), and crystallinity (Xc) can be obtained by DSC testing. The effect of SN plasticizer on the thermal properties of the PEO-LLZTO composite electrolyte was investigated [88]. The Tg, Tm, and Xc of the composite electrolyte gradually decreased with the addition of SN, when the content of SN was increased to 60 wt%, and the composite electrolyte with the highest ionic conductivity was obtained. Although plasticizers can improve the ionic conductivity of OICSEs by reducing polymer crystallization, they can also reduce the mechanical strength and the safety of ASSLBs, requiring a comprehensive consideration of the amount used.

3 Mechanism of Li-Ion Transport in OICSEs

Ionic conductivity is one of the most crucial properties of OICSEs, determining whether OICSEs apply to practical devices. Consequently, the design and development of OICSEs with high ionic conductivity is imperative. This objective necessitates an in-depth understanding of the lithium-ion transport mechanism, a fundamental aspect for advancing the efficacy of these electrolytes in technological applications. The structure of OICSEs is believed to contain three main components: inorganic fillers, polymers, and interfaces formed by the interaction of inorganic fillers with polymers. However, adequate technical knowledge is still lacking to probe these complex microscopic nanoscale interfaces directly. Currently, solid-state nuclear magnetic spectroscopy (NMR) is considered a practical technical approach for understanding the lithium-ion transport mechanisms in OICSEs.

Hu et al. first investigated the Li+ transport pathway in PEO (LiClO4/LLZO) OICSEs using the 6Li-7Li isotope tracing technique [89]. By assembling the 6Li/OICSEs/6Li system, the 6Li replaced the 7Li during the electrochemical cycling. Therefore, quantitative analysis of the resonance before and after isotope labeling can accurately quantify the contribution of different Li-containing components to ion conduction. These results indicated that 6Li in the LLZO increased by 39% after cycling. In contrast, the 6Li in the PEO phase and the interface were negligible, suggesting that the Li-ions prefer to go through LLZO rather than the PEO or PEO/LLZO interface. Subsequently, they further systematically investigated the effect of LLZO content on the ion conduction mechanism (Fig. 3a) [90]. When the LLZO content was below equal to 20 wt%, Li ions were mainly conducted through the PEO matrix. However, when the LLZO content exceeds a critical point, i.e., the LLZO particle forms a permeation network, which blocks the Li-ion conduction channel in PEO, leading to a transition of Li transport from the PEO phase to the LLZO. The specific transition point depends on various factors, such as the inorganic fillers' size, morphology, and composition. Furthermore, incorporating plasticizers into OICSEs results in the ion transport pathway reorientation, favoring the polymer phase [91]. Our recent work further demonstrates that in OICSEs containing plasticizer (SN), Li ions are mainly transported through the polymer phase, with LLZTO and the interface acting as synergistic conductors (Fig. 3b) [88]. This is attributed to the plasticizer reducing the polymer crystallinity and increasing the amorphous region, which is more conducive to lithium-ion transport.

a 6Li NMR spectra of 5, 20, and 50 wt% LLZO-PEO/LiTFSI and 50 wt% LLZO-PEO/LiTFSI with TEGDME OICSEs before and after cycling and the corresponding Li-ion transport pathways [90], Copyright 2018, American Chemical Society. b 6Li NMR spectra of the LCPE-60 OICSEs before and after cycling and the Li-ion pathways [88], Copyright 2023 Elsevier. c 6Li NMR spectra of PAN (LiClO4)-5 wt% LLZO NWs OICSEs before and after cycling [92], Copyright 2017, American Chemical Society. d 6Li MAS NMR of an LGPS-PEO (LiTFSI) OICSE before and after cycling [93], Copyright 2019, American Chemical Society. e Schematic illustration of the ion conduction pathway along the space charge regions [94], Copyright 2018 American Chemical Society. f Schematic diagram of the interface of H-OISE, OISE, and OISE-L Copyright 2024 Wiley‐VCH GmbH [96]

The interfacial region formed by the interaction of inorganic fillers and polymers plays an important role in OICSEs. However, the conduction mechanism of the interfacial region is very complex, and it largely depends on the specific composition and structure of OICSEs. Yang et al. investigated OICSEs containing 5.0 wt% LLZO nanowires combined with PAN using the6Li NMR technique (Fig. 3c) [92]. The results showed that the 6Li ions in the PAN at 0.9 ppm remained unchanged after cycling, while the amount of 6Li in the PAN region modified by LLZO (0.85 ppm) was greatly enhanced. This indicates that Li ions prefer to be transported through the PAN region modified by LLZO (usually understood as the interfacial region) rather than the unmodified PAN phase. Zheng et al. reported OICSEs with different LGPS and Li salt contents using the ball milling method (Fig. 3d) [93]. The results showed that the largest interface in PEO(LiTFSI)-(EO/Li = 9:1)-70 wt% LGPS, while the ionic conductivity of OICSEs was positively correlated with the LGPS-PEO interfaces quantified by 6Li NMR spectrum. Therefore, PEO (LiTFSI)- (EO/Li = 9:1)-70 wt% LGPS electrolytes have stronger Li ions transport and more stable long-term cycling performance with lithium metal. The 6Li NMR tracer exchange technique shows that Li ions are mainly transported through the LGPS/PEO interface. The result further demonstrates the interface plays a significant role in ion conduction. In addition to the interface detected by the 6Li NMR spectrum, Li et al. observed the 3 nm space charge region between Ga-LLZO and PEO with transmission electron microscopy (TEM) [94]. The Li ions in the Ga-LLZO lattice move towards the surface, resulting in vacancies that are positively charged on the surface and negatively charged inside. When the space charge region on the surface of the nanoparticles is connected (Fig. 3e), the results show that the space charge region at the interface is a fast conduction pathway for Li ions. Based on both computational and experimental results, similar behavior was also found in the LATP/PEO OICSE [95]. The LATP in PEO can establish low-energy barrier hopping channels along the surface for lithium-ion migration. In general, the mechanism of ion conduction within OICSEs is complex, and whether the lithium ions are transported through the polymer phase, the bulk phase, or the interface depends on several factors, such as the type and structural composition of the OICSE, including the inorganic fillers content, size, and morphology. In addition, the ability of the interface to be a phase with fast lithium ions conductivity depends on the interfacial interactions between the organic and inorganic materials. Guo et al.[54] investigated that under the coexistence of DMSO and LLZTO, the coupling of DMSO molecules with LLZTO resulted in the redistribution of the electron density of the DMSO molecules, which induced aggregation of the charges around the sulfinyl group, thereby increasing the Lewis basicity of the sulfinyl group and enhancing the interaction between LLZTO filler and PAN matrix. This enhancement facilitates the uniform encapsulation of the polymer on the particles surface and the formation of continuous Li+ conduction channels between the ceramic and polymer, which induces dehydrocyanation of the PAN matrix. The LLZTO@PAN electrolyte shows sufficient ionic conductivity of 1.1 × 10−4 S cm−1, and a high Li+ transference number of 0.66. The Li|LLZTO@PAN/PEO|LFP cell delivers a high reversible capacity of 167 mAh g−1 at 0.1 C, as well as a small polarization of 0.06 V. Therefore, it is beneficial to improve the ionic conductivity of OICSE by constructing a continuous micro interface of composite electrolyte. In recent research, the mechanism of microscopic interface formation in composite electrolytes and the ionic conductivity mechanism has been investigated using 1D 6Li and 2D 6Li-6Li exchange NMR techniques (Fig. 3f) [96]. The interface signals in the 6Li NMR spectra are from the lithium-deficient layer of LLZTO. At high current densities, Li ions are conducted through the polymer phase, and the lithium-deficient layer, as well as LLZTO, play a synergistic role in promoting ionic conduction, but the Li2CO3 on the surface of LLZTO inhibits the transport of the lithium-deficient layer as well as LLZTO.

To compare the pathways of Li-ion conduction more clearly in different OICSEs systems, Table 1 summarizes the ion conduction pathways based on polymer, filler type, content, and the presence or absence of plasticizer. It is shown that the ion conduction pathway of the OICSE is highly dependent on the filler content, polymer system, plasticizer, and circulating current density, but one certain thing is that the micro interface plays an important role in the ion conduction of the OICSE.

4 Key Inorganic Fillers and Advanced Structures in OICSEs

OICSEs are composed of polymers, lithium salts, and inorganic fillers. In 1973, Wright et al. [97] proposed that mixing alkali metal salts with PEO can conduct Li ions. Currently, polymer matrices include PEO [98], copolyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) [99], polyvinylidene fluoride (PVDF) [100], polyethylene glycol diacrylate (PEGDA) [101], polymethyl methacrylate (PMMA) [102], polyvinyl carbonate (PVC) [103], tetramethyleneglycol methacrylate (TEGDMA) [104], and polystyrene (PS). These polymers are primarily semi-crystalline at RT, which limits chain segment movement, leading to low ionic conductivity (10−6 to 10−8 S cm−1) [105]. When the temperature is above the glass transition temperature, these polymers are in the amorphous region, and the ionic conductivity increases significantly. Lithium salts are generally classified as inorganic lithium salts and organic lithium salts. Inorganic lithium salts such as lithium perchlorate (LiClO4), lithium tetrafluoroborate (LiBF4), lithium hexafluoroarsenate (LiAsF6) [106], and lithium hexafluorophosphate (LiPF6), while inorganic lithium salts are organic compounds consisting of an electron-absorbing group added to the anion. Common organic lithium salts include lithium borate dioxalate (LiBOB), lithium difluoroxalate borate (LiDFOB), lithium bis(difluorosulfonyl)imide (LiFSI), and lithium bis(trifluoromethylsulfonyl)imide (LiTFSI), which are highly solubility in polymers and quickly form stable SEI films. The inorganic fillers can be divided into inert fillers and active fillers depending on whether they can conduct Li ions. Inert fillers are not involved in the conductive process and include ZnO, TiO2, SiO2, ZrO2, MgO, Al2O3, Y2O3, LiAlO2, BaTiO3, etc. [107, 108]; active fillers include garnet, chalcocite, NASICON, LISICON, perovskite, sulfide, Li3N, etc. Both inert and active fillers are regarded as plasticizers to reduce crystallization and promote the movement of Li ions. The inorganic fillers are available in various shapes such as nanoparticles (0D), one-dimensional (1D) nanofibers, nanorods, two-dimensional (2D) nanosheets, and three-dimensional (3D) frameworks. The inorganic fillers with different shapes can provide long-range permeation networks through the arrangement to promote Li ions conduction and increase the diffusion rate, thus forming a fast Li ions conduction pathway.

4.1 Polymer with Inert Fillers

4.1.1 0-Dimensional Inert Fillers

0-dimensional (0D) inert materials are typically small filler particles with sizes ranging from a few nanometers to a few micrometers. These particles are introduced into polymer electrolytes with lithium salts to improve their mechanical properties, ionic conductivity, and electrochemical stability. This improvement is usually attributed to the inert fillers inhibiting the polymer crystallization, thus improving the chain segment motility. In addition, the Lewis acid–base interactions between groups on the nanoparticle surface and PEO chain segments, which can also facilitate the dissociation of lithium salts, have attracted extensive research. Croce et al. demonstrated that the improved electrochemical properties of PEO-based OICSEs were attributed to the –OH groups on the Al2O3 surface dispersed in the polymer matrix through the anionic “hydrogen bonding-mediated” solvation to reduce lithium salt association, thereby facilitating specific interactions between the filler, the polymer chain, and the ions from salt dissociation (Fig. 4a) [109]. Therefore, this objective can be achieved by incorporating more acidic sites, changing surface properties, or introducing functionalized nanomaterials. These strategies effectively inhibit polymer crystallization and enhance Lewis acid–base interactions between fillers, lithium salts, and polymer chains.

a Schematic diagram of the interaction between PEO chains and Al2O3 surface groups [109], Copyright 2004, Kluwer Academic Publishers. b Preparation process of SiO2-UPy and schematic diagram of SHCPE with supermolecule network structure [110], Copyright 2019 Royal Society of Chemistry. c Morphology and synthesis diagram of the PEO-LiClO4-SiO2 OICSEs [111], Copyright 2020 American Chemical Society. d Preparation process diagram of p–V–SiO2/PEO cross-linked OICSEs [113], Copyright 2021 Elsevier. e Synthetic routes of the PAN- insitu-SiO2 OICSEs [114]. f Preparation process diagram of hollow PDA composite nanospheres and the TEM images of hollow SiO2 and hollow PDA composites [115], Copyright 2022, American Chemical Society

Xue et al. prepared an OICSE with a self-healing function by incorporating ureidopyrimidinone (UPy)-functionalized SiO2 into a polymer matrix containing UPy units (SiO2-UPy) [110], as shown in Fig. 4b. The OICSE shows a high ionic conductivity of 8.0 × 10−5 S cm−1 at 30 °C compared with that of the CPE blended with pristine SiO2. The improved ionic conductivity is attributed to the SiO2-UPy filler being uniformly dispersed in the polymer matrix through PEG-UPy hydrogen bonding. This increases polymer activity and the number of physical cross-linking sites in the matrix, enhancing the interaction with PEG-UPy. Yang et al. constructed PEO@SiO2 OICSEs with a 3D network structure of PEO and SiO2 particles by in situ assembly (Fig. 4c). The fusion of monodisperse SiO2 nanoparticles with 3D PEO successfully reduced the PEO crystallinity under the synergistic effect of strong Lewis acid–base and weak hydrogen bonding, achieving a high ionic conductivity of 1.1 × 10−4 S cm−1, and wide electrochemical window of 4.8 V. vs Li/Li+[111]. In addition, the construction method significantly promoted the stability of the solid electrolyte interface. Similar research results were published in PAN-based systems [112]. An interconnected fast Li+ conducting network was constructed by in situ hydrolysis of tetraethoxysilane (TEOS) within a polyacrylonitrile (PAN) matrix. This situ-formed interconnected inorganic network provides a robust backbone for the OSE and a sufficiently continuous surface with Lewis acidic sites, which will facilitate the dissociation of Li salts. As a result, the OICSE obtained a promising ionic conductivity of 3.5 × 10−4 S cm−1 and an attractive Young modulus of 8.627 GPa. When paired with a high-voltage cathode of LiNi0.6Mn0.2Co0.2O2, the ASSLBs exhibited a stable discharge capacity of 173.1 mAh g−1 with 93.8% retention after 200 cycles at 3.0–4.3 V. Nanofillers with high specific surface area help increase the interaction between the inorganic filler and the polymer matrix, increase the free volume of the polymer. Park et al. introduced highly mesoporous silica nanoparticles (MSNs) into bulk polypropylene carbonate (PPC) matrices with bendability and high stability (Fig. 4d) [113]. OICSEs have an ultra-high lithium-ion transference number of 0.86 due to the strong Lewis acid sites on the surface of the highly mesoporous MSNs, which enhance the interaction with the polymer matrix, form a homogeneous Li-ion transport phase between the polymer matrix and ceramic fillers, and improve the Li+ transference number ion mobility number of the OICSEs.

In addition to the different Lewis acid–base interactions caused by the surface chemistry of the filler particles, there is another important way to improve the polarity and the dispersion of the filler in the polymer matrix by modifying the nanofiller surface. Zhan et al. reported OICSEs with porous vinyl-functionalized silicon (p–V–SiO2) nanoparticles as fillers for PEO electrolytes with polyethylene glycol diacrylate (PEGDA) as a cross-linking agent (Fig. 4e) [114]. 10% p–V–SiO2/PEO OICSE exhibited the highest ionic conductivity of 5.08 × 10−4 S cm−1 at 60 °C, and a wide electrochemical stability window of 5.2 V vs. Li/Li+ based on Li|10% p–V–SiO2/PEO OICSE|SS cell. The improved electrochemical performance is attributed to well-interfacial compatibility between organic and inorganic materials due to cross-linking polymerization reactions between porous SiO2 and PEGDA in the PEO host, which promotes more lithium salt dissolution. Li et al. showed that the polydopamine (PDA) coated hollow silica nanoparticles were compatible with PEO and had a large interfacial contact area, as shown in Fig. 4f [115]. The thin polydopamine layer improved the compatibility with the polymer matrix and provided an effective and stable ion transport channel. Theoretical calculations show strong adsorption between polydopamine and TFSI−, which can inhibit the movement of TFSI− anions. Compared with hollow SiO2 without PDA coating, this assembled PEO@PDA-SiO2 material exhibits higher ionic conductivity (1.89 × 10−4 S m−1), a wide electrochemical window (5.33 V vs. Li/Li+), and good mechanical strength. In addition, OICSE delivers a reversible capacity of 134.9 mAh g−1 after 205 cycles in comparison to 127.0 mAh g−1 for the undoped electrolyte. The dispersion of inorganic fillers in polymers can also be improved by certain technical methods; for example, Xie et al. used atomic layer deposition (ALD) to uniformly distribute ZnO quantum dots within a PEO-based solid electrolyte matrix. This method achieved a strong chemical interaction between VPI–ZnO and PEO and a uniform distribution of VPI–ZnO in PEO [116]. The results show that the loose O–Li+ coordination on the top surface of the electrolyte and the remaining VPI–ZnO lead to a significant increase in the Li+ migration number and a decrease in the interfacial resistance to Li metal. Furthermore, the NCM811|Li half-cell with the VPI–ZnO/PEO/LiTFSI exhibits a high discharge capacity of 164.7 mAh g−1 at 50 °C and has stable cycling performance.

Besides 0-dimensional inert oxides, ferroelectric materials can be incorporated into the polymer matrix as 0-dimensional inert materials, such as PbTiO3, BaTiO3, and SrBi4Ti4O15 [117, 118]. The ferroelectric materials exhibit strong Lewis acid–base characteristics, which can increase the polarity of polymer chains and further enhance the ionic conductivity in the interface region. Table 2 shows typical examples of 0D inert metal oxides and ferroelectric-filled materials in OICSEs.

4.1.2 1-Dimensional Inert Fillers

One factor that improves the ionic conductivity of inert nanoparticles in OICSEs is the inhibition of the crystallization of polymers and an increase in the amorphous ratio. Another key factor is the suitable filler content that can provide a continuous percolation conduction pathway, thus significantly improving ionic conductivity. When the 0D inert filler concentration reaches a certain level in the polymer matrix, it leads to the accumulation of the particle filler, which severely affects lithium-ion conduction. Therefore, the 1D nanotube and nanofiber instead of 0D inert fillers are a reasonable choice to provide continuous percolation paths and improve the conductive behavior.

Conventional 1D inert materials are mainly metal oxide nanowires, such as Y2O3 [135], TiO2 [136, 137], CeO2 [138], and Al2O3 [30]. Cui et al. reported a CSE containing Y2O3-doped ZrO2 (YSZ) nanowires with positively charged oxygen vacancies [135]. The results showed that the doped 7 mol% YSZ nanowires achieved the highest ionic conductivity of 1.07 × 10−5 S cm−1 at 30 °C, which is much higher than that of the electrolyte (2.98 × 10−6 S cm−1) containing 7% YSZ nanoparticles. The improved conductivity of the OICSE originates from the oxygen vacancies on the nanowire surface, which can act as Lewis acid sites to bind to the anions, as shown in Fig. 5a, effectively improving the ionic conductivity of the PAN-based OICSEs. Tao et al. reported PEO-based OICSEs containing 10% Mg2B2O5 nanowires, as shown in Fig. 5b [139]. The results showed that the ionic conductivity achieved 1.53 × 10−4 S cm−1 at 40 °C. This is attributed to the interaction of Mg2+ ions on the surface of Mg2B2O5 nanowires as Lewis acid centers with the anion TFSI−, thus weakening the interaction between Li+ and TFSI−, which in turn promoted the dissolution of the lithium salt and released more Li ions. In addition, the Mg2B2O5 nanowires have abundant Lewis acid sites [137], which enable the migration of Li ions in the two-phase interface between the electrolyte and Mg2B2O5 nanowires. TiO2 nanorod-filled polypropylene carbonate (PPC)-based OICSEs were prepared for the first time by Jing et al. The results indicate that the OICSE films with TiO2 nanorods can significantly improve the ionic conductivity (1.52 × 10−4 S cm−1) and have a stability electrochemical window (> 4.6 V vs. Li+/Li based on Li|OICSE|SS cell) and a tensile strength of 27 MPa at RT. This is attributed to the TiO2 nanorods providing more continuous lithium-ion transport channels and their surface porosity and composition improving the interfacial contact between polymer and filler and Lewis acid–base reaction sites.

a Schematic illustration for Li-ion transport with nanoparticle and nanowire fillers [135], Copyright 2016, American Chemical Society. b Schematics of lithium-ion migration in Mg2B2O5 enhanced OICSEs [139], Copyright 2018, American Chemical Society. c Schematic diagram of TDI modified TiO2 and OICSE preparation [140], Copyright 2021 Elsevier. d Schematic diagram for the OICSEs fabrication procedure [141], Copyright 2022 Royal Society of Chemistry. e Schematic illustration depicting the formation of OICSEs incorporating silica nanotubes with hollow nanostructures [142] Copyright, 2020 Elsevier. f A mechanism to improve ionic conductivity by adding HNTs [143], Copyright 2018 Royal Society of Chemistry. g Schematic diagram of PEO-based HNTs electrolyte [144], Copyright 2019, American Chemical Society

Beyond integrating one-dimensional (1D) nanomaterials into the polymer matrix, the ionic conductivity can be further augmented through surface chemical modification. Li et al. successfully prepared a novel organic–inorganic cross-linked PEO-TDI-TiO2 electrolyte film using toluene-2,4-diisocyanate (TDI) as a modifier, as shown in Fig. 5c [140]. The OICSE membrane has a high ionic conductivity of 1 × 10−4 S cm−1 at 30 °C, and a high Li+ transference number of 0.36 at 60 °C. The wide electrochemical window (5.5 V vs. Li+/Li) was determined by LSV with the asymmetric battery of Li foil|OICSE| stainless steel (SS). The surface modification of TDI helps reduce the surface energy of TiO2 nanowires, thus enabling the polymer matrix chains to form effective covalent bonds with the nanofillers. Furthermore, the cross-linked and branched network structure effectively increases the amorphous regions in the polymer matrix. Zhao et al. reported a filler surface coating method, which involves coating a polydopamine (PDA) layer on the TiO2 nanofibers surface and then incorporating it into the PEO matrix (Fig. 5d) [141]. This coating method inhibited the filler aggregation in the PEO matrix and enhanced the compatibility between the PEO matrix and the PDA. The strong lithophilic layer of PDA also improved the ionic conductivity behavior at the filler/polymer interface, enabling the OICSEs to exhibit a high ionic conductivity of 4.36 × 10−4 S cm−1 and a wide electrochemical window of 5 V versus Li+/Li at 55 °C were studied by LSV using a Li|OICSE|SS cell. Xue et al. successfully synthesized a series of one-dimensional silica nanotubes (SNts) with hollow nanostructures and high uniformity by etching rod-shaped nickel hydrazine complexes for PEO-SNts (Fig. 5e) [142]. Compared with OICSEs based on 0D silica nanoparticles, PEO-SNts indicate significantly improved conductivity, thermal stability, and cycling stability.

Halloysite nanotubes (HNTs) are a unique natural 1D nanomaterial in addition to metal oxide 1D materials. It has the characteristics of tubular nanostructures, high aspect ratio, versatility, good biocompatibility, and high mechanical strength, and has received widespread attention in many fields. HNTs are a hydrated polycrystalline 1:1 layered silicate clay mineral with an outer siloxane surface and an inner alumina core. Therefore, the outer surface is generally negatively charged, like SiO2. Chen et al. prepared an OICSE-5 by introducing 5% natural halloysite nanotubes (HNTs) into polyvinylidene fluoride (PVDF). The ionic conductivity (3.5 × 10−4 S cm−1) was improved by ten orders of magnitude at 30 °C compared to the electrolyte without HNTs (Fig. 5f) [143]. The improvement in ionic conductivity was mainly attributed to the negatively charged outer surface and high specific surface area of HNTs, which facilitated the migration of Li ions in PVDF. However, the interfacial compatibility of HNT nanotubes with LFP electrodes is poor. To address this issue, Miller et al. reported a modification method in which a small amount of LFP was added during the preparation of OICSEs (Fig. 5g) [144]. This modification increased ionic conductivity, and the compatibility between electrolyte and electrode was significantly enhanced. Moreover, the electrochemical stability window was improved to 5.14 V, and the Li+ transference number was 0.46. The HNTLFP/SPE-based LFP polymer batteries present stable discharge capacities of 120 ± 3 mAh g−1 at 0.5 C after 300 discharge/charge cycles. In addition, metal–organic framework (MOF) nanorods and nickel phosphate (VSB) nanorods can also be introduced into the polymer matrix as effective 1D solid fillers to improve the electrochemical performance of OICSEs [145,146,147,148].

4.1.3 2-Dimensional and 3-Dimensional Inert Fillers

Previous studies have demonstrated that inert nanoparticles and nanofibers can enhance ionic conductivity by suppressing the polymer crystallinity and providing continuous ionic conduction channels. To further enhance the ionic conductivity and improve the mechanical properties of OICSEs, researchers introduced 2D nanosheets and even developed 3D inorganic framework nanostructures. These structures provide continuous three-dimensional channels with no cross-connections between the inorganic phases. The thermal stability and mechanical properties were significantly improved by modulating the contact-specific surface area of the polymer with the filler. In recent works, 2D inert materials in OICSEs mainly include graphene oxide (GO), montmorillonite (MMT), boron nitride (BN), and MXenes nanomaterials. In contrast, 3D inorganic framework materials mainly cover metal oxides (e.g., Al2O3, SiO2, BaTiO3) and glass fibers. The typical examples of the electrochemical performance of OICSEs containing 2D nanosheet structures and 3D network frameworks are summarized in Table 3.

GO is a graphene derivative with a two-dimensional layered structure that contains various hydrophilic functional groups such as –C–O–C, –CO, –COOH, and –OH on the surface, giving it excellent hydrophilicity and dispersibility. Xu et al. added 1 wt% of graphene oxide (GO) to PEO-based electrolytes for OICSEs and achieved an ionic conductivity of 1.54 × 10−5 S cm−1 at 24 °C [149], Li+ transference number of 0.42. The wide electrochemical window (about 5 V vs. Li+/Li) was measured by LSV using Li|GO-modified PEO|SS. The symmetric Li||GO-PEO||Li cell was stably cycled at an overpotential of 27 mV for 600 h, as shown in Fig. 6a. In addition, the LiFePO4//GO-PEO//Li cell exhibited excellent cycling, with a discharge capacity of 142 mAh g−1 at 0.5 C and 91% capacity retention after 100 cycles, indicating that it can inhibit the growth of lithium dendrites. The enhancement of ionic conductivity depends on the continuity of the conduction channels and the lithium-ion concentration. Thus, the ionic conductivity of OICSEs can be further enhanced by increasing the local lithium-ion concentration in the interfacial regions. Wu et al. synthesized lithiated polydopamine-modified graphene oxide nanosheets (LiDGO) and doped them into a PEO matrix, as shown in Fig. 6b [150]. A comprehensive evaluation of the electrochemical properties showed that the long-range conduction pathway with localized lithium-ion concentration constructed at the PEO/LiDGO interface significantly enhanced the ionic conductivity of OICSEs. The ionic conductivity reached 3.4 × 10−5 S cm−1 at 30 °C and had excellent mechanical stability. The full battery achieves a discharge capacity of ~ 156 mAh g−1 after 200 cycles with ultra-high-capacity retention of 98.7%. Xiong et al. introduced interatomic lithium montmorillonite (Li-MMT) into lithium-sulfur batteries for the first time and achieved free migration and exchange of interlayer cations in a thick sulfur cathode [151]. This work demonstrated that natural montmorillonite clay possesses a cation exchange function and can facilitate conduction by replacing other cations with Li ions. Zhang et al. prepared an OICSE consisting of poly(ethylene carbonate), layered lithium montmorillonite (LiMNT), and high-pressure fluorocarbon subethylenes (PEC) using a combination of solution casting and hot pressing [152]. The OICSE acquires a high ionic conductivity of 3.5 × 10−4 S cm−1 and a high Li+ transference number of 0.83 at 25 °C. A wide electrochemical window of 4.6 V versus Li+/Li was evaluated by LSV using Li foil|OICSE|SS. The mechanism of the enhanced Li+ transference number in OICSE is attributed to the selective immobilization of charged species. The upper and lower surfaces of the nanoflake LiMNT equipping –Si–O–Si- silicon tetrahedral sheets are negatively charged, and edge-shared faces consisting of –Al–OH groups are positively charged (Fig. 6c). When the PEC-Li polymer electrolyte is inserted into the intercalation of LiMNT, this surface difference allows selective immobilization of the charged material. The lithium salt anions are more likely to approach the edges of LiMNT, while the Li+ cations are more likely to be present in the intercalation space. Meanwhile, the carbonate group (–O–(C=O)–O–) with many lone pair electrons in the PEC will interact with the free Li+. This interaction leads to an ordered entry of Li+ into the interlayer space. As a result, this arrangement shortens the Li+ transport pathway and provides an efficient transport channel resulting in a high Li+ transfer number. To effectively solve the inhomogeneous ion transport problem and improve the thermal stability and mechanical properties of OICSEs. Ding et al. utilized a directional freezing method to prepare vertically aligned MMT arrays with ultra-low curvature (Fig. 6d) [153]. A uniform and continuous ion-conductive interface was formed in the OICSEs through UV-induced polymerization, facilitating Li+ migration. The results demonstrated that CSE/VAMMT exhibited higher Li-ion transference numbers and ionic conductivity at RT (1.08 mS cm−1). Moreover, it displayed excellent cycling stability, with no short-circuiting during continuous lithium deposition/stripping for 1000 h. The 2D BN nanosheets have attracted considerable attention due to the ability of the B atoms to interact with the anions of lithium salts as Lewis acid sites on the planar surface, thereby releasing more Li ions and enhancing ionic conductivity [154]. Zheng et al. developed a hybrid polymer electrolyte (BN-PEO-PVDF) containing 2D BN nanosheets, as shown in Fig. 6e [155]. In addition to improving ionic conductivity and mechanical properties, BN enhanced the thermal stability of the PEO-based electrolyte, allowing the BN-PEO-PVDF electrolyte to balance thermal changes faster and achieve more uniform ion transport. Ding et al. introduced g-C3N4 nanosheets similar to BN into PEO-based electrolytes, improving electrochemical performance, mechanical properties, and thermal stability [156]. Furthermore, MXene is a common 2-dimensional metal carbide layered material with a negative charge due to the surface with rich polar groups, such as –OH, –Cl, and –F. It has a strong interaction with lithium salts, which helps in the dissociation of lithium salts. Yang et al. incorporated insulating MXene-mSiO2 nanosheets into the PEO electrolyte, as shown in Fig. 6f [157]. Due to the abundant functional groups of MXene-mSiO2, the Lewis acid–base interactions between the PEO chain and anions were promoted, enabling the rapid transport of Li+ ions across the mesoporous nanosheet/polymer interface. As a result, the OICSE exhibited high ionic conductivity of 4.6 × 10−4 S cm−1 and Young's modulus of 10.5 MPa, Young's modulus is 34 orders of magnitude higher than that of the silica particle/ePPO electrolyte. Noteworthy, the full cell exhibits a long and stable cycle performance up to 250 cycles under 0.5 C at 25 °C, and the capacity is well maintained at 141.8 mAh g−1, much higher than that of the LFP cathodes with pure ePPO electrolyte (60.3 mAh g−1).

a Voltage–time profiles of Li||GO-PEO||Li at 60 °C and cyclic performance of full battery at 1C [149], Copyright 2021, American Chemical Society. b Schematic diagram of the preparation of LiDGO nanosheets [150], Copyright 2020 Elsevier. c Schematic diagram of ion migration mechanism of LiMNT interlayer insertion into PEC-based electrolyte [152], Copyright 2019 WILEY. d Schematic diagram of the manufacturing process of GPE/VAMMT [153], Copyright 2022 Xinyang Li. e Schematic diagram of heat transfer in electrolytes with and without BN additives [155], Copyright 2020 Guangyuan Wesley Zheng. f Schematic diagram of the manufacturing containing MXene mSiO2 [157], Copyright 2020 WILEY

In recent years, the ice template method, electrostatic spinning, sol–gel method, and 3D inorganic skeletons have been reported to construct continuous ion transport channels to form 3D OICSEs. The strategy of building OICSE with a three-dimensional skeleton structure solves the accumulation problem and further improves mechanical strength. Zhang et al. reported an OICSE with vertically aligned and continuous nanoscale ceramic-polymer interfaces using modified Al2O3 as the skeleton and PEO as the polymer matrix, as shown in Fig. 7a [158]. The Li+ transport along the ceramic/polymer interface was demonstrated for the first time, and the interfacial ionic conductivity was predicted to be higher than 10−3 S cm−1 at 0 °C, as shown in Fig. 7b. The ionic conductivity was 5.82 × 10−4 S cm−1 at RT, which was four orders of magnitude higher than that of the OICSE with nanoparticles and nanowires. The improvement of ionic conductivity is mainly attributed to the high aspect ratio of the polymer/ceramic interface formed by the vertically aligned 3D Al2O3 and the polymer matrix, which allows Li ions to conduct along the continuous vertically aligned interface and effectively reduces the crystallization of the polymer. Han et al. explored a simple and efficient solution-blowing technique to prepare well-aligned BaTiO3 nanofibers with an average diameter of about 300 nm combined with PEO polymers to form OICSEs [159]. Compared with the electrolyte without BaTiO3, the ionic conductivity increased from 5.74 × 10−6 to 5.83 × 10−5 S cm−1 at 30 °C, and the Li/Li+ electrochemical stability window was increased to about 5.8 V. To further enhance the ionic conductivity and electrochemical stability of OICSEs, Zhang et al. introduced an ionic liquid into a PEO-based 3D glass fiber cloth (PEO@GFC-25%ILs) framework (Fig. 7c) [160]. The results showed that PEO@GFC-25%ILs exhibited a high ionic conductivity of 1.6 × 10−4 S cm1 at RT, and an electrochemical window of 5.2 V versus Li+/Li was performed by assembling a Li|OICSE|SS cell. The Li|PEO@GFC-25%ILs|Li cells also demonstrated excellent cycling performance and rate capability with stable cycling of 2000 h. The full batteries assembled based on LCO and LFP cathode with PEO@GFC-25% ILs electrolyte can achieve specific capacities of 128.3 mAh g−1 and 155.2 mAh g−1, respectively. Furthermore, the LFP/PEO@GFC-25% ILs/Li battery can provide a reversible capacity of 152.0 mAh g−1 after 150 cycles at 0.5 C. To improve the mechanical properties of OICSEs to effectively suppress the occurrence of lithium dendrites and achieve high ionic conductivity at RT. Cui et al. synthesized a novel 3D SiO2 aerogel backbone by sol–gel method, injected with PEGDA, SN, and LiTFSI, and finally formed OICSEs by ultraviolet photocuring (Fig. 7d) [161]. This interconnected SiO2 aerogel strengthens the skeletal structure of all the OICSEs and offers a substantial and uninterrupted surface area for anion adsorption, creating a highly conductive pathway. As a result, the OICSEs achieve a high modulus of approximately 0.43 GPa and a remarkable ionic conductivity of 6 × 10−4 S cm −1 at 30 °C.

a Schematics of OICSEs with three types of geometrical structures. b Ionic conductivity in different regions of composite electrolytes [158], Copyright 2018, American Chemical Society. c Schematic illustration for preparation of PEO@GFC-25%ILs [160], Copyright 2020 Elsevier. d Schematic diagram of the microstructure of OICSEs containing 3D SiO2 aerogel [161], Copyright 2018 WILEY

Although the significant enhancement effect of aligned structures on ion conduction behavior has been demonstrated, the methods for preparing these structures still need to be more thoroughly explored. Some limitations and challenges may still exist in the current preparation methods, such as process complexity, material selection, and interface engineering. Further research can be devoted to the development of simpler, scalable preparation methods while optimizing material combinations and interfacial interactions for more efficient ion conduction and optimized electrochemical properties. In addition, the long-term stability, cycle life, and compatibility with electrodes of these aligned structures also need to be explored to ensure reliability and durability in practical applications. In summary, although the aligned structures have potential in ion conduction behavior, further research extensions are still needed to realize their practical applications.

Table 4 shows the advantages and disadvantages of inert materials with different dimensions, where the 0D inert materials have good mechanical properties and chemical stability, but low ionic conductivity and poor interfacial contact. 1D Nanowires/nanotubes are beneficial to some extent to improve interfacial contact and inhibit crystallization of polymers, especially when the orientation is consistent, and can provide continuous interfacial conduction for Li-ions, but the preparation process is complicated. The 2D inert materials with high specific surface area, good interfacial contact, and rich functional groups on the surface (e.g., MXene-Ti3C2 and BN, which contain functional groups such as –OH, –O, –NH2, and –F.) can interact with Li ions in the OICSEs and further promote Li-ion migration, but have poor mechanical properties. The 3D inert material has high mechanical strength, and thermal stability, which promotes the formation of a continuous conductive interface with the polymer and improves the ionic conductivity of the OICSEs, but the preparation method is complicated and requires special equipment.

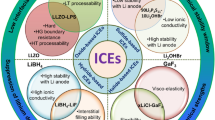

4.2 Polymer with Active Fillers

Active fillers have high ionic conductivity and electrochemical activity relative to inert fillers, and they can participate in electrochemical reactions and provide additional ion transport channels, thereby improving the ionic conductivity and the electrochemical performance. Therefore, active materials are known as fast ion conductors and could provide a highly efficient pathway for Li-ion. However, the active fillers may lead to a certain degree of electrode polarization and capacity degradation, and their properties need to be optimized and regulated to improve the cycle life and stability of the battery. Typical active materials based on solid-state electrolytes consist of sulfide-type, garnet-type, NASICON-type, and perovskite-type materials.

4.2.1 Polymer Matrix Incorporating Sulfide-Type Materials

Sulfide electrolytes are characterized by substituting sulfur ions for oxygen ions, resulting in larger ion transport pathways for Li ions. As a result, they exhibit relatively high ionic conductivity, typically ranging from 10−3 to 10−2 S cm−1, comparable to liquid electrolytes. However, sulfide electrolytes have poor electrochemical stability and unstable interface contact with lithium metal, leading to decomposition reactions and high interfacial impedance [186]. Generally, sulfide electrolytes are combined with polymers or lithium alloys as anodes to improve interface stability.

Xu et al. developed an OICSE by incorporating Li10GeP2S12 (LGPS) as an active filler into a PEO matrix. The OICSE with 1 wt% LGPS exhibited higher ionic conductivity than that of the PEO-LiTFSI electrolyte, with values of 1.18 × 10−5 S cm−1 at 25 °C and 1.21 × 10−3 S cm−1 at 80 °C, and had a wide electrochemical window of 5.7 V versus Li+/Li [187]. This result is attributed to the inhibition of PEO crystallization by LGPS, which weakens the interaction between Li+ and PEO chains. Furthermore, adding LGPS particles to the PEO matrix enhanced the Li+ transference number and electrochemical stability. The LFP||Li batteries using the PEO-LiTFSI-1 wt% LGPS OICSE demonstrated a high capacity of 148.6 mAh g−1 at 0.5 C and 60 °C, with a capacity retention of 92.5% after 50 cycles. To further improve the uniform dispersion of nanofillers within a polymer matrix, Xu et al. introduced a novel in-situ synthesis method for Li3PS4 to create a PEO/Li3PS4 OICSE, as shown in Fig. 8a [188]. The results show that the in-situ synthesized Li3PS4 nanoparticles exhibit superior dispersion within the PEO matrix than mechanical mixing, which is conducive to forming Li+ conductive channels and enhancing ion transport. Specifically, the OICSE containing 2 vol% Li3PS4 by in-situ synthesized method demonstrated the highest ionic conductivity of 8.01 × 10−4 S cm−1 at 60 °C, surpassing the ionic conductivity of mechanically mixed electrolytes at 6.98 × 10−4 S cm−1. Additionally, the assembled solid-state LiFePO4/Li battery with the OICSE displayed outstanding cycling performance with a capacity retention of 80.9% after 325 cycles at 60 °C and remarkable rate capability (127 mAh g−1 at 1 C). In efforts to enhance the chemical stability of sulfides in an air environment, as well as to improve electrode material compatibility, Wang et al. have successfully designed a novel sulfide-doped OICSE. This OICSE combines inorganic sulfide, specifically lithium-sulfur saltpeter (Li7PS6), with a polyvinylidene fluoride-hexafluoropropylene copolymer (PVDF-HFP) [189]. Incorporating Li7PS6 within a PVDF-HFP polymer matrix imparts flexibility and air stability to the OICSE while ensuring commendable chemical and electrochemical stability. Notably, the PVDF-HFP-Li7PS6 electrolyte exhibited excellent ionic conductivity of 1.1 × 10−4 S cm−1 at RT (Fig. 8b), and the Li||Li symmetric cell achieved stable cycling of up to 1000 h at 0.2 mA cm−2. In addition, the LiFePO4||CSE||Li cell displays an impressive specific capacity of 160 mAh g−1 over 150 cycles, indicating that sulfide-doped OICSEs are promising for high-performance solid-state lithium batteries. Zhang et al. engineered a thin sulfide electrolyte film (65 μm) through the modified Li6PS5Cl and PEO, as shown in Fig. 8c [190]. The assembled Li-In ||LiNi0.7Co0.2Mn0.1O2 ASSLBs with the OICSE exhibit 74% capacity retention and an average coulombic efficiency of 99.85% after 1000 cycles at 60 °C with high loading conditions (4.46 mAh cm−2). Liu et al. prepared ultrathin flexible OICSE from Li6PS5Cl and poly(vinylidene fluoride-trifluoroethylene) (P(VDF-TrFE)) through the electrostatic spinning infiltration-hot-pressing method, shown in Fig. 8d [191]. The strong polarity of the polymer facilitates the interaction with LSPSCl. The P(VDF-TrFE) network allows full penetration of the LPSCl particles and the formation of an interpenetrating P(VDF-TrFE) structure. The ionic conductivity reached 1.2 × 10−3 S cm−1, enabling the Li-In||LiNi0.8Co0.1Mn0.1O2 cell to maintain 71% capacity after 20,000 cycles at 1.0 mA cm−2 (Fig. 8e). To inhibit the growth of polysulfide shuttles and lithium dendrites, Su et al. designed an ASSLB with a flexible composite cathode and PEO-LSPSCl-LiTFSI (S-CPE) [192]. The cell still maintained 97.8% capacity retention after 100 cycles of 0.1 A g−1. Low-temperature transmission electron microscopy (Cryo-TEM) revealed the presence of abundant Li2CO3 particles at the Li/PEO interface (Fig. 8f), which hindered the Li+ transport. However, at the Li/S-CPE interface, LSPSCl promoted the decomposition of TFSI− to form abundant Li2O nanocrystals, amorphous LiF, and Li2S layers, which suppressed the Li dendrites growth of and stabilized the interface (Fig. 8g). Furthermore, the comprehensive elemental mapping through EDS unveiled the distinct presence of elemental constituents such as O, F, S, and C within the structure of S-CPE (Fig. 8h). It is notably imperative to highlight that the pronounced O signal strength in the analysis suggests an intricate process involving Li deposition coupled with the formation of Li2O. This work provides a strategy to mitigate the polysulfide shuttle effect and lithium dendrite formation for the design of solid-state lithium-based batteries with high energy density. Table 5 summarizes typical examples of the electrochemical performance of OICSE with sulfide-type fillers.

a Process flow diagram of in-situ preparation of PEO-Li3PS4 OICSE [188], Copyright 2018 Elsevier. b Schematic illustration of OICSE and Arrhenius plots of Li7PS6, OICSE, and PVDF-HFP/LiTFSI polymer electrolyte. [189], Copyright 2020, American Chemical Society. c Cycling performance of modified Li6PS5Cl-PEO and Li in alloy cathodes [190], Copyright 2020 Elsevier. d Schematic illustration of LPSCl@P(VDF-TrFE) OICSEs via an electrospinning-infiltration hot-pressing method. e Long-term cycling performance of LPSCl@P(VDF-TrFE) OICSEs at 1.0 mA cm−2 [191], Copyright 2022 Wiley. f Cryo-TEM characterization of the Li/PEO interfaces. g Cryo-TEM characterization of the Li/S-CPE interfaces. h EDS elemental maps of S-CPE [192], Copyright 2022 Wiley

4.2.2 Polymer Matrix Incorporating Garnet-Type Materials

The garnet-type solid-state electrolyte materials are typically lithium-ion conductors like Li7La3Zr2O12 (LLZO) and their derivatives. They are known as fast ion conductors, exhibiting relatively high ionic conductivity from 10−4 to 10−3 S cm−1 [204]. When using LLZO particles, it is important to ensure that the surface is fresh, as Li2CO3 and LiOH are easily formed when exposed to the air. In addition, these materials possess a wide electrochemical window, outstanding chemical stability, excellent mechanical strength, and the ability to suppress lithium dendrite growth effectively. Incorporating garnet-type fillers within polymer electrolytes has demonstrated promise in mitigating the issues associated with lithium dendrite growth while enhancing the overall electrochemical performance.